Table of Contents

Advertisement

v

For Future Reference

,9__ARS

owners

manual

MODEL NO.

113.244530

VARIABLE SPEED

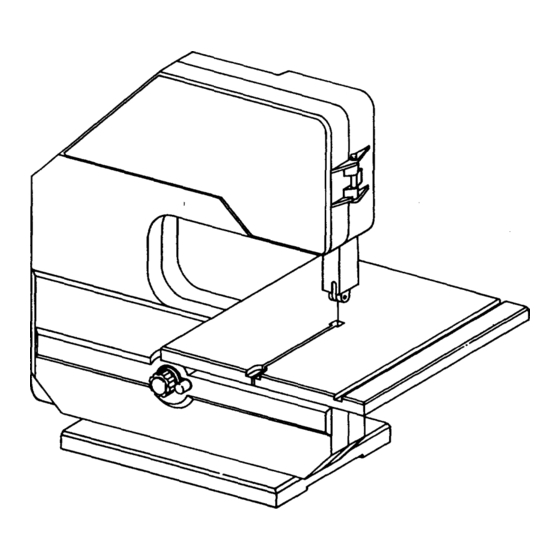

10-1NCH BAND SAW

Serial

Number.

Model and serial numbers

may be found on the back

of the saw.

You should record

both

model and serial number

in

a safe place

for future use.

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

r

___AIRS / r.RRFT$ MRN_._

VARIABLE SPEED

10-1NCH BAND SAW

• assembly

• operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago,

IL 60684 U.S.A.

Part No. SP5620

Advertisement

Table of Contents

Summary of Contents for Craftsman 113.244530

- Page 1 FOR YOUR SAFETY: READ ALL INSTRUCTIONS CAREFULLY Sold by SEARS, ROEBUCK AND CO., Chicago, Part No. SP5620 ___AIRS / r.RRFT$ MRN_._ VARIABLE SPEED 10-1NCH BAND SAW • assembly • operating • repair parts...

-

Page 2: Safety Instructions For Band Saw

FULL ONE YEAR WARRANTY ON CRAFTSMAN If within one year from the date of purchase, this Craftsman Band Saw fails due to a defect in material or workmanship, Sears will repair it, free of charge. WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERV- ICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES. - Page 3 Plan your work. • USE THE RIGHT TOOL. Don't force tool or attachment to do a job it was not designed to do. • Use this band saw to cut wood, wood like prod- ucts, plastics, non-ferrous and ferrous (ferrous metals 1/16 inch thick or less).

-

Page 4: Before Leaving The Saw

Before starting your cut, watch the saw while it runs. If it makes an unfamiliar noise or vibrates a lot, stop imme- diately. Turn the saw off. Unplug the saw. Do not restart until finding and correcting the problem. -

Page 5: Motor Specifications And Electrical Requirements

120 volts, 60 Hz., alternating current. CAUTION: A direct current motor is used in this I saw. Changes to the internal wiring will create a I fire hazard and may also create a shock hazard. For replacement motor and control board refer to parts list in this manual. -

Page 6: Table Of Contents

Model 113.244530 Band Saw is shipped complete in one carton. Separate all parts from packing materials and check each item with illustration and "Table of Loose Parts". -

Page 7: Assembly Mounting Band Saw To Workbench

MOUNTING BAND SAW TO WORKBENCH If band saw is to be used in a permanent location, it should be fastened securely to a firm supporting sur- face such as a workbench. If mounting to a workbench, holes should be drilled... -

Page 8: Installing The Table

An alternate method of mounting is to fasten band saw to a mounting board. The board should be of suf- ficient size to avoid tipping of saw while in use. Any good grade of plywood or chipboard with a 3/4" mini- mum thickness is recommended. -

Page 9: Installing The Blade

1. Loosen the upper slide lock knob and position the guide assembly about half way between the table and the frame. Tighten the lock knob. 2. Open the front cover of the saw by pulling forward on the finger hold located on the left side of the band saw. -

Page 10: Tensioning The Blade

7. The upper wheel needs to be placed in its lowest position. Locate the tension lock knob on the back of the saw and turn it counterclockwise approximately two turns. Lift the tension catch away from the teeth and move it to its lowest position. -

Page 11: Tracking The Blade

3. a. If the blade moved toward the front of the saw turn the adjustment screw in (clockwise) while turning the wheel by hand, until the blade rides in the center of the tire. -

Page 12: Final Table Assembly

Never start the saw with the cover l open. Thrown blades can cause injury. FINAL TABLE ASSEMBLY 1. Close the front cover of the band saw and snap in place. 2. Locate a 1/4-20 x 5/8 truss head screw, and a 1/4- 20 wing nut in loose parts. - Page 13 Hose Clip in the loose Identify the barbs on the clip. 2. Open the front cover of the saw by pulling forward on the finger hold located on the left side of the band saw. Locate the notch in the Frame at the sawdust ejection port.

-

Page 14: Getting To Know Your Band Saw

Always adjust the upper guide assembly and lock the upper slide by tightening the upper slide lock knob before turning on the band saw. 3. Table lock knob... Loosening the knob allows the table to be tilted and tightening the knob locks the table in place. - Page 15 (-*-------) to reduce the strokes per minute. NOTE: To protect the motor the band saw will auto- matically shut off if the work piece is fed into the blade too aggressively or if the blade binds. To restart the band saw;...

-

Page 16: Choice Of Blade And Speed

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents. Floor must not be slip- pery. To avoid burns or other fire damage, never use the saw near flammable liquids, vapors or gases. Plan ahead to protect your eyes, hands, KNOW YOUR SAW. -

Page 17: Whenever Saw Is Running

They can get Before starting your cut, watch the saw while it runs. If it makes an unfamiliar noise or vibrates a lot, stop imme- diately. Turn the saw off. Unplug the saw. Do not restart until finding and correcting the problem. -

Page 18: Basic Band Saw Operation

The blade should cut in the middle of the pattern line (saw kerf) since wood cutting band saw blades are thin. NOTE: When cutting tight curves in metal feed the workpiece at a slow rate. The blade may bind causing... -

Page 19: Sears Recommends The Following Accessories

6. Close the front cover of the saw. sears recommends the following accessories Sears may recommend other accessories not listed in manual. See your nearest Sears Store for other accessories. Do not use any accessory un!ess you have received andread complete instructions for its use. -

Page 20: Troubleshooting

Push on-off 1. Replace damaged parts before using Band Saw again. Consult Sears Service. Any attempt to repair this motor may create a HAZARD unless repair is done by a qualified service technician. Repair service is available at your nearest Sears Store. -

Page 21: Repair Parts

FOR 10-INCH BAND SAW 113.244530 Always order by Part Number- FIGURE 1 Part Description 820286 Guard Blade STD601103 * Screw Pan Cr Ty 'q'T" 10-32 x 817899 Screw Soc Set 1/2 Dog Pt. 1/4-20 x 1/2 STD502502 * Screw Soc Set 1/4-20 x 1/4... - Page 22 repair parts _>, (Jr) 'r" (_0 L'O €_4...

- Page 23 repair parts • t_O • i.i. o t---...

-

Page 24: How To Order Repair Parts

MODEL NUMBER 113.244530 All parts listed may be ordered from any Sears Service Center and most Sears stores. If the parts you need are not stocked locally, your order will be electronically Repair Parts Distribution Center for handling. Form No. SP5620 and Co.

Need help?

Do you have a question about the 113.244530 and is the answer not in the manual?

Questions and answers