Subscribe to Our Youtube Channel

Summary of Contents for Spectra Precision Focus 30

-

Page 1: Service Manual

Focus 30/35 Total Station Service Manual 2016-09-30 P/N 79000035_SM, Version 1.5... - Page 2 Focus 30/35 Service Manual P/N 79000035_SM, Version 1.5...

- Page 3 This is the Seppember 2016 release version 1.5 of the This Trimble software product, whether provided as a Focus 30/35 Total Station Service Manual, part number stand-alone computer software product, built into 79000035_SM. It applies to the Focus 30/35 Series hardware circuitry as firmware, embedded in flash total station.

- Page 4 ” harmful interference to radio communication. AND WITHOUT EXPRESS OR IMPLIED WARRANTY OF However, there is no guarantee that interference will ANY KIND BY EITHER TRIMBLE NAVIGATION LIMITED not occur in a particular installation. If this equipment OR ANYONE WHO HAS BEEN INVOLVED IN ITS does cause harmful interference to radio or television CREATION PRODUCTION...

- Page 5 The compliance to the applicable requirements is http://partners.spectraprecision.com detailed in the official Declaration of Conformity 2. In the panel on the left, click Land Survey. document, which is filed at Trimble. 3. Go to Technical Support/Documentation/Trimble S6 Total Station Documentation/Declaration of Australia and New Zealand Conformity.

- Page 6 Focus 30/35 Service Manual P/N 79000035_SM, Version 1.5...

- Page 7 1.3.0 2013-10-01 Implementation Collimator Monitor software description, improvements 1.3.1. 2014-11-03 Rename to Focus 30/35; Ch.5 improvement 500Ncm for retainer ring 1.3.2 2015-07-06 Tolerance for coarse tilt adjustment set to 1400cc, PASS module improved. 2016-06-10 Added Focus 35 RX, 2nd Battery compartment instead of Control unit.

- Page 8 Focus 30/35 Service Manual Page 2 P/N 79000035_SM, Version 1.5...

- Page 9 General Information and Safety General Information and Safety Statement of Disclamation Preface Basic Assumptions General Safety Electrostatic Discharge (ESD) Laser Safety Service procedure recommendations P/N 79000035_SM, Version 1.5 1 - 1 Focus 30/35...

- Page 10 This manual contains PROPRIETARY information from Trimble Inc. This manual may not be duplicated, disclosed, copied, or re-transmitted in any form without prior written permission from Trimble Inc. ©2016 Trimble Inc., All Rights Reserved. Focus 30/35 Service Manual 1 - 2 P/N 79000035_SM, Version 1.5...

- Page 11 9. Replacement Parts: Lists the available service replacement parts and parts ordering information (will be provided as separated document on Partners). 10. Appendix: Provides additional information such as Service Bulletins, updates, notes, software procedures, etc. P/N 79000035_SM, Version 1.5 1 - 3 Focus 30/35...

- Page 12 Refer to the parts ordering section of this manual when replacing parts or making any adjustments. Torque specifications, adhesives, and procedures specified on assembly drawings are essential for continued successful operation of this product. Focus 30/35 Service Manual 1 - 4 P/N 79000035_SM, Version 1.5...

- Page 13 Warning – indicates a special procedure or special steps that must be taken in the course of completing the procedure in which the warning is found. These special procedures are necessary to avoid injury to the person performing the procedure. P/N 79000035_SM, Version 1.5 1 - 5 Focus 30/35...

- Page 14 Chapter 1 General Information and Safety Electrostatic Discharge (ESD) The Focus 30 was constructed in an ESD-protected environment. Most of the semiconductor devices in the instrument are susceptible to ESD damage. ESD is generated in many ways. For example, it can be the result of simple contact, the separation of materials, or the normal motion of people working with the device.

- Page 15 It is now safe to handle components and printed circuit assemblies on the mat. Always repackage all ESD-sensitive components before you disconnect the wrist strap. P/N 79000035_SM, Version 1.5 1 - 7 Focus 30/35...

- Page 16 Laser Safety Officer, Quality Assurance Group Phone (937) 233-8921 ext 5824 or (800) 538-7800 Fax (937) 233-9661 Spectra Precision Focus 30 Total Station The Spectra Specision Focus 30 is a CLASS 3R LASER PRODUCT Fig. 1-2 Laser warning label LASER RADIATION...

- Page 17 • Do not measure towards prisms up to 1000m in DR mode. • Make sure that unauthorized personnel do not get access to the instrument. Fig. 1-3 Laser aperture label P/N 79000035_SM, Version 1.5 1 - 9 Focus 30/35...

- Page 18 Chapter 1 General Information and Safety Laser and LED Information Focus 30 Fig. 1-4 Spectra Precision Focus 30 Laser and LED information Distance measurement Autolock and Laser aperture Laser pointer label aperture Tracklight aperture The laser warning label, is located on top of the distance unit cover.

- Page 19 Chapter 1 General Information and Safety Fig. 1-5 Location of Laser warning label on a Focus 30 Laser warning label P/N 79000035_SM, Version 1.5 1 - 11 Focus 30/35...

- Page 20 It is recommended to update the instruments firmware to latest version during service / repair. After repair it could be necessary due to customer request (application software compatibility, see “Software Compatibility” on page 3-60.) to downgrade the instrument before running Final Test & Report. Focus 30/35 Service Manual 1 - 12 P/N 79000035_SM, Version 1.5...

- Page 21 Chapter 2 General product Information General product Information Product description Models and serial numbers Product description & Service information Product specification P/N 79000035_SM, Version 1.5 2 - 1 Focus 30/35 Service Manual...

-

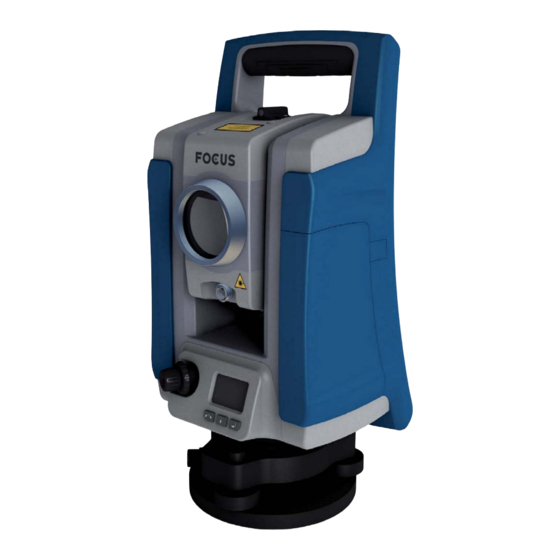

Page 22: Product Description

The speed of observation and precise positioning of the FOCUS 30/35 robotic total station is provided by patented StepDrive technology. StepDrive controls the horizontal and vertical motion of the motors, so there is no need for traditional motion locks. - Page 23 FOCUS 30/35 with a low-cost GPS receiver and Survey Pro software. This combination of technologies allows the user to take full advantage of the Spectra Precision GeoLock™ technology to keep locked on target.

- Page 24 Focus 35 3" StepDrive Focus 35-3 StepDrive/DR/2mm+2ppm 89100001 .. 89199999 Focus 35 5" StepDrive Focus 35-5 StepDrive/DR/2mm+2ppm 89200001 .. 89299999 Spectra Precision Focus 35 RX Robotic Label text Spectra model Model Serial number ranges code Focus 35 RX 1" Robotic...

- Page 25 Chapter 2 General product Information Product specification See Spectra Precision Focus 35 Spec Sheet on www.spectraprecision.com for infomation. P/N 79000035_SM, Version 1.5 2 - 5 Focus 30/35 Service Manual...

- Page 26 Chapter 2 General product Information Focus 30/35 Service Manual 2 - 6 P/N 79000035_SM, Version 1.5...

- Page 27 Tilt sensor Vertical and horizontal angle unit Servo drive units Base part F30 and USB connector Control Unit F30 (Focus 30/35) 2nd Battery compartment (Focus 35RX) Face two keyboard Optical plummet Main control board MCB ...

- Page 28 Servo side cover Servo drive V Battery/radio side cover Optical plummet Face 2 keyboard Servo drive Hz Tilt sensor Face 1 keyboard (F35) 2nd Battery compartment (F35RX) Base unit Focus 30/35 Service Manual 3 - 2 P/N 79000035_SM, Version 1.5...

- Page 29 Chapter 3 Theory of Operation Fig. 3-2 Telescope parts Transmitter Transceiver Tracker camera Servo focus Track light P/N 79000035_SM, Version 1.5 3 - 3 Focus 30/35 Service Manual...

- Page 30 It also receives the target signal and directs them to the distance meter and the tracker receiver camera. Location of telescope Fig. 3-3 Section view of the telescope Focusing lens Porro prism Reticle Selective Eyepiece mirrors Frontlens Motorized focussing drive Transmitter prism Focus 30/35 Service Manual 3 - 4 P/N 79000035_SM, Version 1.5...

- Page 31 2 reflects the wavelength of 660 nm to and from the EDM. Fig. 3-4 Principle schematic of the telescope Mirror 1 Focussing lens Camera Tracker Porro prism Transmitter prism Mirror 2 Reticle Eyepiece Front lens Motorized focusing drive Reticle illumination P/N 79000035_SM, Version 1.5 3 - 5 Focus 30/35 Service Manual...

- Page 32 Clean optical surface of Front lense, Porro prism, Eye piece. Don‘t touch the mirrors. Replacement of service parts • Eyepiece • Porro prism • Reticle • Reticle illumination • Front lens • Servo focus • Servo focus tracker board Focus 30/35 Service Manual 3 - 6 P/N 79000035_SM, Version 1.5...

- Page 33 • Length focusing track 19,5 mm Function description The servo focus drive is placed in the telescope behind the eyepiece and is reached from the upper side in second face. P/N 79000035_SM, Version 1.5 3 - 7 Focus 30/35 Service Manual...

- Page 34 During start-up routine the light barrier detects the position of the focusing lens. The light barrier controls the position of both breakers and protects the servo focus unit against accidental overrun. Focus 30/35 Service Manual 3 - 8 P/N 79000035_SM, Version 1.5...

- Page 35 Check of correct positioning (supported by Service Software) • Adjustment and calibration (supported by Service Software) Replacement of service parts • Tracker servo focus board • Servo focus mechanic part P/N 79000035_SM, Version 1.5 3 - 9 Focus 30/35 Service Manual...

- Page 36 EDM beam divergenz horizontal: 0,4mrad • EDM beam divergenz vertical: 0,3mrad • Principle: Phase shift • Accuracy Prism mode 2mm + 2ppm • Accuracy DR mode 3mm + 2ppm Focus 30/35 Service Manual 3 - 10 P/N 79000035_SM, Version 1.5...

- Page 37 MCB board. The phase measurement needs multiple modulation frequencies to reach a non ambiguous results because the phase measurement can only measure the phase of the wave rest piece. P/N 79000035_SM, Version 1.5 3 - 11 Focus 30/35 Service Manual...

- Page 38 When the EDM is in DR mode the Tracker transmitter is closed by a shutter. Fig. 3-10 Transmitter board Laser driver board Reference fiber incl. diode Switch DR/prism mode Tracker transmitter board Tracker shutter incl. diode Focus 30/35 Service Manual 3 - 12 P/N 79000035_SM, Version 1.5...

- Page 39 Coax cable connect Laser drive board to Transceiver board EDM offset The Focus 30 instrument has the same offset when measuring in EDM mode (to reflector) and DR mode (to DR target). This offset is measured in Offset determination in PASS.

- Page 40 Offset determination, and verification of EDM offset Replacement of service parts • Transmitter unit F30 • Receiver unit F30 • Reference greywedge foil • Reference fibre • Receiver fibre Focus 30/35 Service Manual 3 - 14 P/N 79000035_SM, Version 1.5...

- Page 41 Tracking range: 1m to 300m /800m depend on typ of prism • Passive tracking system to Trimble/SP prism targets. Functional description In the Focus 30 a Tracker system (transmitter and receiver) to passive prism targets is used. An P/N 79000035_SM, Version 1.5 3 - 15 Focus 30/35 Service Manual...

- Page 42 EDM tracking was started Principle schematic of Tracker unit Fig. 3-13 Principle of Tracker unit Tracker transmitter diode 2° Tracker servo focus board Tracker camera Tracker mirror Front lense prism Focus 30/35 Service Manual 3 - 16 P/N 79000035_SM, Version 1.5...

- Page 43 • Function test with service software • Final Tracker collimation test (reference pixel) Replacement of service parts • Transmitter module • Tracker camera module • Tracker servo focus board P/N 79000035_SM, Version 1.5 3 - 17 Focus 30/35 Service Manual...

- Page 44 Location of Tracklight Fig. 3-15 Location of Tracklight Tracklight Technical specification • Wavelength: Red, 645 nm / Green, 520 nm • Range 150 m Focus 30/35 Service Manual 3 - 18 P/N 79000035_SM, Version 1.5...

- Page 45 Tracklight is connected to the Tracker servo focus board. Block diagram Fig. 3-17 Tracklight block diagram TSF board MCB board Tracklight Service Maintenance • Alignment of Tracklight Replacement of service parts • Tracklight unit P/N 79000035_SM, Version 1.5 3 - 19 Focus 30/35 Service Manual...

- Page 46 Slip ring board tilt with coarse tilt Technical specification Working range: Coarse measurement = 3,3gon; Fine measurement = 111mgon Update rate = 4,7 times/sec Accuracy: < 0,15mgon Focus 30/35 Service Manual 3 - 20 P/N 79000035_SM, Version 1.5...

- Page 47 • Coarse tilt sensor as Electronic component on SCH board. Block diagram Fig. 3-19 Tilt sensor in zero position Vessel Vertical axis of instrument Area sensor Electronic board Optics Silicon oil Prism Point LED P/N 79000035_SM, Version 1.5 3 - 21 Focus 30/35 Service Manual...

- Page 48 Chapter 3 Theory of Operation Fig. 3-20 Tilt sensor in positiv position Vessel Vertical axis of instrument Area sensor Electronic board Optics Silicon oil Prism Point LED Focus 30/35 Service Manual 3 - 22 P/N 79000035_SM, Version 1.5...

- Page 49 The tilt sensor includes a PCB board for calculating levelling data. The data are sent to the Main control processor board. The tilt sensor is pre-calibrated and the correction data are stored in the sensor. P/N 79000035_SM, Version 1.5 3 - 23 Focus 30/35 Service Manual...

- Page 50 Slip contact board Service Maintenance • Tilt sensor offset for Coarse & Fine Tilt sensor Replacement of service parts • Tilt sensor • SCH board with coarse tilt sensor Focus 30/35 Service Manual 3 - 24 P/N 79000035_SM, Version 1.5...

- Page 51 Glass circle horizontal Housing Angle control board Illumination bridge Technical specification • Diametral reading • Accuracy = 2" (6cc) • Resolution = 0,3" (1cc) • Angle reading 200 Hz P/N 79000035_SM, Version 1.5 3 - 25 Focus 30/35 Service Manual...

- Page 52 The LED light is transmitted through an encoder glass disc. A pattern from the encoder glass disc is projected on the detector, a CMOS sensor reads the pattern from the coarse and fine code on the disc. Focus 30/35 Service Manual 3 - 26...

- Page 53 The information from the both CMOS sensors will be calculated in the Angle control board into an angle. The final angle correction will be done in the MCB board. P/N 79000035_SM, Version 1.5 3 - 27 Focus 30/35 Service Manual...

- Page 54 Maintenance • Self calibration by PASS service software Replacement of service parts • Horizontal Base part complete • Vertical angle disc • Angle control board • LED on bridge Focus 30/35 Service Manual 3 - 28 P/N 79000035_SM, Version 1.5...

- Page 55 Technical specification • Maximum speed up to 100 gon/sec • Single step at coarse motion: 60cc • Single step at fine motion: 0,9cc • Motion range of 10000steps = 0,9gon P/N 79000035_SM, Version 1.5 3 - 29 Focus 30/35 Service Manual...

- Page 56 The right and the left light barriers of the MCB board limits the motion of the spindle.The return of the lever arm to the centre position,reaching the end stops, will be done automatically by the Focus 30/35 Service Manual 3 - 30...

- Page 57 Switching the solenoid to open position 1 the coarse drive works again, driving the axis. P/N 79000035_SM, Version 1.5 3 - 31 Focus 30/35 Service Manual...

- Page 58 Chapter 3 Theory of Operation Fig. 3-31 Solenoid clamp Coarse motor housing Solenoid Clamp disc Break material Latch Coarse drive lever Focus 30/35 Service Manual 3 - 32 P/N 79000035_SM, Version 1.5...

- Page 59 This part of software, a “virtual gearbox” turns the instrument faster or slower like the knob will be turned by P/N 79000035_SM, Version 1.5 3 - 33 Focus 30/35 Service Manual...

- Page 60 Test of coarse and fine drive by PASS service software Replacement of service parts • Fine drive V • Coarse drive V • Fine drive Hz • Coarse drive Hz • Slip contact Hz (SCH board) Focus 30/35 Service Manual 3 - 34 P/N 79000035_SM, Version 1.5...

- Page 61 The Base part is assembled into one unit and not possible to open. The Hirose connector is the communication connector and transmits the external power supply. The foot connector board is connected via cable to the Hz slip ring board. P/N 79000035_SM, Version 1.5 3 - 35 Focus 30/35 Service Manual...

- Page 62 Fig. 3-34 Base part Cable USB conector (Hirose) Base unit Block diagram Fig. 3-35 Block diagram base unit Main control board Hz slip ring board Foot connector board Hirose 12V/COM Focus 30/35 Service Manual 3 - 36 P/N 79000035_SM, Version 1.5...

- Page 63 Maintenance • Check of foot connector Replacement of service parts • Base part F30 • USB connector • Cable between foot connector board (FCB) and slip ring board (SRB) P/N 79000035_SM, Version 1.5 3 - 37 Focus 30/35 Service Manual...

- Page 64 Chapter 3 Theory of Operation Control Unit F30 (Focus 30/35) Location Control Unit F30 Fig. 3-36 Location Control Unit F30 Control Unit Technical specification • Main APC board with operating system (OS) Windows CE 6.00 • Frontside keys 24 •...

- Page 65 Theory of Operation Fig. 3-37 Control unit F30, exploded Rear Beeper Back side housing Sealing sealing Holder TFT touch panel Processor board Key pad board Rubber key pad Front housing P/N 79000035_SM, Version 1.5 3 - 39 Focus 30/35 Service Manual...

- Page 66 Front side keys Face one keyboard main CPU board with Windows CE Main control board MCB Service Maintenance • Test with service software • Update operating system • Update application software Focus 30/35 Service Manual 3 - 40 P/N 79000035_SM, Version 1.5...

- Page 67 Theory of Operation Replacement of service parts • Face one keyboard complete • Rubber key pad • key pad board • TFT touch panel • Sealing • Rubber • Beeper P/N 79000035_SM, Version 1.5 3 - 41 Focus 30/35 Service Manual...

- Page 68 Service Maintenance • Test with service software • Update operating system • Update application software Replacement of service parts • 2nd Battery compartment complete • 2nd Battery compartment door Focus 30/35 Service Manual 3 - 42 P/N 79000035_SM, Version 1.5...

- Page 69 The face two panel is a graphical display with backlight and four key control. Functions: • Coarse level control • Measure button • Change face button • Instrument Adjustment • Service/diagnostics • Radio channel ID • BT On/ Off P/N 79000035_SM, Version 1.5 3 - 43 Focus 30/35 Service Manual...

- Page 70 Display board Cable to MCB board Rubber key pad Sealing Housing Block diagram Fig. 3-42 Face two keyboard, block diagram Face two keyboard LCD Display Backlight Four keys MCB board Focus 30/35 Service Manual 3 - 44 P/N 79000035_SM, Version 1.5...

- Page 71 Chapter 3 Theory of Operation Service Maintenance • Test with service software Replacement of service parts • Face two keyboard complete • Sealing • Rubber key pad P/N 79000035_SM, Version 1.5 3 - 45 Focus 30/35 Service Manual...

- Page 72 Accuracy/range: ± 0,3 mm/ 0,5 m-infinity • Field of view:± 2,5 • Magnification: 2,4 Functional description optical plummet The optical plummet is used to position the instrument above a point. Focus 30/35 Service Manual 3 - 46 P/N 79000035_SM, Version 1.5...

- Page 73 Chapter 3 Theory of Operation Fig. 3-44 Optical plummet Crosshair Eyepiece Focus Service Maintenance Alignment of optical plummet. Replacement of service parts • Optical plummet P/N 79000035_SM, Version 1.5 3 - 47 Focus 30/35 Service Manual...

- Page 74 EDM. IM is the host when communicating with internal units, in case of communicating via footconnector, IM can be either host or device mode depending on the external unit. Focus 30/35 Service Manual 3 - 48 P/N 79000035_SM, Version 1.5...

- Page 75 Angle V Knob Knob Batt. Knob Knob Serial Service Maintenance After replacement of MCB board: • Update firmware sensors • Initialize instrument data Replacement of service parts • MCB board P/N 79000035_SM, Version 1.5 3 - 49 Focus 30/35 Service Manual...

- Page 76 Fig. 3-47 Location of Battery/radio side cover Batterie/radio side cover Technical specification • Battery LiIon with capacity 4,4Ah • Radio frequency : 2401 to 2470 MHz • Output power: 100 mW • Range: 1100m Focus 30/35 Service Manual 3 - 50 P/N 79000035_SM, Version 1.5...

- Page 77 A Backup module on BCR board supports the replacement of the internal Battery without lost of data for two minutes. The Focus 30 is available with an internal radio to support robotic operations. The radio operates in the public free 2.4GHz ISM band. It applies frequency hopping spread spectrum technology. The radio meets FCC rules 15.247 and ETSI (European) 300.328 for worldwide license free operation.

- Page 78 Battery cover Connector board Internal battery Side cover left The Battery/radio side cover includes: • Internal battery compartment • Radio module • Connector board to internal battery, with Backup module. Focus 30/35 Service Manual 3 - 52 P/N 79000035_SM, Version 1.5...

- Page 79 Radio configuration by PASS service software • Function test • Range test Replacement of service parts • Side cover complete,without battery • Radio module • Sealing • Battery Connector Radio board- BCRB P/N 79000035_SM, Version 1.5 3 - 53 Focus 30/35 Service Manual...

- Page 80 This signal is sent to the MCB board to control the Hz and V servo motors units. A Bluetooth module is implemented. Focus 30/35 Service Manual 3 - 54 P/N 79000035_SM, Version 1.5...

- Page 81 Blue tooth module Fig. 3-51 Servo side cover Sealing Blue tooth Blue tooth board Servo focus knob Vertical knob Horizontal knob Trigger key Sealing cover Servo drive board Servo side cover P/N 79000035_SM, Version 1.5 3 - 55 Focus 30/35 Service Manual...

- Page 82 Check Servo Focus and Servo Hz/V knobs • Check of the Blue tooth module Replacement of service parts • Blue tooth module • Servo side cover complete • Servo drive board • Power key Focus 30/35 Service Manual 3 - 56 P/N 79000035_SM, Version 1.5...

- Page 83 Servo knob board-SKB Blue tooth-BT Angle control V-ACB Tracker servo focus board-TSF Application control board-ACB Angle control Hz-ACB TFT touch panel Key pad board-F1K Slip ring board-SRB Foot connector board-FCB P/N 79000035_SM, Version 1.5 3 - 57 Focus 30/35 Service Manual...

- Page 84 Fig. 3-54 Overview electronic boards face 2 Radio module Battery Connector Radio board BCRB with Backup module Key pad board Application control board-ACB Display board -F2D Camera tracker Hz slip contact board-SCH Focus 30/35 Service Manual 3 - 58 P/N 79000035_SM, Version 1.5...

- Page 85 Angle control Coarse motor Hz board V-ACB Battery connector Fine motor Hz radio board-BCRB Tilt sensor Display board-F2D Angle control board Hz-ACB Battery2 compartment Hz slip contact board-SCH Solenoid Hz P/N 79000035_SM, Version 1.5 3 - 59 Focus 30/35 Service Manual...

- Page 86 Instrument Firmware vs. SPS Pro & OS The tables below describes the compatibility between the instrument firmware, OS and the control unit field software Spectra Precision Survey Pro (SPS Pro). Compatibility table Instrument Firmware vs. & SPS Pro & OS Instr.

- Page 87 Overwrite constants from PC to instrument ( for level 4 only) Error and eventlog viewer Check unites states, basic measure function & units Trouble shooting sensors Instrument selftest, System Monitor & onboard Diagnostics P/N 79000035_SM, Version 1.5 4 - 1 Focus 30/35 Service Manual...

- Page 88 Instrument and press and shows an printed. data Analyze overview with Run Operation serial number, FW version and status. Fig. 4-1 Instrument status check Focus 30/35 Focus 30/35 Service Manual 4 - 2 P/N 79000035_SM, Version 1.5...

- Page 89 Performance Action Result Notes The 10 digit serial number for Model Focus 30 was introduced since Q4/2015. The instrument model Focus 35 RX starts with 10 digits serial number, see “Models and serial numbers” on page 2-3. Fig. 4-2 Instrument status check Focus 35 RX Exit the program.

- Page 90 (10 digits), e.g. Model code Focus 35 RX (5“) 865 plus serial number 1550601296 to search string number 8651550601296, or search with *1550601296*. Refer also to bulletin JE-01-0116-000 and, see “Models and serial numbers” on page 2-3. Focus 30/35 Service Manual 4 - 4 P/N 79000035_SM, Version 1.5...

- Page 91 Write constants from PC to instrument Performance Item Performance Action Result Notes Start up instrument / how to set- See page 7-3 PASS. up the instrument. P/N 79000035_SM, Version 1.5 4 - 5 Focus 30/35 Service Manual...

- Page 92 The Instrument data D. The Instrument After writing the manager is will be written to the data to the preselected Instrument manager. instrument, the program response with a status message. Focus 30/35 Service Manual 4 - 6 P/N 79000035_SM, Version 1.5...

- Page 93 Overwrite constants from PC to instrument ( for level 4 only) Performance Item Performance Action Result Notes Start up instrument / how to set- See page 7-3 PASS. up the instrument. P/N 79000035_SM, Version 1.5 4 - 7 Focus 30/35 Service Manual...

- Page 94 The Instrument data program response the list and press will be written to the with a status Next Instrument manager message. and each satellite. Focus 30/35 Service Manual 4 - 8 P/N 79000035_SM, Version 1.5...

- Page 95 Chapter 4 Troubleshooting Item Performance Action Result Notes Fig. 4-5 Overwrite constants from PC to instrument P/N 79000035_SM, Version 1.5 4 - 9 Focus 30/35 Service Manual...

- Page 96 TILT instrument ANGLE_HZ corrections. ANGLE_VE Sensor sections SERVOFOCUS with variables, TRACKER production data, DRIVES runtime data and collector KNOBS messages. DISTV3 F2DISPLAY Focus 30/35 Service Manual 4 - 10 P/N 79000035_SM, Version 1.5...

- Page 97 Chapter 4 Troubleshooting Item Performance Action Result Notes Fig. 4-6 Error and eventlog viewer P/N 79000035_SM, Version 1.5 4 - 11 Focus 30/35 Service Manual...

- Page 98 See page 7-3 PASS. up the instrument. Track Unit States Select Track unit status from Basic function test see Fig. 4-7 on Analyze page 4-12 Fig. 4-7 Track Unit states Focus 30/35 Service Manual 4 - 12 P/N 79000035_SM, Version 1.5...

- Page 99 Fig. 4-8 Check basic functions Check Units: A. Select Check Units B. Press on Tilt sensors Check Tilt button to get Start the raw tilt data for Coarse or Fine tilt sensor. P/N 79000035_SM, Version 1.5 4 - 13 Focus 30/35 Service Manual...

- Page 100 B. Press to adjust fine steps. drive the Servo Focus Check infinite Unit from close to infinite position in and close fine or coarse steps. position. Fig. 4-10 Check units-Servo focus Focus 30/35 Service Manual 4 - 14 P/N 79000035_SM, Version 1.5...

- Page 101 Performance Item Fault / error message Description Solution / Notes Subsystem error on Subsystem error:Tilt Check connectivity of tilt sensor to MCB. Control unit F2 Check firmware. Exchange sensor. P/N 79000035_SM, Version 1.5 4 - 15 Focus 30/35 Service Manual...

- Page 102 Performance Item Fault / error message Description Solution / Notes Subsystem error on Subsystem error:SF Check connectivity of Servo focus. Control unit F2 Check firmware Replace servo focus hardware. Focus 30/35 Service Manual 4 - 16 P/N 79000035_SM, Version 1.5...

- Page 103 Fine drive. Some movements did not start. Please check the correct function of the clamp and further the Coarse drive. P/N 79000035_SM, Version 1.5 4 - 17 Focus 30/35 Service Manual...

- Page 104 Performance Item Fault / error message Description Solution / Notes Subsystem error on Subsystem error:DistV3 Check connectivity of transmitter and Control unit F2 receiver board. Check firmware Replace hardware. Focus 30/35 Service Manual 4 - 18 P/N 79000035_SM, Version 1.5...

- Page 105 F2 Display:MainMenu/Service Menu/ has been exceeded, the Next Service Date, see “Service Interval” instrument needs on page 6-164. service. F2Display Performance Item Fault / error message Description Solution / Notes P/N 79000035_SM, Version 1.5 4 - 19 Focus 30/35 Service Manual...

- Page 106 Montor is activ and watches the sensors during the customer application is running. System Monitor & onboard Diagnostics After successful start up, the instrument will be observed by the System Monitor. The tracked status Focus 30/35 Service Manual 4 - 20 P/N 79000035_SM, Version 1.5...

- Page 107 A. Press arrow buttons to reach the diagnostics System diagnostics B. Enter System System diagnostics diagnostics Exit Show system state Show system state Run system diag. Run system diag. are now accessible. P/N 79000035_SM, Version 1.5 4 - 21 Focus 30/35 Service Manual...

- Page 108 B. After saving, the Save Status menu goes back to Save result in permanent error log? System diagnostics see item Focus 30/35 Service Manual 4 - 22 P/N 79000035_SM, Version 1.5...

- Page 109 Instrument is moving. Please do not touch! Selftest checks coarse drive and fine Check Drives drive values, testing the lightbarriers. Instrument is moving. P/N 79000035_SM, Version 1.5 4 - 23 Focus 30/35 Service Manual...

- Page 110 The Monitor error log file by using Pass Service FocusInstrument_Serialnumber_Date_Sys Software, see can be displayed by Save Monitor.fsmx Error in Pass, see constants from instrument Error and eventlog viewer and eventlog viewer. Focus 30/35 Service Manual 4 - 24 P/N 79000035_SM, Version 1.5...

- Page 111 Fig. 4-11 FocusInfo Report shows file *.fsmx System monitor - Error codes and event messages in *.fsmx The error message codes are displayed in combination of numerics 1-6 and characters A-D. The P/N 79000035_SM, Version 1.5 4 - 25 Focus 30/35 Service Manual...

- Page 112 General status combined from communication status 1 - 6 and sensor specific messages A - D: Unknown Not communicating... Not initialized... Not active... Timeout warning Failed warning Error message warning Readings disturbed Reading error Not enough readings Focus 30/35 Service Manual 4 - 26 P/N 79000035_SM, Version 1.5...

- Page 113 FI: 10 Code: 0xf002 Message: Angle Drive system Turn event measurement failed error warning 6 B D1 Error: 0x9868 (39016) brown out reset dedected Fsmxfile Hz: reading error 6 A = error P/N 79000035_SM, Version 1.5 4 - 27 Focus 30/35 Service Manual...

- Page 114 General status combined from communication status 1 - 6 and sensor specific messages A - D: Unknown Not communicating... Not initialized... Not active... Timeout warning Failed warning Error message warning Readings disturbed Reading error Not enough readings Focus 30/35 Service Manual 4 - 28 P/N 79000035_SM, Version 1.5...

- Page 115 Exchange Illumination V- A A1 FI: 25 Code: 0x9c54 ACB (left). Message: Angle Drive system Turn event measurement failed error warning 6 B D1 0x9868 brown out reset dedected P/N 79000035_SM, Version 1.5 4 - 29 Focus 30/35 Service Manual...

- Page 116 General status combined from communication status 1 - 6 and sensor specific messages A - D: Unknown Not communicating... Not initialized... Not active... Timeout warning Failed warning Reading time out Not enough readings Focus 30/35 Service Manual 4 - 30 P/N 79000035_SM, Version 1.5...

- Page 117 General status combined from communication status 1 - 6 and sensor specific messages A - D: Unknown Not communicating... Not initialized... Not active... Timeout warning Failed warning Turn failed warning Turn event error warning Turns blocked Turns failed P/N 79000035_SM, Version 1.5 4 - 31 Focus 30/35 Service Manual...

- Page 118 3 6 B D D1 vertical faile FI: 10 Code: 0x9c52 Message: Req x6e got res 9 FI: 1 Code: 0x9c4e Message: Drive system: Not initialized ( 2 3 6 B D Focus 30/35 Service Manual 4 - 32 P/N 79000035_SM, Version 1.5...

- Page 119 Drives: Error: 0xf000 (61440), ReportingFI: 10, Info: Code: 0xf000 P0: 0x0000 P1: 0x80000000 P2: 0x0000000 Knobs:Error: 0xf000 (61440), ReportingFI: 16, Info: Code: 0xf000 P0: 0x0000 P1: 0x80000000 P2: 0x0000000 P/N 79000035_SM, Version 1.5 4 - 33 Focus 30/35 Service Manual...

- Page 120 If one knob fails the stops the aiming to target. Run System diag. SF Knob - Ok status - Error message VA Knob - Ok status - Error message Focus 30/35 Service Manual 4 - 34 P/N 79000035_SM, Version 1.5...

- Page 121 3 times to prism. Diagnostics: Could NOT measure 3 times to DR target. Value description Ok Counter Weak Signal To Strong Sig- Fatal error Counter counter Counter PR Results DR Results P/N 79000035_SM, Version 1.5 4 - 35 Focus 30/35 Service Manual...

- Page 122 Exchange the Failed ( C1 C EDM. Sensor specific messages Subsystem: FI_Darwin_Tracker General status combined from communication status 1 - 6 and sensor specific messages A - D: Focus 30/35 Service Manual 4 - 36 P/N 79000035_SM, Version 1.5...

- Page 123 Sensor specific messages Subsystem: FI_Darwin_Servofocus General status combined from communication status 1 - 6 and sensor specific messages A - D: Unknown Not communicating... Not initialized... Not active... Timeout warning Failed warning P/N 79000035_SM, Version 1.5 4 - 37 Focus 30/35 Service Manual...

- Page 124 A A1 C D FI: 25 Code: 0x9c54 ACB (right). Message: Angle Drive system Turn event measurement failed error warning 6 B D D1 0x9868 brown out reset dedected Focus 30/35 Service Manual 4 - 38 P/N 79000035_SM, Version 1.5...

- Page 125 Message: Angle Drive system Turn event measurement failed error warning 6 B D1 Error: 0x9868 (39016) brown out reset dedected Fsmxfile Hz: reading error 6 A C D = error P/N 79000035_SM, Version 1.5 4 - 39 Focus 30/35 Service Manual...

- Page 126 5046|PositionHV faile turns D1 oder Turn command failed 6A A1 B D D1 C FI: 1 Code: 0x9c4e Message: Tilt sensor: Not communicating, FI 35 0x9c4f Tilt retry ini. Focus 30/35 Service Manual 4 - 40 P/N 79000035_SM, Version 1.5...

- Page 127 Check Coarse drive motor V error warning 6 B D1 C C1 Message: 3|0|99|100|- Exchange the Coarse drive V 126229100|PositionHV faile FI: 0 Code: 0x9c5d Message: SNPInCompletionCallback Status: 262 P/N 79000035_SM, Version 1.5 4 - 41 Focus 30/35 Service Manual...

- Page 128 Check Filter motor with IF_DISTV3 displayed PASS Exchange EDM Transmitter PR meas. Failed C1 C No error in *.irep Check Filter motor with IF_DISTV3 displayed PASS Exchange EDM Transmitter Focus 30/35 Service Manual 4 - 42 P/N 79000035_SM, Version 1.5...

- Page 129 FI: 60 Code: 0x9c52 Check TSF-TLD cable locked" C,C1 Message: Req xca got res 10 Check Tracker Camera/ Tracker sensor"Target not Transmitter adjustment locked"A,A1 Exchange Camera Exchange Tracker transmitter P/N 79000035_SM, Version 1.5 4 - 43 Focus 30/35 Service Manual...

- Page 130 Chapter 4 Troubleshooting Focus 30/35 Service Manual 4 - 44 P/N 79000035_SM, Version 1.5...

- Page 131 Coarse tilt sensor on Slip contacts Hz Vertical angle unit Horizontal turning unit Vertical servo drive unit Horizontal servo drive unit What to do after replacement? P/N 79000035_SM, Version 1.5 5 - 1 Focus 30/35 Service Manual...

- Page 132 O-rings and lift off instruction see page the cover, see See Fig. 5-1 1-8. on page 1-2 Fig. 5-1 Telescope covers Screw O-ring Rubber sealing Distance unit cover Servo focus unit cover Focus 30/35 Service Manual 5 - 2 P/N 79000035_SM, Version 1.5...

- Page 133 Rubber plugs are positioned correctly(only in Distance unit cover), See Fig. 5-2 on page 1-3. Fig. 5-2 Rubber plug position P/N 79000035_SM, Version 1.5 5 - 3 Focus 30/35 Service Manual...

- Page 134 35 Ncm/3,1lbfin B. Use two torque drivers and tighten the screws in pairs simultaneously. Fig. 5-3 Telescope cover-tighten screws 35Ncm 3,1lbfin Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 4 P/N 79000035_SM, Version 1.5...

- Page 135 Servo focus replacement Performance Item Performance Action Result Notes Remove Telescope see page 5-2 tracker cover. Remove Track light. see page 5-25 Disconnect the see Fig. 5-4 on page cables. P/N 79000035_SM, Version 1.5 5 - 5 Focus 30/35 Service Manual...

- Page 136 60Ncm/5,31bfin the 3 bearing surfaces of the telescope body and tighten the three screws. Connect all cables to Tracker servo focus board TSF, Fig. 5-4 on page Focus 30/35 Service Manual 5 - 6 P/N 79000035_SM, Version 1.5...

- Page 137 B. Lift off the board TSF. Fix the board centred and exchange it. to the screw holes. C. Tighten the screws. 35 Ncm/3,1lbfin Don’t forget the two tooth washers. P/N 79000035_SM, Version 1.5 5 - 7 Focus 30/35 Service Manual...

- Page 138 Maintenance and Repair Item Performance Action Result Notes Fig. 5-6 Board TSF - Tracker servo focus - replacement A /C 35Ncm 3,1lbfin Adjustment and What to do after calibration. replacement? Focus 30/35 Service Manual 5 - 8 P/N 79000035_SM, Version 1.5...

- Page 139 Eyepiece. B. Clip off the Cover. 60Ncm/5,31bfin C. Unscrew three screws. D. Remove the Lubricate the O-ring mounted with Isoflex3000. Reticle. Exchange parts and remount it in reverse order. P/N 79000035_SM, Version 1.5 5 - 9 Focus 30/35 Service Manual...

- Page 140 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-7 Reticle replacement 60Ncm 5,31bfin Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 10 P/N 79000035_SM, Version 1.5...

- Page 141 Click out the Fibre Not necessary if bender clip in previous version of direction of the red fibre bender arrows and take off without clip is used. the complete Reference fibre. P/N 79000035_SM, Version 1.5 5 - 11 Focus 30/35 Service Manual...

- Page 142 Fibre bender clip. D. Curve the fibres Take care of the arround the minimum fibre Adjusting screw bender radius according the avoiding any laying. demage of the glas fibre. Focus 30/35 Service Manual 5 - 12 P/N 79000035_SM, Version 1.5...

- Page 143 Fig. 5-9 Remount Reference fibre Adjustment and What to do after calibration replacement? Exchange Receiver fibre Performance Item Performance Action Result Notes Remove Distance see page 5-2 unit cover. P/N 79000035_SM, Version 1.5 5 - 13 Focus 30/35 Service Manual...

- Page 144 Figure 5-13 see Fig. demage of the glas 5-14 on page 5-18 fibre with the tool (e.g. tweezer) Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 14 P/N 79000035_SM, Version 1.5...

- Page 145 5Ncm/0,44lbfin Reference fibre bender clip. ferule. C. Disconnect TSF- TLD cable. D. Unplug the cable of filter motor. Disconnect TSF- REC cable. P/N 79000035_SM, Version 1.5 5 - 15 Focus 30/35 Service Manual...

- Page 146 D. Exchange delivered with position of cables and Receiver board mounted Receiver fibres see Figure 5- and mount it in fibre. reverse order. see Fig. 5-14 on page 5-18 Focus 30/35 Service Manual 5 - 16 P/N 79000035_SM, Version 1.5...

- Page 147 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-12 Remove Receiver board Fig. 5-13 Laying of the fibres Reference fibre with fibre holder Coaxcable Receiver fibre P/N 79000035_SM, Version 1.5 5 - 17 Focus 30/35 Service Manual...

- Page 148 Adjustment and What to do after calibration. replacement? Disassembly/Assembly Transmitter unit Performance Item Performance Action Result Notes Remove Distance see page 5-2 unit cover. Focus 30/35 Service Manual 5 - 18 P/N 79000035_SM, Version 1.5...

- Page 149 Torx T8 B. Remove screw 60Ncm/5,31lbfin M2,5x14. Transmitter unit is C. Lift off the Transmitter unit delivered with Be careful, don’t with Reference mounted reference scratch the optics. fibre. fibre. P/N 79000035_SM, Version 1.5 5 - 19 Focus 30/35 Service Manual...

- Page 150 What to do after calibration replacement? Exchange Holder receiver fibre Performance Item Performance Action Result Notes Remove Distance see page 5-2 unit cover. Remove see page 5-15 Transceiver board. Focus 30/35 Service Manual 5 - 20 P/N 79000035_SM, Version 1.5...

- Page 151 After exchange the EDM F35 High Precision 1mm, you have to determine the offset and to verify the accuracy with special calibrated baselines, see“Focus 35 EDM 1mm - Verify the 1mm accuracy” on page 6-85. P/N 79000035_SM, Version 1.5 5 - 21 Focus 30/35 Service Manual...

- Page 152 Assemble the RX board with receiver fibre. Follow the instruction, see“Disassembly/ Assembly Receiver board” on page 5-15. Adjustment and What to do after calibration replacement? Fig. 5-18 EDM High Precision 1mm Focus 30/35 Service Manual 5 - 22 P/N 79000035_SM, Version 1.5...

- Page 153 B. Lift off the tracker camera module. C. Insert new tracker camera unit and The module is shift it to the end preadjusted. stops. D. Tighten two screws. Torque wrench 60Ncm/5,31lbfin Torx T8 P/N 79000035_SM, Version 1.5 5 - 23 Focus 30/35 Service Manual...

- Page 154 Connect cables. see page 5-6 Align the camera. see page 6-91 Mount the Servo see page 5-2 focus cover. Adjustment and What to do after calibration. replacement? Focus 30/35 Service Manual 5 - 24 P/N 79000035_SM, Version 1.5...

- Page 155 Unscrew two Torque wrench screws, to remove Torx T8 the Tracklight with holder. 60Ncm/5,31 lbfin Align Tracklight. see page 6-103 Mount Servo focus see page 5-3 unit cover. P/N 79000035_SM, Version 1.5 5 - 25 Focus 30/35 Service Manual...

- Page 156 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-20 Replace Tracklight 60Ncm 5,31lbfin Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 26 P/N 79000035_SM, Version 1.5...

- Page 157 Be careful with the in reverse order. red cable, avoid to 4x O-ring Tighten the four sqeeze it by the fine screws. drive. 35 Ncm/3,1 lbfin; P/N 79000035_SM, Version 1.5 5 - 27 Focus 30/35 Service Manual...

- Page 158 SCK-MCB Adjustment and What to do after calibration replacement? Servo knob board-SKB and Trigger key replacement Performance Item Performance Action Result Notes Remove Side cover see page 5-27 right. Focus 30/35 Service Manual 5 - 28 P/N 79000035_SM, Version 1.5...

- Page 159 Torque wrench T8 screws. 35 Ncm/3,1 lbfin Fig. 5-23 Board SCK and Trigger/Release key A/D (10x) 35Ncm/ 3.1 lbfin Cable SCK- BT (Bluetooth) Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 29 Focus 30/35 Service Manual...

- Page 160 Torque wrench T6 reverse order and tighten the four 35 Ncm/3,1 lbfin screws. Fig. 5-24 Blue tooth replacement 35Ncm/ 3.1 lbfin Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 30 P/N 79000035_SM, Version 1.5...

- Page 161 D. Replace the Gasket the four black O- if necessary. rings into the Replace the cover. instrument. Mount the parts in Fig. 5-25 O-ring reverse order and tighten the four O-ring screws. P/N 79000035_SM, Version 1.5 5 - 31 Focus 30/35 Service Manual...

- Page 162 Fig. 5-26 Side cover left (Battery+Radio) replacement 35Ncm/ 3.1 lbfin Adjustment and What to do after calibration replacement? Replacement Antenna connection cable Performance Item Performance Action Result Notes Remove Side cover see page 5-31 left. Focus 30/35 Service Manual 5 - 32 P/N 79000035_SM, Version 1.5...

- Page 163 D. Lock the screw with lacquer. Adjustment and What to do after calibration replacement? Replacement radio modul Performance Item Performance Action Result Notes Remove Side cover see page 5-31 left. P/N 79000035_SM, Version 1.5 5 - 33 Focus 30/35 Service Manual...

- Page 164 Action Result Notes Remove Side cover see page 5-31 left. Remove radio Remove radio module if module. the battery side cover is equiped with radio module, see page 5-33. Focus 30/35 Service Manual 5 - 34 P/N 79000035_SM, Version 1.5...

- Page 165 D. Remove the BCRB board. Replace Gasket battery contacts if necessary. Assembly the parts in reverse order. Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 35 Focus 30/35 Service Manual...

- Page 166 C. Take down the Handle cover rubber. D. Unscrew the two screws. Remove the Handle cover. Torque wrench Replace handle Torx T10 parts and mount them in reverse 100 Ncm/8,85 lbfin order. Focus 30/35 Service Manual 5 - 36 P/N 79000035_SM, Version 1.5...

- Page 167 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-30 Handle replacement 100Ncm 60Ncm 8,85 lbfin 5.1 lbfin Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 37 Focus 30/35 Service Manual...

- Page 168 Main control board-MCB • Overview connectors and laying of cables - MCB • MCB replacement Tools and equipment Description Part number Torx T8 bit Local tool Torque wrench 120 Ncm T71600280 Focus 30/35 Service Manual 5 - 38 P/N 79000035_SM, Version 1.5...

- Page 169 Coarse motor V Angle control Coarse motor Hz board V-ACB Battery connector Fine motor Hz radio board Tilt sensor Display board-F2D Angle control board Hz-ACB Hz slip contact board-SCB Solenoid Hz P/N 79000035_SM, Version 1.5 5 - 39 Focus 30/35 Service Manual...

- Page 170 Blue tooth Servo knob board Cable holder Fine V Coarse V Batterry/ radio Coarse Hz connector Fine Hz Hz slip contact board Display Solenoid Hz Angle control board Hz Focus 30/35 Service Manual 5 - 40 P/N 79000035_SM, Version 1.5...

- Page 171 Blue tooth Servo knob board Cable holder Fine V Coarse V Batterry/ radio Coarse Hz connector Fine Hz Hz slip contact board Display Solenoid Hz Angle control board Hz P/N 79000035_SM, Version 1.5 5 - 41 Focus 30/35 Service Manual...

- Page 172 5-27 right. Remove the see page 5-80 Vertical coarse drive system or the see page 5-104 divided lever arm only. Disconnect all see page 5-39 cables to MCB board. Focus 30/35 Service Manual 5 - 42 P/N 79000035_SM, Version 1.5...

- Page 173 A6. Toothed lock to their tracks. washer under A6. Pass and connect all cables see page 5-39. Set the jumper to the right position, see Figure 5-31. The internal timer starts. P/N 79000035_SM, Version 1.5 5 - 43 Focus 30/35 Service Manual...

- Page 174 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-35 Replace MCB A1-6 Adjustment and What to do after calibration. replacement? Focus 30/35 Service Manual 5 - 44 P/N 79000035_SM, Version 1.5...

- Page 175 Find opening in to see the hole on the alhidade under Tension gear Hz battery side cover. through the opening of the alhidade, see Fig. 5- 36 on page 5-46 P/N 79000035_SM, Version 1.5 5 - 45 Focus 30/35 Service Manual...

- Page 176 B. Unscrew the handle dismantle further. of the clamp tool. Fig. 5-37 Clamp the cogwheel Focus 30/35 Service Manual 5 - 46 P/N 79000035_SM, Version 1.5...

- Page 177 Performance Action Result Notes Remove Slip ring A. Remove three Torque wrench screws. board SRB. Torx T8 B. Disconnect cable 60Ncm/5,31lbfin SRB-FCB. C. Take off the Slip ring board. P/N 79000035_SM, Version 1.5 5 - 47 Focus 30/35 Service Manual...

- Page 178 Tension gear. D. Unscrew the handle of the Clamping tool. Torque wrench Remount the Slip Torx T8 ring board with 3 screws, see page 5- 60Ncm/5,31lbfin Focus 30/35 Service Manual 5 - 48 P/N 79000035_SM, Version 1.5...

- Page 179 Tension gear. B. Thread the Cable ACB Hz-MCB in the opening of alhidade. C. Fix the Base part with four screws. D. Remove the 200Ncm/16,7lbfin Clamping tool through the opening. P/N 79000035_SM, Version 1.5 5 - 49 Focus 30/35 Service Manual...

- Page 180 Plug in the ACB Hz see page 3-59 cable. Mount the battery see page 5-31 side cover. Mount the servo see page 5-27 side cover. Adjustment and What to do after calibration. replacement? Focus 30/35 Service Manual 5 - 50 P/N 79000035_SM, Version 1.5...

-

Page 181: Usb Connector

Torx T6 B. Remove USB 20Ncm/1,77bfin connector until you reach the cable. C. Unplug the cable FCB2- SRBH. D. Exchange the USB connector and mount it in reverse order. P/N 79000035_SM, Version 1.5 5 - 51 Focus 30/35 Service Manual... - Page 182 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-42 Replace USB connector Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 52 P/N 79000035_SM, Version 1.5...

- Page 183 MCB & SCK/ MCB. BT to ACB. D. Mount the parts in reverse order and tighten the two screws see Fig. 5- 43 on page 5-54 P/N 79000035_SM, Version 1.5 5 - 53 Focus 30/35 Service Manual...

- Page 184 What to do after calibration replacement? Disassembly / Assembly Control Unit F30 Performance Item Performance Action Result Notes Remove Control Remove Control Use torque wrench Unit F30 Unitsee page TORX T8. 5-53. Focus 30/35 Service Manual 5 - 54 P/N 79000035_SM, Version 1.5...

- Page 185 ACB board. TORX T6. Disconnect the 4 cables from ACB to MCB & SCK/BT. Be very careful with the small and fragile connectors. Don’t pullout the connector on the cable. P/N 79000035_SM, Version 1.5 5 - 55 Focus 30/35 Service Manual...

- Page 186 Pressure Frame. B. Remove the Display Touchscreen. C. Remove Gasket Display. D. Unscrew 4x EJOT screws and remove the F1K Board. Use torque wrench Remove Key pad TORX T6. Focus 30/35 Service Manual 5 - 56 P/N 79000035_SM, Version 1.5...

- Page 187 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-45 Disassemble F1K board and Display Touchscreen F1K board Pressure Frame (4xEJOT) 6xM2 D (4xEJOT) P/N 79000035_SM, Version 1.5 5 - 57 Focus 30/35 Service Manual...

- Page 188 Tighten the M2 important notes) screws crosswise with pressing down the 40Ncm/3,54lbfn. Pressure Frame at first and than the 6x M2 screws. Check that the Pressure Frame is complete fixed. Focus 30/35 Service Manual 5 - 58 P/N 79000035_SM, Version 1.5...

- Page 189 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-46 Assembly F1K Board and Display Touchcsreen F1K Board Pressure Frame E (4xEJOT) (4xEJOT) 6xM2 P/N 79000035_SM, Version 1.5 5 - 59 Focus 30/35 Service Manual...

- Page 190 4 cable to the opening window and mount the Rear Panel with the 6 x M2 screws. 50Ncm/4,4lbfn Exchange the Gasket CU F30 if necessary. Use a torque wrench TORX T8 Focus 30/35 Service Manual 5 - 60 P/N 79000035_SM, Version 1.5...

- Page 191 Use a torque Unit F30. F30 to alhidade wrench TORX T8 see page and execute the 5-53 display and keyboard test. Adjustment and What to do after calibration. replacement? P/N 79000035_SM, Version 1.5 5 - 61 Focus 30/35 Service Manual...

- Page 192 Attend the cable MCB. from MCB. D. Mount the parts in reverse order and tighten the two screws see Fig. 5- 43 on page 5-54 Focus 30/35 Service Manual 5 - 62 P/N 79000035_SM, Version 1.5...

- Page 193 D. The pins guide the door in the holes of the compartment. Mount the parts in reverse order. Lock the door again with the two clips. P/N 79000035_SM, Version 1.5 5 - 63 Focus 30/35 Service Manual...

- Page 194 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-49 Exchange 2nd Battery compartment door Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 64 P/N 79000035_SM, Version 1.5...

- Page 195 B. Unhook and remove the Control unit F2. C. Unplug the Cable F2D. D. Replace Gasket CU Mount the parts in reverse order. Fig. 5-50 Exchange Control unit F2 P/N 79000035_SM, Version 1.5 5 - 65 Focus 30/35 Service Manual...

- Page 196 C. Remove Keypad D. Remove Gasket CU Fig. 5-51 Disassemble/ Assemble Control unit F2 A(6x) Assemble Control A. Exchange faulty parts unit F2. B. Remount it in reverse order. Focus 30/35 Service Manual 5 - 66 P/N 79000035_SM, Version 1.5...

- Page 197 Attach the Control Attach the Control unit unit F2. F2 to alhidade ,see page and perform 5-65 display and keyboard test. Adjustment and What to do after calibration. replacement? P/N 79000035_SM, Version 1.5 5 - 67 Focus 30/35 Service Manual...

- Page 198 Torx T10x80 through the hole of Don’t drop the MCB board screw inside the C. Pull out the Optical alhidade. plummet. Fig. 5-52 Exchange Optical plummet 60Ncm 5,31lbfn Focus 30/35 Service Manual 5 - 68 P/N 79000035_SM, Version 1.5...

- Page 199 Fig. 5-53 Grease Optical plummet Align optical See page 6-148 plummet. Mount servo side see page 5-27 cover. Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 69 Focus 30/35 Service Manual...

- Page 200 5-109 drive has to be taken installed version. out. Disassembly/ assembly adjustable Coarse drive lever arm see page 5- Only the divided lever arm has to be taken out Focus 30/35 Service Manual 5 - 70 P/N 79000035_SM, Version 1.5...

- Page 201 60Ncm/5,31lbfn D. Exchange the Tilt sensor and mount the parts in reverse order. Fig. 5-54 Remove Tilt sensor B (underneath) Adjustment and What to do after calibration. replacement? P/N 79000035_SM, Version 1.5 5 - 71 Focus 30/35 Service Manual...

- Page 202 SCH Hz- MCB. paper containing D. Exchange Slip the Coarse tilt contacts with Coarse tilt sensor temperature and remount it in calibration values. reverse order. Focus 30/35 Service Manual 5 - 72 P/N 79000035_SM, Version 1.5...

- Page 203 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-55 Remove Coarse tilt sensor Coarse tilt sensor Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 73 Focus 30/35 Service Manual...

- Page 204 D. Remove the two lose. the loosen Angle black O-rings. control board. The two O-rings centre the Illumination V- ACB to the Angle control board ACB. Focus 30/35 Service Manual 5 - 74 P/N 79000035_SM, Version 1.5...

- Page 205 Steal ball. The ball D. Exchange the Angle control functionality is to board ACB-V. give the electrical ground from body to the telescope of the instrument. P/N 79000035_SM, Version 1.5 5 - 75 Focus 30/35 Service Manual...

- Page 206 Fig. 5-57 Exchange Angle control board-ACB-V Assembly Vertical Remount the parts in 35 Ncm/3.1lbfn angle unit. reverse order see page 5- see page 5-76 Adjustment and What to do after calibration. replacement? Focus 30/35 Service Manual 5 - 76 P/N 79000035_SM, Version 1.5...

- Page 207 5-45 Remove Slip ring A. Remove three screws. board SRB. B. Disconnect cable SRB-FCB. C. Take off the Slip ring board. Fig. 5-58 Remove Slip ring board P/N 79000035_SM, Version 1.5 5 - 77 Focus 30/35 Service Manual...

- Page 208 D. Take off the Tension gear. Fig. 5-59 Remove Tension gear Clean Encoder disc A. Unclip the Angle board cover. B. Clean the Encoder disc Hz with isopropanol. Focus 30/35 Service Manual 5 - 78 P/N 79000035_SM, Version 1.5...

- Page 209 Fig. 5-60 Clean Encoder disc Hz Assembly Mount the parts in reverse order, (500Ncm/ and tight verry strong 44,42Lbfin) as the Retainer ring. estimated value. Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 79 Focus 30/35 Service Manual...

- Page 210 Tension gear tool V in the hole to is fixed, in case fix the tension of the the Coarse drive Tension gear. V has to be exchanged only. Focus 30/35 Service Manual 5 - 80 P/N 79000035_SM, Version 1.5...

- Page 211 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-61 Clamping the Tension gear Tension gear Clamping tool V P/N 79000035_SM, Version 1.5 5 - 81 Focus 30/35 Service Manual...

- Page 212 H. Unplug the motor cable and pull it out see Fig. 5-63 on page 5-84 Exchange Fine drive V and mount it back in reverse order. Focus 30/35 Service Manual 5 - 82 P/N 79000035_SM, Version 1.5...

- Page 213 A. Pull out the two motor cables from the cable holders. B. Unplug cable of the fine drive motor. C. Unplug cable of the coarse drive motor. D. Unplug cable of the solenoid. P/N 79000035_SM, Version 1.5 5 - 83 Focus 30/35 Service Manual...

- Page 214 Dismantle Coarse drive V. Don’t remove the Attend the ball ball bearing out of bearing in the the alhidade. alhidade, it takes the axis of the Coarse drive V. Focus 30/35 Service Manual 5 - 84 P/N 79000035_SM, Version 1.5...

- Page 215 Remove Slip ring A. Loosen the three 60Ncm/5.31Lbfin screws. board SRB. B. Disconnect cable TSF-SRB. C. Remove Slip ring board SRB. D. Exchange it and mount in reverse order. P/N 79000035_SM, Version 1.5 5 - 85 Focus 30/35 Service Manual...

- Page 216 Tension gear is D. Take out carefully married to the axis. the Tension gear V together with the Clamping tool V. Press the tension gear and remove the clamp tool. Focus 30/35 Service Manual 5 - 86 P/N 79000035_SM, Version 1.5...

- Page 217 C. Plug in the Check the tension Clamping tool in and the offset of the the hole and fix one tooth again. the tension of the cogwheels. P/N 79000035_SM, Version 1.5 5 - 87 Focus 30/35 Service Manual...

- Page 218 Mount Main control Position MCB to the board, Slip ring board to see page 5-42. centre the slider contacts to the middle of their tracks see Fig. 5-68 on page 5-89 Focus 30/35 Service Manual 5 - 88 P/N 79000035_SM, Version 1.5...

- Page 219 100Ncm/8,85 lbfin D. Check the position of Fine drive to Coarse drive arm and 100Ncm/8,85 lbfin tighten the two screws. Plug out the Clamping tool Fig. 5-69 on page 5-90 P/N 79000035_SM, Version 1.5 5 - 89 Focus 30/35 Service Manual...

- Page 220 Adjustment and What to do after calibration. replacement? Disassembly Vertical servo drive unit - adjustable version Performance Item Performance Action Result Notes Remove servo side see page 5-27 cover. Focus 30/35 Service Manual 5 - 90 P/N 79000035_SM, Version 1.5...

- Page 221 V in the hole to in case only the fix the tension of Coarse drive V has to the Tension gear. be exchanged. Fig. 5-70 Clamping Tension gear Tension gearl Clamping tool P/N 79000035_SM, Version 1.5 5 - 91 Focus 30/35 Service Manual...

- Page 222 H. Unplug the motor cable and pull it out see Fig. 5-63 on page 5-84 Exchange Fine drive V and mount it back in reverse order. Focus 30/35 Service Manual 5 - 92 P/N 79000035_SM, Version 1.5...

- Page 223 A. Pull out the two motor cables from the cable holders. B. Unplug cable of the fine drive motor. C. Unplug cable of the coarse drive motor. D. Unplug cable of the solenoid. P/N 79000035_SM, Version 1.5 5 - 93 Focus 30/35 Service Manual...

- Page 224 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-72 Unplug cables Focus 30/35 Service Manual 5 - 94 P/N 79000035_SM, Version 1.5...

- Page 225 P/N 79000035_SM, Version 1.5 5 - 95 Focus 30/35 Service Manual...

- Page 226 Torx T20 bit, flat D. Remove the three screw driver. screws with 100Ncm/8.85lbfin Be careful, avoid a washer. jumping out of the Take out the Coarse extension spring. drive V. Focus 30/35 Service Manual 5 - 96 P/N 79000035_SM, Version 1.5...

- Page 227 Remove Slip ring A. Loosen the three 60Ncm/5.31Lbfin screws. board SRB. B. Disconnect cable TSF-SRB. C. Remove Slip ring board SRB . D. Exchange it and mount in reverse order. P/N 79000035_SM, Version 1.5 5 - 97 Focus 30/35 Service Manual...

- Page 228 Tension gear is Clamping ring. married to the axis. D. Take out carefully the Tension gear together with the clamp tool. Press the tension gear and remove the clamp tool. Focus 30/35 Service Manual 5 - 98 P/N 79000035_SM, Version 1.5...

- Page 229 Only some old instruments can have weake grease between the two cogwheels and the distortion of the cogwheels is 3 teeth. In this case follow item 2 but with distortion of three teeth. Otherwise you can exchange the Tension gear Hz/V (79226035). P/N 79000035_SM, Version 1.5 5 - 99 Focus 30/35 Service Manual...

- Page 230 C. Plug in the Clamping tool in the hole and fix the tension of the Tension gear. Fig. 5-77 Clamp the Tension gear Plier Clamping tool Focus 30/35 Service Manual 5 - 100 P/N 79000035_SM, Version 1.5...

- Page 231 V. spring in the holder and fix it with the holding screw till you find a first resistance. B. Lay down the instrument on the Side cover left. P/N 79000035_SM, Version 1.5 5 - 101 Focus 30/35 Service Manual...

- Page 232 Lock the screw alhidade. clockwise. visible 1mm out of G. Plug out the the holder with Clamping tool.See lacquer. Fig. 5-77 on page 1-100 Focus 30/35 Service Manual 5 - 102 P/N 79000035_SM, Version 1.5...

- Page 233 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-79 Assembly Coarse drive V and Fine drive V Compression spring Adjustment and What to do after calibration replacement? P/N 79000035_SM, Version 1.5 5 - 103 Focus 30/35 Service Manual...

- Page 234 MCB board without a complete disassembling of the Vertical drive. Fig. 5-80 Disassembly / assembly Coarse drive lever arm Lever arm Fine drive pin Focus 30/35 Service Manual 5 - 104 P/N 79000035_SM, Version 1.5...

- Page 235 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Assembly Coarse Mount the parts in Check the laying of drive lever arm. reverse order. cables according page 5-39. P/N 79000035_SM, Version 1.5 5 - 105 Focus 30/35 Service Manual...

- Page 236 5-31 left. Remove Base part. see page 5-45 Remove Optical see page 5-68 plummet. Remove Control see page 5-65 unit F2. Remove Slip see page 5-72 contacts Hz-SCH. Focus 30/35 Service Manual 5 - 106 P/N 79000035_SM, Version 1.5...

- Page 237 Disassembly / assembly Fine drive • Disassembly / assembly Coarse drive lever arm • Disassembly / assembly adjustable Coarse drive lever arm • Disassembly Coarse drive • Assembly Coarse drive P/N 79000035_SM, Version 1.5 5 - 107 Focus 30/35 Service Manual...

- Page 238 5-109 Disassembly/ Unhook the spindle assembly adjustable from the Coarse drive lever arm. Coarse drive lever C. Pull out the Fine see page 5-111 drive Hz. Focus 30/35 Service Manual 5 - 108 P/N 79000035_SM, Version 1.5...

- Page 239 Fine drive stops (red exchange the arrow), see page 6-133 compensator. Prepare the Prepare the instrument Put the Instrument instrument. according item (1-8) in the Holder Instrument F30 page 5-108 79297035 P/N 79000035_SM, Version 1.5 5 - 109 Focus 30/35 Service Manual...

- Page 240 At this point it is pin of the spindle and take out the possible to lever arm. exchange the Tilt sensor without a complete disassembling of the Horizontal drive. Focus 30/35 Service Manual 5 - 110 P/N 79000035_SM, Version 1.5...

- Page 241 Drive the Fine drive Hz It is easier in case exchanging the to the position of the you will only compensator. Fine drive stops (red exchange the arrow), see page 6-133 compensator. P/N 79000035_SM, Version 1.5 5 - 111 Focus 30/35 Service Manual...

- Page 242 At this point it is Fine drive pin of possible to the spindle and take exchange the Tilt out the lever arm. sensor without a complete disassembling of the Horizontal drive. Focus 30/35 Service Manual 5 - 112 P/N 79000035_SM, Version 1.5...

- Page 243 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-84 Disassembly adjustable Coarse drive lever arm Lever arm Spring Fine drive pin P/N 79000035_SM, Version 1.5 5 - 113 Focus 30/35 Service Manual...

- Page 244 D. Hook the extension spring in to the hole of the lever arm. Fig. 5-85 Assembly the divided adjustable lever Hz Lever arm Fine drive pin Extension spring Focus 30/35 Service Manual 5 - 114 P/N 79000035_SM, Version 1.5...

- Page 245 Screw driver flat C. Unscrew the bolt screw with spring. D. Unscrew the bolt Screw driver flat screw. Unscrew 4x fixing screws. Take out the Coarse drive Hz. P/N 79000035_SM, Version 1.5 5 - 115 Focus 30/35 Service Manual...

- Page 246 Chapter 5 Maintenance and Repair Item Performance Action Result Notes Fig. 5-86 Disassembly Coarse drive Hz Spring Focus 30/35 Service Manual 5 - 116 P/N 79000035_SM, Version 1.5...

- Page 247 Torque wrench T8 C. Fix the Coarse 60 Ncm/5,31bfn drive Hz with four screws. Fig. 5-87 Mount the Coarse drive Hz Adjusting screw P/N 79000035_SM, Version 1.5 5 - 117 Focus 30/35 Service Manual...

- Page 248 Course drive is far the screw head of disappears, see red from the Tension the bolt screw arrow. contacts the holder. gear position. Fig. 5-88 Preparation for adjustment Holder Adjusting screw B Focus 30/35 Service Manual 5 - 118 P/N 79000035_SM, Version 1.5...

- Page 249 Hz board. Slip contacts Hz board the adjustment of the Hz Coarse drive lever has to be done, see page 6-125 Remount the Base see page 5-47 part F30. P/N 79000035_SM, Version 1.5 5 - 119 Focus 30/35 Service Manual...

- Page 250 Remount MCB see page 5-42 board. Remount Vertical see page 5-90 servo drive unit. Remount Side see page 5-31 cover left. Adjustment and What to do after calibration replacement? Focus 30/35 Service Manual 5 - 120 P/N 79000035_SM, Version 1.5...

- Page 251 Receiver fibre adjustment Check motors Reference fibre adjustment Tracker test Tracker transmitter adjustment Service check list EDM offset determination Focus 35 EDM 1mm - Verify the 1mm accuracy P/N 79000035_SM, Version 1.5 5 - 121 Focus 30/35 Service Manual...

- Page 252 Calibration Coarse tilt sensor Adjustment of Optical Plummet Horizontal Coarse drive lever arm adjustment Vertical Drive adjustment (for adjustable drive only) Horizontal Drive adjustment (for adjustable drive only) Service check list Focus 30/35 Service Manual 5 - 122 P/N 79000035_SM, Version 1.5...

- Page 253 Servo drive test Hz/V Adjustment of Optical Plummet Service check list Horizontal divided Horizontal Coarse drive lever Service check list coarse drive lever arm adjustment P/N 79000035_SM, Version 1.5 5 - 123 Focus 30/35 Service Manual...

- Page 254 Maintenance and Repair Item Board / module re- Adjustment Check / Test placed Base part F30 Horizontal Drive adjustment (for Service check list adjustable drive only) Servo drive test Hz/V Focus 30/35 Service Manual 5 - 124 P/N 79000035_SM, Version 1.5...

- Page 255 Servo drive units Tilt sensor Angle measurement system Optical plummet Display and keyboard tests Final test and report Focus 30 Check list after service/repair P/N 79000035_SM, Version 1.5 6 - 1 Focus 30/35 Service Manual...

- Page 256 C. Connect the SFU Tracker and Distance with the adapter and between MCB unit will be missing cable combination to and TSF board. the instrument. when instrument starts up. Focus 30/35 Service Manual 6 - 2 P/N 79000035_SM, Version 1.5...

- Page 257 Service Preparation of A. Select The focusing lens is Servo Focus check maintenance. running to defined Unit Adjust box. start position. B. Click or use Adjust short-cut key P/N 79000035_SM, Version 1.5 6 - 3 Focus 30/35 Service Manual...

- Page 258 Use a torque wrench spindle cover. The Toque value = with TORX T6 bit. spindle is visible for 35 Ncm/3.1 maintenance. lbfin Fig. 6-3 SFU maintenance setup Removable lens protective cover Focus 30/35 Service Manual 6 - 4 P/N 79000035_SM, Version 1.5...

- Page 259 Fig. 6-4 Lubricate the spindle End stops Spindle Terminate A. Exit the program. maintenance B. Remount the spindle cover and TSF board. C. Unplug the cables and the lens protect cover. P/N 79000035_SM, Version 1.5 6 - 5 Focus 30/35 Service Manual...

- Page 260 The test is checking Check Light Barriers Positions. shown on SFU the light barriers Barriers Positions check box. Status as positions. B. Click Light Barrier Successful! to start the test. Test Focus 30/35 Service Manual 6 - 6 P/N 79000035_SM, Version 1.5...

- Page 261 The test will be stored in the shown on SFU Status SFU module. G. If all tests be done, ... Successful! The collimator click Exit should sharp visible. P/N 79000035_SM, Version 1.5 6 - 7 Focus 30/35 Service Manual...

- Page 262 7-3. how to set-up the instrument. Precondition HA/VA of reticle is in tolerance, see page 6-12. Preparation Mount a 1,5m Target in Thin cross target in direction of collimator 1,5m +/-0,05m aiming. Focus 30/35 Service Manual 6 - 8 P/N 79000035_SM, Version 1.5...

- Page 263 Camera Illuminate the reticle D. Store the correction settings with the Illumination values CPK and IPK. green(546nm) tool (yellow LED). light. Fig. 6-6 HA/VA Collimation Short Range Test P/N 79000035_SM, Version 1.5 6 - 9 Focus 30/35 Service Manual...

- Page 264 D. Check the result in message box. As shown in Program Tolerance: status/ messages. <20cc Difference (CHz Diff, CV Diff) between infinity and short range HA/VA Collimation. Focus 30/35 Service Manual 6 - 10 P/N 79000035_SM, Version 1.5...

- Page 265 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-7 Verify HA/VA collimation P/N 79000035_SM, Version 1.5 6 - 11 Focus 30/35 Service Manual...

- Page 266 Reticle illumination tool (yellow LED) 79706001 Front lens mirror 79292035 Check Reticle collimation (HA/VA collimation) Performance Item Performance Description Result Notes Run the tilt offset See “Calibration Fine tilt sensor” on page 6-139. Focus 30/35 Service Manual 6 - 12 P/N 79000035_SM, Version 1.5...

- Page 267 Level the Use the <10cc in both instrument software to view directions. Level instrument and the collimator click Level OK and instrument reticle, set Camera settings to green light (546nm). P/N 79000035_SM, Version 1.5 6 - 13 Focus 30/35 Service Manual...

- Page 268 =10cc the lower line end for deviation, see Fig. 6- 15 on page 6-22 B. If out of tolerance go See “Erecting the Reticle F30” on page 6-19. Focus 30/35 Service Manual 6 - 14 P/N 79000035_SM, Version 1.5...

- Page 269 0,0083gon values in tolerance. correction values are See “Servo Focus Unit CV: 30” / in tolerance. HA/VA collimation short 0,0083gon range test” on page 6-8. P/N 79000035_SM, Version 1.5 6 - 15 Focus 30/35 Service Manual...

- Page 270 Quit the message box with No value will be and go to see stored in to the MCB “Adjustment of Reticle board. F30 in Hz direction keeping the vertical orientation” on page 6-23. Focus 30/35 Service Manual 6 - 16 P/N 79000035_SM, Version 1.5...

- Page 271 “Adjustment of Reticle angle system was be stored in to F30 in Hz direction with disassembled or the MCB board storing a new VA partly replaced. memory. correction” on page 6-28. P/N 79000035_SM, Version 1.5 6 - 17 Focus 30/35 Service Manual...

- Page 272 Fig. 6-12 on page 6-19 and go to see “Adjustment of Reticle F30 in Hz and V direction with Front lens mirror tool” on page 6- Focus 30/35 Service Manual 6 - 18 P/N 79000035_SM, Version 1.5...

- Page 273 7-3. how to set-up the instrument. Run the tilt offset. See “Calibration Fine tilt sensor” on page 6-139. Start Reticle Select Reticle adjustment adjustment. from Reticle Maintenance & Service P/N 79000035_SM, Version 1.5 6 - 19 Focus 30/35 Service Manual...

- Page 274 See “Reticle replacement” on page 5-9. D. Select checkbox Tolerance: Level the instrument. <10cc in both Level instrument and directions click Level OK. Fig. 6-13 Disassemble the Eyepiece cover Focus 30/35 Service Manual 6 - 20 P/N 79000035_SM, Version 1.5...

- Page 275 A. Adjust the vertical Tolerance: angle to noticed reference position 1 line width reference position. =10cc B. Repeat step until reticle erection and V reference angle are in tolerance. P/N 79000035_SM, Version 1.5 6 - 21 Focus 30/35 Service Manual...

- Page 276 In case CHz > 0,0083 gon/30” and CV < 0,0083gon/30” Adjustment of Reticle F30 in Hz direction keeping the vertical orientation In case CHz 0,0083 gon/30” and CV > 0,0083 gon/30” and vertical angle system was • Focus 30/35 Service Manual 6 - 22 P/N 79000035_SM, Version 1.5...

- Page 277 CV < 30” / page 6-12. 0,0083gon Prepare the A. Unscrew the eyepiece. instrument. B. Unplug the cover behind the eyepiece and mount the eyepiece again, See “Reticle replacement” on page 5-9.. P/N 79000035_SM, Version 1.5 6 - 23 Focus 30/35 Service Manual...

- Page 278 The collimation Click to start measurement. error CHz, the appropriate adjustment position AP Hz and the V- reference angle will be shown. Focus 30/35 Service Manual 6 - 24 P/N 79000035_SM, Version 1.5...

- Page 279 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-17 Adjust HA collimation P/N 79000035_SM, Version 1.5 6 - 25 Focus 30/35 Service Manual...

- Page 280 V angle. orientation was not D. Repeat item Tolerance: stored before! until the tolerance is CHz < 10cc reached. CV < 30cc Focus 30/35 Service Manual 6 - 26 P/N 79000035_SM, Version 1.5...

- Page 281 CHz <30cc and the correction values CV <83cc, the can be stored. message box Store B. Save the correction new corrections? values pushing appears. the message box. P/N 79000035_SM, Version 1.5 6 - 27 Focus 30/35 Service Manual...

- Page 282 The VA correction will be new determined and stored in the memory. Keeping the new orientated vertical angle, the reticle will be adjusted in horizontal direction only. Focus 30/35 Service Manual 6 - 28 P/N 79000035_SM, Version 1.5...

- Page 283 “Adjustment of Reticle will be stored. F30 in Hz and V direction with Front lens mirror tool” on page 6-34.. Fig. 6-20 Vertical collimation out of tolerance P/N 79000035_SM, Version 1.5 6 - 29 Focus 30/35 Service Manual...

- Page 284 HZ collimation B. Unplug the cover adjustment. behind the eyepiece and mount the eyepiece again, See “Reticle replacement” on page 5-9.. Fig. 6-21 Disassemble the Eyepiece cover Focus 30/35 Service Manual 6 - 30 P/N 79000035_SM, Version 1.5...

- Page 285 1 collimators cross- automatically. hair in face1. Click to start The collimation measurement. error CHz and the appropriate adjustment position APHz will be shown. Fig. 6-22 Adjust HA collimation P/N 79000035_SM, Version 1.5 6 - 31 Focus 30/35 Service Manual...

- Page 286 Fig. 6-15 on page 6- C. The vertical adjustment screws should hold the reticle in the displayed vertical reference position. Tolerance: D. Repeat item until the tolerance is CHz <10cc reached. CV <30cc Focus 30/35 Service Manual 6 - 32 P/N 79000035_SM, Version 1.5...

- Page 287 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-23 Reticle adjustment B-Horizontal adjustment screw C Vertical adjustment screw P/N 79000035_SM, Version 1.5 6 - 33 Focus 30/35 Service Manual...

- Page 288 Front lens mirror tool to align the telescope to the collimator and shift the reticle of the instrument to the collimators crosshair. Based on this new reference, the vertical Focus 30/35 Service Manual 6 - 34...

- Page 289 MCB memory. disassembled or partly was anwered replaced? with Fig. 6-25 Vertical collimation out of tolerance Confirm the next message box with and follow the steps. P/N 79000035_SM, Version 1.5 6 - 35 Focus 30/35 Service Manual...

- Page 290 Fig. 6-26 Vertical collimation out of tolerance - use tool as reference Prepare the A. Unscrew the eyepiece. instrument. B. Unplug the cover behind the eyepiece and mount the eyepiece again, See “Reticle replacement” on page 5-9. Focus 30/35 Service Manual 6 - 36 P/N 79000035_SM, Version 1.5...

- Page 291 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-27 Disassemble the eye piece cover P/N 79000035_SM, Version 1.5 6 - 37 Focus 30/35 Service Manual...

- Page 292 H. Step 4: Remove the tool Front lens mirror and switch on the attached reticle Deviation illumination tool. between instruments reticle and collimator is visible now. Focus 30/35 Service Manual 6 - 38 P/N 79000035_SM, Version 1.5...

- Page 293 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-28 Alignment telescope to collimator with Front lens mirror Tool front lens mirror End stop for the tool P/N 79000035_SM, Version 1.5 6 - 39 Focus 30/35 Service Manual...

- Page 294 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-29 Reflected collimator crosshair in Auto-collimation (magnified for explanation only) Step1 Step2 Step3 Step4 Focus 30/35 Service Manual 6 - 40 P/N 79000035_SM, Version 1.5...

- Page 295 D. After adjustment in Hz and V, clamp the Torque value: screws to fix the 20-25 Ncm position. Remove the reticle illumination tool. P/N 79000035_SM, Version 1.5 6 - 41 Focus 30/35 Service Manual...

- Page 296 Chapter 6 Adjustment and Verification Item Performance Action Result Notes Fig. 6-30 Reticle adjustment B-Horizontal adjustment screw C Vertical adjustment screw Focus 30/35 Service Manual 6 - 42 P/N 79000035_SM, Version 1.5...

- Page 297 Front lens mirror was values. to adjust the reticle in done successfully! horizontal direction. Repeat the measurment with answering P/N 79000035_SM, Version 1.5 6 - 43 Focus 30/35 Service Manual...

- Page 298 1,5 allan key. Fig. 6-15 on page 6- C. The vertical adjustment should hold the reticle in the displayed vertical reference position. Focus 30/35 Service Manual 6 - 44 P/N 79000035_SM, Version 1.5...

- Page 299 CV < 83cc appears, corrections? see Fig. 6-32 on page 6-45 Fig. 6-32 Store new correction HA/VA Final collimation test See “Check Reticle collimation (HA/VA collimation)” on page 6- P/N 79000035_SM, Version 1.5 6 - 45 Focus 30/35 Service Manual...

- Page 300 C. Toggle the 15 steps button. of brightness, verify the visibility by looking at the reticle through the eyepiece. Fig. 6-33 Check of reticle illumination Focus 30/35 Service Manual 6 - 46 P/N 79000035_SM, Version 1.5...

- Page 301 Transmitter beam / Laser pointer The Focus 30 is a Laser class 3R product. Do not touch the potentiometer on the PCB of Transmitter/ Laser pointer, this will change the output power of the Laser and may cause hazardous exposure.

- Page 302 7027229001979 Collimator adjustment cap 79020019 Light trap 79700001 Laser adjustment plate 71199035 Target Spot size 30m Print Other tools Torque wrench, 120 Ncm T71600280 Torx T8 bit Local tool Focus 30/35 Service Manual 6 - 48 P/N 79000035_SM, Version 1.5...

- Page 303 EDM DR STD (3R) Maintenance & the fibre adjustment. Service C. Level instrument and collimator. D. Switch on Holding mode. Aim with cross hair to collimator. P/N 79000035_SM, Version 1.5 6 - 49 Focus 30/35 Service Manual...

- Page 304 Tolerance: by turning the 1-2mm in collimator horizontally. horizontal/vertical direction. Check without cap according item correct if necessary in the same sequence. Fig. 6-35 Preparing instrument and collimator Focus 30/35 Service Manual 6 - 50 P/N 79000035_SM, Version 1.5...

- Page 305 B. Remove the Cover Front lens ring. C. Mount the Screen attachment with adapter on the Front lens. Fig. 6-36 Eyepiece illumination (bright green LED) and Screen attachment mounted P/N 79000035_SM, Version 1.5 6 - 51 Focus 30/35 Service Manual...

- Page 306 The shadow of Switch on the reticle the prism can be illumination tool.see seen on the Fig. 6-39 on page 6- screen attachment. Fig. 6-37 Adjustment Transmitter unit / Laser pointer Focus 30/35 Service Manual 6 - 52 P/N 79000035_SM, Version 1.5...

- Page 307 C. Tighten the three arround the prism. screws. D. Remove the Screen 60 Ncm /5,31 attachment and the lbfin reticle illumination tools. Fig. 6-38 Transmitter unit adjustment Vertical Shifting of Transmitter unit P/N 79000035_SM, Version 1.5 6 - 53 Focus 30/35 Service Manual...

- Page 308 Software user guide instrument reticle is sufficent light, if chapter in the Trimble sharp detected. the green cross Collimator Bench is intermitting manual on: available only. Collimator Bench manual Focus 30/35 Service Manual 6 - 54 P/N 79000035_SM, Version 1.5...