Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for AuCom MVS

-

Page 2: Table Of Contents

Section 9 Operation ....................................47 Using the Soft Starter to Control a Motor ..............................47 Using the MVS to Control a Slip-Ring Motor ............................47 Operating States ........................................50 Motor Protection ........................................51 ... - Page 3 CONTENTS Section 11 Appendix ....................................59 11.1 Parameter Record ........................................59 11.2 Accessories ........................................... 61 11.3 Maintenance ..........................................64 Page 2 MVS User Manual 710-13019-00A...

-

Page 4: Caution Statements

Follow this manual and local electrical safety codes. SHORT CIRCUIT MVS soft starters are not short circuit proof. After severe overload or short circuit, the operation of the soft starter should be fully tested by an authorised service agent. - Page 5 © 2011 AuCom Electronics Ltd. All Rights Reserved. As AuCom is continuously improving its products it reserves the right to modify or change the specification of its products at any time without notice. The text, diagrams, images and any other literary or artistic works appearing in this document are protected by copyright.

-

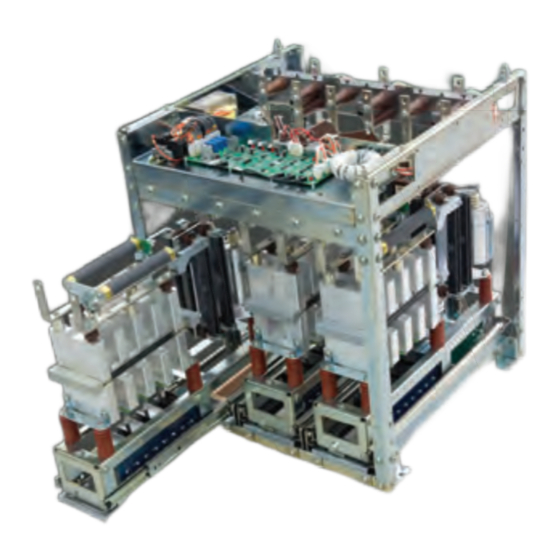

Page 6: General Description

Each MVS is also supplied with two fibre-optic cables, to connect the controller module to the power assembly, and three non-conduction lead assemblies, allowing the soft starter to be tested with a low-voltage motor (< 500 VAC). -

Page 7: Key Features

GENERAL DESCRIPTION Key Features MVS soft starters offer several special functions to ensure ease of use and to provide optimal motor control in all environments and applications. Customisable Protection The MVS offers comprehensive protection to ensure safe operation of the motor and soft starter. The protection characteristics can be customised extensively to match the exact requirements of the installation. -

Page 8: Model Code

0230 = 230 A @ AC53b 4-20 : 1780 0321 = 321 A @ AC53b 4-20 : 1780 0500 = 500 A @ AC53b 4-20 : 1780 0600 = 600 A @ AC53b 4-20 : 1780 710-13019-00A MVS User Manual Page 7... -

Page 9: Specifications

In addition to the dimensions of the soft starter power assembly, an enclosure must allow space for the following required components: MVS soft starters must always be installed with a main contactor and bypass contactor. Models with current ratings 500 A and above require forced air ventilation when installed in an enclosure. -

Page 10: Controller

SPECIFICATIONS Controller The Controller is suitable for use with all MVS soft starters. Control input LEDs Keypad ST ART ST OP RESET Ready Tr ip Local INPUTA L CL S ta r t S t o p R e se t... - Page 11 It is critical that the circuit breaker and associated protection relay are set to trip <150 ms. Failure to do so could result in SCR rupture and subsequent arc fault. Excludes contactors and/or circuit breakers. Page 10 MVS User Manual 710-13019-00A...

-

Page 12: Installation

INSTALLATION Section 4 Installation NOTE The MVS soft starter should only be installed in a restricted access location suitable for electrical equipment. NOTE Ensure that the equipment room is clean and relatively dust-free before unpacking and installing the MVS soft starter. -

Page 13: Mounting Instructions - Controller

Serial number MVS 0321-V04-C12 O/C: MVS 0321-411 S/N: 197803-459 INPUT RATING: 4160 VAC 50/60 Hz OUTPUT RATING:... -

Page 14: Power Terminations

(6.46) (8.72) (10.55) (10.55) (10.55) * For models MVSxxxx-V02 to MVSxxxx-V04, these dimensions apply up to 321 A. For the same models with current ratings of 500 and 600 A, the MVSxxxx-V06 dimensions apply. 710-13019-00A MVS User Manual Page 13... -

Page 15: Earth Terminations

The STOP button on the Controller is always enabled. The MVS has three fixed inputs for remote control. These inputs should be controlled by contacts rated for low voltage, low current operation (gold flash or similar). Page 14... -

Page 16: Terminal Block (Controller)

Main Contactor The MVS must always be installed with a main contactor. Select a contactor with an AC3 rating greater than or equal to the full load current rating of the connected motor or there is an option for a circuit breaker above 7.2 kV. - Page 17 To ensure that the potentially dangerous medium voltage area is isolated from the low voltage control area, power is Internal Wiring supplied to the bypass contactor coil from the control voltage terminal block (refer to Page 16 MVS User Manual 710-13019-00A...

- Page 18 INSTALLATION Power Circuit Configuration MVS power circuit with main contactor, bypass contactor, main isolator/ earth switch, R Rated fuses and control supply. Configured for four-wire start/ stop control. Models V02 to V07 must be installed with backup/R-rated fuses (refer to...

-

Page 19: Internal Wiring

130 VAC A2(2) to A2-3(2) 130 VAC 220 VAC A2(2) to A2-1(2) 220 VAC 230 VAC A3 and A2 A2(2) to A2-2(2) 230 VAC A3(2) to 13(2) 240 VAC A2(2) to A2-3(2) 240 VAC Page 18 MVS User Manual 710-13019-00A... -

Page 20: Keypad And Feedback

41, for further details. Programming Menu The Programming Menu lets you view and change programmable parameters that control how the MVS operates. To open the Programming Menu, press the MENU button while viewing the monitoring screens. You can access the Programming Menu at any time, including while the soft starter is running. Any changes to the start profile take effect immediately. - Page 21 Enter Access Code 0### STORE Access Allowed SUPERVISOR To change the access code, use parameter 15A. The simulation tools and counter resets are also protected by the security access code. The default access code is 0000. Page 20 MVS User Manual 710-13019-00A...

- Page 22 KEYPAD AND FEEDBACK Logs Menu The Logs Menu provides information on events, trips and starter performance. To open the Logs Menu, press ALT then F1 (LOGS). Logs Menu Refer to on page 45, for further details. 710-13019-00A MVS User Manual Page 21...

-

Page 23: Programming Menu

Standard Menu The standard menu provides access to commonly used parameters, allowing the user to configure the MVS as required for Parameter Descriptions the application. For details of individual parameters, refer to on page 26. -

Page 24: Extended Menu

User Screen - Top Right User Screen - Bottom Left User Screen - Bottom Right Extended Menu The extended menu gives access to all of the MVS's programmable parameters. Motor Data-1 Motor Full Load Current Locked Rotor Time Locked Rotor Current... - Page 25 Display A or kW User Screen - Top Left User Screen - Top Right User Screen - Bottom Left User Screen - Bottom Right Graph Data Graph Timebase Graph Maximum Adjustment Graph Minimum Adjustment Page 24 MVS User Manual 710-13019-00A...

- Page 26 Excess Start Time Undercurrent Instantaneous Overcurrent Current Imbalance Frequency Input A Trip Input B Trip Motor Thermistor Starter Communication Network Communication Reserved Battery/Clock Ground Fault Reserved Reserved Reserved Reserved Reserved Reserved Reserved Undervoltage Overvoltage 710-13019-00A MVS User Manual Page 25...

-

Page 27: Load/Save Settings

Save the current parameter settings to an internal file In addition to the factory default values file, the MVS can store two user-defined parameter files. These files contain default values until a user file is saved. To load or save settings:... - Page 28 If a main contactor is installed, the contactor must remain closed until the end of the stop time. 3 Auto-Stop The MVS can be programmed to stop automatically, after a specified delay or at a specified time of day. WARNING This function should not be used in conjunction with remote two-wire control.

- Page 29 4A, 4B – Excess Start Time Excess start time is the maximum time the MVS will attempt to start the motor. If the motor does not transition to Run mode within the programmed limit, the starter will trip. Set for a period slightly longer than required for a normal healthy start.

- Page 30 4H, 4I – Current Imbalance The MVS can be configured to trip if the currents on the three phases vary from each other by more than a specified amount. The imbalance is calculated as the difference between the highest and lowest currents on all three phases, as a percentage of the highest current.

- Page 31 Slows the starter's response to ground fault variation, avoiding trips due to momentary fluctuations. 4Q, 4R – Undervoltage The MVS can be configured to trip if the average voltage on all three phases of the mains supply falls below a specified level while the motor is running. Parameter 4Q...

- Page 32 Shaded area indicates motor operation 5 Auto-Reset Trips (Reserved) This parameter group is reserved for future use. 6 Inputs The MVS has two programmable inputs, which allow remote control of the soft starter. 6A – Input A Function Options: Motor Set Select (Default) The MVS can be configured with two separate sets of motor data.

- Page 33 (refer to parameter 15C for details). Closing the circuit across C53, C54 activates emergency run. Opening the circuit ends emergency run and the MVS stops the motor. Emergency Stop The MVS can be commanded to emergency stop the motor, ignoring the soft stop mode set in parameter 2H.

- Page 34 Remote mode. The Force Comms Trip and Local/Remote commands are always enabled. 7 Outputs The MVS has three programmable outputs, which can be used to signal different operating conditions to associated equipment. 7A – Relay A Function Options: Relay A is not used.

- Page 35 7M, 7N – Low Current Flag and High Current Flag The MVS has low and high current flags to give early warning of abnormal operation. The current flags can be configured to indicate an abnormal current level during operation, between the normal operating level and the undercurrent or instantaneous overcurrent trip levels.

- Page 36 Sets the level at which the motor temperature flag operates, as a percentage of the motor's thermal capacity. 7P, 7Q, 7R, 7S – Analog Output A The MVS has an analog output, which can be connected to associated equipment to monitor motor performance. Analog Output A...

- Page 37 User Screen - Bottom Right Default: Hours Run 8I, 8J, 8K, 8L – Performance Graphs The MVS has a real-time performance graph to report the behaviour of critical operating parameters. Parameter 8I Graph Data Options: Current (% FLC) (Default) Current as a percentage of motor full load current.

- Page 38 Default: 100% Description: Adjusts the soft starter's voltage monitoring circuits. The MVS is factory-calibrated with an accuracy of ± 5%. This parameter can be used to adjust the voltage readout to match an external voltage metering device. Set as required, using the following formula:...

- Page 39 Parameter 12A selects the ramp configuration for the primary motor and parameter 12B selects the ramp configuration for the secondary motor. 12C – Changeover Time Range: 100 - 500 (milliseconds) Default: 150 milliseconds Page 38 MVS User Manual 710-13019-00A...

- Page 40 Description: Selects the soft starter's response to each protection. Motor Overload Excess Start Time Undercurrent Instantaneous Overcurrent Current Imbalance Frequency Input A Trip Input B Trip 710-13019-00A MVS User Manual Page 39...

- Page 41 Starter Communication Network Communication Reserved Battery/Clock Ground Fault Reserved 16O~16U Undervoltage Overvoltage 20 Restricted These parameters are restricted for Factory use and are not available to the user. Page 40 MVS User Manual 710-13019-00A...

-

Page 42: Commissioning

Scroll to Run Simulation and press Ready Press START or activate the start input. Apply Start Signal Run Simulation The MVS simulates its pre-start checks and closes the main contactor (if Pre-Start Checks installed). The Run LED flashes. STORE to Continue Run Simulation... - Page 43 . The MVS simulates running. The Run LED stays on without flashing and the bypass contactor closes (if installed) Running Apply Stop Signal Press STOP or activate the stop input. The MVS simulates stopping. The Run Simulation Run LED flashes and the bypass contactor opens (if installed) Stopping X:XXs...

- Page 44 Reset Thermal Models The MVS's advanced thermal modelling software constantly monitors the motor's performance. This allows the MVS to calculate the motor's temperature and ability to start successfully at any time. The thermal model for the active motor can be reset if required.

-

Page 45: Low Voltage Test Mode

Switch on con ntrol and mains s supply, and us se the MVS to s start the motor r. The start co ommand can be e sent from the Controller or via the remote e input. -

Page 46: Maintenance Tools

The resettable counters (hours run, starts and motor kWh) can only be reset if the Adjustment Lock (parameter 15B) is set to Read & Write. To view the counters: Open the Logs Menu. Scroll to Counters and press Use the buttons to scroll through the counters. Press to view details. 710-13019-00A MVS User Manual Page 45... - Page 47 To reset a counter, press STORE (enter access code if required) then use the button to select Reset. Press STORE to confirm the action. To close the counters and return to the main display, press the repeatedly. Page 46 MVS User Manual 710-13019-00A...

-

Page 48: Operation

(parameters 6A and 6F). The soft starter will remove power from the motor and open the main contactor, and the motor will coast to stop. Using the MVS to Control a Slip-Ring Motor The MVS can be used to control a slip-ring motor, using rotor resistance. Sub-states States... - Page 49 Run mode (I < 120% FLC) Parameter 7B KM3 closes Parameter 12C Time NOTE For this installation to function correctly, only use the primary motor settings. Only use the constant Start Mode current start method (parameter 2A Page 48 MVS User Manual 710-13019-00A...

- Page 50 Programmable Relay output B Relay outputs 61, 62, 64 Programmable Relay output C C73~C74 Bypass contactor feedback signal Motor thermistor input 13~14 Main contactor KM1 Analog output 23~24 Bypass contactor KM2 33~34 Run output contactor 710-13019-00A MVS User Manual Page 49...

-

Page 51: Operating States

OPERATION Operating States Start and Run States The MVS soft starter has six operating states, and performs the following actions in each state: State Starter actions Not ready Control power is on and the starter performs system checks. The starter may be waiting for the motor to cool before allowing a start. -

Page 52: Motor Protection

Motor, System and Soft Starter Protection Mechanisms The MVS incorporates extensive protection features to ensure safe operation of the motor, system and soft starter. Most protection features can be customised to suit the installation. Use parameter group 4 to control the situation where the protections will activate and parameter group 16 to select the soft starter's response. - Page 53 Ready M1 000% 00000kW Programmable screen The MVS's user-programmable screen can be configured to show the most important information for the particular application. Use parameters 8E to 8H to select which information to display. Ready 00000 kWh 00000hrs ...

- Page 54 The performance graph provides a real-time display of operating performance. Use parameters 8I~8L to select which information to display. 0000 A 0%-400% SCR Conduction Bargraph The SCR conduction bargraph shows the level of conduction on each phase. L1 Cond L2 Cond L3 Cond 710-13019-00A MVS User Manual Page 53...

-

Page 55: Troubleshooting

Protection Responses When a protection condition is detected, the MVS will write this to the event log and may also trip or issue a warning. The soft starter's response to some protections may depend on the Protection Action settings (parameter group 16). - Page 56 Check for other equipment in the area that could be affecting the mains supply (particularly supply) variable speed drives and switch mode power supplies (SMPS). If the MVS is connected to a generator set supply, the generator may be too small or could have a speed regulation problem. Related parameters: 4J, 4K, 4L, 16F Gate Drive Fail There is a problem with the SCR gate drive.

- Page 57 Check that the main contactor closes when a start command is given, and remains closed until the end of a soft stop. Check MVS fuses and confirm that all three mains supply phases are present. This trip is not adjustable. Starter There could be a problem with the connection between the soft starter and the optional communications module.

-

Page 58: General Faults

Check Input A (C53, C54). The emergency stop function may be active. If parameter 6A or 6F is set to Emergency Stop and there is an open circuit on the corresponding input, the MVS will not start. The soft starter does not respond to ... - Page 59 Erratic motor operation. The SCRs in the MVS require at least 5 A of current to latch. If you are testing the soft starter on a motor with full load current less than 5 A, the SCRs may not latch correctly.The SCRs in the MVS require at least 5 A of current to latch.

-

Page 60: Appendix

Motor set select Input A Name Input trip Input A Trip Always active Input A Trip Delay 00m:00s Input A Initial Delay 00m:00s Input B Function Input trip (N/O) Input B Name Input trip 710-13019-00A MVS User Manual Page 59... - Page 61 Current (%FLC) Graph Timebase 10 seconds Graph Maximum Adjustment 400% Graph Minimum Adjustment Current Calibration 100% Mains Reference Voltage 400 V Voltage Calibration 100% Motor Data-2 Reserved Motor FLC-2 100 A Reserved Reserved Reserved Page 60 MVS User Manual 710-13019-00A...

-

Page 62: Accessories

Trip starter Restricted 11.2 Accessories Communication Modules MVS soft starters support network communication using the Profibus, DeviceNet, Modbus RTU and USB protocols, via an easy-to-install communications module. Installing Communication Modules Communication modules attach to the back of the Controller:... - Page 63 Current imbalance Frequency Phase sequence Instantaneous overcurrent Power loss Undercurrent Motor connection Input A trip Starter communication (between module and soft starter) Network communication (between module and network) Internal error Overvoltage Undervoltage Ground fault Page 62 MVS User Manual 710-13019-00A...

- Page 64 Upload parameter settings Download parameter settings To use WinMaster with the MVS, the soft starter must be fitted with a USB Module (PIM-USB-01) or a Modbus Module (PIM-MB-01). Other MVS Accessories Other accessories available to enhance your MVS starter include: ...

-

Page 65: Maintenance

Control Supply Transformer (PT/VT) The MVS requires a low voltage control supply. If low voltage is not available, a transformer is required. Use a transformer with primary voltage matching the MV mains voltage, and secondary voltage to suit the MVS starter. Use a single phase 500 VA transformer with protection fuses on both the primary and secondary sides. - Page 66 MV Insulation tester Thermal Image After completing commissioning of the MVS and after the motor has been running fully loaded, take a thermal image of the bus bars and other critical parts. As part of the maintenance program, compare a recent thermal image with the post-commissioning image.

- Page 67 APPENDIX Page 66 MVS User Manual 710-13019-00A...

- Page 68 APPENDIX 710-13019-00A MVS User Manual Page 67...

- Page 69 APPENDIX Page 68 MVS User Manual 710-13019-00A...

Need help?

Do you have a question about the MVS and is the answer not in the manual?

Questions and answers