Table of Contents

Advertisement

Quick Links

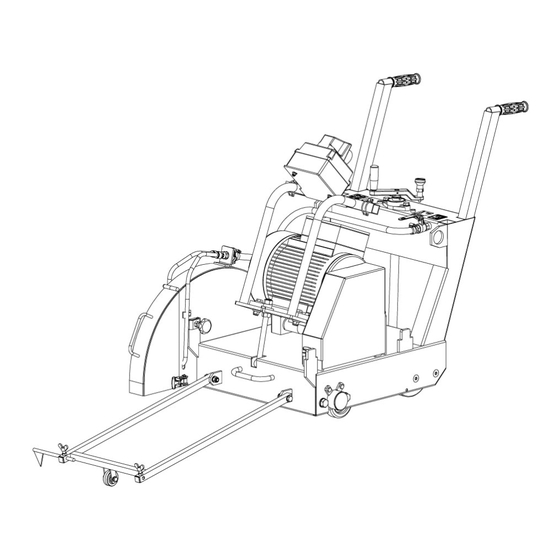

FS 240 E

Operating manual

Art.-Nr. der Bedienungsanleitung

ZN der Bedienungsanleitung:

Erstellt am:

Erstellt von:

Datei:

GÖLZ GmbH

Dommersbach 51

53940 Hellenthal-Blumenthal

Telefon: (02482) 120

Telefax: (02482) 12135

Floor saw

FS 240 E

02822400988

5006148-01

10 / 2010

Mireille Szidat

K:\KDV\5006xxx\5006148-Bedienungsanleitung\

5006148-01-Bedienungsanleitung-doc.doc

- 1-

02822400988

5006148-01

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for GÖLZ FS 240 E

- Page 1 FS 240 E Operating manual Floor saw FS 240 E Art.-Nr. der Bedienungsanleitung 02822400988 ZN der Bedienungsanleitung: 5006148-01 Erstellt am: 10 / 2010 Erstellt von: Mireille Szidat Datei: K:\KDV\5006xxx\5006148-Bedienungsanleitung\ 5006148-01-Bedienungsanleitung-doc.doc GÖLZ GmbH Dommersbach 51 53940 Hellenthal-Blumenthal Telefon: (02482) 120 Telefax: (02482) 12135...

- Page 2 FS 240 E Operating manual EG-KONFORMITÄTSERKLÄRUNG EC-DECLARATION OF CONFORMITY DECLARATION DE CONFORMITE DE LA CE Die Firma Manufacturer La Société GÖLZ GmbH Dommersbach 51, 53940 Hellenthal - Blumenthal Tel.: (02482) 120 Fax: (02482) 12135 Erklärt in alleiniger Verantwortung, dass Hereby certifies on it’s sole responsibility Déclare sous sa seule responsabilité...

-

Page 3: Table Of Contents

FS 240 E Operating manual Contents Preface .......................... 5 General safety references....................5 Basic operation and designated use of the machine ............6 Organizational measures....................6 Selection and qualification of person...................7 Normal operation of the machine..................7 Special work related to the maintenance and repair of the machine ........8 Information about special risks electrical energy ..............8... - Page 4 FS 240 E Operating manual Troubleshooting......................17 Wearing parts ......................19 10. Ersatzteilliste/Spare parts list/Liste des pièces de rechange........20 11. Wiring diagram ......................31 - 4- 02822400988 5006148-01...

-

Page 5: Preface

FS 240 E Operating manual Preface Thanks for choosing a GÖLZ-product. This operating instruction is designed to familiarize the user with the machine and its designated use. The operating instruction contains important information on how to operate the machine safely, pro- perly and most efficiently. -

Page 6: Basic Operation And Designated Use Of The Machine

FS 240 E Operating manual Basic operation and designated use of the machine The machine has been built in accordance with state-of-the-art standards and the recognized safety rules. Nevertheless, its use may constitute a risk to life and limb of the user or of third parties, or cause damage to the machine and to other material property. -

Page 7: Selection And Qualification Of Person

FS 240 E Operating manual In case event of safety-relevant modifications or changes in the behaviour of the product, stop the product immediately and report the malfunction to the competent authority/ person. Do not remove or make inoperative any safety devices the product is equipped with. -

Page 8: Special Work Related To The Maintenance And Repair Of The Machine

FS 240 E Operating manual During start-up and shut-down procedures always watch the indicators in accordance with the operating instructions. Before starting up or setting the machine in motion, make sure that nobody is at risk. Always keep at a distance from the edges of building pits and slopes. -

Page 9: Gas, Dust, Steam, Smoke

FS 240 E Operating manual The electrical equipment of machines is to be inspected and checked at regular intervals. Defects such as loose connections or scorched cables must be rectified immediately. Necessary work on live parts and elements must be carried out only in the presence of a second person who can cut off the power supply in case of danger by actuating the emergency shut-off or main power switch. -

Page 10: 2.10 Changing The Location Of The Machine

FS 240 E Operating manual 2.10 Changing the location of the machine Use only suitable means of transport and lifting gear of sufficient capacity when loading or transporting the machine! Appoint an experienced instructor for the lifting operation! Always observe the instructions given in the operating manual when lifting the machine (use only the prescribed lifting eyes for attaching the lifting gear)! Use only suitable transport vehicles with sufficient load capacity! Secure the load carefully. -

Page 11: Technical Data

FS 240 E Operating manual Technical data Engine 3-phase electric motor, 400V, 50 Hz, 16 A Power 7,5 kW (10 HP) Engine speed 1500 rpm Blade shaft speed 1500 rpm Max. cutting speed 47 m/s Max. blade size Ø 600 mm - Ø 23.6 in. -

Page 12: Storing

FS 240 E Operating manual Secure with the linch pins and lower the electric motor. Now the locking (9) is free and the electric motor is detachable. Remount in opposite order and check V-belts for correct tension (see chapter maintenance). -

Page 13: Water Supply

FS 240 E Operating manual Pay attention to the correct rotation. Direction signs are on the blade and blade guard. Mount the outside flange and fix it correctly with the washer and the flange screw. Mount the blade guard and secure it with the star grips. -

Page 14: Cutting Line

FS 240 E Operating manual Never touch rotating parts like blade, motor or blade shaft and V-belts! Before starting the machine must be completely lifted. The blade may not have any ground contact! Cutting line Mark the cutting line with chalk. Make sure the soil is clean and align the blade with the cutting line. -

Page 15: Feed

FS 240 E Operating manual Feed Operate with even feed. The electric motor will overstress and the machine might rise out of cut if the feed is too high. The segments will become dull if the feed is too low. -

Page 16: Lubrication Chart

FS 240 E Operating manual Lubrication chart Grease the bearings of the blade shaft, cutting depth selector and the undercarriage every 20-30 working hours with heat resistance fat. Clean periodically lose parts like pointer unit and wheels and grease them with some drops of oil. -

Page 17: Troubleshooting

FS 240 E Operating manual Troubleshooting Problem Cause Remedy Electric motor Mains plug not connected Check conection Fuse of power distribution on Electric motor does not Check fuses building sites has been released operate! The electrical installation Malfunction of electrical installation... - Page 18 FS 240 E Operating manual - 18- 02822400988 5006148-01...

-

Page 19: Wearing Parts

FS 240 E Operating manual Wearing parts Wearing parts for construction devices mentioned in the operating manual such as drilling and sawing machines Wearing parts are the parts subject to operation-related (natural) wear during proper use of the device. The wearing time cannot be uniformly defined, and differs according to the intensity of use. The wearing parts must be adjusted, maintained and, if necessary, replaced for the specific device in accordance with the manufacturer’s operating manual. -

Page 20: Ersatzteilliste/Spare Parts List/Liste Des Pièces De Rechange

FS 240 E Operating manual Ersatzteilliste/Spare parts list/Liste des pièces de rechange So bekommen Sie schnell und richtig Ihr Ersatzteil - für Maschine - Modell - Masch.-Nr. - Artikelnummer - Bezeichnung des Ersatzteiles - Anzahl der gewünschten Ersatzteile - Wohin liefern? - Womit liefern (Post, Eilpost etc.)? - Page 21 FS 240 E Operating manual - 21- 02822400988 5006148-01...

- Page 22 FS 240 E Operating manual Pos Artikelnummer Menge Norm Info Benennung Description Désignation 0282 240 0103 Grundgestell Frame Châssis UCFL 202 0282 150 0008 Flanschlager Bearing Flasque bride Ø 15 DIN EN 0286 570 0047 B 10,5 Scheibe Washer Rondelle...

- Page 23 FS 240 E Operating manual - 23- 02822400988 5006148-01...

- Page 24 FS 240 E Operating manual Pos Artikelnummer Menge Norm Info Benennung Description Désignation 0282 240 0026 Schneidflansch aussen Outside flange Flasque extérieur 0282 240 0008 Richtungsanzeiger Pointer unit Tiges de guidage 20 x 20 x 0282 120 0045 Stopfen Plug...

- Page 25 FS 240 E Operating manual - 25- 02822400988 5006148-01...

- Page 26 FS 240 E Operating manual Pos Artikelnummer Menge Norm Info Benennung Description Désignation UCFL 204 0282 240 0022 Flanschlager Bearing Flasque bride Ø 20 DIN EN 0282 520 0118 M 12 x 45 Schraube Screw ISO 10642 DIN EN 0282 250 0105...

- Page 27 FS 240 E Operating manual - 27- 02822400988 5006148-01...

- Page 28 FS 240 E Operating manual Pos Artikelnummer Menge Norm Info Benennung Description Désignation Réception arrière du 0282 240 0005 Motoraufnahme hinten Rear mounting plate moteur 0282 900 0101 Motor Motor Moteur 0282 240 0006 Motoraufnahme Front mounting plate Réception moteur...

- Page 29 FS 240 E Operating manual - 29- 02822400988 5006148-01...

- Page 30 FS 240 E Operating manual Pos Artikelnummer Menge Norm Info Benennung Description Désignation Capot de protection 0282 240 0100 Pos. 1-16 Schutzhaube kpl. Blade guard assy. complete 0282 240 0104 Schutzhaube Blade guard Capot de protection DIN EN 0285 300 0090...

-

Page 31: Wiring Diagram

FS 240 E Operating manual Wiring diagram - 31- 02822400988 5006148-01...

Need help?

Do you have a question about the FS 240 E and is the answer not in the manual?

Questions and answers