Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Rizzoli L 90

- Page 1 L - LT - S - ST RANGE Part 1: Operational Manual for USA/Canada...

-

Page 3: General Instructions

Your choice fell upon a Rizzoli cooker, result of a tradition started in 1912 when Carlo Rizzoli began the production of wood fired cookers with the typical style of the valley in the dolomites. Year after year Rizzoli continued to refine its cookers using even more advanced technologies, but without losing contact with the elegance, the beauty and the functionality of the original product. - Page 4 • After a long period in which you do not use the cooker, check carefully that obstructions are not present and that the cooker works regularly. • Use only original or authorized spare parts. • Do not make any unauthorized modification. 1.3 RECOMMENDED COMBUSTIBLES Wood fired cookers L - S Range and thermal wood fired cookers LT - ST Range are built to use wood for burning.

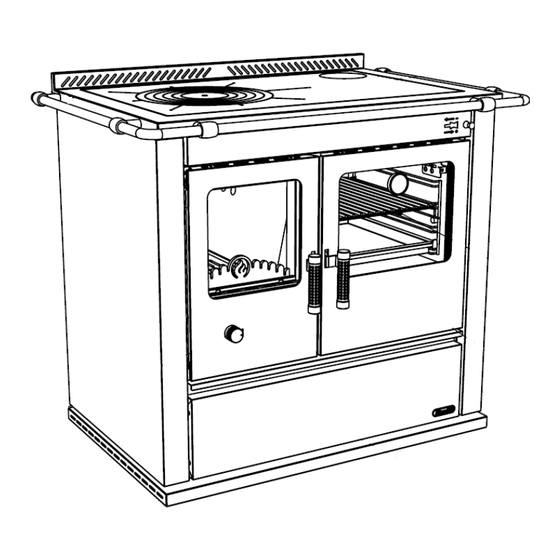

- Page 5 Fire door Plate Boiler 1.6 ACCESSORIES Together with the wood fired cookers and thermal cookers Rizzoli you will find some accessories that simplify the installation, the maintenance and the daily use of the device. • Ash drawer • Glove • Poker •...

-

Page 6: Installation

(see paragraph 7.2 and safety label page 10 in Part 2 Installation Instruction). Rizzoli also produces isolated spacers to reduce distances. The device is very heavy and must be placed on floor that can support its load capacity. -

Page 7: Chimney Flue

2.4 DIMENSIONS AND CORRECT FORMS OF CHIMNEY Chimney must be dimensioned in a correct way according to the type of device it is connected with, minding the environmental and general conditions of the place in which it is placed. The section of the chimney must permit the flow of the fumes produced by the cooker or thermal cooker without difficulties, but it must not be too big otherwise the chimney will experience problems in heating itself and this may generate problems like weak draught and condensation. -

Page 8: Chimney Pot

2.6 CHIMNEY POT The chimney pot must have an exit section doubled than the one of the chimney, in order to make easier the exit of the smoke. The chimney pot must be enough tall to lean out over the reflow zone generated by the roof: if you are not sure about this contact experienced technicians. -

Page 9: Air Intake

The air intake in the room must have a minimum surface of 80 . On demand, Rizzoli can give specific valves which can allow the automatic opening of the air intake only when it is necessary for the correct working of the device in order to warrant a maximum depression of 4 Pa in the place of installation. - Page 10 (see table 2 and picture 11). Are also possible other solutions for the connection but they must be decided together with Rizzoli. WARNING! Aspiring hoods or extracting air fans in the room may generate problems to the device if there is not a suited air intake or in case of air intake sub- dimensioned.

- Page 11 Dimensions Models ø 248 mm (9,76”) 118 mm (4,64”) 664 mm (26,14”) 95 mm (3,74”) L 90 LT 90 248 mm (9,76”) 118 mm (4,64”) 664 mm (26,14”) 95 mm (3,74”) S 80 248 mm (9,76”) 118 mm (4,64”) 664 mm (26,14”) 95 mm (3,74”)

-

Page 12: First Lighting

Picture 13 - Modification of the handrail WARNING! Do not lean flammable objects on the handrail, like kitchen rags orpinches. Do not hang the linen to dry on the handrail. 2.12 FIRST LIGHTING Before starting to use the cooker, remove the packaging materials in the oven and in the wood box, remove the stickers and remove the plastic film in which is wrapped the plate and remove with a rag the most of the oil on its surface. - Page 13 2.13 SETTLEMENTS The refractory mortar used for the internal walling contains always a little moisture that is eliminated after the first periods of use: so it is normal that the first times you light the cooker or the thermal cookers a little condensation is being generated. All the refractory materials inside the cooker experience a settlement process that may generate small holes on the bricks, such holes do not preclude anyway the working of the cooker.

-

Page 14: Auxiliary Connections

3. HEATING SYSTEM (LT 90 - ST 90) 3.1 GENERAL NOTES LT - ST thermal cookers are endowed with boiler to use the heating produced by the device through a system with fluid vector for heating and for the production of hot water. Usually the system shall be designed according to UNI 10412-2 law by a qualified thermal technician and installed by specialized staff according to the existing laws and the UNI 10683 law. - Page 15 Picture 14 Connection thermostat detector Ø 1/2’’ female Return connection Ø 1’’1/4 female Going connection Ø 1’’1/4 female Connection discharge Ø ½” female Connection for thermal discharge detector Ø 1/2’’ female External air intake (optional) Connections for thermal discharge circuit Ø 1/2’’ male 3.5 SAFETY On every solid combustible based boilers it is not technically possible to break the combustion immediately as happens for boilers based on liquid or gas combustible according to necessity.

- Page 16 The functional verify must be done regularly: we suggest at least once a year. The thermal discharge circuit must not be used for the production of hot water for domestic use. On demand, Rizzoli can provide a thermal discharge valve suited for its devices. Picture 15 – Thermal discharge circuit scheme.

- Page 17 Picture 17 – Simplified schemes for the installing of a heating system with the thermal cooker LT 90 or ST 90 as heat generator.

- Page 18 Picture 18 – Simplified schemes for the installing of a heating system with the thermal cooker LT 90 or ST 90 as heat generator.

-

Page 19: Operation

4. USE 4.1 OPERATION During the operation, inside the cooker happens a combustive reaction of combustible (the wood inserted in the combustion chamber) and burning (the oxygen present in the air of the room in which the cooker is placed). The wood fired cooker makes an intermittent combustion: after the lighting, the combustion goes on till the exhaustion of the combustible but it can be maintained lighted by making another load of combustible and so on. - Page 20 Picture 19 - Starting key. With lever outside, the key is open and the starting is easier; with lever inside the key is closed for the normal working. 4.3 AIR INTAKE REGULATION On every model the entrance of oxidising air inside the device is ruled by a valve controlled by a lever placed below the fire door.

- Page 21 autonomy. The regulator is automatic and has the task to keep steady the heat produced by the cooker. When the device is not operating, we suggest to close the lever below the fire door in order to limit the undesired air flow that may cause an anticipated cooling of the device and the room. This operation is particularly important when the external air intake of the device is directly connected.

-

Page 22: Oven Cooking

4.5 GLASS CLEANING AIR REGULATION On wood fired cookers and thermal cookers the glass cleaning air is fixed and set so that the combustion is optimal and the glass of the fire door is clean. When the device is installed on a chimney with high draught, it is possible to experience an excessive air inflow. -

Page 23: Glove Box

temperature steady. L - S and LT - ST range models are endowed with fire door with glass and thermometer that makes easier the temperature controlling operations; the temperature indicated by the thermometer is approximate ad is useful only for the cooking of foods. If you want to brown the meals, you should keep them in the upper part of the oven: instead, if you want to cook in a steadier way you should keep the meals in the centre. - Page 24 4.10 TELESCOPIC PULLOUT FOR BAKING PAN Picture 25 - Instructions for the variation of the position of the telescopic pullout. All the devices have a telescopic pullout for endowed baking pan system. In this way, it is possible to extract the baking pan without the necessity to sustain it, ensuring a better practicality. On the cookers and thermal cookers the telescopic pullout is placed in a single position inside the oven but this can be changed by moving it in the lowest part or in the middle-upper and upper position.

- Page 25 4.12 FIRE DOOR PROTECTION (OPTIONAL) The L - S and LT - ST range wood fired cookers are endowed with a steel protection which could be placed on the fire door. This protection is designed to shield the door when the cooking operations require the continuous presence of the user in front of the cooker or in presence of children.

-

Page 26: Maintenance

Also in these situations, an accurate cleaning will restore the state of the product as it was new. On request Rizzoli gives specific products to clean stainless steel. For enamelled or painted parts, do not use abrasive or aggressive solution and in case of stains pour some oil and wait while it absorbs the halo, then clean with a soft rag. - Page 27 Picture 28 – Maintenance of the combustion chamber sheets 5.5 GRILL CLEANING Every time you use the cooker or the thermal cooker you have to clean the wood carrying grill before, at least you have to clean the more rough deposits: the holes of the grill should not be obstructed.

-

Page 28: Oven Cleaning

5.7 FUME-CIRCUIT INSPECTION In the cookers and thermal cookers with oven the combustion fumes are forced to turn completely around the oven. For this reason, the devices with oven are endowed with an inspection door to clean the fume-circuit. The cleaning must be done at least every six months of normal use, like for the chimney sweeping: according to use, you could have to make the cleaning more often. - Page 29 WARNING! Do not clean the glass before waiting for its cooling. Suddenly changes in temperature may cause breakings in the glass. 5.11 WOODBOX EXTRACTION The woodbox is endowed with a sliding rails system that allows an easy closure. It would be enough to juxtapose the box to close it automatically.

-

Page 30: Extraordinary Maintenance

Picture 30 – Correct position of the rounded washers. 5.14 THERMIC DILATATION During the use all the materials of the device are subjected to dilatation and light moving due to the temperature variations. This phenomenon must not be prevented otherwise deformations and breakings may occur. - Page 31 6. WHAT TO DO IF… Problems Effects Possible solutions • Verify that the air regulations is at its maximum opening • Verify that ash or other residuals do not obstruct the grill • Verify that the grill is not inserted correctly (the flat part is up) •...

-

Page 32: Technical Data

7. TECHNICAL DATA 7.1 TECHNICAL DATA Model L 90 S 80 S 90 LT 90 ST 90 Weight 569 lbs 419 lbs 463 lbs 630 lbs 485 lbs 34'803 34'803 34'803 81'209 81'209 Nominal power BTU/hr BTU/hr BTU/hr BTU/hr BTU/hr... -

Page 33: Warranty

8. WARRANTY 8.1 DECLARATION OF PERFECTLY MADE PRODUCT Rizzoli warrants that the device has passed all the quality controls and internal tests. Rizzoli also warrants that the device is working, without imperfections due to building or due to materials. This device is the result of the multi-decennial experience of Rizzoli, who warrants a perfectly made product. - Page 34 8.8 RESPONSIBILITY Rizzoli is not responsible for incidental or consequential damages due to the lack of application of the national and local law and of the instructions written in this booklet. 8.9 LIMITED WARRANTY AND LAW Rizzoli S.rl.

- Page 35 INDEX INSTRUCTIONS pag. 3 GENERAL INSTRUCTIONS pag. SAFETY INSTRUCTIONS pag. RECOMMENDED COMBUSTIBLES pag. OTHER COMBUSTIBLES pag. PARTS OF COOKERS AND THERMAL COOKERS pag. ACCESSORIES pag. INSTALLATION pag. 6 GENERAL NOTES pag. SAFETY DISTANCES pag. CHIMNEY pag. DIMENSIONS AND CORRECT FORMS OF CHIMNEY pag.

- Page 36 MAINTENANCE OF THE COMBUSTION CHAMBER SHEETS (LT 90 - ST 90) pag. 26 GRILL CLEANING pag. 27 ASH BOX pag. 27 FUME-CIRCUIT INSPECTION pag. 28 OVEN CLEANING pag. 28 CHIMNEY CLEANING pag. 28 5.10 GLASS CLEANING pag. 28 5.11 WOODBOX EXTRACTION pag.

- Page 37 Part:2 Installation Instructions for US and Canada users only Rizzoli Cook Stoves L90, S90, S80, LT90, ST90 Tested and Certified to UL 1482, ULC-S627 Tested to: EN 12815 PLEASE READ ALL INSTRUCTIONS BEFORE YOU INSTALL YOUR NEW STOVE. FAILURE TO FOLLOW INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY, OR EVEN DEATH.

-

Page 38: Safety Instructions

SAFETY INSTRUCTIONS Read all instructions carefully. 1. The installation of this stove must comply with your local building codes. Please observe the clearance to combustible. Stove must be 18“(46cm) side and 18“(46cm) back, from any combustible material, wall, wood, furniture, paper, etc. 2. -

Page 39: Installation Instruction

INSTALLATION INSTRUCTION NOTE: FLOOR EMBER PROTECTION IS REQUIRED FOR SPARK AND ASH SHIELDING, NOT FOR LIMITING FLOOR TEMPERATURE FROM THE RADIANT HEAT OF THE APPLIANCE. 1. Proper clearances must be maintained for adequate air circulation. Adequate ventilation must be provided while operating this stove. - Page 40 Chimney connector systems and clearances Chimney connector shall not pass through attic or roof space, closet or similar concealed space, or a floor, or ceiling. When passage through a wall, or partition of combustible is desired, the installation shall conform to CAN/CSA-B365, Installation Code for Solid-Fuel-Burning Appliances and Equipment: Page 4...

- Page 41 STOVE CLEARANCES WITH SINGLE WALL CONNECTOR: Combustible *NON-combustible (Protected Walls) Back of Stove 18" (46cm) *Reduction by 33- 66% Side of Stove 18" (46cm) *Reduction by 33- 66% STOVE CLEARANCES WITH DOUBLE WALL CONNECTOR: Combustible * NON-combustible Back Of Stove 12“(30cm) *Reduction by 33- 66% Side of Stove...

- Page 42 Page 6...

-

Page 43: Minimum Clearances To Combustible Surfaces

MINIMUM CLEARANCES TO COMBUSTIBLE SURFACES Single Wall Connector Unit to Sidewall - - - - - - - - - - - -18" (46 cm) CAUTION: KEEP FURNISHING AND OTHER COMBUSTIBLE MATERIALS AWAY FROM THE Unit to Backwall - - - - - - - - - - - -18" (46 cm) STOVE. -

Page 44: Operating Safety Precautions

CAUTION: HOT WHILE IN OPERATION. KEEP CHILDREN, ANIMALS, CLOTHING AND FURNITURE AWAY FROM THE STOVE. DO NOT TOUCH HOT STOVE. CONTACT MAY CAUSE SKIN BURNS. TRAIN CHILDREN TO STAY A SAFE DIS-TANCE FROM THE UNIT. CHILDREN SHOULD BE ALL THE TIME CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME ROOM WITH THE STOVE. - Page 45 causing the stove or chimney pipe joins to smoke. SOLUTION: Open nearby window, and use small strips of newspaper or tinder loosely placed in the firebox that will provide quick and hot heat up the chimney, thereby reversing draft. SINGLE WALL PIPE-MINIMUM CLEARANCES FOR USA/CANADA Some example of clearance reduction;...

- Page 46 Manufactured by: Imported and Distributed by: Listed and Labeled by: Rizzoli S.r.l. Sopka Inc., USA Guardian Fire Testing Laboratory Evaluated to: Zona Artigianale 1 Frazione San Lugano 216-543-7002 UL 1482, ULC-S627 39040 Trodena nel Parco Naturale (BZ) www.sopkainc.com Tested to: Made in Italy contact@sopkainc.com...

- Page 48 THICKNESS QUANTITY Frame S90 Fire grill holder S60 KN fire grill LATERAL CERAMIC L 90 RUSTIK SERPENTINO DASHBOARD CERAMIC L 90 RUSTIK SERPENTINO FRONT S90 RIGHT (2013) OVEN DOOR RIGHT L 90 WOOD BOX L 90 FIRE DOOR LEFT L 90...

- Page 50 Components S 90 (2015) Number Code Description Material THICKNESS QUANTITY Frame S90 Fire grill holder S60 KN fire grill FRONT S90 RIGHT (2013) MOBILE PART FIRE DOOR S 90 RIGHT (2013) CASSA LEGNA S90 (2013) MOBILE PART FIRE DOOR S 90 LEFT (2013) OVEN BOX S90 (2013) AIR SHUTTER S (2015) HOOK ROD STARTING KEY...

- Page 52 Description Material THICKNESS QUANTITY Frame S90 OVEN DOOR RIGHT L 90 CERAMIC L 90 RUSTIK SERPENTINO DASHBOARD CERAMIC L 90 RUSTIK SERPENTINO LATERAL FRONT S90 RIGHT (2015) WOOD BOX L 90 FIRE DOOR LEFT L 90 OVEN BOX S90 (2013)

- Page 53 7LM34306 REINFORCEMENT LATERAL CHIMNEY S Galvanized 15/10 7LM34310 PIECE FRAME FIXING S Galvanized 15/10 7LM34320 INTERNAL FILLER OVEN S 80/90 Galvanized 15/10 7LM34330 FUME CIRCUIT SHOULDER S 80/90 Galvanized 15/10 7LM34331 STEEL SHEET REAR FUME CIRCUIT S 80/90 Galvanized 15/10 7LM34332 STEEL SHEET FUME CIRCUIT PIECE S 80/90 Galvanized...

- Page 55 Components ST 90 (2015) Number Code Description Material THICKNESS QUANTITY FRAME S90 MOBILE PART OVEN DOOR RIGHT S 90 (2013) FRONT S90 RIGHT (2015) WOOD BOX S90 (2013) MOBILE PART FIRE DOOR LEFT S 90 (2013) OVEN BOX S90 (2013) BOILER ST 90 (2015) AIR SHUTTER S (2015) HOOK ROD STARTING KEY...

- Page 56 7LM34331 STEEL SHEET REAR FUME CIRCUIT S 80/90 Galvanized 15/10 7LM34332 STEEL SHEET FUME CIRCUIT PIECE S 80/90 Galvanized 15/10 7LM34335 FUME CIRCUIT PIECES S 80/90 RIGHT Galvanized 15/10 7LM34641 SHUTTER RIGHT SECONDARY AIR ST90 Galvanized 15/10 7LM34642 SHUTTER LEFT SECONDARY AIR ST90 Galvanized 15/10...

Need help?

Do you have a question about the L 90 and is the answer not in the manual?

Questions and answers