Advertisement

Quick Links

Advertisement

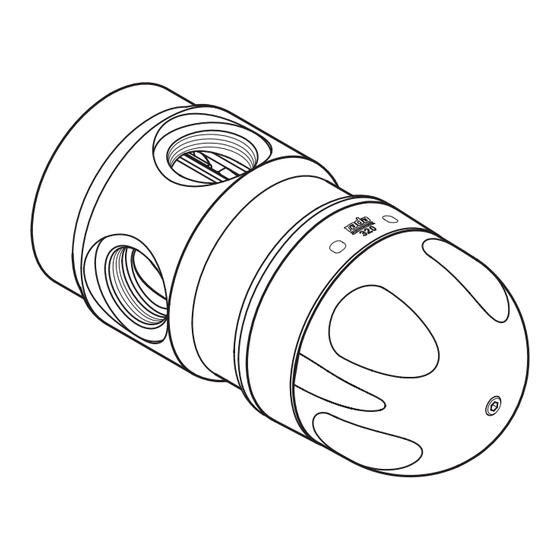

Summary of Contents for rada 320

- Page 1 1300905-W2-A...

- Page 2 The designed service life of all critical components used in this product is 5 years providing the Rada 320 is operated within the recommended operating conditions and parameters. However when supply conditions and/or usage patterns do not conform to the recommended operating parameters and/or conditions the critical components may need to be replaced more frequently (refer to 'Specification').

- Page 3 320 IC X 1 q X 1 q X 1 q X 2 q X 1 q X 1 q X 1 q X 2 q X 3 q 1300905-W2-A...

- Page 4 320 IF X 1 q X 1 q X 1 q X 2 q X 1 q X 1 q X 1 q X 2 q 1300905-W2-A...

- Page 5 320 F X 1 q X 1 q X 1 q X 1 q X 3 q 1300905-W2-A...

- Page 6 320 M X 1 q X 1 q X 1 q X 1 q X 3 q 1300905-W2-A...

- Page 7 320 IC RADA 320 C Ø83.5 mm 49 mm 256 mm 185 mm 314.5 mm 320 IF RADA 320 CX Ø83.5 mm 49 mm 256 mm 185 mm 314.5 mm 1300905-W2-A...

- Page 8 320 F RADA 320 CF 118.5 mm Ø83.5 mm 49 mm 185 mm 320 M 137 mm RADA 320 OEM Ø83.5 mm 49 mm 185 mm 1300905-W2-A...

-

Page 9: Specification

Specification Normal Operating Conditions are considered as: inlet dynamic pressures nominally balanced to within 10% of each other during flow. a differential of 15-35°C between the blend setting and either supply. daily usage of 1-6 hours. installation and usage environment not subject to extremes of temperature, unauthorised tampering or wilful abuse. - Page 10 Maximum Flow Rate: 120 l/min Flow Control Rada 320 mixing valves do not have integral flow control; appropriate provision must be made for this in the outlet pipework. This can be in the form of a stop-cock, mechanical timed-flow controller, solenoid or basin/bath tap. The device chosen must be non-concussive in operation.

-

Page 11: Installation

11. Inlet isolators must be used in the fully open position. 12. Do not install the Rada 320 valve in a position where it may become frozen. Outlet Position/Reversed Inlets All Rada 320 mixing valves are supplied with the inlet connections configured hot - left, cold... - Page 12 6.0 mm 3.0 mm 3.0 mm 6.0 mm 6.0 mm 1300905-W2-A...

- Page 13 Install the connections 320 IC 320 IF 1300905-W2-A...

- Page 14 320 F 320 M 1 min 1300905-W2-A...

- Page 15 3.0 mm Install the pipework 320 IC 320 IF 1300905-W2-A...

- Page 16 320 F 320 M 1300905-W2-A...

- Page 17 320 IC shown. The rest of the installation procedure is similar for all variants of the 320 valve. 1300905-W2-A...

- Page 18 The maximum blend temperature obtainable by the user should be limited, to prevent accidental selection of a temperature which is too hot. All Rada Thermostatic mixing valves are fully performance tested individually and the maximum temperature is pre-set to approximately 43 C under ideal installation conditions at the factory.

- Page 19 For Adjustable Temperature Remove the concealing cap, temperature knob and then the screw using the 3 mm hexagonal wrench (supplied). Remove the temperature knob and the hub. Rotate the spindle until required blend temperature is obtained at outlet point (clockwise = decrease temperature, anticlockwise = increase temperature).

- Page 20 For Locked Temperature Remove the concealing cap, temperature knob and then the screw using the 3 mm hexagonal wrench (supplied). Remove the temperature knob and the hub. Rotate the spindle until required blend temperature is obtained at outlet point (clockwise = decrease temperature, anticlockwise = increase temperature).

-

Page 21: Operation

Commissioning Checks (Temperatures should always be recorded with a thermometer with proven accuracy). Check inlet pipework temperatures for correct function of checkvalves i.e. that hot water does not cross flow into the cold supply and vice versa. Check that the supply pressures are within the range of operating pressures for the valve. -

Page 22: Troubleshooting

Hot water in cold supply or vice versa Indicates check valve require maintenance, refer to Maintenance. Note! Some 320 variants are not supplied with checkvalves. Therefore, in-line checkvalves may require maintenance. These may be away from the product. Maximum blend temperature setting too hot or too cool a. -

Page 23: Maintenance

The maintenance of this product must be carried out in accordance with instructions given in this Manual, and must be conducted by designated, qualified and competent personnel. Rada products are precision-engineered and should give continued superior and safe performance, provided: - They are installed, commissioned, operated and maintained in accordance with the recommendations stated in this Product Manual. - Page 24 Performance Check Six Monthly Exercising the Thermostat: If the valve has not been in regular or recent use the thermostat should be exercised before any other checking. Where user adjustment of the blend temperature is available the exercising of the thermostat can be achieved as described in COMMISSIONING.

- Page 25 Details of in-service testing and maintenance Initial commissioning test data (Supply pressures and temperatures, mixed water temperature, flow rate, result of cold water isolation test, date carried out, signature of maintenance person). First in-service test due date First in-service test data (As for initial commissioning) Details of any remedial work carried out to valve or supply system Second in-service test due date Second in-service test data (As for initial commissioning)

- Page 26 Components are precision-made, so care must be taken while servicing to avoid damage. When ordering spare parts, please state product type, i.e. Rada 320 IC, and identify part name and number (refer to PARTS LIST). A Seal pack is available, containing all the seals that may be necessary for renewal during maintenance or servicing.

- Page 27 Cartridges may only be cleaned by flushing through under a jet of clean water to remove debris. Do not descale. Descaling solution MUST not be used on any parts of the 320 valve. Cartridges are not serviceable, and must not be dismantled.

- Page 28 Identify which is the hot inlet to the mixing valve body, and align the cartridge assembly accordingly. Note! There is a 'H' and 'C' marked on the cartridge. Make sure that the 'H' aligns with the hot inlet and that the 'C' aligns with the cold inlet. Align the cartridge guides with the slots in the body and carefully push the cartridge assembly back into the body, checking that the 2 cartridge inlet port seals remain in place.

- Page 29 ☺ 1300905-W2-A...

- Page 30 414.80 414.51 414.92 1847.111 1847.230 1847.242 1847.184 1847.232 1847.236 1847.233 523.19 1847.235 1300905-W2-A...

- Page 31 Description 414.51 Cartridge Assembly 414.80 Hub Pack 414.92 Knob Pack Compression Fitting 523.19 1847.093 (3/4" BSP) Connector Pack 1847.111 (1" BSP) Female BSP Pack 1847.153 Elbow Connection Pack 1847.184 Isolating Elbow Pack 1847.227 Seal Pack - Not illustrated 1847.229 Screw Pack - 'A' 1847.230 Indicator Trim 1847.233 (3/4")

- Page 32 Your product has the benefit of our manufacturer’s guarantee which commences from date of purchase or from the date of commissioning when product commissioning has been conducted by the UK Rada Commercial Field Team (available UK Only). Please visit www.radacontrols.com or contact your local agent for all terms and conditions including details of the Rada commissioning service for the UK UK Customer Service &...

Need help?

Do you have a question about the 320 and is the answer not in the manual?

Questions and answers