Table of Contents

Advertisement

Quick Links

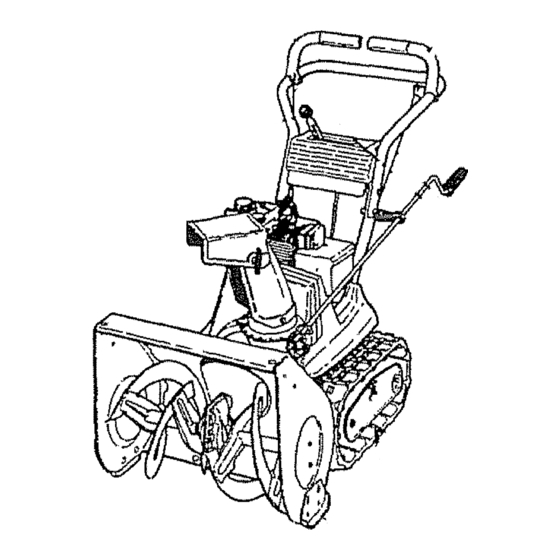

OWNER'S

MANUAL

MODEL NO=

536.884811

Caution'.

Read and Follow

all Safety Rules

and Instructions

Before Operating

This Equipment

CRA FI" SMAH®

5 HORSEPOWER

23" DUAL STAGE

TRAC=PLUS

OPTIONAL

ELECTRIC

START

SNOW THROWER

• Assembly

° Operation

• Maintenance

° Service and Adjustments

° Repair Parts

ROEBUCK AND Co., Chicago, IL. 60684 U.S.A.

SEARS,

Advertisement

Table of Contents

Summary of Contents for Craftsman 536.884811

- Page 1 OWNER'S MANUAL MODEL NO= 536.884811 Caution'. Read and Follow all Safety Rules and Instructions Before Operating This Equipment SEARS, ROEBUCK AND Co., Chicago, IL. 60684 U.S.A. CRA FI" SMAH® 5 HORSEPOWER 23" DUAL STAGE TRAC=PLUS OPTIONAL ELECTRIC SNOW THROWER • Assembly °...

- Page 2 CAUTION: ALWAYS PLACE WIRE WHERE PREVENT ACCIDENTAL TRANSPORTING, SAFETY STANDARDS REQUIRE RISK INJURY. YOUR ATTEMPT DEFEAT CONTROL UNDER CIRCUMSTANCES. BEFORE USE • Read the owner's manual carefully. oughly familiar with the controls and the proper use of the snow thrower. Know how to stop the snow thrower...

- Page 3 Never operate the snow thrower near glass en- closures, automobiles, window offs, and the like without proper adjustment the snow discharge angle. Keep children pets away. ® Never operate the snow thrower at high trans- port speeds on slippery surfaces. and use care when backing.

-

Page 4: Warranty

TWO YEAR LIMITED WARRANTY For two years from the date of purchase, when this Craftsman Snow Thrower is maintained, lubricated and tuned-up according to the instructions in the owner's manual, Sears will repair, free of charge, any defect in material and workmanship. -

Page 5: Table Of Contents

SAFETY RULES ... PRODUCT SPECIFICATIONS CUSTOMER RESPONSIBILITIES WARRANTY ... 4 TABLE OF CONTENTS ... 5 INDEX ... ASSEMBLY OPERATION Adjustment: Auger Drive Belt ... 18, 19 Belts ... 18-20 Belt Guide ... Cables ... Carburetor ... Friction Wheel ... Scraper Bar ... Spark Plug ... - Page 6 THIS SNOW THROWER MOVES EFFECTIVELY if your snow thrower must be moved without the aid of the engine, it will be easier' to pull the snow thrower back- ward by the handles, rather than pushing. On start up, the track drive system may be tight and will loosen up as the snow thrower is used. After first use, check the track for tension and adjust if necessary_ See the Track Adjustment paragraph in the Service and Adjust- ments section of this manual.

-

Page 7: Cables

Figure i showsthe snowthrowerin the shipping position,, Figure 2 shows the snow thrower completely assembled,, Reference to the right and left hand side of the snow thrower is from the operator's position at the handler TO REMOVE SNOW THROWER FROM CARTON (See Fig 1) Cut all four corners of the carton from top to bottom and lay the panels flat.. - Page 8 TO INSTALL THE UPPER HANDLE CRANK ASSEMBLY On the right side of the handle, install and secure the following parts (found in parts bag) in the lower handle hole as shown in figure 4A: 1 - 3/8" x 2" bolt 2 - 3/8"...

- Page 9 INSTALL THE SHIFTER LEVER ® Stand the snow thrower up on the frontof the auger housing, as shown in Figure 6. Cut the plastic tie which holds the shifter lever as- sembly to the shift bracket° • Remove the Iocknut, washer, spring and the bolt.. Reposition the shifter lever into the slot in the control panel, as shown in Figure 6 and reinstall the bolt, spring washer and the Iocknut.

- Page 10 LEVER CHUTE DEFLECTOR DISCHARGE CHUTE SEARS TRAC-PLUS SNOW THROWERS conform to the safety standards of the American National Standards Institute. AUGER DRIVE LEVER: Starts and stops the auge'r"and" impeller (snow gathering and throwing)= TRACTION DRIVE LEVER - Propels the snow thrower' forward and in reverse.

- Page 11 Always wear safety glasses or eye shields while operating the snow thrower° We recommend standard safety glasses or Wide Vision Safety Mask for over your glasses available at SEARS Retail or Catalog Stores,. HOW TO USE YOUR SNOW THROWER...

-

Page 12: Carburetor

TO USE WEIGHT TRANSFER In hard packed or heavy snow conditions, conventional snow throwers tend to rideup and leave uneven mounds of snow behind. For these conditions, your new tracked snow thrower has a unique weight transfer system (See Fig. 11) designed to minimize ride-up. Stepping on the weight transfer pedal shins more weight to the auger housing°... - Page 13 CAUTION: NEVER RUN ENGINE IN- DOORS OR IN ENCLOSED, POORLY VENTILATED AREAS. HAUST CONTAINS CARBON MON- OXIDE, AN ODORLESS AND DEADLY GAS. KEEP HANDS, FEET, HAIR AND LOOSE CLOTH- ING AWAY FROM ANY MOVING PARTS ON ENGINE AND SNOW THROWER. WARNING: TEMPERATURE OF MUFFLER AND NEARBY AREAS MAY EXCEED 150 °...

- Page 14 SNOW THROWING For maximum snow thrower efficiency, adjust ground speed, not throttle° If the track slips, reduce forward speed. The engine is designed to deliver maximum performance at full throttle and should be run at this power setting at all times. Most efficient snow blowing is accomplished when the snow is removed immediately after it falls For complete snow removal, slightly overlap each...

-

Page 15: Maintenance

GENERAL RECOMMENDATIONS The warranty on this snow thrower does not cover items that have been subjected to operator abuse or negli- gence,. To receive full value from the warranty, operator must maintain snow thrower as instructed in this manual., Some adjustments will need to be made periodically to properly maintain your snow thrower., All adjustments in the Service and Adjustments section of this manual should be checked at least once each sea-... -

Page 16: Friction Wheel

MAIN IENANCE NOTE: Any greasing or oiling of the above components can cause contamination of the friction wheel drive plate or friction wheel come in contact with grease or oil, damage to the friction wheel will resulL Should grease or' oil come in contact with the disc drive plate or friction wheel, be sure to clean the plate and wheel thoroughly. -

Page 17: Scraper Bar

CEAN CAUTION: ALWAYS DISCONNECT THE SPARK PLUG WIRE AND TIE BACK AWAY FROM THE PLUG BEFORE MAKING ANY ADJUSTMENTS OR REPAIRS. TO ADJUST SKIDS HEIGHT This snow thrower is equipped with two height adjust- ment skids, located on the outside of the auger housing These skids elevate the front of the snow thrower°... -

Page 18: Adjust Clutch Control Cables & Belts

SERVICE AND TO ADJusT THE CLU'TCH CONTROL CABLES Periodic adjustment of the cables may be required due to normal stretch and wear on the belts, To check for corr ect adjustment, the control lever must be in the full forward position, resting onthe plastic bumper.. - Page 19 The drive belts on this snow thrower are of special con- struction and should be replaced with original equipment belts available from your nearest SEARS Store or Serv- ice Center° You will need the assistance of a second person while...

-

Page 20: Shifter Lever

SERVICE AND ADJUSTMEN TRACK DRIVE BELT If your snow thrower will not move forward, check the track drive belt for wear. If the track drive belt needs to be replaced, proceed as follows: • Disconnect the spark plug wire. • Remove the belt cover, •... - Page 21 SERVICE AN TO REPLACE FRICTION WHEEL If the snowthrower will not move forward, and the friction wheel is worn or damaged, you need to replace it, as follows: Drain the gasoline from the fuel tank by removing the fuel lineoDrain the fuel and reinstall the fuel line,. Disconnect the spark plug wire, ®...

- Page 22 IJlJ ],lll,ll,i, _ SERVICEAND TO REPLACE AUGER SHEAR BOLT The augers are secured to the auger shaft with special bolts (See Fig. 34) that are designed to break (to protect the machine) if an object becomes lodged in the auger housing°...

- Page 23 ABOVE THE FACTORY HIGH SPEED SETTING CAN BE DANGEROUS. IF YOU THINK THE ENGINE GOVERNED HIGH SPEED NEEDS ADJUSTING, CONTACT YOU R NEAREST SEARS SERVICE CENTER, WHICH HAS THE PROPER EQUIPMENT AND EXPERIENCE TO MAKE ANY NECESSARY ADJUSTMENTS,. TO ADJUST...

-

Page 24: Storage

ii ii. CAUT'iON: NEVE"STORE WITH FUEL IN THE TANK INDOORS OR IN AN ENCLOSED, POORLY VENTILATED AREAWHERE FUEL FUMES MAY REACH AN OPEN FLAME, SPARK LIGHT AS ON A FURNACE,. WATER ttEATER, CLOTHES DRYER, ETC,. NOTE: Immediately prepare your snow thrower for stor- age at the end of the season or'if the unit will not be used for 30 days or more,. -

Page 25: Replacement

SERVICE SERVICE RECORDS Fill in dates as you com- After plete regular service First 2 Each hours Use Check Engine Oil Leve! Change Engine Oil v" 33gfiten All Sc'rews and Nuts ... Check Traction Cfutch Cable Adjustment (See Cable AdjusLrnent) Replace Sp_ Plug A_djustDrive"... - Page 26 TROUBLE SHOOTING POINTS TROUBLE CAUSE Difficult'starting Defective spark plug Water or dirt in fuel system ' 'B'locked Engine tuns erratic ,,,,,,,,, , Engine stalls Unit running on CHOKE Engine runs erratic; Water or dirt in fuel system Loss of power Carburetor Excessive vibration Loose parts;damaged impeller...

- Page 27 NOTES...

- Page 28 CRAFTSMAN 23" SNOW THROWER 536.884811 Handle Assembly Repair Parts _--4 _132 45 51, 47 46 46 47 24 26...

- Page 29 7288 3/8-16 x 3 In. Screw 3/8 In. Lockwasher 71062 3/8-16 Hex Nut 71044 7289 Plastic Stop 71045 3/8-16 Jam Nut 536.884811 REF. PART NO. PART NAME 71457 Eye Bolt 70984 5/16-18 x 3/4 In Screw 308011 Lower Handle 1672...

- Page 30 CRAFTSMAN 23" SNOW THROWER Motor Mount Assembly Repair Parts 536.884811 © 8 29 54 52 87 74 7 73 60 77...

- Page 31 Auger Brake Spring 301545 5 In. Impeller Pulley 5939 Special Traction Drive Belt 3526 Special Auger Drive Belt 85495 Shift Control Shaft 536.884811 REF. t No. I PART NO. PART NAME 73812 1/2 In Flatwasher 71111 3/8-16 Hex Locknut 71461...

- Page 32 CRAFTSMAN 23" SNOW THROWER 536.884811 Track Assembly Repair Parts 21 22 ÷ 29 26 25 35 19 26 19 36 37 16 15...

- Page 33 1/4-28 x 3-3/4 In, Screw 71067 1/4 In. Flatwasher 6108 1/4-28 Locknut ! 21 71348 5/16-18 x t/2 In. Screw 5951 5/16 In,.BeIleville Washer 536.884811 REF. PART NAME PART NO, 5950 1/2 In. Flatwasher 4-3/4 In_Track 9724 302024 Track Wheel Shaft...

- Page 34 CRAFTSMAN 23" SNOW THROWER 536.884811 Auger Housing Assembly )air Parts ,o f il 3 15 16...

- Page 35 71071 308059 Bearing & Retainer 308119 R,H Side Plate 302922 Danger Decal, Read From Side 20556 3/16 In_ Square Key 536.884811 REF. PART NO. PART NAME 71032 8-32 x 1/2 Ino Bolt 309057 Retainer w/Stop Clip,Chute 85480 Lower Chute Ring Clip...

- Page 36 Oil Seal 53737 Quad Ring 10905 Flange Bearing 53735 7/8 In,, Flatwasher 53734 7/8 In, Roller Bearing 53733 7/8 In_Flatwasher 50795 3/4 in_ Key 536.884811 15 16 REF, PART NO. 53732 50683 50688 5373 t 53749 53743 53748 53730 PART NAME 1-3/4 In,.

- Page 37 REWIND STARTER NO. 590646 Refo Part Part Name 59O646 iStarter, Rewind 590599A iPin, Spring _(}_cLNo. 4) 590600 Washer 590615 Retainer 590601 iWasher 590598 ISpring, Brake 590616 Dog, Starter 590617 Spring, Dog 590645 Pulley 590619 Spring, Rewind 590620 Cover, Spring 590647 Housing Assyo, Starter 590451A Rope, Starter (Length 69"...

- Page 38 CRAFTSMAN 4 -CYCLE ENGINE 290C MODEL 102 ___31 > NUMBER: 143.804072 IIIII II II IIIII ,,,...-"*' . J'e.,..._ _'-,-.. 219 " ..f202 " "_'-186 203 30_i MODELand SERIAL NUMBERS HERE...

- Page 39 CRAFTSMAN 4=CYCLE E NGINE Ref. Part Part Name " 33674B Cylinder Assy. (lncl, Nos, 7 8 46) 34171 Nipple, Pipe 3O969 Cap, Oil drain 326O0 Seal, Oil 28277 Washer, Flat 31334 Rod, Governor 31510 Lever, Governor 31335 Clamp, Governor lever 65O548 Screw, Hex washer hdo, 8-32 x 5/t6 _33342...

- Page 40 CRAFTSMAN 4 -CYCLE ENGINE Part Part Name 34182 Bracket, Fuel tank mounting 65O675 Washer, Flat 65O805 Screw, Hex hd. w/bellevilie washer, 1/4-20 x 11/16 "33670A Gasket, Exhaust 33697A Muffler 650327 Screw, Fil. hd_ Seres, 1/4-20 x 2-i/2 8345 Washer, Flat 30O63 Screw, Hex washer hd.

- Page 41 NOTES...

- Page 42 * ENGINE MODEL NUMBER 143.804072 * PART NUMBER * PART DESCRIPTION "Your Sears merchandise has added value when you consider that Sears has service units nationwide staffed with Sears trained technicians ,,.Professional technicians specifically trained on Sears Products, having the parts, tools and equipment to insure that we meet our pledge to you._we service what we sell,"...

Need help?

Do you have a question about the 536.884811 and is the answer not in the manual?

Questions and answers