Summary of Contents for Wessex TRMX TRIPLE 560

- Page 1 A Broadwood International Product Operation Manual RMX TRIPLE 560/680 ROLLER MOWERS Product Code: L2043 Issue March 2013 Manufacturers and Distributors of Quality Equipment...

-

Page 3: Table Of Contents

Welcome to your new Wessex Product ........ - Page 4 CONTENTS Parts Illustration - Triple Chassis Assembly ........36, 38 Parts List - Triple Chassis Assembly .

-

Page 5: Welcome To Your New Wessex Product

WELCOME TO YOUR NEW WESSEX PRODUCT Thank you for purchasing a Wessex product. As a Broadwood customer, you now number among the most important people of our business and we will endeavour to give you the best service available through our dealer network. -

Page 6: Safety Decals

SAFETY DECALS GB ATTENTION Description of pictograms. ATTENTION Description des pictogrammes. VORSICH Beschreibung von Piktogrammen. GB Read Operating manual before use. Lire le Manuel d’utilisation avant l’utilisation. Vor Benutzung Betriebsanleitung lesen. GB Ear defenders must be worn. Porter des protections d’oreilles. Gehörschutz muss getragen werden. -

Page 7: Safety Decals

SAFETY DECALS GB Lifting Point Point de levage Hebepunkt GB CORRECT BELT TENSION: Check belt tension regulary: 10 mm 10mm of belt deflection at thumb pressure between pulleys. TENSIONNEMENT CORRECT DE LA COURROIE : Contrôler le tensionnement régulièrement : la déflexion de la courroie sous la pression du pouce entre les deux poulies doit être de 10 mm. KORREKTE RIEMENSPANNUNG: Riemenspannung regelmäßig überprüfen: 10 mm Eindrücktiefe bei Daumenduck zwischen Riemenscheiben. -

Page 8: Important Safety Warnings

IMPORTANT SAFETY WARNINGS Wessex machines are guarded for your protection, but you must always observe certain elementary precautions. Machines are potentially dangerous and should be used with the greatest respect and ALL OPERATORS MUST read this manual and be are aware of all safety precautions. -

Page 9: Warranty

WARRANTY Your Broadwood product or equipment is warranted free from defect in workmanship or manufacture for one year from date of purchase. Any parts which appear to us to be defective, either in material or workmanship shall be replaced or repaired at no cost to the purchaser, subject to the following conditions: 1. -

Page 10: Linking Up To The Tractor

LINKING UP TO THE TRACTOR 1. Always hitch and unhitch on level ground for safety reasons. 2. When hitching up, never allow anyone to stand between the tractor and the implement. 3. Reverse the tractor up to the RMX Triple and hitch up to the towing hitch. When using a drawbar pin ensure that it is secured with a lynch pin. -

Page 11: Altering The Cutting Height

USING THE RMX TRIPLE 9. When mowing the RMX Triple is capable of following very undulating ground conditions and with care the side arms will happily run up or down banks of up to 30 degrees. 10.When the mowing decks go beyond 30 degrees the drive will automatically disengage from driving the mowing decks. -

Page 12: Maintenance

At the end of the grass cutting season always clean the RMX thoroughly and grease before winter storage. Only use genuine Wessex parts in the event of replacing worn parts. This will ensure the continued safe use of your RMX Triple and the validity of your warranty. -

Page 13: Lubrication / Belt Adjustment (Mowing Decks)

LUBRICATION DAILY:- (Every 8-10 hours of operation). Grease Cutter Spindle bearings. Grease Roller bearings. Grease P.T.O. Shaft bearings and P.T.O. Shaft Safety Cover bearings. (See separate P.T.O. handbook originally zip tied to each P.T.O. Shaft). Grease P.T.O. Tube slides. PERIODICALLY:- (Every 40 hours of operation). Grease height adjustment points. -

Page 14: Replacing Drive Belts On The Main Drive Chassis

Remove the gearbox mounted belt retainers, See Figure ‘B’. Remove the worn or damaged belts from the pulleys. Figure ‘A’ Replace with new belts, Wessex Part No. WX-5934. Refit the gearbox mounted belt retainers. Lower the side decks to the ground. Ensure that all bystanders are clear of the decks when lowering. -

Page 15: Travelling On The Public Highway

TRAVELLING ON THE PUBLIC HIGHWAY 1. Check the local highway code of regulations before travelling on the highway. 2. Before travelling on the highway always ensure that all mower deck retaining safety catches are in locked position. 3. Ensure that all lights, indicators and flashing beacon are working and that the number plate is visible. -

Page 16: Troubleshooting / Winter Storage

TROUBLESHOOTING FAULT CAUSE REMEDY Leaving wheel track uncut 1. Forward speed too fast Reduce forward speed 2. Cutting height too high Lower cutting height Poor cut quality 1. Forward speed too fast Reduce forward speed 2. Excessive blade wear Replace blades 3. -

Page 17: Cutting Blades / Specifications

Always lift machine with a hoist when changing blades. Never work beneath an unsupported machine. To change the blade tips remove the blade retaining bolt using a 19mm socket/spanner. Replace blade tips using new locking nuts. SPECIFICATIONS Wessex Proline RMX Roller Mowers Model: RMX 560 RMX 680 Cutting Width: 5.6m... -

Page 18: Parts Illustration - Rmx 180 / 240 / 300 - Mainframe Assembly

PARTS ILLUSTRATION - RMX 180 / 240 / 300 MAINFRAME 3,4,5,6 10,11 15,16 17,18 27,28... -

Page 19: Parts List - Rmx 180 / 240 / 300 - Mainframe Assembly

PARTS LIST - RMX 180 / 240 / 300 MAINFRAME Item RMX180 RMX240 RMX300 QTY Description Part No. Part No. Part No. WX-11457 WX-11457 WX-11457 Gearbox Mounting Plate WX15003 WX15003 WX15003 Gearbox Plate Fastening Set WX-5857 WX-5857 WX-5857 Gearbox WX-0801 WX-0801 WX-0801 Gearbox Fastening Set... -

Page 20: Parts Illustration / Parts List - Drive Belts Rmx180

PARTS ILLUSTRATION - RMX 180 DRIVE BELTS PARTS LIST - RMX 180 DRIVE BELTS Item No. Part No. Description Qty. per Machine WX-10362 2 Row Pulley WX-11362 Taper Lock WX-0234 Belt WX-10562 Jockey Pulley WX-6038 Jockey Bearing WX-4022 Circlip WX-15903 Jockey Bolt WX-11162 Gearbox Pulley... -

Page 21: Parts Illustration / Parts List - Drive Belts Rmx240

PARTS ILLUSTRATION - RMX 240 DRIVE BELTS PARTS LIST - RMX 240 DRIVE BELTS Item No. Part No. Description Qty. per Machine WX-10362 2 Row Pulley WX-11362 Taper Lock WX-4534 Belt WX-10462 4 Row Pulley WX-11362 Taper Lock WX-11162 Gearbox Pulley WX-8662 Taper Lock WX-0647... -

Page 22: Parts Illustration / Parts List - Drive Belts Rmx300

PARTS ILLUSTRATION - RMX 300 DRIVE BELTS PARTS LIST - RMX 300 DRIVE BELTS Item No. Part No. Description Qty. per Machine WX-10362 2 Row Pulley WX-11362 Taper Lock WX-10562 Jockey Pulley WX-6038 Jockey Bearing WX-4022 Circlip WX-15903 Jockey Bolt WX-10462 4 Row Pulley WX-11362... - Page 23 PARTS ILLUSTRATION - DECK GEARBOX PARTS ILLUSTRATION - DECK GEARBOX Item No. Part No. Description Qty. GXS-0.151.0300.00 Casing GXS-8.0.1.00870 Bearing GXS-8.7.00744 GXS-8.6.5.00006 Plug GXS-8.5.2.00131 Snap Ring GXS-0.248.7500.00 Shim GXS-0.244.7500.00 Shim GXS-8.0.9.00024 Bearing GXS-8.5.1.00680 Snap Ring GXS-0.151.6001.00 Pinion Shaft GXS-8.7.3.00027 Oil Seal GXS-0.253.6201.00 Gear Z36 GXS-8.6.7.00269...

-

Page 24: Parts Illustration - Rmx 180 / 240 / 300 Spindles Assembly

PARTS ILLUSTRATION - RMX 180 / 240 / 300 SPINDLES ASSEMBLY... -

Page 25: Parts List - Rmx 180 / 240 / 300 Spindles Assembly

PARTS LIST - RMX 180 / 240 / 300 SPINDLES ASSEMBLY Item No. Part No. Description Qty. per Spindle WX-1947 WX-15066 Spindle Nut WX-0120 Tab Washer WX-4401 Fastening Set WX-0145 Seal WX-0338 Top Spindle Bearing WX-15166 Spindle WX-0220 Fibre Washer WX-7270 Blade Bar WX-2701... -

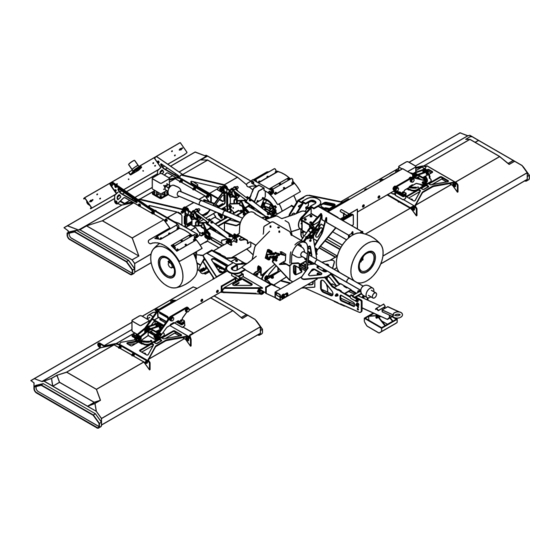

Page 26: Parts Illustration - Triple Main Assembly

PARTS ILLUSTRATION - TRIPLE MAIN ASSEMBLY 46 43 3, 5 2, 4... -

Page 27: Parts List - Triple Main Assembly

PARTS LIST - TRIPLE MAIN ASSEMBLY Item No. Part No. Description Qty. WX-27280 Chassis Assembly WX-15351 Left Hand Trailing Arm Assembly WX-15451 Right Hand Trailing Arm Assembly WX-16051 Left Hand Trailing Arm Assembly - Unbraked WX-16151 Right Hand Trailing Arm Assembly - Unbraked WX-9928 Trailing Axle Bearing Pin WX-0246... - Page 28 PARTS ILLUSTRATION - TRIPLE MAIN ASSEMBLY...

- Page 29 PARTS LIST - TRIPLE MAIN ASSEMBLY Item No. Part No. Description Qty. WX-5125 Gas Strut End Fitting WX-25780 Lever - Catch Release WX-10576 Guide Catch Release WX-27580 Belt Cover F-XWF227 Flat Washer F-XBM20150 Bolt F-XWF220 Flat Washer F-XNN220 Nylock Nut F-XWF240 Washer WX-5422...

-

Page 30: Parts Illustration - Right Hand Wing Assembly

PARTS ILLUSTRATION - RIGHT HAND WING ASSEMBLY... -

Page 31: Parts List - Right Hand Wing Assembly

PARTS LIST - RIGHT HAND WING ASSEMBLY Item No. Part No. Description Qty. WX-15879 Right Hand Wing Fabrication WX-26680 Gimbal Carriage Fabrication WX-26780 Gimbal Fabrication WX-11858 Gimbal Bracket WX-26880 Deck Hanger Fabrication Deck Assembly WX-8476 Buffer Rest WX-14057 Gearbox WX-12762 Pulley WX-12962 Taperlock Bush... - Page 32 PARTS ILLUSTRATION - RIGHT HAND WING ASSEMBLY...

- Page 33 PARTS LIST - RIGHT HAND WING ASSEMBLY Item No. Part No. Description Qty. F-XSM0835 Set Screw F-XNN208 Nylock Nut F-XSM3060 Set Screw F-XWF216 Flat Washer F-XSM1650 Set Screw F-XSM1660 Set Screw F-XNN216 Nylock Nut F-XSM1235 Set Screw F-XSM0820 Set Screw F-XWF210 Flat Washer F-XSM1025...

-

Page 34: Parts Illustration - Left Hand Wing Assembly

PARTS ILLUSTRATION - LEFT HAND WING ASSEMBLY 22, 43 14, 33 39, 40... -

Page 35: Parts List - Left Hand Wing Assembly

PARTS LIST - LEFT HAND WING ASSEMBLY Item No. Part No. Description Qty. WX-15779 Left Hand Wing Fabrication WX-26680 Gimbal Carriage Fabrication WX-26780 Gimbal Fabrication WX-11858 Gimbal Bracket WX-26880 Deck Hanger Fabrication Deck Assembly WX-8476 Buffer Rest WX-14157 Gearbox WX-12762 Pulley WX-12962 Taperlock Bush... -

Page 36: Parts Illustration - Left Hand Wing Assembly

PARTS ILLUSTRATION - LEFT HAND WING ASSEMBLY 22, 43 14, 33 39, 40... - Page 37 PARTS LIST - LEFT HAND WING ASSEMBLY Item No. Part No. Description Qty. F-XSM0835 Set Screw F-XNN208 Nylock Nut F-XSM3060 Set Screw F-XWF216 Flat Washer F-XSM1650 Set Screw F-XSM1660 Set Screw F-XNN216 Nylock Nut F-XSM0820 Set Screw F-XWF210 Flat Washer F-XSM1025 Set Screw F-XNN210...

-

Page 38: Parts Illustration - Triple Chassis Assembly

PARTS ILLUSTRATION - TRIPLE CHASSIS ASSEMBLY... -

Page 39: Parts List - Triple Chassis Assembly

PARTS LIST - TRIPLE CHASSIS ASSEMBLY Item No. Part No. Description Qty. WX-14679 Chassis Fabrication WX-31280 Bracket WX-8438 Pillow Block Bearing WX-28980 Sleeve - Drive Shaft WX-7581 Shaft - Splined WX-9728 WX-2247 WX-12762 Pulley WX-12862 Taperlock WX-5981 Flail P.T.O. Shaft WX-13879 Tensioner Mount WX-26080... - Page 40 PARTS ILLUSTRATION - TRIPLE CHASSIS ASSEMBLY...

- Page 41 PARTS LIST - TRIPLE CHASSIS ASSEMBLY Item No. Part No. Description Qty. F-XWF210 Flat Washer F-XNM210 Full Nut F-XWM206 Form A Washer F-XSK0625 Socket Cap Bolt F-XWF206 Flat Washer F-XNN206 Nylock Nut F-XWF212 Flat Washer F-XSM1245 Set Screw F-XSM1025 Set Screw F-XSK1020 Socket Cap Bolt F-XNN212...

-

Page 42: Parts Illustration - Rear Deck Assembly

PARTS ILLUSTRATION - REAR DECK ASSEMBLY... -

Page 43: Parts List - Rear Deck Assembly

PARTS LIST - REAR DECK ASSEMBLY Item No. Part No. Description Qty. WX-13979 WX-24780 Linkage - Rear Upper WX-17279 Rear Deck Frame WX-8328 Pin - Rear Deck Ram WX-8428 Pin - Rear Deck Linkage WX-3720 Nylon Washer WX-3520 Linkage Washer WX-3828 Lower Link Pin Bush WX-8938... -

Page 44: Parts Illustration / Parts List - Tensioner Arm Assembly

PARTS ILLUSTRATION - TENSIONER ARM ASSEMBLY PARTS LIST - TENSIONER ARM ASSEMBLY Item No. Part No. Description Qty. WX-25480 Right Hand Arm Fabrication Tensioner WX-29380 Left Hand Arm Fabrication Tensioner WX13266 Jockey Pulley - Plain WX-30080 Sleeve - Tensioner Wheel WX-6038 Bearing WX-5322... -

Page 45: Pto Shaft Operation And Maintenance

PTO SHAFT OPERATION AND MAINTENANCE IMPORTANT! P.T.O. drive shafts must only be used for their intended purpose. P.T.O. drive shafts are designed for specific machine types and power requirements. They must not be replaced by other models. Ensure that the P.T.O. drive shaft is securely connected. Only use a completely protected drive system: P.T.O. - Page 46 PTO SHAFT OPERATION AND MAINTENANCE LENGTH ADJUSTMENT To adjust the length, hold the half-shafts next to each other in the shortest working position and mark them. Shorten inner and outer guard tubes equally. Shorten inner and outer sliding profiles by the same length as the guard tubes.

-

Page 47: Safety Training Induction

SAFETY TRAINING INDUCTION The undersigned personnel have been trained in the safe use of this Wessex machine and have understood the contents of the Operator’s Manual. OPERATOR INSTRUCTOR/TRAINER Date Name Signature Name Signature... -

Page 48: Daily Inspection Record

DAILY INSPECTION RECORD OPERATOR’S DATE OF HOURS NAME INSPECTION... -

Page 49: Ce Certificate

RMX 560 / 680 RMX TRIPLE MARCH 2013... - Page 50 Manufacturers and Distributors of Quality Equipment Broadwood International Trading Estate, Oakhanger Road, Bordon, Hampshire. GU35 9HH Telephone: 01420 478111 Fax 01420 483000 e-mail: sales@broadwoodintl.co.uk www.broadwoodintl.co.uk...

Need help?

Do you have a question about the TRMX TRIPLE 560 and is the answer not in the manual?

Questions and answers