Advertisement

Quick Links

f

Save

This Manual

"_

For Future

Reference

___JRS

owner's

manual

MODEL NO.

113.234600

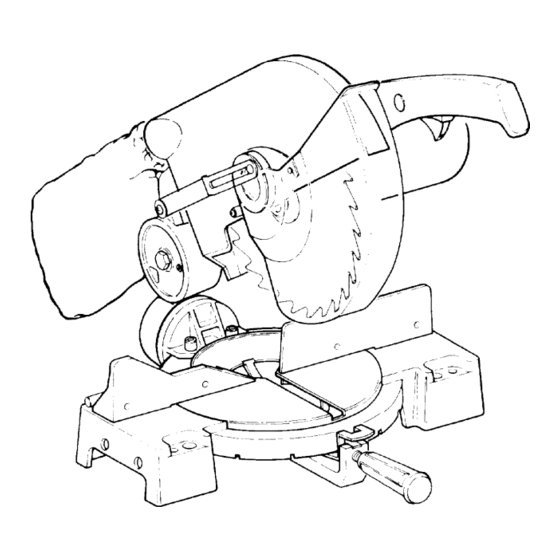

10" COMPOUND

MITER SAW

Serial

Number

Model and serial numbers

may be found on the motor

cover.

You should record both

model and serial number in

a safe place for future use.

FOR YOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

_'_:_AIRS / CRRFT$ IVl R N

10-1NCH COMPOUND

MITER SAW

• assembly

• operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago,

IL 60684

U.S.A.

Part No. SP5404

Printed

in Taiwan.

Advertisement

Summary of Contents for Craftsman 113.234600

- Page 1 Save This Manual "_ For Future Reference ___JRS owner's manual MODEL NO. 113.234600 10" COMPOUND MITER SAW Serial Number Model and serial numbers may be found on the motor cover. _'_:_AIRS / CRRFT$ IVl R N You should record both model and serial number in a safe place for future use.

- Page 2 ON CRAFTSMAN MITER SAW If within one year from the date of purchase, this Craftsman Miter Saw fails due to a defect in material or workmanship, Sears will repair it, free of charge. WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERV- ICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

- Page 3 Plan ahead to protect your eyes, CHECK DAMAGED PARTS. Check for: hands, face, ears. • Alignment of moving parts, KNOW YOUR MITER SAW. Read and understand the • Damaged electric cords. owner's manual and labels affixed to the tool. Learn its _.,.O_ application and limitations as well as the specific poten- •...

- Page 4 • Roll long sleeves above the elbow. WARNING: If planning to cut aluminum or other • Noise levels vary widely. To avoid possible hearing non-ferrous metals: Under adverse conditions, the damage, wear ear plugs or muffs when using miter blade can grab and throw the workpiece suddenly saw for hours at a time.

- Page 5 glossary of terms for woodworking Arbor Resin {:=: The shaft on which a cutting tool =s mounted A sticky, sap based substance that has hardened. Bevel Revolutions Per Minute (RPM) An angle cuthng operation made through the face of The number of turns completed t_y a spinning obiect =n the work p_ece.

- Page 6 MOTOR SAFETY PROTECTION 5. Most motor troubles may be traced to loose or incor- rect connections, overload, low voltage (such CAUTION: To avoid motor damage, this motorl small size wire in the supply circuit) or to overly )ong should be blown out or vacuumed frequently to J...

- Page 7 UNPACKING AND PREASSEMBLY 2. Place the saw on a secure stationary work surface WARNING: To avoid injury from unexpected start- and look the saw over carefully. ing or electrical shock, do not plug the power cord into a source of power during unpacking assembly.

- Page 8 knowing your miter saw WARNING LABEL 1. Warning label Handle Latch--The miter saw can be locked in the lowered position for compact storage 3. Fence Lock Handles--The fence has two positions for increased crosscut capacity. The lock handles secure the fence to the base The saw is shipped HANDLE...

- Page 9 assembly and alignment HANDLE ASSEMBLY ALIGNMENT LATCH Assembling the Lower Blade Guard NOTE: For compact shipment the lower blade guard has been partially disconnected 1. The miter saw =s equipped with a handle latch used to lock the miter in the lowered position, release, push the handle...

- Page 10 Step Two--Checking and Aligning Blade with Turn Table Slot 1. The blade should look like it's parallel to the sides of the turn table slot. The blade should be 'W' closer to left side than right. If blade looks parallel with turn table slot proceed to step three.

- Page 11 Step Four--Pivot Adjustments PIVOT BOLT NOTE: These adjustments were made at the factory and normally do not require readjustment. 1. The miter saw should rise completely to the up posi- tion by itself. If the saw will not raise by itself or if there is play in the pivot joints the following adjust- ments are necessary.

- Page 12 Fence Positions The miter saw has two fence positions, The front fence position is used for workpieces up to standard 2 x 4 for cut off and bevel operation, floor and ceiling moldings, door casings. rear fence position is used ..

- Page 13 NOTE: Pay attention to pieces removed, noting their ARBOR 10" BLADE position and direction they face (see illustration) Wipe WASHER the blade collars clean of any sawdust before installing the new blades. 8. Install the new 10" blade (see recommended acces- sory list).

- Page 14 If the saw is to be used in a portable application, mount the saw to a 34" piece of plywood. The mounting board can then be clamped down to prevent it from tipping. MOUNTING BOLTS MOUNTING BOARD FOR CATALOG 3/4" P LYWOOD NO.

- Page 15 14" .,,! Attach mounting board to holes indicated SIDE FRONT CATALOG NO. 9-22244 LEG SET o"J ._, rn O...

- Page 16 BEFORE USING THE MITER SAW: To avoid injury from jams, slips or thrown pieces: • USE ONLY RECOMMENDEDACCESSORIES. (See WARNING: To avoid mistakes that could cause page 23). Consult this Owner's manual for recom- serious permanent injury, do not plug the miter mended accessories.

- Page 17 Use extra caution with large, very small or awkward Dress for safety. workpieces: Any power miter saw can throw foreign objects into the • Use extra supports (tables, saw horses, blocks, etc.) eyes. This can cause permanent eye damage. Wear for any workpieces large enough to tip when not held safety goggles (not glasses)

- Page 18 After finishing a cut: Never confine the piece being cut off. Never hold it, clamp it, touch it, or use length stops against it while • Keep holding the power head down the blade is spinning. It must be free to move sideways •...

- Page 19 MiterCut Whena mitercut is required, m ovethe sawto the desired angle.Donot standin frontofthe sawtable. Move withthehandte t othemiter a ngle tomake thecut NOTE:Remember to loosenthe fencelockhandles beforechanging the miteranglewiththe fencein the rearposition. Bevel When a bevel cut is required, tilt the blade to desired bevel angle.

- Page 20 Compound When a compound cut is required, select the correct bevel and miter position. Move with the handle to the miter angle to make the cut if the fence is in the rear position, loosen the two lock handles before changing the miter angle Cutting Bowed Material Before cutting a workpiece, check to make sure it is...

- Page 21 Workpiece Support Long pieces need extra supports• The supports should be placed along the workpiece so the workpiece does your hand holding workpiece positioned 4" or more from the blade path. The support should let the workpiece lay flat on the base and work table during the cutting operation...

- Page 22 Filler Blocks for Cutting Crown Moldings placed on the table upside down The majority of crown moldings have contact surfaces When the filler blocks are attached to the fence with of 52: and 38 to the rear surface of the molding. When the face of the filler blocks...

- Page 23 maintenance and lubrication Maintenance Always unplug the power cord before any maintenance WARNING: If blowing sawdust, wear proper eye check on this saw. protection to keep debris from blowing into eyes. DANGER: Never put lubricants on the blade while Recommended Accessories it's spinning.

- Page 24 TROUBLE SHOOTING GUIDE - MOTOR SUGG ESTED CORRECTIVE ACTION PROBABLE CAUSE PROBLEM Brushes not seated -Inspect/clean/replace brushes Brake does not stop (see maintenance section). blade within or lightly sticking. 2-3 seconds. --Use a recommended blade 2. Motor brake winding-- overheated from use of not- --Let cool down.

- Page 25 BRUSH SHORT BLUE WHITE LONG BLACK BRAKE TRIGGER SWITCH BRUSH CIRCUIT DIAGRAM NOTES...

- Page 26 PARTS LIST FOR CRAFTSMAN 10" COMPOUND MITER SAW MODEL NO. 113.234600 2o._ 19 ---,-_ _ 23 "''_...

- Page 27 PARTS LIST FOR CRAFTSMAN 10" COMPOUND MITER SAW MODEL NO. 113.234600 Always order by Part Number--Not by Key Number FIGURE Part Part Description Description 816669 Handle-Miter Blade Guard Asm. STD523108 ,I]L* Bolt-Hex HD. 5/16-18 x 7/8 (see Fig. 4)

- Page 28 PARTS LIST FOR CRAFTSMAN 10" COMPOUND MITER SAW MODEL NO. 113.234600 .-_+-- ° Always order by Part Number - Not by Key Number FIGURE 2 -- ARM AND MOTOR ASSEMBLY WARNING: For your safety, this miter saw is specially insulated. To avoid electrical shock, fire or injury, use only parts identical to those identified in the parts list.

- Page 29 PARTS LIST FOR CRAFTSMAN 10" COMPOUND MITER SAW MODEL NO. 113.234600 9 16 Always order by Part Number--Not by Key Number FIGURE 3-- PIVOT ASSEMBLY Part Part Description Description 816664 Plate-Lock STD551137 * Lockwasher 3/8 816674 Screw Pan HD, 141594-44 Screw Soc HD.

- Page 30 PARTS LIST FOR CRAFTSMAN 10" COMPOUND MITER SAW MODEL NO. 113.234600 /"...

- Page 31 PARTS LIST FOR CRAFTSMAN 10" COMPOUND MITER SAW MODEL NO. 113.234600 Always order by Part Number--Not by Key Number FIGURE 4. Blade & Blade Guard AsmJ; Part Part Description Description Guard Asm. 816677 507758 :1: S pring-Guard Plate-Retainer...

- Page 32 CARBIDE TIPPED BLADES SAFETY INSTRUCTIONS & WARNINGS OSHA required industrial users to inspect tool prior to mounting for cracks, chipped or bent teeth, or cutting edges that sharp. The tool must be completely clean to allow proper inspection. See CFR § 1910.213 WOODWORKING MACHINERY REQUIREMENTS-ITEM...

- Page 33 _AIRS 10-1NCH COMPOUND MITER SAW owner's manual SERVICE Now that you have purchased your 10-inch Compound Miter Saw, should a need ever exist for repair parts or service, simply contact Sears Service Center most Sears, Roebuck Co. stores. Be sure to provide all pertinent facts when you call or visit.

Need help?

Do you have a question about the 113.234600 and is the answer not in the manual?

Questions and answers