Summary of Contents for Perkins 2506F-E15TA

- Page 1 M0076814-01 (en-us) June 2018 Operation and Maintenance Manual 2506F-E15TA Industrial Engine PP5 (Engine)

- Page 2 If a tool, procedure, work method or operating technique that is not specifically recommended by Perkins is used, you must satisfy yourself that it is safe for you and for others. You should also ensure that you are authorized to perform this work, and that the product will not be damaged or become unsafe by the operation, lubrication, maintenance or repair procedures that you intend to use.

-

Page 3: Table Of Contents

M0076814-01 Table of Contents Table of Contents Maintenance Section Refill Capacities..........55 Foreword ............4 Maintenance Recommendations ....69 Safety Section Maintenance Interval Schedule....... 72 Safety Messages..........6 Warranty Section Additional Messages ......... 7 Warranty Information........107 General Hazard Information......8 Reference Information Section Burn Prevention..........11 Reference Materials ........ -

Page 4: Foreword

State of arises regarding your engine, or this manual, please California to cause cancer, birth defects, consult with your Perkins dealer or your Perkins distributor for the latest available information. and other reproductive harm. WARNING – This product can... - Page 5 Perkins distributor offers various options regarding overhaul programs. If you experience a major engine failure, there are also numerous after failure overhaul options available. Consult with your Perkins dealer or your Perkins distributor for information regarding these options.

-

Page 6: Safety Section

Replace any safety message that is damaged or missing. If a safety message is attached to a part of the engine that is replaced, install a new safety message on the replacement part. Your Perkins distributor can provide new safety messages. Illustration 1... -

Page 7: Additional Messages

Replace any message that is damaged, or missing. If a message is attached to a part that is replaced, install a message on the replacement part. Any Perkins distributor can provide new messages. Illustration 3 g01382725 Illustration 4... -

Page 8: General Hazard Information

M0076814-01 Safety Section General Hazard Information This notice should be located next to the battery • When work is performed around an engine that is disconnect switch. operating, wear protective devices for ears in order to help prevent damage to hearing. NOTICE •... - Page 9 M0076814-01 Safety Section General Hazard Information • Start the engine from the operators station (cab). • Use all cleaning solutions with care. Never short across the starting motor terminals or • Report all necessary repairs. the batteries. This action could bypass the engine neutral start system and/or the electrical system Unless other instructions are provided, perform could be damaged.

- Page 10 Perkins equipment and replacement parts that are shipped from Perkins engine company limited are The removal of sulfur and other compounds in ultra- asbestos free. Perkins recommends the use of only low sulfur diesel fuel (ULSD fuel) decreases the genuine Perkins replacement parts. Use the following...

-

Page 11: Burn Prevention

M0076814-01 Safety Section Burn Prevention • Avoid brushing materials that contain asbestos. DEF is not expected to produce significant adverse health effects when the recommended instructions for use are followed. • Avoid grinding materials that contain asbestos. • Do not breathe DEF vapor or mist. •... -

Page 12: Fire Prevention And Explosion Prevention

Wash hands after touching batteries. The use of gloves is recommended. If the application involves the presence of combustible gases, consult your Perkins dealer and/ or your Perkins distributor for additional information Engine and Aftertreatment System about suitable protection devices. - Page 13 M0076814-01 Safety Section Fire Prevention and Explosion Prevention Illustration 11 g00704059 Illustration 12 g00704135 Use caution when you are refueling an engine. Do Gases from a battery can explode. Keep any open not smoke while you are refueling an engine. Do not flames or sparks away from the top of a battery.

-

Page 14: Crushing Prevention And Cutting Prevention

Refer to the OEM for the location of foot and hand holds for your specific application. Leaks can cause fires. Consult your Perkins dealer or your Perkins distributor for replacement parts. i04257031 Replace the parts if any of the following conditions... -

Page 15: Engine Starting

M0076814-01 Safety Section Engine Starting i02583384 i06088340 Engine Starting Electrical System Never disconnect any charging unit circuit or battery circuit cable from the battery when the charging unit is operating. A spark can cause the combustible Do not use aerosol types of starting aids such as gases that are produced by some batteries to ignite. -

Page 16: Engine Electronics

However, the monitoring system and the engine monitoring control will be similar for all engines. Note: Many of the engine control systems and display modules that are available for Perkins Engines will work in unison with the Engine Monitoring System. Together, the two controls will provide the engine monitoring function for the specific engine application. -

Page 17: Product Information Section

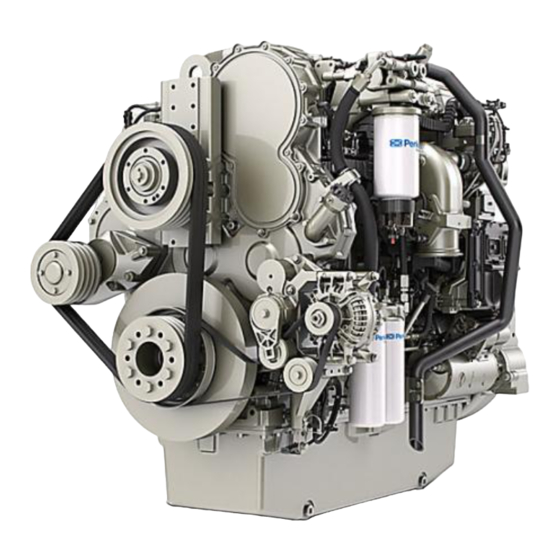

M0076814-01 Product Information Section Model Views Product Information Section Model Views i06822953 Model View Illustrations The following model views show typical features of the engine. Due to individual applications, your engine may appear different from the illustrations. Engine Views Illustration 13 g06134993 Typical example (1) Oil filler... - Page 18 M0076814-01 Product Information Section Model View Illustrations Illustration 14 g06135026 Typical example (10) Rear lifting eye (14) Coolant pump (19) Oil sample valve (11) Turbocharger (15) Oil cooler (20) Oil drain plug (12) Front lifting eye (16) ECM for aftertreatment (21) Flywheel (13) Water temperature regulator housing (17) Primary fuel filter/priming pump...

- Page 19 M0076814-01 Product Information Section Model View Illustrations The ECM (16) will be supplied loose. Aftertreatment System The aftertreatment items are supplied loose by Perkins. Clean Emission Module Illustration 15 g06044166 Typical example (1) Clean Emission Model (CEM) (4) DEF Injector...

- Page 20 (2) DEF heated line (3) DEF tank header (4) DEF pump filter i06823092 (5) DEF tank drain Product Description The Perkins 2506F-E15TA Industrial Engine has the following characteristics: • Four-stroke cycle • Mechanically actuated, electronically controlled fuel injection system • Turbocharged •...

- Page 21 ECM. The topic. electronic engine control system provides the following features: Aftermarket Products and Perkins • Engine speed governor Engines • Automatic air/fuel ratio control Perkins does not warrant the quality or performance of non-Perkins fluids and filters.

- Page 22 Product Description When auxiliary devices, accessories, or consumables (filters, additives, catalysts) which are made by other manufacturers are used on Perkins products, the Perkins warranty is not affected simply because of such use. However, failures that result from the installation...

-

Page 23: Product Identification Information

M0076814-01 Product Information Section Product Identification Information Product Identification Information i06823820 Plate Locations and Film Locations Illustration 20 g01403841 Serial number plate The following information is stamped on the serial number plate: engine serial number, engine model, and arrangement number. The engine information plate is on top of the valve cover near the middle of the engine. - Page 24 Record the information on the CEM and PETU serial level, and configuration ID code. This information plates. The information will be required by your may be needed by the Perkins distributor when Perkins distributor to identify replacement part inquiries are being made on the CEM.

-

Page 25: Operation Section

Alterations to the lifting eyes and/or the engine make the lifting eyes and the lifting fixtures obsolete. If alterations are made, ensure that proper lifting devices are provided. Consult your Perkins distributor for information regarding fixtures for proper engine lifting. - Page 26 5 degree tilt angle can be maintained. For most packages,Perkins recommended the spreader bar be set at 142 cm (56 inch). The lift hook locations should be approximately 25 mm (1 inch) from...

- Page 27 (1) PETU lifting eyes i06605082 Product Storage (Engine and Aftertreatment) Your Perkins distributor can help in preparing the engine for extended storage periods. Some applications, the engine can be equipped with delayed engine shutdown. Allow at least 2 minutes after the engine has stopped before you turn the battery disconnect switch to OFF.

- Page 28 M0076814-01 Operation Section Engine and Aftertreatment Engine Apply a small amount of oil to the threads on the fuel tank filler neck and install the cap. Seal all openings to the tank to prevent evaporation of the 1. Clean the engine of any dirt, rust, grease, and oil. fuel and as a preservative.

- Page 29 (1) Plug forming. 4. Ensure that the DEF filler cap is correctly installed. 8. If an engine is stored for more than 1 year, Perkins recommends Pre lubrication of the engine to avoid Remove Engine from Storage dry starting. Use a suitable pump to put engine oil into the engine oil system.

- Page 30 M0076814-01 Operation Section Engine and Aftertreatment Test the coolant mixture for proper nitrite level. If necessary, adjust the coolant mixture. Prime the engine with clean diesel fuel before starting. 11. Ensure that the cooling system is clean. Ensure that the system is full. Ensure that the system has the correct amount of supplemental cooling system conditioner.

-

Page 31: Features And Controls

M0076814-01 Operation Section Features and Controls Features and Controls Note: Some items have been removed from engine for clarity. i06163203 Monitoring System The monitoring system is designed to alert the operator to an immediate problem with any of the engine systems that are monitored. The monitoring system is also designed to alert the operator to an impending problem with any of the engine systems that are monitored. - Page 32 M0076814-01 Operation Section Sensors and Electrical Components Engine Illustration 30 g06130474 Typical example (1) Secondary Speed/timing sensor (6) NRS differential pressure sensor (11) Oil pressure sensor (2) Boost pressure sensor (7) NRS temperature sensor (12) Barometer pressure sensor (3) Inlet air temperature sensor (8) Air control solenoid valve (13) Fuel pressure sensor (4) NOx Reduction System (NRS) solenoid...

- Page 33 M0076814-01 Operation Section Sensors and Electrical Components Illustration 31 g06130477 Typical example (16) Coolant temperature sensor...

- Page 34 M0076814-01 Operation Section Sensors and Electrical Components Illustration 32 g06130480 Typical example (17) Location for Top Dead Center (TDC) probe Aftertreatment System Illustration 33 g06048751 Typical example (1) Diesel Exhaust Fluid (DEF) injector (3) Coil for spark plug (2) Temperature sensor...

- Page 35 M0076814-01 Operation Section Sensors and Electrical Components (4) Diesel Particulate Filter (DPF) differential (7) 40-Pin connector (10) Fuel main pressure sensor pressure sensor (8) Selective Catalytic Reduction (SCR) (11) Identification Module (5) DPF pressure sensor temperature sensor (12) Temperature sender for Aftertreatment (6) Temperature sender (9) Fuel pilot pressure sensor Regeneration Device (ARD)

- Page 36 M0076814-01 Operation Section Battery Disconnect Switch DEF header (1) contains level sensor temperature The battery disconnect switch and the engine start sensor and quality sensor. switch perform different functions. The entire electrical system is disabled when you turn the battery disconnect switch to the OFF position. The i05422613 battery remains connected to the electrical system Battery Disconnect Switch...

- Page 37 M0076814-01 Operation Section Selective Catalytic Reduction Warning System Self-correct – Fault condition no longer exists. An active fault code will no longer be active. Notification – Action taken by the system to alert the operator of pending Inducement. Inducement – Engine derates, vehicle speed limits, or other actions intended to prompt the operator to repair or maintain the emission control system.

- Page 38 M0076814-01 Operation Section Selective Catalytic Reduction Warning System Illustration 38 g03676111 Illustration 40 g03676127 If the DEF level falls below 13.5%, a level 1 Reduced Time inducement event will occur. The check engine lamp If the ECM is configured to “Reduced Time” and the and the emissions malfunction indicator lamp will DEF level is 0%, the engine will be in level 3 illuminate.

- Page 39 2. The check engine lamp and the emissions malfunction indicator lamp will illuminate Note: Contact your Perkins dealer for repairs if a fault and flash slowly. If the inducement is a result of a occurs.

- Page 40 M0076814-01 Operation Section Selective Catalytic Reduction Warning System Illustration 45 g03676169 Illustration 47 g03676210 If the DEF level falls below 13.5%, a level 1 If the ECM is configured to “Reduced Performance” inducement event will occur. The check engine lamp and the DEF tank has been emptied of all DEF, the and the emissions malfunction indicator lamp will engine will be in a level 3 final inducement.

- Page 41 For repeat occurrence, a category 1 level 2 inducement fault will occur for a Note: Contact your Perkins dealer for repairs if a fault duration of 5 minutes. occurs. If the inducement is a result of a category 2 fault, then a level 2 inducement will occur for a duration of 10 hours.

-

Page 42: Engine Diagnostics

Engine Diagnostics Engine Diagnostics i05194988 Self-Diagnostics Perkins Electronic Engines have the capability to perform a self-diagnostics test. When the system detects an active problem, a diagnostic lamp is activated. Diagnostic codes will be stored in permanent memory in the Electronic Control Module (ECM). -

Page 43: Engine Starting

M0076814-01 Operation Section Engine Starting Engine Starting • Do not start the engine or move any of the controls if there is a “DO NOT OPERATE” warning tag or similar warning tag attached to the start switch or i02109067 to the controls. Before Starting Engine •... - Page 44 M0076814-01 Operation Section Starting the Engine Starting the Engine Note: Oil pressures and fuel pressures should be in the normal range on the instrument panel. Engines that are equipped with “WARNING” lamps do not Refer to the Owners Manual of the OEM for your type of controls.

- Page 45 Pull the wire again in order to ensure Cables that the wire is secure. (Do Not Use This Procedure in 3. Start the engine. If the engine does not start, check for a diagnostic code and consult your Perkins Hazardous Locations that have distributor. Explosive Atmospheres) i04132731...

- Page 46 M0076814-01 Operation Section After Starting Engine 5. Immediately after the engine is started, disconnect the jump-start cables in reverse order. Improper jump start cable connections can cause After jump starting, the alternator may not be able to an explosion resulting in personal injury. recharge fully batteries that are severely discharged.

-

Page 47: Engine Operation

M0076814-01 Operation Section Engine Operation Engine Operation This design of DPF will require a service maintenance interval. Refer to this Operation and Maintenance Manual, “Maintenance Interval Schedule” for more information. The DPF can be i06603162 expected to function properly for the useful life of the engine (emissions durability period), as defined by Engine Operation regulation, subject to prescribed maintenance... - Page 48 M0076814-01 Operation Section Diesel Particulate Filter Regeneration Note: If the engine start switch key is cycled or the Disabled: When the regeneration system is in disabled mode, automatic regenerations will not be “Force Regeneration” switch is pressed for longer performed. The DPF indicator will illuminate if manual than 2 seconds the system will no longer be disabled.

- Page 49 Once the amount of soot collected reaches a The efficiency of the engine can affect the fuel threshold level or 6.4 hours of run time has passed economy. Perkins design and technology in since the red stop lamp was illuminated without manufacturing provides maximum fuel efficiency in successful regeneration, the engine will have a 100% all applications.

- Page 50 M0076814-01 Operation Section Fuel Conservation Practices One faulty battery cell will overwork the alternator. This fault will consume excess power and excess fuel. • The belt should be in good condition. Refer to the Systems Operation, Testing and Adjusting, “V-Belt Test”...

-

Page 51: Engine Stopping

M0076814-01 Operation Section Engine Stopping Engine Stopping Leaving the machine unattended when the engine i05798719 is running may result in personal injury or death. Before leaving the machine operator station, neu- Stopping the Engine tralize the travel controls, lower the work tools to the ground and deactivate all work tools, and place the lever for the hydraulic lockout control in the LOCKED position. - Page 52 M0076814-01 Operation Section Manual Stop Procedure i01465494 After Stopping Engine Note: Before you check the engine oil, do not operate the engine for at least 10 minutes in order to allow the engine oil to return to the oil pan. •...

-

Page 53: Cold Weather Operation

The following components can provide a means of fan blades could cause a fan failure. minimizing fuel waxing problems in cold weather: Perkins recommends a warning device for the inlet • Fuel heaters, which may be an OEM option manifold temperature and/or the installation of an inlet air temperature gauge. - Page 54 Fuel Related Components in the fuel in warm-weather operation. Cold Weather For further information on fuel heaters, consult your Perkins distributor . Fuel Tanks Condensation can form in partially filled fuel tanks. Top off the fuel tanks after operating the engine.

-

Page 55: Maintenance Section

3 . (General Fuel Information) NOTICE The footnotes are of the key part Perkins Specifica- tion for Distillate Diesel Fuel Table. Read ALL of the • Glossary footnotes. • ISO International Standards Organization •... - Page 56 M0076814-01 Maintenance Section General Fuel Information Table 3 Perkins Specification for Distillate Diesel Fuel Property UNITS Requirements “ASTM”Test “ISO”Test Aromatics %Volume 35% maximum D1319 “ISO”3837 %Weight 0.01% maximum D482 “ISO”6245 Carbon Residue on 10% %Weight 0.35% maximum D524 “ISO”4262 Bottoms...

- Page 57 EPA and other appropriate regulatory agencies. NOTICE Operating with fuels that do not meet the Perkins rec- ommendations can cause the following effects: Start- ing difficulty, reduced fuel filter service life, poor combustion, deposits in the fuel injectors, signifi-...

- Page 58 “EU Off-Road Diesel fuel. Acceptable from 2011 MUST have less than 10 PPM sulfur level” All the fuels must comply with the specification in the table for the Perkins Specification Distillate Diesel Fuel. Diesel Fuel Characteristics Perkins recommends kinematic viscosities of 1.4 and 4.5 mm2/sec that is delivered to the fuel injection...

- Page 59 Your fuel supplier Protection Agency (EPA) and European Certification can make recommendations for additives to use, and fuels. Perkins does not certify engines on any other for the proper level of treatment. fuel. The user of the engine has the responsibility of...

- Page 60 Consult your supplier of fuel for • Perkins recommend the use of oil analysis to assistance in selecting appropriate anti-microbial additive. check the quality of the engine oil if biodiesel fuel is used.

- Page 61 If biodiesel or biodiesel blends of fuel are to be used, enable very clean burning and efficient engine Perkins require the use of Perkins fuel cleaner. The operation. Chemically these fuels are similar to diesel use of the fuel is to remove deposits within the fuel fuel derived from petroleum and are therefore system that is created with the use of biodiesel.

- Page 62 “EMA Recommended Guideline on Diesel Engine Oil”. In addition to Perkins definitions, there are other Note: API FA-4 oil is designed for use in selected definitions that will be of assistance in purchasing on-highway applications and is NOT designed to lubricants.

- Page 63 Maintenance Section Fluid Recommendations Refer to illustration 57 (maximum temperature) to To achieve the best performance from a Perkins select the oil viscosity for engine operation at the engine, conform to the following guidelines: highest ambient temperature that is anticipated.

- Page 64 M0076814-01 Maintenance Section Fluid Recommendations Table 6 NOTICE If the engine is to be stored in, or shipped to an area Acceptable Water with below freezing temperatures, the cooling system Property Maximum Limit must be either protected to the lowest outside tem- perature or drained completely to prevent damage.

- Page 65 American Society for Testing and • Heavy-duty diesel engines Materials • Automotive applications The following two coolants are used in Perkins diesel engines: The anti-corrosion package for ELC is different from the anti-corrosion package for other coolants. ELC is Preferred – Perkins ELC an ethylene glycol base coolant.

- Page 66 Perkins ELC and operate the engine (SCA). ensure that the thermostat opens. Stop the engine and allow to cool. When using Perkins ELC, do not use standard SCA's or SCA filters. 5. Drain the cooling system. NOTICE ELC Cooling System Cleaning...

- Page 67 SCA that is required when the cooling ness of the ELC and shortens the ELC service life. system is initially filled. Use only Perkins Products for premixed or concen- trate coolants. Failure to follow these recommenda- Table 10...

- Page 68 M0076814-01 Maintenance Section Refill Capacities and Recommendations Table 13 Example Of The Equation For Adding The SCA To The Heavy- Duty Coolant For Maintenance Total Volume of the Multiplication Amount of SCA Cooling System (V) Factor that is Required 15 L (4 US gal) ×...

-

Page 69: Maintenance Recommendations

Consult the OEM of the equip- To relieve the pressure from the coolant system, turn ment or your Perkins dealer regarding welding on a off the engine. Allow the cooling system pressure cap chassis frame or rail. - Page 70 M0076814-01 Maintenance Section Welding on Engines with Electronic Controls • Electronic components for the driven equipment • ECM • Sensors • Electric operated fuel pump • Electronically controlled valves • Relays • Aftertreatment ID module NOTICE Do not use electrical components (ECM or ECM sen- sors) or electronic component grounding points for grounding the welder.

- Page 71 • The temperature of the fluid in the engine coolant/antifreeze Refer to the standards for the engine or consult your Perkins distributor to determine if the engine is operating within the defined parameters. Severe service operation can accelerate component wear. Engines that operate under severe conditions...

-

Page 72: Maintenance Interval Schedule

M0076814-01 Maintenance Section Maintenance Interval Schedule “ Cooling System Supplemental Coolant Additive i06826164 (SCA) - Test/Add” ......84 Maintenance Interval Schedule “... - Page 73 M0076814-01 Maintenance Section Maintenance Interval Schedule “ Injector (Diesel Exhaust Fluid) - Replace” ..104 Every 6000 Service Hours or 3 Years “ Cooling System Coolant Extender (ELC) - Add” ........83 Every 10 000 Service Hours “...

- Page 74 M0076814-01 Maintenance Section ARD Spark Plug - Clean 2. Debris may have collected in the spark plug well. i06615956 Thoroughly remove any debris. Use compressed ARD Spark Plug - Clean air. The maximum air pressure for cleaning purposes must be below 205 kPa (30 psi). Ensure that the area around the spark plug is clean and free of dirt and debris.

- Page 75 All personnel should also stay clear of the air compressor when the engine is operating and the air compressor is exposed. Consult your Perkins distributor for assistance. Do not disconnect the air line from the air com- pressor governor without purging the air brake i00847451 and the auxiliary air systems.

- Page 76 M0076814-01 Maintenance Section Battery - Replace • An authorized battery collection facility 7. Connect the cable from the starting motor to the POSITIVE “+” battery terminal. • A recycling facility 8. Connect the cable from the NEGATIVE “-” terminal on the starter motor to the NEGATIVE “-” battery i01878164 terminal.

- Page 77 M0076814-01 Maintenance Section Battery or Battery Cable - Disconnect i05424317 i06940875 Battery or Battery Cable - Belts - Inspect/Adjust/Replace (Vee Belt General Information) Disconnect The information within this section may be used as a guide to adjust the tension of the belt. If the Original Equipment Manufacture (OEM) has installed the belt The battery cables or the batteries should not be system, then refer to OEM information.

- Page 78 M0076814-01 Maintenance Section Vee Belt General Information Link adjuster Rod adjuster Illustration 64 g06108813 Illustration 65 g06109400 Typical example Typical example 1. Remove guards, refer to the OEM for the correct 1. Remove the belt guard, refer to OEM for the procedure.

- Page 79 M0076814-01 Maintenance Section Belts - Inspect/Replace Fan Belt Adjustment To replace the fan belts, refer to Disassembly and Assembly, V-Belts- Remove and Install. Belt Tension Table 16 Alternator and Fan Belt Tension Belt Type Belt Size New Belt Used Belt Reset Belt Tension Tension...

- Page 80 M0076814-01 Maintenance Section Cooling System Coolant (DEAC) - Change To maximize the engine performance, inspect the belt for wear and for cracking. Replace the belt if the belt is worn or damaged. • Inspect the belt for cracks, splits, glazing, grease, displacement of the cord and evidence of fluid contamination.

- Page 81 M0076814-01 Maintenance Section Cooling System Coolant (DEAC) - Change NOTICE Fill the cooling system no faster than 19 L (5 US gal) per minute to avoid air locks. 3. Fill the cooling system with clean water and operate the engine, ensure that the thermostat opens.

- Page 82 Cooling System Coolant (ELC - Change NOTICE Perkins ELC must be using with an extender in order to achieve 12000 hours operation. For more informa- tion on a suitable extender contact your Perkins distributor. Clean the cooling system and flush the cooling...

- Page 83 49 °C to 66 °C (120 °F to 150 °F). For Perkins ELC to achieve 12000 hours an extender must be added at 6000 hours. For a suitable 5. Stop the engine and allow the engine to cool.

- Page 84 M0076814-01 Maintenance Section Cooling System Supplemental Coolant Additive (SCA) - Test/Add Use a Coolant Conditioner Test Kit in order to check the concentration of the SCA. Add the SCA, If Necessary NOTICE Do not exceed the recommended amount of supple- mental coolant additive concentration.

- Page 85 M0076814-01 Maintenance Section DEF Filler Screen - Clean 4. Clean the cooling system filler cap and inspect the 3. The filter screen can be cleaned in clean water and gasket. If the gasket is damaged, discard the old dried using compressed air. Refer to this filler cap and install a new filler cap.

- Page 86 M0076814-01 Maintenance Section DEF Manifold Filters - Replace Illustration 74 g03806578 Illustration 75 g03806580 2. Remove band clamp (2) from filter base (1). 3. Remove filter (3) from filter base (1).

- Page 87 M0076814-01 Maintenance Section DEF Manifold Filters - Replace Illustration 76 g03806581 Illustration 78 g06159487 1. Note the location of clamp (2). The clamp (2) must be between the marked location (A). 2. Loosen clamp (2) and remove outer filter (3) from DEF tank header (1) and discard outer filter (3).

- Page 88 M0076814-01 Maintenance Section Diesel Exhaust Fluid - Fill 6. Install the retaining plate (6) and install screws (7). Caution should be used when dispensing DEF near an engine that has recently been running. Spilling Tighten screws (7) to a torque of 1.1 N·m DEF onto hot components may cause the release of (9.8 lb in).

- Page 89 Diesel Particulate Filter - Clean 1. Remove the DEF filter cap (3) with a 27mm Bi-Hex socket. Consult your Perkins distributor when the diesel 2. Remove the rubber cone insert (2) from the DEF particulate filter needs to be cleaned for the options filter (1).

- Page 90 Servicing the Air Cleaner Element • Maximum heat transfer characteristics Note: The air filter system may not have been provided by Perkins. The procedure that follows is for • Ease of maintenance a typical air filter system. Refer to the OEM information for the correct procedure.

- Page 91 M0076814-01 Maintenance Section Engine Air Cleaner Service Indicator - Inspect • Check the air cleaner service indicator daily. Note: Before removal, check the orientation of the end cover (3). Some air cleaners the end cover must • Check the pre-cleaner (if equipped) and the dust be installed in the correctly aligned position.

- Page 92 Engine Mounts - Inspect Note: The engine mounts may not have been supplied by Perkins. Refer to the OEM information for further information on the engine mounts and the correct bolt torque. Inspect the engine mounts for deterioration and for...

- Page 93 M0076814-01 Maintenance Section Engine Oil Sample - Obtain Perkins recommends using a sampling valve in order NOTICE to obtain oil samples. The quality and the consistency Engine damage can occur if the crankcase is filled of the samples are better when a sampling valve is above the “FULL”...

- Page 94 Use of an oil filter that is not recommended Engine Oil sample - Obtain for more information. by Perkins could result in severe damage to the en- gine bearings, and crankshaft. As a result of the larg- If the engine is operated infrequently less than 500...

- Page 95 Special Precautions Contaminated oil can cause accelerated wear to en- gine components. Your Perkins distributor can help in preparing the engine for extended storage periods. 4. Install the new oil filter (3). Spin on the oil filter until Some applications, the engine can be equipped with the O ring contacts the sealing surface (1).

- Page 96 M0076814-01 Maintenance Section Engine Storage Procedure - Check 4. Drain the crankcase oil. Replace the crankcase oil Use a bar or a turning tool to turn over the engine slowly. This procedure puts the oil on the cylinder and change the oil filters. For the proper walls.

- Page 97 (1) Plug Removing Application from Storage 8. If an engine is stored for more than 1 year, Perkins recommends Pre lubrication of the engine to avoid Follow the OEM recommendation for application dry starting. Use a suitable pump to put engine oil removal from storage.

- Page 98 Only qualified service personel should perform this Clean/Replace”. maintenance. Refer to the Service Manual or your au- thorized Perkins dealer or your Perkins distributor for 3. Ensure that the drive belt is correctly installed. the complete valve lash adjustment procedure.

- Page 99 M0076814-01 Maintenance Section Fuel System - Prime Refer to Systems Operation, Testing and Adjusting, 5. If the engine starts and the engine runs rough or “Engine Valve Lash - Inspect/Adjust” for more the engine misfires, operate at low idle until the information.

- Page 100 M0076814-01 Maintenance Section Fuel System Primary Filter/Water Separator - Drain i06616051 Fuel System Primary Filter/ Water Separator - Drain Fuel leaked or spilled onto hot surfaces or electri- cal components can cause a fire. To help prevent possible injury, turn the start switch off when changing fuel filters or water separator elements.

- Page 101 M0076814-01 Maintenance Section Fuel System Secondary Filter - Replace i06605835 Fuel System Secondary Filter - Replace Fuel leaked or spilled onto hot surfaces or electri- cal components can cause a fire. To help prevent possible injury, turn the start switch off when changing fuel filters or water separator elements.

- Page 102 M0076814-01 Maintenance Section Fuel Tank Water and Sediment - Drain Some fuel tanks use supply pipes that allow water i02348492 and sediment to settle below the end of the fuel Fuel Tank Water and Sediment supply pipe. Some fuel tanks use supply lines that take fuel directly from the bottom of the tank.

- Page 103 M0076814-01 Maintenance Section Hoses and Clamps - Inspect/Replace The grounding stud must have a wire ground to the A constant torque hose clamp can be used in place battery. Tighten the grounding stud at every oil of any standard hose clamp. Ensure that the constant change.

- Page 104 Overhaul Considerations Fuel System For an overhaul solution, contact your Perkins The fuel system is split into two different sections, distributor. high pressure, and low pressure. Ensure that the fuel pressure has been purged before any parts are removed loosened or replaced.

- Page 105 Proper safeguards Starting Motor - Inspect must be followed to help prevent accidents. i04020194 Perkins recommends a scheduled inspection of the starting motor. If the starting motor fails, the engine Radiator - Clean may not start in an emergency situation.

- Page 106 Service Manual for the engine or consult your Perkins distributor . • Inspect the lubrication system for leaks at the front crankshaft seal, the rear crankshaft seal, the oil pan, the oil filters, and the valve cover.

-

Page 107: Warranty Section

(“emission-related components”), are: For a detailed explanation of the Emission Control Warranty, contact your authorized Perkins dealer or a. Designed, built, and equipped so as to conform, your authorized Perkins distributor. at the time of sale, with applicable emission... -

Page 108: Reference Information Section

• Establish maintenance schedules for other repair cost (parts, labor, and travel). engines that are operated in the same environment. 2. Enjoy longer lasting product support from Perkins global network. • Show compliance with the required maintenance practices and maintenance intervals. - Page 109 M0076814-01 Reference Information Section Maintenance Log unit number and engine serial number. The following types of documents should be kept as proof of maintenance or repair for warranty: Keep the following types of documents as proof of maintenance for warranty. Also, keep these types of documents as proof of repair for warranty: •...

- Page 110 M0076814-01 Reference Information Section Maintenance Log (Table 18, contd)

-

Page 111: Index

M0076814-01 Index Section Index Cooling System Coolant Extender (ELC) - Add ..............83 Additional Messages ......... 7 Cooling System Coolant Level - Check... 83 After Starting Engine ........46 Cooling System Supplemental Coolant Extended Idle at Cold Ambient Additive (SCA) - Test/Add......84 Temperature.......... - Page 112 M0076814-01 Index Section Oil and Filter Change Intervals ....94 Fuel System - Prime........99 Engine Oil Level - Check......... 92 Fuel System Primary Filter (Water Engine Oil Sample - Obtain......93 Separator) Element - Replace....... 99 Obtain the Sample and the Analysis ... 93 Fuel System Primary Filter/Water Engine Operation ..........

- Page 113 Aftertreatment System......... 34 Power Take-Off Clutch - Check..... 104 Engine............32 Product Description ......... 20 Pump Electronic Tank Unit (PETU) ..... 35 Aftermarket Products and Perkins Severe Service Application ......71 Engines ............21 Environmental Factors......... 71 Electronic Engine Features ......21 Incorrect Maintenance Procedures .....

- Page 114 M0076814-01 Index Section Table of Contents ..........3 Walk-Around Inspection ........ 105 Inspect the Engine for Leaks and for Loose Connections ..........105 Warranty Information........107 Warranty Section........... 107 Welding on Engines with Electronic Controls ............69...

- Page 115 Product and Dealer Information Note: For product identification plate locations, see the section “Product Identification Information” in the Operation and Maintenance Manual. Delivery Date: Product Information Model: Product Identification Number: Engine Serial Number: Transmission Serial Number: Generator Serial Number: Attachment Serial Numbers: Attachment Information: Customer Equipment Number: Dealer Equipment Number:...

- Page 116 M0076814 ©2018 Perkins Engines Company Limited All Rights Reserved June 2018...

Need help?

Do you have a question about the 2506F-E15TA and is the answer not in the manual?

Questions and answers