Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Jungheinrich HC 10

- Page 1 HC 10 05.02- Operating instructions 50274119 07.08...

- Page 2 Used to indicate standard equipment. Used to indicate optional equipment. Our trucks are subject to ongoing development. Jungheinrich reserves the right to alter the design, equipment and technical features of the truck. No guarantee of particular features of the truck should therefore be inferred from the present operating instructions.

-

Page 4: Table Of Contents

Table of contents Correct use and application of the truck Description of the truck Application ................... B 1 Description of the assemblies and functions ........B 2 Truck ....................B 3 Technical data - standard version ............B 4 Performance data for standard trucks ..........B 4 Dimensions .................. - Page 5 Maintenance of the fork-lift truck Operational safety and environmental protection .........F 1 Safety regulations applicable to truck maintenance ......F 1 Maintenance and Inspection ..............F 3 Maintenance checklist HC ..............F 4 HC Lubrication Schedule ..............F 5 Fuels, coolants and lubricants ..............F 6 Notes regarding maintenance ..............F 6 Preparing the truck for maintenance work ...........F 6 Checking the electric fuses ..............F 7...

-

Page 6: A Correct Use And Application Of The Truck

A Correct use and application of the truck The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are included in the scope of delivery for this truck. The guidelines are part of these ope- rating instructions and must always be heeded. National regulations are fully applica- ble. -

Page 8: B Description Of The Truck

The truck is intended for transporting goods on a level floor. It can pick up pallets that are open to the ground or trolleys. The capacity of the truck can be found on the ca- pacity label Q Truck type, load capacity and motor output: Type Load capacity Motor output HC 10 1000 kg 1,8 kW... -

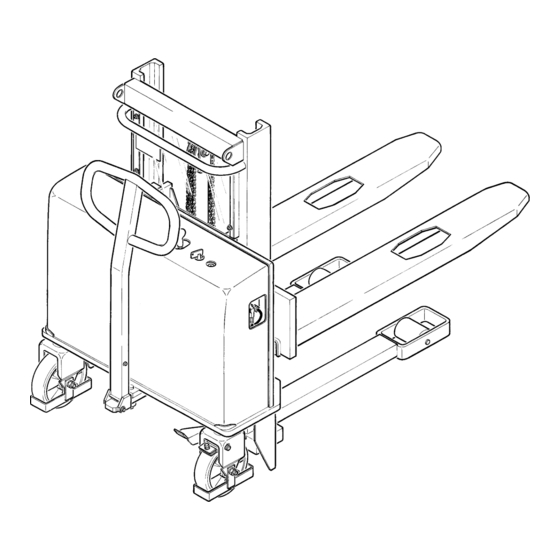

Page 9: Description Of The Assemblies And Functions

Description of the assemblies and functions Item Designation Battery monitor Key switch Operating lever, raise / lower fork Control shaft Hoist frame Load lifting device Load-bearing wheel arm Battery charge plug 230 VAC (integrated battery charger) Wheel guard Steering wheels Parking brake Brake pedal (parking brake) t = Standard equipment... -

Page 10: Truck

Truck Construction: The HC is a four-wheeled vehicle incorporating two steering wheels (11) and two load-bearing wheel arms (8). An easily opened cover gives very good access to all units. The operating controls are located on top of the cover. Safety features: –... -

Page 11: Technical Data - Standard Version

Technical data - standard version Technical data specified according to VDI 2198. Technical data are subject to alteration and additions. Performance data for standard trucks Designation Rated load capacity 1000 Load centre Lifting speed with / without load 8 / 10 cm/s Lowering speed with / without load 27 / 15... -

Page 13: En Standards

EN standards Continuous sound level: 61,0 dB(A) according to prEN 12053 as stipulated in ISO 4871 The continuous sound level is a value averaged according to standard regulations, taking the sound pressure level into account when driving, lifting and idling. The sound pressure level is measured at the ear. -

Page 14: Labels

Labels Item Designation Load capacity Q Load diagram Eye for crane loading Danger: Risk of crushing Do not ride on the lifting fork Do not stand under the load. Truck identification plate... -

Page 15: Truck Identification Plate

Truck identification plate Item Designation Item Designation Type Load centre distance in mm Serial No. Min./max. battery weight in kg Rated capacity in kg Empty weight without battery in kg Battery: Voltage V Year of manufacture Ampere hours Ah Manufacturer Manufacturer logo In the event of queries relating to the truck or spare part orders, please state the serial no. -

Page 16: C Transportation And Commissioning

C Transportation and commissioning Transportation by crane Only use lifting gear of adequate capacity (loading weight = dead weight + battery weight; see truck identification plate). Lifting points (1) are provided or loading the truck by means of crane gear. –... - Page 17 C 17...

-

Page 18: D Battery-Servicing,Recharging,Replacement

D Battery-Servicing,recharging,replacement Safety regulations governing the handling of lead-acid batteries The truck must be parked and rendered safe before any operations on batteries are undertaken (refer to chapter E). Servicing staff: Recharging, servicing and replacing of batteries must only be per- formed by qualified personnel. -

Page 19: Charging The Battery Using The Integrated Charger

Charging the battery using the integrated charger The mains cable of the charger is accessible from outside. Do not remove the cover before or during the charging process. If the cover is open, there is a risk of electrocution and danger to life. It is essential to disconnect the vehicle from the mains electricity supply before chang- ing the fuse (1). -

Page 20: Replacing The Batteries

Replacing the batteries – Park the vehicle and secure it (see chapter E). – Loosen the screws (11) and lift off the cover (10) (allen key is supplied). Route the battery cables in such a way that they do not catch on the battery when it is lifted out. -

Page 21: Battery Monitor

Battery Monitor (o) The charge status of the battery is shown by the light-emitting diode (12) once the key switch has been turned on. Light-emitting diode (12) steady green: – Normal condition, battery voltage 1,7 V per cell. Light-emitting diode (12) flashes red: –... -

Page 22: E Operation

E Operation Safety regulations governing the operation of the fork lift truck Driving permission: The fork lift truck must only be operated by persons who have been trained in the operation of trucks, who have demonstrated to the user or his re- presentative their capability of moving and handling loads, and who have expressly been charged by the user or his representative with the operation of the truck. -

Page 23: Description Of The Operating Controls And Indicators

Description of the operating controls and indicators Item Control or indicator Function Brake pedal Prevents the vehicle rolling. Integrated charger The battery is charged when the (incl. safety cut-out) mains plug is plugged into an electric outlet. Battery monitor Shows the charging condition of the battery (refer to chapter D). -

Page 24: Starting Up The Truck

Starting up the truck The driver must make sure that nobody is within the danger area of the truck before the truck is switch on or operated or before a load is lifted. Checks and operations to be performed before starting daily work –... -

Page 25: Operation Of The Fork-Lift Truck

Operation of the fork lift truck Safety regulations applicable when operating the truck Driving lanes and work areas: Only such lanes and routes that are specially alloca- ted for truck traffic must be used. Unauthorized persons must stay away from work areas. -

Page 26: Driving, Steering, Braking

Driving, steering, braking It is not admissible to stay on the vehicle during driving. Driving Only drive with the hoods closed and properly locked. – Start up the truck (see section 3). – Tilt the control shaft (6) downwards and move it in the desired direction by either pulling the vehicle forwards (V) or pushing it backwards (R). -

Page 27: Picking Up And Setting Down Loads

Picking up and setting down loads Before picking up a load, the driver must make sure that the load rests properly on its pallet and that it does not exceed the maximum load capacity of the truck. Picking up long loads crosswise is not permitted. –... -

Page 28: F Maintenance Of The Fork-Lift Truck

F Maintenance of the fork-lift truck Operational safety and environmental protection The checks and servicing operations contained in this chapter must be performed in accordance with the intervals as indicated in the servicing checklists. Modifications of fork-lift truck assemblies, especially of the safety installations, are not permitted. - Page 29 Work on the electric system: Work on the electric system of the truck must only be performed by personnel specially trained for such operations. Before commencing any work on the electric system, all measures required to prevent electric shocks have to be taken. In the case of battery driven vehicles, the battery plug is to be dis- connected additionally or the batteries are to be disconnected to ensure that the ve- hicle is electrically isolated.

-

Page 30: Maintenance And Inspection

Maintenance and Inspection One of the most important factors for the safe operation of the vehicle is a thorough and competent maintenance service. If regular maintenance is neglected, the vehicle may suffer breakdowns and in addition it creates a potential source of danger for the personnel and the workplace. -

Page 31: Maintenance Checklist Hc

Maintenance checklist Maintenance intervals Standard = t W W M M M Cold store = k 1 6 12 t t t t t Chassis / 1.1 Check all load bearing elements for damage super- t t t t t 1.2 Check all bolted connections structure: t t t t t... -

Page 32: Hc Lubrication Schedule

HC Lubrication Schedule Sliding surfaces Grease nipple Filler plug for hydraulic oil... -

Page 33: Fuels, Coolants And Lubricants

Fuels, coolants and lubricants Handling consumption-type material: Consumption-type material must always be handled properly. Manufacturer’s instructions are to be observed. Improper handling is injurious to health, life and environment. Consumption-type ma- terials must be stored in adequate containers. They might be inflammable and, the- refore, must not come into contact with hot components or open fire. -

Page 34: Checking The Electric Fuses

Checking the electric fuses – Prepare the truck for maintenance work (see section 6.1). – Remove cover. – Check all fuses for the correct rating and, if necessary, replace. Item Designation Type of fuse: Power fuse 100 A Control fuse Fuse, battery charger Recommissioning the truck Recommissioning of the truck following the performance of cleaning or maintenance... -

Page 35: Recommissioning The Truck

Decommissioning the fork-lift truck If the fork-lift truck is to be decommissioned for more than 6 months, it must be parked in a frost-free and dry location and all measures to be taken before, during and follo- wing decommissioning must be performed as detailed below. During decommissioning, the fork-lift truck must be jacked up, ensuring that the wheels are clear of the ground. -

Page 36: Safety Checks To Be Performed At Regular Intervals And Following Any Unusual Incidents

Carry out a safety check in accordance with national regulations. Junheinrich recom- mends checks in accordance with FEM Guideline 4.004. Jungheinrich has a special safety department with trained personnel to carry out such checks. The truck must be inspected at least annually (refer to national regulations) or after any unusual event by a qualified inspector. -

Page 37: Faul Localisation And Identification

Faul localisation and identification 10.1 Fault localisation Fault Possible cause Remedial action Vehicle does – Battery is still being – Disconnect 230 V connection not work. charged – The key switch is set to – Turn the key clockwise as far as it will OFF.

Need help?

Do you have a question about the HC 10 and is the answer not in the manual?

Questions and answers