Table of Contents

Advertisement

Ii

Future Reference

_AIRS

MODEL

O.

113.236150

Serial

Number

Model and serial number may be

found attached to the right side of

arm housing.

You should

record

both model

and serial number in a safe place

for future use.

i ii llllINNI

'

II

................

FOR YOUR

SAFETY:

Read

ALL

iNSTRUCTIONS

carefully

16 INCH

RIABLE

SPEED SCROLL

SAW

, assembly

• operating

repair parts

...........

,

.........

J

_

........................

Sold by SEARS,

ROEBUCK

AND CO., Chicago,

IL. 60684 U.S.A.

Part No_SP5641

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Craftsman 113.23615

- Page 1 FOR YOUR SAFETY: Read iNSTRUCTIONS carefully Sold by SEARS, Part No_SP5641 16 INCH SPEED SCROLL , assembly • operating repair parts ROEBUCK AND CO., Chicago, RIABLE IL.

- Page 2 • Support the saw so the table is level and the saw does not rock. = Bolt the saw to the work surface if it tends to slip, walk, or slide during operations like cutting long heavy boards, or when using an auxiliary table.

- Page 3 • Keep Work Area Clean. Cluttered areas and benches invite accidents. Floor must not be slippery. To avoid burns or other fire damage, never use the saw ._nearflammable liquids, vapors or gases. !tan Ahead to Protect Your Eyes, Face and Ears , Know Your Saw.

- Page 4 A careless fraction enough to cause a Severe injury, • Before starting your cut, watCh the saw while it runs. If it makes an unfamiliar noise or Vibrates excessively, stop' immediately Turn the saw off:Unplug the:saw:_ Do not restart until findingand correctin gthe problem, •...

- Page 5 120V, 60Hz, alternating current. CAUTION: A direct current motor is used in thisj saw. Changes to the internal wiring will create a fire I hazard and may also create a shock hazard. For replacement motor and control board, refer to parts list in this manual.

- Page 6 Make certain all items are accounted for before discard- ing any packaging material. If any parts are missing, do not attempt to assemble the Scroll Saw, plug in the power cordor turn the switch on until the missing parts are obtained and installed cor- rectly.

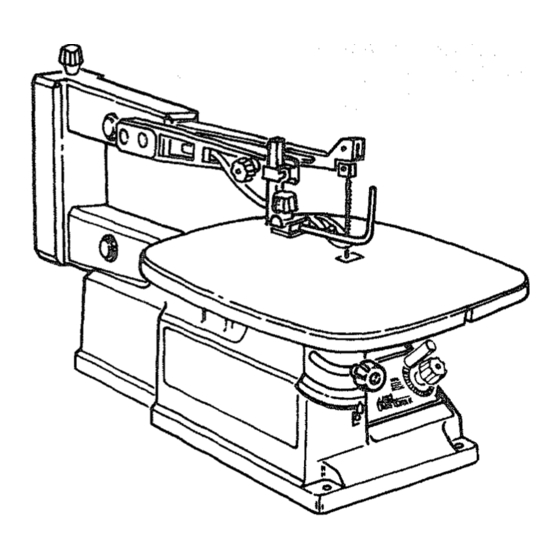

- Page 7 1. Lift the saw by the frame and base and place scrolt saw on work bench. 2. Familiarize yourself with the controls and features of '_ this scroll saw indicated in the illustration.

- Page 8 2. A bevel scale is provided under the work table as a convenient reference for setting the approximate table angle for bevel cutting. When greater precision is requiredl make practice cuts and :adjust the table as necessary:for your require- : ... ments. •...

- Page 9 2_Use a small square to set the table at 90" to the blade. If there is too much space between the square and the blade, the table must be adjusted. 3. When the space between the square and the blade is minimal, tighten the bevel lock knob, The table should now be approximately 90 °...

- Page 10 Ing power, rotate the motor shaft by hand using a screwdriver in the motor shaft slot as shown, injury remove the blade change rod and all tools from the IWARNING: To avoid from thrown saw. Upper Blade Holder NOTE: Teeth pointing downward. line up. Blade Clamp "V"...

- Page 11 OFF"and • • lfrom outlet before removing or,replacing the blade. OTE: Saw comes set up, for pin end blades. For plain =end blades, the blade clamp needs to be reinstalled with the flat surface placed against the blade holder. Removing Plain End Blades 1.

- Page 12 wARNING: To avoid i'njury from accidental starting, alwwsturn switch:"OFP and unplug power cord ;, fromoutlet before removing or replacing the blade; The purpose of the work hold_down foot is to hold the work against the table so that it :is less likely io liftwith:the up stroke of the blade, tt should lie flat on the work with the front prongs straddling the blade.

- Page 13 Do NOT over tighten mounting bolts - leave some cush- ion in the foam pad for absorbing noise and vibration. If you prefer to mount your saw to a leg set, we rec- ommend the leg set for bench top tools which is available through Sears Retail Stores.

- Page 14 Lower Blade Holder 1. Tension Knob ... Tightening the knob (clockwise) will increase the tension on the blade. Loosening it (coun- terclockwise) will deCreaSe the tension. 2. Work Hold-Down and Blade Support added control of work-p!ece, protection for operator and support for the blade_ 3.

- Page 15 This will prevent the machine ing up again when the power comes Until It to the \,,. (_"_) Rotate through lock the saw.) always push in the lights go out), from start- back on. Push...

- Page 16 Listed below are examples of some blades and their intended uses: Pin and Plain end Biades :'Teeth/inch Width Thickness i, ..__2 .012" : _110_'..0t 8" +:+o666' 12:5 .038" .0i8" 11.5 .053'_ .110" :,018" 3. Use a blade that will have at least 2 teeth in the mate- dal at ail times.

- Page 17 =_lease, read and understand the following scroll saw before attempting to use the saw. 1. The saw does not Cut wood by itself. You allow the saw to cut wood by guiding the wood into the blade as it moves.

- Page 18 They are not safety glassesi:: ...with_apossible thrown piece if the blade should break. Safety goggles: are available :at Sears Retail Stores. Glasses or goggles not in compliance with ANSi Z87.1 could seriously hurt you when they break_ •...

- Page 19 Making interior Scroll Cuts 1. One of the features of this saw is that it can be used to make scroll cuts on the interior of a board without breaking or cutting into the outline or perimeter of the board.

- Page 20 Lubricate the arm bearings after 10 _ours of use. Re-oil after every 50 hours of use or whenever there is a squeak coming from the bearings_ 1. Turn saw on its side. 2_Squirt a generous amount 0f SAE 30 oil around the -::shaft end and bronze bearing._ 3_ Let tl_e:oil soak inoVernight in this condition.

- Page 21 /ARNING: To avoid fire or shock, use only recom- _ended service parts and reassemble [originally assembled. Sears recommends Item Leg Set ... Blades ... See Sears Retail Store for 5" long Plain End/Pin End blades Troubleshooting power source outlet before troubleshooting WARNING: For your own safety, turn switch "OFF",...

- Page 22 "...

- Page 23 63 { 820315 SP5641 ;-A_'attempt to repair this motor may create a hazard unless repair is done by a qualified service technician. Repair service is available at your nearest Sears store. SPEED SCROLL Description Support, Plate Spring, Hold Down Guard, Blade Clamp, Hold Down Screw, Hex Soc Set,M5 x 0.8-5...

- Page 24 The instructions and illustrations shown on blades. scroll saw owner's manual for safety instructions and proper use of the scroll saw. rBlades starting, i 113.236150 Knob...

- Page 25 Installing Pin End Blades NOTE: The saw come s from the factory already set up for pin end blades. Pin End Blade Set Up: Insert the blade change rod through the hole above the upper blade holder, Use the "T" handle wrench to loosen the hex socket screw...

- Page 26 tel:clockwise _ about three full turns. 3, Insert the blade change rod through the hole above the blade holder and loosen the hex socket screw of the blade holder with the "T" wrench. 4!. Remove blade from upper blade holder. 5i: Loosen th:e lower blade holder he×...

- Page 27 WARNING: To avoid injury from thrown objects, remove the blade change rod and all tools from the saw. Beveled Edge Circular ImiDression Blade Clam_ t (_ Thin Boss Upper Blade Holder Form No.

- Page 28 SPEED SCROLL Now that you have purchased your scroll saw, should a need ever exist for repair parts or service, simply contact any Sears Service Center and most Sears, Roebuck and Co. stores, Be sure to provide all pertinent facts when you call or visit.

Need help?

Do you have a question about the 113.23615 and is the answer not in the manual?

Questions and answers