Table of Contents

Advertisement

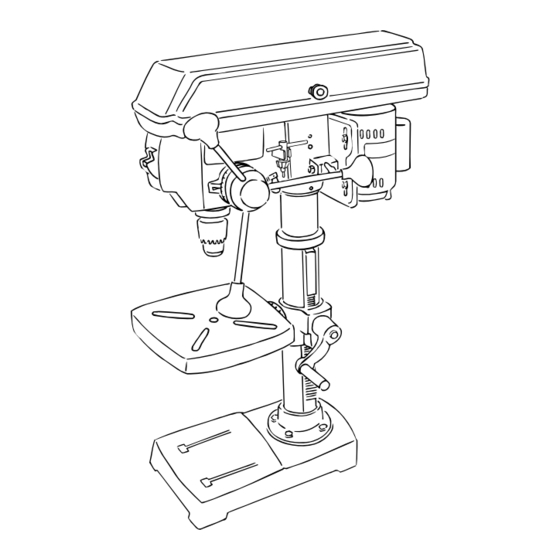

THANK YOU FOR BUYING A RYOBI BENCH TOP DRILL PRESS.

Your new Drill Press has been engineered and manufactured to Ryobi's high standards for dependability, ease of operation,

and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

CAUTION: Carefully read through this entire operator's manual before using your new machine.

Pay close attention to the Rules for Safe Operation, Warnings, and Cautions. If you use your machine properly and only for

what it is intended, you will enjoy years of safe, reliable service.

Please fill out and return the Warranty Registration Card so we can be of future service to you.

Thank you again for buying Ryobi tools.

SAVE THIS MANUAL FOR FUTURE REFERENCE

OPERATOR'S MANUAL

10 in. (254 mm) DRILL PRESS

MODEL DP101

1

Advertisement

Table of Contents

Summary of Contents for Ryobi DP101

- Page 1 THANK YOU FOR BUYING A RYOBI BENCH TOP DRILL PRESS. Your new Drill Press has been engineered and manufactured to Ryobi's high standards for dependability, ease of operation, and operator safety. Properly cared for, it will give you years of rugged, trouble-free performance.

-

Page 2: Table Of Contents

Your safety is involved. WARNING: WEAR YOUR The operation of any drill press can result in foreign objects being thrown into your eyes, SAFETY GLASSES which can result in severe eye damage. Before beginning power tool operation, always wear safety goggles or safety glasses with side shields and a full face shield when needed. -

Page 3: Rules For Safe Operation

Servicing requires extreme care and knowledge and should be performed only by a qualified service technician. For service we suggest you return the tool to your nearest RYOBI AUTHORIZED SERVICE CENTER for repair. When servicing, use only identical Ryobi replacement parts. -

Page 4: Safety Precautions

WARNING: Do not connect your drill press to a power source until you have assembled and adjusted the drill press as described in this manual and have read and understood all precautions and operating instructions in the manual and printed on the tool. -

Page 5: Specific Safety Rules For Drill Presses

30. ALWAYS TURN SWITCH OFF before disconnecting it to avoid accidental starting. 31. ALL REPAIRS, WHETHER ELECTRICAL OR MECHANICAL, should be made at a Ryobi Authorized Service Center. Use only Ryobi identical replacement parts. 32. SAVE THESE INSTRUCTIONS. Refer to them frequently and use to instruct other users. -

Page 6: Grounding Instructions

ELECTRICAL GROUNDING INSTRUCTIONS In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an equipment-grounding conductor and a grounding plug. -

Page 7: Glossary Of Terms

Drill Press Head The assembly at the top of the column which houses the motor, quill, and spindle. Feed The speed and force with which the drill bit is lowered into the workpiece. GLOSSARY OF TERMS Feed Handles Three handles attached to the quill which allow the operator to lower the chuck and bit during a drilling operation. -

Page 8: Know Your Drill Press

Equipped with an industrial duty, 1/4 HP induction motor for long lasting, smooth performance. Spindle Speeds 5 spindle speeds allow you to drill a wide variety of material from wood to plastic to metal. Drill Chuck Standard 3-jaw type with a self-ejecting chuck key included. -

Page 9: Unpacking

9. M5 Pan Head Screw 10. M8 1.25 Hex Bolts (4) UNPACKING Do not allow familiarity with your drill press to make you careless. Remember that a careless fraction of a second is sufficient to inflict severe injury. Do not attempt to assemble the drill press, plug in the power cord, or turn on switch if any parts are damaged or missing. -

Page 10: Assembly

TOOLS NEEDED FOR ASSEMBLY #1 and #2 Philips Screwdriver Adjustable Wrench Hammer or rubber mallet 1. Place the base on a flat surface and assemble the column to the base using the four M8 hex bolts. 2. Locate the worm gear and feed the D-shaft through the hole in the table assembly as shown in Figure 4. -

Page 11: Assembly

8. Attach the three feed handles by screwing them into the threaded holes in the hub. 9. Using the pre-drilled holes in the base, mount your drill press securely on a sturdy surface such as a work stand, workbench or counter top. See Figure 9. If your drill press... -

Page 12: Adjustments

See Figures 11 and 12 . Your drill press is equipped with a tilting table that allows you to drill angled holes. The table can be tilted left or right, from 0-45 degrees. To tilt the table, loosen the large hex bolt located underneath the table. -

Page 13: Operation

Your drill press is equipped with an on/off switch key. When removed, the switch key prevents the drill press from being turned on. The key must be in place to turn the drill press on. If the key is removed during operation, the drill press can be turned off but may not be turned on again until the key is replaced. -

Page 14: Operation

DRILLING TIPS If the hole is large, it’s a good idea to drill a smaller pilot hole before drilling the final one. Your hole will be more accurately positioned, rounder, and the bits will last longer. -

Page 15: Troubleshooting

Feed fast enough, allow drill to cut. Lubricate bit for metal work. Replace bit. Install bit properly. See page 14. Install chuck properly. See page 10. Contact Ryobi Authorized Service Center. Reduce feed pressure. Adjust belt tension. See page 12. Check support and/or re-clamp... -

Page 16: Parts Ordering / Service

Ryobi Authorized Service Center. Be sure to provide all pertinent facts when you call or visit. Please call 1-800-525-2579 for your nearest Ryobi Authorized Service Center. You can also check our web site at www.ryobitools.com for a complete list of Authorized Service Centers.

Need help?

Do you have a question about the DP101 and is the answer not in the manual?

Questions and answers