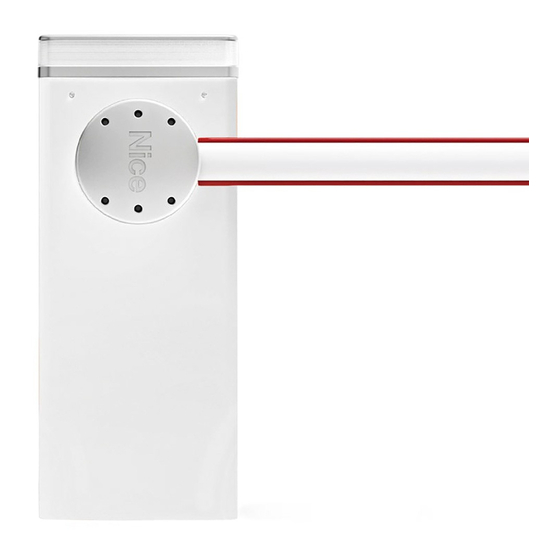

Nice MBar Programmer's Manual

Programmable functions using the oview programmer

Hide thumbs

Also See for MBar:

Summary of Contents for Nice MBar

- Page 1 MBar / LBar Programmable functions using the Oview programmer STF XBA3 – Rev00 Firmware: XB02a, XU01, XF01...

-

Page 2: Common Functions

COMMON FUNCTIONS name This parameter enables the user to assign the automation with a name other than the original, to facilitate identification (e.g. “northern gate”). A name comprising maximum 24 characters, including spaces, is admitted. series This parameter can be set with a value from 0 to 63; the factory setting is “0”. The series is a number that has to be assigned to each gearmotor, receiver or other device potentially connectable on a BusT4 network, to define its “clas- sification area”. -

Page 3: Basic Parameters

• closing initial deceleration position (0x33) This function is expressed in degrees. This enables programming the precise position at which the pole starts accelerating during a closing manoeuvre. To save the position, press “OK”. • closing deceleration (0x25) This function is expressed in degrees. During the closing manoeuvre this enables programming of the precise position at which the pole should start decel- erating before reaching the limit switch. - Page 4 • Start Close after photo (0x7a) This parameter determines which safety device restarts closing after a trip. You can choose between: - Photocells and Loop (0x40). Default setting - Loop only (0x41). - Photocells only (0x42). • wait time (0x85) This parameter is expressed in seconds and can be set with a value from 0 to 250 sec.;...

- Page 5 • closing speed (0x43) This parameter can be set with a value from 15% to 100%; the factory setting depends on the version. The function enables programming of the required motor speed during a Closing manoeuvre. Important – This parameter also affects the impact forces. •...

-

Page 6: Advanced Parameters

Advanced parameters This item covers the commands available and associable with inputs 1 - 2 – 3 and the Loop Detector on the control unit of an automation. The commands available for the inputs are given in Table 1; the command categories and modes are given in Table 1a, 1b, 1c etc.. Important – For correct operation of the control unit, the command programmed on an input must be associated with the corresponding command category and lastly the required operating mode. - Page 7 Timed Courtesy light This command enables activation of the courtesy light on the control unit and that programmable on Output 1. The courtesy light remains active for the time as programmed in the func- tion “courtesy light time” (Control unit functions > advanced parameters >...

- Page 8 Step-by-step Master When this command is sent to the master control unit, the Mas- ter/Slave barriers open or close, depending on the previous command. Input configured as normally open. Open master When this command is sent to the master control unit, the Mas- ter/Slave barriers open.

-

Page 9: Command Configuration

COMMAND CONFIGURATION This item covers the command categories associable with inputs 1 - 2 - 3 (refer to the section “input configuration - Table 1” to check the commands avail- able). Each command category features various operating modes as described in a table (1-A, 1-B, etc.): Step-by-step In this command category the user can select one of the operating modes specified in Table 1-A. - Page 10 stop and brief inversion When the control unit receives the “stop” command, it stops the manoeuvre in progress and activates the applica- tion to perform a brief inversion in the opposite direction. Photo In this category, you can choose one of the operating modes listed in table 1-F. TABLE 1-F: COMMAND CONFIGURATION MODE DESCRIPTION...

-

Page 11: Output Configuration

alt and inversion Operating mode set in factory. When the control unit receives the command, it stops the Closing manoeuvre in progress and activates a total inversion (Open). Caution! – During execution of the Opening manoeuvre, this com- mand is ignored. Detect obstacle in opening In this command category the user can select one of the operating modes specified in Table 1-N. - Page 12 Green traffic light (0x0e) This function indicates activity of the application during the phases of an Opening manoeuvre. slow flashing = execution of Opening manoeuvre; light permanently on = application in maximum Opening position; light off = application in other positions. One way traffic light (0x1a) This function requires the XBA8 flasher, and operates as follows: - With the pole up, green - In all other cases, red.

- Page 13 flashing light This function enables the flasher to indicate execution of a manoeuvre in progress with flashes at regular intervals (0,5 sec. ON; 0,5 sec. OFF). Output active 12 Vdc / max 21 W Flasher 1 This function enables the flasher to flash constantly at regular intervals (0.5 sec ON; 0,5 sec. OFF) both during a manoeuvre and when the pole is stationary.

- Page 14 output 3 This output can be set to one fo the functions described in Table 3, including those described below Fan (0x20) This function activates the output (fan) when the barrier is moving, and for 1 minute after the end of a manoeuvre. Output active 24 V DC / max 10W Electric lock time This parameter (in seconds) can be set to 0.1 - 10 s;...

- Page 15 Stop Indicates whether there is an error in the memorised data regarding the configuration of the alt input. Bluebus Indicates whether there is an error in the memorised data regarding the configuration of the devices connected to the bluebus input. Positions Indicates whether there is an error in the memorised data regarding positions.

-

Page 16: Maintenance

This function enables the firmware of a control unit to be updated with another compatible version, without the obligation to change the board. To update, proceed as follows: 01. Download the firmware update file (the software update is available from www.nice-service.com); 02. In “Advanced Functions” select “Update firmware”;...

Need help?

Do you have a question about the MBar and is the answer not in the manual?

Questions and answers