Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Monoprice MP Maker Pro Mk.1

- Page 1 MP Maker Pro Mk.1 P/N 33013 User's Manual...

-

Page 2: Table Of Contents

CONTENTS SAFETY WARNINGS AND GUIDELINES ............................3 INTRODUCTION ........................................ 5 FEATURES ..........................................5 CUSTOMER SERVICE ....................................5 PACKAGE CONTENTS ....................................6 PRODUCT OVERVIEW ....................................7 Front View........................................7 Rear View ........................................8 GOOD 3D PRINTING PRACTICES ............................... 9 Before Printing ......................................9 During Printing ...................................... -

Page 3: Safety Warnings And Guidelines

DEFAULT SETTINGS ....................................19 CURA ............................................21 PRINTING FROM SD CARD ................................... 21 REMOVING PRINTED MODELS ................................ 22 SERVICING ......................................... 22 Replacing the Print Mat .................................. 22 Cleaning the Nozzle ................................... 23 Routine Component Maintenance ............................23 TROUBLESHOOTING ....................................24 TECHNICAL SUPPORT .................................... - Page 4 Do not install this device on an unstable surface where it could fall and cause either personal injury or damage to the device and/or other equipment. Do not subject the product to extreme force, shock, or fluctuations in temperature or humidity.

-

Page 5: Introduction

INTRODUCTION Thank you for purchasing this MP Maker Pro Mk.1 3D printer! This printer features a single MK12 extruder and a heated, aluminum build plate. It can print any 1.75mm diameter filament with a melting temperature less than or equal to +250°C, including PLA, ABS, and most exotic materials. -

Page 6: Package Contents

PACKAGE CONTENTS Please take an inventory of the package contents to ensure you have all the items listed below. If anything is missing or damaged, please contact Monoprice Customer Service for a replacement. 1x MP Maker Pro Mk.1 3D Printer... -

Page 7: Product Overview

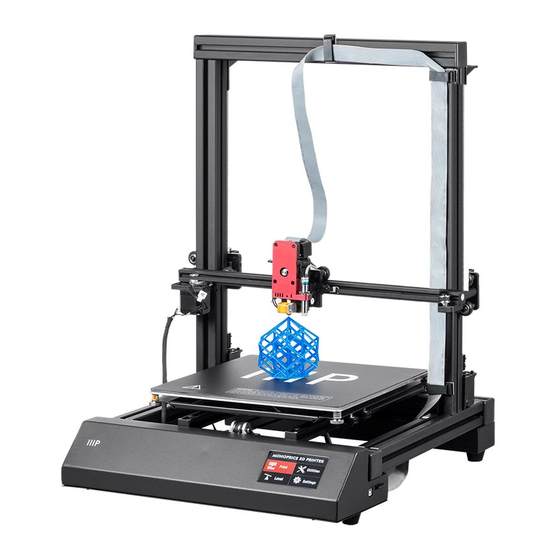

PRODUCT OVERVIEW Front View 1. Extruder Cable 2. Near End Filament Feeding System 3. Full Metal Hot End 4. Heated Build Plate 5. Anti-backlash System 6. MK12 Full Metal Extruder 7. Locking Level System 8. LCD Touch Screen... -

Page 8: Rear View

Rear View 9. Anti-backlash System 10. Z-Axis Lead Screw 11. Super Precise Nozzle 12. Cable Chain 13. Y-Axis Bearing... -

Page 9: Good 3D Printing Practices

GOOD 3D PRINTING PRACTICES Before Printing 1. Ensure that your gcode file is correctly setup, with the filament diameter set to 1.75mm and the correct temperature settings for the type of filament you are printing. 2. Check that all cables and connectors are properly connected. 3. -

Page 10: After Printing

After Printing 1. Wait for the Heated Build Plate, Extruder, and printed model to cool before attempting to remove the print. 2. Carefully remove the 3D object. Never direct the scraper towards your fingers or body. Keep the scraper evenly flat when scraping to avoid damage to the Heated Build Plate and the Print Mat, which will affect adhesion for future prints. - Page 11 Place the base on its side. Locate the Z-axis pillar with the sticker No.2. Slide the No.2 pillar into the base vertical locker, then tighten the bolt at the bottom of the base. Tighten the locking bolt by turning it clockwise, then flip the base onto its other side and install the other Z-axis pillar onto the base using the same method.

- Page 12 Remove the plastic end caps from the X-axis gantry, then slide it under the bolt heads and locking washers. Ensure that the No.3 and No.4 stickers are mated. If there is insufficient space for the gantry to fit under the bolt head, loosen it a bit more and try again.

- Page 13 Screw the X-axis spacers (No.5 and No.6) onto the X- axis rail, but do not tighten them so much that the spacers cannot move along the rail. Mount the X-axis rail assembly by inserting the X-axis spacers in between the rubber wheels on the Z-axis steppers.

- Page 14 Insert the MK12 extruder into the extruder holder on the X-axis rail. Using the four remaining hex bolts, secure the extruder the X-axis rail assembly in four places, two on each side.

-

Page 15: Wiring

WIRING Connect the wires and cables as shown in the image to the left. Route the ribbon cable through the ribbon cable clips before connecting it at each end. AUTOMATIC LEVELING Turn the couplers on the Z-axis steppers to make the X-axis rail level. Use a small level on the X-axis rail to ensure that it is level. -

Page 16: Manual Leveling

Plug the included AC power cord into the printer, then plug the other end into a nearby AC power outlet. Flip the power switch on the printer to turn it on. From the Home page on the printer screen, select Level >... -

Page 17: Adding Filament

7. Once the printer has finished initializing, press Utilities > Home XYZ to move the extruder and build plate to the home position. 8. Turn the printer off. 9. With the power turned off, manually move the extruder to each corner and to the middle of the build plate. -

Page 18: Removing Filament

REMOVING FILAMENT Perform the following steps to remove filament from the extruder. 1. With the printer turned on and initialized, press Utilities >Change Filament > Remove Filament. The printer will automatically heat and, once the target temperature is reached, will remove the filament from the extruder. 2. -

Page 19: Change Filament Menu

Change Filament Menu Add Filament Remove Filament Raise Extruder Preheat PLA Preheat ABS Settings Menu PID Settings Motor Settings Factory Reset DEFAULT SETTINGS The printer has been set at the factory with the following values for optimal print quality. General Baudrate: 115200 Stepper Inactive: 360s Max Inactive: 0s... - Page 20 Move: Y Move: Z Jerk: 20.0 Z-Jerk: 0.3 Feedrate Max X: 200 Max Y: 200 Max Z: 2 Home X: 40 Home Y: 40 Home Z: 2 Extruder Steps/mm: 96.0 Start FR: 20 Max FR: 50 Accel: 5000 Stab. Time: 1 Wait Units: 0mm Wait Temp.: 150C Control: Dead Time...

-

Page 21: Cura

Drive Min: 40 Drive Max: 230 PID Max: 255 CURA Cura is a program that lets you load a premade model file, adjust it to your liking, then slice the model to create a gcode file, which can be printed from the included SD™ card. We have included a version of Cura on the SD card that has already been configured with the proper settings for this printer. -

Page 22: Removing Printed Models

REMOVING PRINTED MODELS Perform the following steps to remove a printed model from the build plate. 1. Wait for the build plate, extruder, and printed model to fully cool before reaching into the printer to remove the model. 2. Using the included scraper, slide it under a corner of the model. Ensure that the blade is not directed at your fingers or body. -

Page 23: Cleaning The Nozzle

3. Peel the protective paper from the back of the replacement print mat, then carefully attach it to the build plate, making sure to align the edge of the new mat with the build plate. Note: If you do not have a replacement print mat, you can use masking tape instead. We recommend using blue painter's tape. -

Page 24: Troubleshooting

TROUBLESHOOTING Q1: There is a clicking sound from one of the stepper motors. A1: One of the stepper motors may not be connected properly. Check each connection, then inspect the cables for damage. Q2: The selected print model on the SD™ card is not printing. A2: Remove the SD card from the printer, then mount it on your computer. - Page 25 Q6: The model appears very "stringy". A6: Ensure that the filament diameter is set to match your filament (1.75mm), then try recreating the gcode file again. Ensure that the extruder and build plate temperatures are set to the correct values for the type of filament being used. Q7: The print stops somewhere in the middle.

-

Page 26: Technical Support

TECHNICAL SUPPORT Monoprice is pleased to provide free, live, online technical support to assist you with any questions you may have about installation, setup, troubleshooting, or product recommendations. If you ever need assistance with your new product, please come online to talk to one of our friendly and knowledgeable Tech Support Associates.

Need help?

Do you have a question about the MP Maker Pro Mk.1 and is the answer not in the manual?

Questions and answers