Subscribe to Our Youtube Channel

Summary of Contents for Fleck 9500

- Page 1 MODEL 9500 Service Manual IMPORTANT: Fill in pertinent information on page 2 for future reference.

- Page 2 • MINERAL TANK SIZE DIA.________ HEIGHT_________ • BRINE TANK SIZE & SALT SETTING PER REGENERATION: _________________________________ * 9500 CONTROL VALVE SPECIFICATIONS 1) Type of Timer A) 82 minute available regeneration time, 1/15 RPM B) 164 minute available regeneration time, 1/30 RPM 2) Type of Meter A) Std.

- Page 3 MODEL 9500 ECONOMINDER General & Commercial Installation Checklist WATER PRESSURE: A minimum of 25 pounds of water pressure is required for the valve to operate effectively. ELECTRICAL FACILITIES: A continuous 110 volt, 60 Hertz current supply is required. Make certain the current supply is always hot and cannot be turned off with another switch.

- Page 4 MODEL 9500 ECONOMINDER General & Commercial Installation Checklist (Cont’d.) 13. Tank #1 has control 14. Cycle timer into backwash position. Turn manual knob valve. (figure 1) so that the micro switch is riding on the 1st set of pins (figure 2). In this position the tanks will...

- Page 5 MODEL 9500 ECONOMINDER Regeneration Cycle Program Setting Procedure (Brine Tank Refill Separate From Rapid Rinse) How To Set The Regeneration Cycle Program: The regeneration cycle program on your water conditioner PROGRAM BRINE & RINSE has been factory preset, however, portions of the cycle or...

- Page 6 =1 min.). The other allows for 164 minute maximum regeneration time (each pin or hole = 2 min.). 2. The 9500 Control has a separate brine tank fill cycle. Your desired salt setting must be calculated, using the brine line flow control rate of refill (in gpm) times your timer setting. Then using one gallon of fresh water dissolving approximately 3 lbs.

- Page 7 MODEL 9500 ECONOMINDER Time Brine Refill & Meter Setting Procedure (Cont’d.) If we have 4800 gallons available from Step 3, we want to subtract the regeneration water used from the total water available. 4800 gallons available - 342 gallons used (in regeneration, step 4) = 4458 gallons setting 5.

- Page 8 MODEL 9500 ECONOMINDER BRINE VALVE FLOW CONTROL DRAIN 1 - SERVICE POSITION Hard water enters the unit at the valve inlet, flows around the lower piston, and down through the mineral in the first tank. Conditioned water enters the center tube through the bottom distributor, flows up through...

- Page 9 MODEL 9500 ECONOMINDER BRINE VALVE FLOW CONTROL DRAIN 3 - BACKWASH Conditioned water from the second mineral tank flows around the lower piston, around the upper piston, through the center of the lower piston, down the center tube, up through the mineral, around the upper piston, and out the drain line.

- Page 10 MODEL 9500 ECONOMINDER BRINE VALVE FLOW CONTROL DRAIN 5 - SLOW RINSE Conditioned water from the second mineral tank flows around the lower piston, around the upper piston, into the injector housing, down through the nozzle and throat, around the upper piston, down through the...

- Page 11 MODEL 9500 ECONOMINDER BRINE VALVE FLOW CONTROL DRAIN 7 - BRINE TANK FILL POSITION Conditioned water from the second mineral tank flows around the lower piston, around the upper piston, into the injector housing, through the brine line flow control, through the brine valve, and into to brine tank.

- Page 12 MODEL 9500 ECONOMINDER Drive Assembly (See Opposite Page for Parts List) Page 12 Printed in U.S.A.

- Page 13 MODEL 9500 ECONOMINDER Drive Assembly Parts List Item No. Quantity Part No. Description 1 ... . 2 ... . . 11335 ....Screw 2 .

- Page 14 MODEL 9500 ECONOMINDER Control Valve Assembly (See Opposite Page for Parts List) OPTIONAL 1600 INJECTOR Page 14 Printed in U.S.A.

- Page 15 MODEL 9500 ECONOMINDER Control Valve Assembly Parts List Item No. Quantity Part No. Description 1 ... .1 ... . 16919-01....Valve Body 2 .

- Page 16 MODEL 9500 ECONOMINDER 1600 Series Brine System PARTS LIST Item No. Quantity Part No. Description 1 ... 1... . 12748....Brine Valve Body 2 .

- Page 17 MODEL 9500 ECONOMINDER 1700 Series Brine System PARTS LIST Item No. Quantity Part No. Description 1 ... . 1 ... . . 14792 ....End Plug 2 .

- Page 18 MODEL 9500 ECONOMINDER Air Check PARTS LIST Item No. Quantity Part No. Description 1 ... 1... . 10332....Tube Insert 3/8″...

- Page 19 MODEL 9500 ECONOMINDER 1-1/2″ Meter Assembly PARTS LIST Item No. Quantity Part No. Description 1 ... 1 ... 17569 ....Meter Body 2 .

- Page 20 MODEL 9500 ECONOMINDER Timer Assembly (See Opposite Page for Parts List) Page 20 Printed in U.S.A.

- Page 21 MODEL 9500 ECONOMINDER Timer Assembly Parts List Item No. Quantity Part No. Description 1 ... .1 ... . 13870-03....Timer Housing Assy.

- Page 22 MODEL 9500 ECONOMINDER Service Instructions PROBLEM CAUSE CORRECTION Softener fails to regenerate. A. Electrical service to unit has A. Assure permanent electrical service been interrupted. (check fuse, plug, pull chain or switch). B. Timer is defective. B. Replace timer.

- Page 23 MODEL 9500 ECONOMINDER Service Instructions (Cont’d.) PROBLEM CAUSE CORRECTION D. Foreign material in brine valve. D. Replace brine valve seat and clean valve. E. Foreign material in brine line flow E. Clean brine line flow control. control. Power loss during brine fill.

- Page 24 MODEL 9500 ECONOMINDER Flow Data & Injector Draw Rates SERVICE AND BACKWASH FLOW RATE (GPM) INJECTOR DRAW RATE ON EMPTY TANK SLOW RINSE RATE ON EMPTY TANK DRAW RATE GPM DRAW RATE GPM Page 24 Printed in U.S.A.

- Page 25 MODEL 9500 ECONOMINDER Typical Timer Settings At Various Salting Levels Salting @ 6# Per Ft Tank Volume Inj. Brine and Slow Rinse Fast Brine Brine Tank Refill Dia. of Resin Rate- Time- Size Time-Minutes @ 6# Per Ft Rinse Refill...

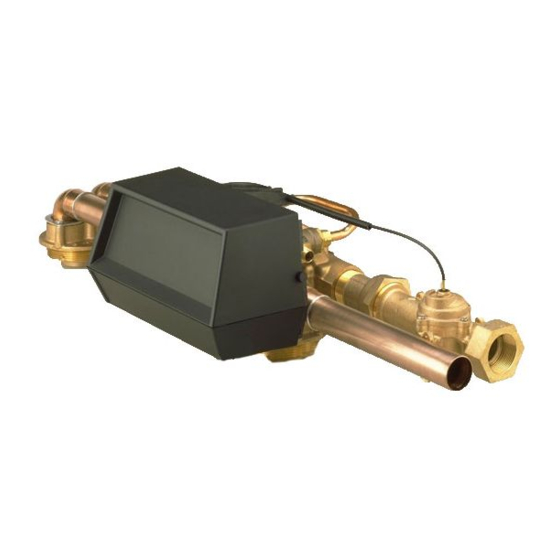

- Page 26 MODEL 9500 ECONOMINDER 2 Tank Wiring & Control Dimensions 1″-11.5 NPT DRAIN PORT 1600 BRINE VALVE 3/8 O.D. TUBE 1700 BRINE VALVE 1/2 O.D. TUBE METER DOME MUST FACE UP 10.5 3.06 24″ PIPE = 27.7″ 1.50″ -11 NPT INTERNAL TYPICAL 11.4...

- Page 27 MODEL 9500 Valve Wiring Diagram Page 27 Printed in U.S.A.

- Page 28 1 ..16123 ..Nut 1/2″ 60134..9500 Seal and Spacer Kit - Upper 1 ..16124 ..Ferrule 1/2″...

- Page 29 Notes Page 29 Printed in U.S.A.

- Page 30 Notes Page 30 Printed in U.S.A.

- Page 32 P/N 17440 Rev. 3 3/00 Printed 3/00...

Need help?

Do you have a question about the 9500 and is the answer not in the manual?

Questions and answers