Summary of Contents for RoboteQ Dual Channel Digital Motor Controller AX1500

- Page 1 AX1500 Dual Channel Digital Motor Controller User’s Manual v1.9b, June 1, 2007 visit www.roboteq.com to download the latest revision of this manual ©Copyright 2003-2007 Roboteq, Inc.

- Page 2 AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 3: Revision History

Revision History Revision History Date Version June 1, 2007 1.9b January 10, 2007 March 7 , 2005 1.7b February 1, 2005 April 17 , 2004 March 15, 2004 August 25, 2003 August 15, 2003 April 15, 2003 March 15, 2003 The information contained in this manual is believed to be accurate and reliable. - Page 4 AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 5: Table Of Contents

Revision History 3 SECTION 1 Important Safety Warnings 13 This product is intended for use with rechargeable batteries 13 Avoid Shorts when Mounting Board against Chassis 13 Do not Connect to a RC Radio with a Battery Attached 13 Beware of Motor Runaway in Improperly Closed Loop 13 SECTION 2 AX1500 Quick Start 15... - Page 6 SECTION 5 SECTION 6 SECTION 7 AX1500 Motor Controller User’s Manual General Operation 39 Basic Operation 39 Input Command Modes 39 Selecting the Motor Control Modes 40 Open Loop, Separate Speed Control 40 Open Loop, Mixed Speed Control 40 Closed Loop Speed Control 41 Close Loop Position Control 41 User Selected Current Limit Settings 42 Temperature-Based Current Limitation 42...

- Page 7 Recommended Encoder Types 68 Installing the Encoder Module 69 Connecting the Encoder 70 Cable Length and Noise Considerations 71 Motor - Encoder Polarity Matching 72 Voltage Levels, Thresholds and Limit Switches 72 Wiring Optional Limit Switches 73 Wiring Limit Switches Without Encoders 75 Effect of Limit Switches 75 Using the Encoder Module to Measure Distance 76 Using the Encoder to Measure Speed 76...

- Page 8 SECTION 10 SECTION 11 SECTION 12 SECTION 13 AX1500 Motor Controller User’s Manual Adjust Offset and Max Speed 96 Control Loop Description 96 PID tuning in Speed Mode 97 Normal and Fault Condition LED Messages 99 Power On LED 99 Diagnostic LED 99 Normal Operation Flashing Pattern 99 Output Off / Fault Condition 100...

- Page 9 Connector I/O Pin Assignment (RS232 Mode) 122 Cable configuration 123 Extending the RS232 Cable 123 Communication Settings 124 Establishing Manual Communication with a PC 124 RS232 Communication with the Encoder Module 125 Entering RS232 from R/C or Analog mode 126 Data Logging String in R/C or Analog mode 126 RS232 Mode if default 127 Commands Acknowledge and Error Messages 127...

- Page 10 SECTION 14 AX1500 Motor Controller User’s Manual Controller Identification Register 144 Current Amps Limit Registers 144 RS232 Encoder Command Set 145 Read Encoder Counter 145 Set/Reset Encoder Counters and Destination Registers 145 Read Speed 146 Read Distance 147 Read Speed/Distance 147 Read Encoder Limit Switch Status 147 Read / Modify Encoder Module Registers and Parameters 148 Register Description 150...

- Page 11 Logging Data to Disk 173 Connecting a Joystick 174 Using the Console 174 Viewing and Logging Data in Analog and R/C Modes 176 Loading and Saving Profiles to Disk 176 Operating the AX1500 over a Wired or Wireless LAN 176 Updating the Controller’s Software 178 Updating the Encoder Software 178 Creating Customized Object Files 179...

- Page 12 AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 13: Section 1 Important Safety Warnings

Important Safety SECTION 1 Warnings Read this Section First The AX1500 is a high power electronics device. Serious damage, including fire, may occur to the unit, motors, wiring and batteries as a result of its misuse. Transistors may explode and require the use of safety glasses when operated in direct view. - Page 14 Important Safety Warnings AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 15: Section 2 Ax1500 Quick Start

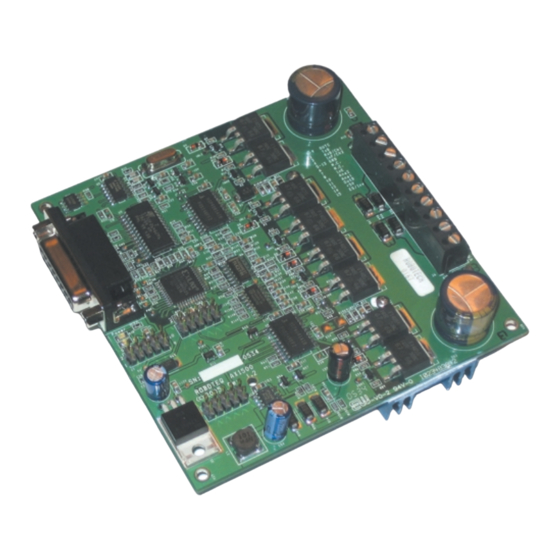

AX1500 SECTION 2 Quick Start This section will give you the basic information needed to quickly install, setup and run your AX1500 controller in a minimal configuration. What you will need For a minimal installation, gather the following components: • One AX1500 Controller and its provided cables •... - Page 16 AX1500 Quick Start The front side (shown in Figure 1) contains the Power/Status LED and the 15-pin connector to the R/C radio, joystick or microcomputer, as well as connections to optional switches and sensors. Connector to Receiver/Controls and sensors Power LED Status LED FIGURE 1.

-

Page 17: Connecting To The Batteries And Motors

Connecting to the Batteries and Motors Connecting to the Batteries and Motors Connection to the batteries and motors is shown in the figure below and is done by con- necting wires to the controller’s terminal strip. Motor2 Motor1 Notes: The Battery Power connection are doubled in order to provide the maximum current to the controller. If only one motor is used, only one set of motor power cables needs to be connected. -

Page 18: Connecting To The 15-Pin Connector

AX1500 Quick Start Important Warning Do not rely on cutting power to the controller for it to turn off if the Power Control is left floating. If motors are spinning because the robot is pushed are pushed or because of inertia, they will act as generators and will turn the controller, possibly in an unsafe state. -

Page 19: Connecting The R/C Radio

Connecting the R/C Radio Connecting the R/C Radio Connect the R/C adapter cables to the controller on one side and to two or three channels on the R/C receiver on the other side. If present, the third channel is for activating the accessory outputs and is optional. -

Page 20: Default Controller Configuration

Version 1.9b of the AX1500 software is configured with the factory defaults shown in the table below. Although Roboteq strives to keep the same parameters and values from one version to the next, changes may occur from one revision to the next. Make sure that you have the matching manual and software versions. -

Page 21: Connecting The Controller To Your Pc Using Roborun

USB to serial adapter if needed. Apply power to the controller to turn it on. Load your CD or download the latest revision of Roborun software from www.Roboteq.com, install it on your PC and launch the program. The software will auto- matically establish communication with the controller, retrieve the software revision num- ber and present a series of buttons and tabs to enable its various possibilities. -

Page 22: Obtaining The Controller's Software Revision Number

PC connection discussed previously. Now that you know your controller’s software version number, you will be able to see if a new version is available for download and installation from Roboteq’s web site and which features have been added or improved. -

Page 23: Product Description

AX1500 Motor SECTION 3 Controller Overview Congratulations! By selecting Roboteq’s AX1500 you have empowered yourself with the industry’s most versatile, and programmable DC Motor Controller for mobile robots. This manual will guide you step by step through its many possibili- ties. -

Page 24: Section 3 Ax1500 Motor Controller Overview

AX1500 Motor Controller Overview The motors are driven using high-efficiency Power MOSFET transistors controlled using Pulse Width Modulation (PWM) at 16kHz. The AX1500 power stages can operate from 12 to 40VDC and can sustain up to 30A of controlled current, delivering up to 1200W (approx- imately 1.5 HP) of useful power to each motor. - Page 25 Technical features • User defined purpose (RS232 mode only) • 2 Extra analog inputs. Used as: • Potentiometer input for position while in analog command mode • User defined purpose (RS232 mode only) • One Switch input configurable as • Emergency stop command •...

- Page 26 AX1500 Motor Controller Overview Advanced Safety Features Data Logging Capabilities Compact Open Frame PCB Design AX1500 Motor Controller User’s Manual • 20A extended • High current operation may be extended with forced cooling • 125A peak Amps per channel • 16kHz Pulse Width Modulation (PWM) output •...

-

Page 27: Section 4 Connecting Power And Motors To The Controller

Power Connections Connecting SECTION 4 Power and Motors to the Controller This section describes the AX1500 Controller’s connections to power sources and motors. Important Warning Please follow the instructions in this section very carefully. Any problem due to wir- ing errors may have very serious consequences and will not be covered by the prod- uct’s warranty. -

Page 28: Controller Power

Connecting Power and Motors to the Controller Note: Both VMot terminals are connected to each other in the board and must be wired to the same voltage. FIGURE 7 . Controller Rear View and Power Connector Tabs Controller Power The AX1500 uses a flexible power supply scheme that is best described in Figure 8. In this diagram, it can be seen that the power for the Controller’s microcomputer is separate from this of the motor drivers. - Page 29 Controller Power Channel 1 MOSFET Power Stage Microcomputer & MOSFET Drivers Channel 2 MOSFET Power Stage FIGURE 8. Representation of the AX1500’s Internal Power Circuits When powered only via the Power Control input, the controller will turn On but motors will not be able to turn until power is also present on the VMot terminals.

-

Page 30: Powering The Controller From A Single Battery

Connecting Power and Motors to the Controller TABLE 2. Controller Status depending on Power Control and VMot Power Control input is connected to 10.5V to 40V 10.5V to 40V All 3 ground (-) are connected to each other inside the controller. The two main battery wires are also connected to each other internally. -

Page 31: Powering The Controller Using A Main And Backup Battery

Controller Powering Schemes There is no need to insert a separate switch on Power cables, although for safety reasons, it is highly recommended that a way of quickly disconnecting the Motor Power be provided in the case of loss of control and all of the AX1500 safety features fail to activate. The two VMot terminals are connected to each other inside the controller. -

Page 32: Connecting The Motors

Connecting Power and Motors to the Controller FIGURE 10. Powering the AX1500 with a Main and Backup Supply Important Warning Unless you can ensure a steady 12V to 40V voltage in all conditions, it is recom- mended that the battery used to power the controller’s electronics be separate from the one used to power the motors. -

Page 33: Converting The Ax1500 To Single Channel

Single Channel Operation If you are using this type of motor, make sure that it is mounted on isolators and that its casing will not cause a short circuit with other motors and circuits which may also be inadvertently connected to the same metal chassis. Single Channel Operation The AX1500’s two channel outputs can be paralleled as shown in the figure below so that they can drive a single load with twice the power. -

Page 34: Wire Length Limits

Connecting Power and Motors to the Controller It will be safe to wire in parallel the controller’s outputs only after you have verified that both outputs react identically to channel 1 commands. FIGURE 12. AX1500 Jumper setting for Single Channel Operation Power Fuses For low Amperage applications (below 30A per motor), it is recommended that a fuse be inserted in series with the main battery circuit as shown in the Figure 9 on page 30. -

Page 35: Electrical Noise Reduction Techniques

Electrical Noise Reduction Techniques be amplified beyond the controller’s capability to correct them. This is particularly the case for the main battery power wires. Important Warning Avoid using long cable lengths (beyond 2 feet) from the main power battery to the controller as the added inductance may cause damage to the controller when oper- ating at high currents. -

Page 36: Using The Controller With A Power Supply

Connecting Power and Motors to the Controller Please download the Application Note “Understanding Regeneration” from the www.roboteq.com for an in-depth discussion of this complex but important topic. Important Warning Use the AX1500 only with a rechargeable battery as supply to the Motor Power wires (VMot terminals). - Page 37 Using the Controller with a Power Supply • Use a power supply that will not suffer damage in case a voltage is applied at its output that is higher than the transformer’s own output voltage. This information is seldom published in commercial power supplies, so it is not always possible to obtain positive reassurance that the supply will survive such a condition.

- Page 38 Connecting Power and Motors to the Controller AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 39: Section 5 General Operation

Basic Operation General SECTION 5 Operation This section discusses the controller’s normal operation in all its supported operating modes. Basic Operation The AX1500’s operation can be summarized as follows: • Receive commands from a radio receiver, joystick or a microcomputer •... -

Page 40: Selecting The Motor Control Modes

General Operation Selecting the Motor Control Modes For each motor, the AX1500 supports multiple motion control modes. The controller’s fac- tory default mode is Open Loop Speed control for each motor. The mode can be changed using any of the methods described in “Loading, Changing Controller Parameters” on page 164. -

Page 41: Close Loop Position Control

Selecting the Motor Control Modes Controller FIGURE 14. Effect of commands to motors examples in mixed mode Closed Loop Speed Control In this mode, illustrated in Figure 16, an analog tachometer or an optical encoder is used to measure the actual motor speed. If the speed changes because of changes in load, the controller automatically compensates the power output. -

Page 42: Temperature-Based Current Limitation

General Operation FIGURE 16. Motor with potentiometer assembly for Position operation User Selected Current Limit Settings The AX1500 has current sensors at each of its two output stages. Every 16 ms, this current is measured and a correction to the output power level is applied if higher than the user preset value. -

Page 43: Battery Current Vs. Motor Current

Battery Current vs. Motor Current The numbers in the table are the max Amps allowed by the controller at a given tempera- ture point. If the Amps limit is manually set to a lower value, then the controller will limit the current to the lowest of the manual and temperature-adjusted max values. -

Page 44: Regeneration Current Limiting

General Operation FIGURE 17 . Current flow during operation FIGURE 18. Instant and average current waveforms The relation between Battery Current and Motor current is given in the formula below: Example: If the controller reports 10A of battery current while at 10% PWM, the current in the motor is 10 / 0.1 = 100A. -

Page 45: Programmable Acceleration

Programmable Acceleration Programmable Acceleration When changing speed command, the AX1500 will go from the present speed to the desired one at a user selectable acceleration. This feature is necessary in order to minimize the surge current and mechanical stress during abrupt speed changes. This parameter can be changed by using the controller’s front switches or using serial com- mands. -

Page 46: Command Control Curves

General Operation TABLE 4. Acceleration setting table Acceleration Setting Using RS232 15 Hex 05 Hex Important Warning Depending on the load’s weight and inertia, a quick acceleration can cause consider- able current surges from the batteries into the motor. A quick deceleration will cause an equally large, or possibly larger, regeneration current surge. -

Page 47: Left / Right Tuning Adjustment

Left / Right Tuning Adjustment FIGURE 19. Exponentiation curves The AX1500 is delivered with the “linear” curves selected for both joystick channels. To select different curves, the user will need to change the values of “E” (channel 1) and “F” (channel 2) according to the table below. - Page 48 General Operation is found on all R/C transmitters, and which is actually an offset correction, the Left/Right Adjustment is a true multiplication factor as shown in Figure 20 FIGURE 20. Left Right adjustment curves The curves on the left show how a given forward direction command value will cause the motor to spin 3 or 5.25% slower than the same command value applied in the reverse direction.

-

Page 49: Activating Brake Release Or Separate Motor Excitation

Activating Brake Release or Separate Motor Excitation TABLE 6. Left/Right Adjustment Parameter selection Parameter Value Speed Adjustment -1.5% -0.75% Activating Brake Release or Separate Motor Excitation The controller may be configured so that the Output C will turn On whenever one of the two motors is running. -

Page 50: Using The Inputs To Turn Off/On The Power Mosfet Transistors

General Operation Special Use of Accessory Digital Inputs The AX1500 includes two general purpose digital inputs identified as Input E and Input F . When an Encoder Module is installed, input E is disabled. The location of these inputs on the DB15 connector can be found in the section “I/O List and Pin Assignment”... -

Page 51: Section 6 Connecting Sensors And Actuators To Input/Outputs

AX1500 Connections Connecting SECTION 6 Sensors and Actuators to Input/Outputs This section describes the various inputs and outputs and provides guidance on how to connect sensors, actuators or other accessories to them. AX1500 Connections The AX1500 uses a set of power wires (located on the back of the unit) and a DB15 con- nector for all necessary connections. -

Page 52: Ax1500'S Inputs And Outputs

Connecting Sensors and Actuators to Input/Outputs DC Motors Optional sensors: - Tachometers (Closed loop Speed mode) - Potentiometers (Servo mode) - Encoders when Module present Motor Power supply wires Power Control wire5- Controller FIGURE 21. Typical controller connections AX1500’s Inputs and Outputs In addition to the RS232 and R/C channel communication lines, the AX1500 includes sev- eral inputs and outputs for various sensors and actuators. - Page 53 AX1500’s Inputs and Outputs When the controller operates in modes that do not use these I/O, these signals become available for user application. Below is a summary of the available signals and the modes in which they are used by the controller or available to the user. TABLE 7 .

-

Page 54: I/O List And Pin Assignment

Connecting Sensors and Actuators to Input/Outputs I/O List and Pin Assignment The figure and table below lists all the inputs and outputs that are available on the AX1500. FIGURE 22. Controller’s DB15 connector pin numbering TABLE 8. DB15 connector pin assignment Input or Number Output... -

Page 55: Connecting Devices To Output C

Connecting devices to Output C TABLE 8. DB15 connector pin assignment Input or Signal depending Number Output on Mode RC/RS232: Ana in 2 Analog in Analog: Command 2 Analog in RC/RS232: Ana in 1 Analog: Command 1 Analog in RC: Unused RS232: Ana in 3 Ana: Ana in 3 Power Out... -

Page 56: Connecting Switches Or Devices To Input E

Connecting Sensors and Actuators to Input/Outputs Important warning: Overvoltage spikes induced by switching inductive loads, such as solenoids or relays, will destroy the transistor unless a protection diode is used. Connecting Switches or Devices to Input E Input E is a general purpose, digital input. This input is only available if no encoder module is present and is active when in the RS232 and Analog modes. -

Page 57: Connecting Switches Or Devices To Estop/Invert Input

Connecting Switches or Devices to EStop/Invert Input +5V Out 14 +5V Out 14 +5V Out 14 +5V Out 14 +5V In 7 +5V In 7 +5V In 7 +5V In 7 10kOhm 10kOhm 10kOhm 10kOhm Input F 4 Input F 4 Input F 4 Input F 4 GND In 6... -

Page 58: Connecting Position Potentiometers To Analog Inputs

Connecting Sensors and Actuators to Input/Outputs FIGURE 26. Emergency Stop / Invert switch wiring The status of the EStop/Inv can be read at all times in the RS232 mode with the ?i com- mand string. The controller will respond with three sets of 2 digit numbers. The status of the ES/Inv Input is contained in the last set of numbers and may be 00 to indicate an Off state, or 01 to indicate an On state. -

Page 59: Connecting Tachometer To Analog Inputs

Connecting Tachometer to Analog Inputs Connecting the potentiometer to the controller is as simple as shown in the diagram on Figure 28. FIGURE 28. Potentiometer wiring in Position mode The potentiometer must be attached to the motor frame so that its body does not move in relationship with the motor. - Page 60 Connecting Sensors and Actuators to Input/Outputs Since the controller only accepts a 0 to 5V positive voltage as its input, the circuit shown in Figure 29 must be used between the controller and the tachometer: a 10kOhm potentiom- eter is used to scale the tachometer output voltage to -2.5V (max reverse speed) and +2.5V (max forward speed).

-

Page 61: Connecting External Thermistor To Analog Inputs

Connecting External Thermistor to Analog Inputs Connecting External Thermistor to Analog Inputs Using external thermistors, the AX1500 can be made to supervise the motor’s tempera- ture and adjust the power output in case of overheating. Connecting thermistors is done according to the diagram show in Figure 30. The AX1500 is calibrated using a 10kOhm Negative Coefficient Thermistor (NTC) with the temperature/resistance characteristics shown in the table below. -

Page 62: Using The Analog Inputs To Monitor External Voltages

Connecting Sensors and Actuators to Input/Outputs FIGURE 31. Signed binary reading by controller vs. NTC temperature To read the temperature, use the ?p command to have the controller return the A/D con- verter’s value. The value is a signed 8-bit hexadecimal value. Use the chart data to convert the raw reading into a temperature value. -

Page 63: Connecting User Devices To Analog Inputs

Connecting User Devices to Analog Inputs Measured volts = ((controller reading + 128) * 0.255) -5 Note: The A/D converter’s reading is returned by the ?p command and is a signed 8-bit hexadecimal value. You must add 128 to bring its range from -127/+127 to 0/255. Connecting User Devices to Analog Inputs The two analog inputs can be used for any other purpose. -

Page 64: Temperature Conversion C Source Code

Connecting Sensors and Actuators to Input/Outputs These sensors are used to automatically reduce the maximum Amps that the controller can deliver as it overheats. However, the temperature can be read using the RS232 port using the ?m query, or during data logging (see “Analog and R/C Modes Data Logging String Format”... - Page 65 Internal Heatsink Temperature Sensors else LoTemp = i * 5 - 40; HiTemp = LoTemp + 5; lobound = TempTable[i]; hibound = TempTable[i+1]; temp = LoTemp + (5 * ((AnaValue - lobound)*100/ (hibound - lobound)))/100; return temp; AX1500 Motor Controller User’s Manual...

- Page 66 Connecting Sensors and Actuators to Input/Outputs AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 67: Section 7 Installing, Connecting And Using The Encoder Module

Optical Incremental Encoders Overview Installing, SECTION 7 Connecting and Using the Encoder Module This section describes the Encoder input module that may be added to the AX1500. Optical Incremental Encoders Overview Optical incremental encoders are a means for capturing speed and travelled distance on a motor. -

Page 68: Recommended Encoder Types

Installing, Connecting and Using the Encoder Mod- 1 Pulse = 4 Transitions = 4 Counts FIGURE 35. Quadrature encoder output waveform The figure below shows the typical construction of a quadrature encoder. As the disk rotates in front of the stationary mask, it shutters light from the LED. The light that passes through the mask is received by the photo detectors. -

Page 69: Installing The Encoder Module

Installing the Encoder Module Specifically, the encoder module can process 250,000 counts per seconds. As discussed in the previous section, a count is generated for each transition on the Channel A and Channel B. Therefore the module will work with encoders outputting up to 62,500 pulses per second. -

Page 70: Connecting The Encoder

Installing, Connecting and Using the Encoder Mod- 2- Carefully insert the encoder module on top of the two headers present on the control- ler’s main board and shown in Figure 38. Beware that the two matting connectors are pre- cisely aligned. 3- The encoder module will be held in place by the headers and connectors. -

Page 71: Cable Length And Noise Considerations

Cable Length and Noise Considerations FIGURE 40. Encoder connector TABLE 12. Encoder Connector Pinout Name Encoder 2 - Channel B. Optional Limit Switch 4 Encoder 2 - Channel A. Optional Limit Switch 3 Ground (same as pin 7) 5V Out (same as pin 8) Encoder 1 - Channel B. -

Page 72: Voltage Levels, Thresholds And Limit Switches

Installing, Connecting and Using the Encoder Mod- Important Warning Excessive cable length will cause electrical noise to be captured by the controller and cause erratic functioning that may lead to failure. In such situation, stop operation immediately. Motor - Encoder Polarity Matching When using the Encoder module for closed loop speed control, it is imperative that when the motor is turning in the forward direction, the counter increments its value and a posi- tive speed value is measured. -

Page 73: Wiring Optional Limit Switches

Wiring Optional Limit Switches Signal on Channel A or B Quadrature Signal Switch Detect Signal (Not meaningful) FIGURE 42. Signals seen by encoder using direct connection and no limit switches In Figure 42, the encoder and switches are wired to the encoder module using a set of resistors designed to create a multi-level signal combining both pieces of information. - Page 74 Installing, Connecting and Using the Encoder Mod- FIGURE 44. Signals seen by encoder using multi-levels and limit switches Using this circuit when the switch is open, a 0V (low-level) output from the encoder goes through a 1k and 4.7k voltage divider, thus creating a voltage that will never be below 0.8V at the encoder module’s input.

-

Page 75: Wiring Limit Switches Without Encoders

Wiring Limit Switches Without Encoders Wiring Limit Switches Without Encoders If no encoder is used, the Encoder Module’s inputs can be used to wire limit switches directly with solely a pull-up resistor as shown in the diagram below. FIGURE 45. Signals seen by encoder using multi-levels and limit switches Effect of Limit Switches Each pair of limit switches will stop the motion of a given motor in a given direction. -

Page 76: Using The Encoder Module To Measure Distance

Installing, Connecting and Using the Encoder Mod- TABLE 14. Effects of Limit Switches 3 and 4 on Motor 2 In Single Channel Mode, limit switches 3 and 4 are used. This is to allow direct connection of an encoder on the inputs for channel 1 and direct connection of switches on the inputs for channel 2 TABLE 15. -

Page 77: Using The Encoder To Track Position

Using the Encoder to Track Position A simple procedure is included in the Roborun PC utility to easily determine and set these parameters. For information, the exact formula is shown below: Measured Speed Value = RPM * PPR * 4 * (Time Base+1) * 256 / (60 * 1000000) or Measured Speed Value = RPM * PPR * (Time Base + 1) / 58593.75 Example: a motor spinning at 1,000 RPM, with an encoder with 200 Pulses per Revolution, and a Time Base set at 4 will produce the following measurement:... -

Page 78: Rs232 Communication With The Encoder Module

Installing, Connecting and Using the Encoder Mod- The actual formula is as follows: Where: divider is a configurable parameter of value 1, 2, 4, 8, 16, 32, 64 or 127 If computed distance is less than -127 , then reported distance is -127 If computed distance is larger than +127 , then reported distance is +127 FIGURE 46. -

Page 79: Encoder Testing And Setting Using The Pc Utility

Encoder Testing and Setting Using the PC Utility Encoder Testing and Setting Using the PC Utility Extensive diagnostic, calibration, setting and testing support is provided in the Roborun PC utility. Basic instructions on how to install and run the PC utility can be found in “Encoder Setting and Testing”... - Page 80 Installing, Connecting and Using the Encoder Mod- AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 81: Section 8 Closed Loop Position Mode

Mode Description Closed Loop SECTION 8 Position Mode This section describes the AX1500 Position mode, how to wire the motor and position sen- sor assembly and how to tune and operate the controller in this mode. Mode Description In this mode, the axle of a geared-down motor is coupled to a position sensor that is used to compare the angular position of the axle versus a desired position. -

Page 82: Position Sensor Selection

Closed Loop Position Mode Position Sensor Selection The AX1500 may be used with the following kind of sensors: The first two are used to generate an analog voltage ranging from 0V to 5V depending on their position. They will report an absolute position information at all times. Optical encoders report incremental changes from a reference which is their initial position when the controller is powered up or reset. -

Page 83: Feedback Potentiometer Wiring In Rc Or Rs232 Mode

Feedback Potentiometer wiring The mechanical coupling between the motor and the sensor must be as tight as possible. If the gear box is loose, the positioning will not be accurate and will be unstable, potentially causing the motor to oscillate. Some sensor, such as potentiometers, have a limited rotation range of typically 270 degrees (3/4 of a turn), which will in turn limit the mechanical motion of the motor/potenti- ometer assembly. -

Page 84: Feedback Potentiometer Wiring In Analog Mode

Closed Loop Position Mode FIGURE 49. Pot wiring for RS232 or RC Command and Analog Feedback Feedback Potentiometer wiring in Analog Mode When the controller is configured in Analog mode, the analog inputs 1 and 2 are used for commands while the analog inputs 3 and 4 are used for feedback. Analog inputs 3 and 4 have different characteristics than inputs 1 and 2, and so require a lower resistance poten- tiometer in order to guarantee accuracy Roborun will detect the new hardware revision and display Rev B on the screen. -

Page 85: Feedback Wiring In Rc Or Rs232 Mode On Single Channel Controllers

Analog Feedback on Single Channel Controllers Analog Feedback on Single Channel Controllers On Single Channel controllers (SC Version - not to be confused with Dual Channel control- lers of which only one channel is used for position control - See “Single Channel Opera- tion”... -

Page 86: Using Optical Encoders In Position Mode

Closed Loop Position Mode This wiring is also the one to use when the controller is in Analog mode but switched to RS232 after reset using the method discussed in “Entering RS232 from R/C or Analog mode” on page 126 Using Optical Encoders in Position Mode The AX2550 and AX1500 may be equipped with an optional Optical Encoder Module. -

Page 87: Encoder Error Detection And Protection

Encoder Error Detection and Protection 10. If the motor turns in the direction away from the sensor, then the polarity is reversed. The wire polarity on the motors should be exchanged. If using a potenti- ometer as sensor, the GND and +5V wires on the potentiometer may be swapped instead. - Page 88 Closed Loop Position Mode The diode polarity depends on the particular wiring and motor orientation used in the appli- cation. If the diode is mounted backwards, the motor will not stop once the limit switch lever is pressed. If this is the case, reverse the diode polarity. The diodes may be eliminated, but then it will not be possible for the controller to move the motor once either of the limit switches has been triggered.

-

Page 89: Control Loop Description

Using Current Limiting as Protection Manual Emergency Stop Switch FIGURE 54. Safety limit using AX1500’s Emergency Stop input Important Warning Limit switches must be used when operating the controller in Position Mode. This will significantly reduce the risk of mechanical damage and/or injury in case of dam- age to the position sensor or sensor wiring. -

Page 90: Pid Tuning In Position Mode

Closed Loop Position Mode A higher Proportional Gain will cause the algorithm to apply a higher level of power for a given measured error, thus making the motor move quicker. Because of inertia, however, a faster moving motor will have more difficulty stopping when it reaches its desired position. It will therefore overshoot and possibly oscillate around that end position. - Page 91 PID tuning in Position Mode The Roborun PC utility makes this experimentation easy by providing one screen for chang- ing the Proportional, Integral and Differential gains and another screen for running and monitoring the motors. When tuning the motor, first start with the Integral Gain at zero, increasing the Proportional Gain until the motor overshoots and oscillates.

- Page 92 Closed Loop Position Mode AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 93: Section 9 Closed Loop Speed Mode

Mode Description Closed Loop SECTION 9 Speed Mode This section discusses the AX1500 Close Loop Speed mode. Mode Description In this mode, an analog or digital speed sensor measures the actual motor speed and com- pares it to the desired speed. If the speed changes because of changes in load, the control- ler automatically compensates the power output. -

Page 94: Tachometer Or Encoder Mounting

Closed Loop Speed Mode Detailed information on how to install and wire optical encoders is provided at “Installing, Connecting and Using the Encoder Module” on page 67. If using optical encoders, omit the Analog Tachometer discussion in this section and resume reading from “Control Loop Description”... -

Page 95: Speed Sensor And Motor Polarity

Speed Sensor and Motor Polarity Speed Sensor and Motor Polarity The tachometer or encoder polarity (i.e. which rotation direction produces a positive of negative speed information) is related to the motor’s rotation speed and the direction the motor turns when power is applied to it. In the Closed Loop Speed mode, the controller compares the actual speed, as measured by the tachometer, to the desired speed. -

Page 96: Adjust Offset And Max Speed

Closed Loop Speed Mode Adjust Offset and Max Speed For proper operation, the controller must see a 0 analog speed value (2.5V voltage on the analog input). To adjust the 0 value when the motors are stopped, use the Roborun utility to view the analog input value while the tachometer is not turning. -

Page 97: Pid Tuning In Speed Mode

PID tuning in Speed Mode The Differential component of the algorithm computes the changes to the error from one 16 ms time period to the next. This change will be a relatively large number every time an abrupt change occurs on the desired speed value or the measured speed value. The value of that change is then multiplied by a user selectable Differential Gain and added to the out- put. - Page 98 Closed Loop Speed Mode In Speed Mode, the Integral component of the PID is the most important and must be set first. The Proportional and Differential component will help improve the response time and loop stability. In the case where the load moved by the motor is not fixed, tune the PID with the mini- mum expected load and tune it again with the maximum expected load.

-

Page 99: Normal Operation Flashing Pattern

Power On LED Normal and SECTION 10 Fault Condition LED Messages This section discusses the meaning of the various messages and codes that may be dis- played on the LED display during normal operation and fault conditions. Power On LED The AX1500 features an LED that comes on whenever the board is powered on. -

Page 100: Output Off / Fault Condition

Normal and Fault Condition LED Messages FIGURE 59. Status LED Flashing pattern during normal operation Output Off / Fault Condition The controller LED will tun On solid to signal that the output stage is off as a result of a any of the recoverable conditions listed below. -

Page 101: Section 11 R/C Operation

Mode Description R/C Operation SECTION 11 This section describes the controller’s wiring and functions specific to the R/C radio control mode. Mode Description The AX1500 can be directly connected to an R/C receiver. In this mode, the speed or posi- tion information is contained in pulses whose width varies proportionally with the joysticks’... -

Page 102: Connector I/O Pin Assignment (R/C Mode)

R/C Operation Selecting the R/C Input Mode The R/C Input Mode is the factory default setting. If the controller has been previously set to a different Input Mode, it will be necessary to reset it to the R/C mode using the serial port and the PC utility. See “Using the Roborun Configuration Utility”... -

Page 103: R/C Input Circuit Description

R/C Input Circuit Description TABLE 16. Connector pin-out in R/C mode Input or Number Output Signal Power Out Input Input EStop/Inv R/C Input Circuit Description The AX1500 R/C inputs are directly connected to the MCU logic. Figure 63 shows an elec- trical representation of the R/C input circuit. -

Page 104: Powering The Radio From The Controller

R/C Operation FIGURE 64. RC Cable wiring diagram FIGURE 65. RC connection cable Powering the Radio from the controller The 5V power and ground signals that are available on the controller’s connector may be used to power the R/C radio. The wire loop is used to bring the controller’s power to the the radio as well as for powering the optocoupler stage. - Page 105 Powering the Radio from the controller Channel 2 Channel 1 FIGURE 66. Wiring for powering R/C radio from controller R/C Radio Power R/C Radio FIGURE 67 . R/C Radio powered by controller electrical diagram Important Warning Do not connect a battery to the radio when in this mode. The battery voltage will flow directly into the controller and cause permanent damage if its voltage is higher than 5.5V.

-

Page 106: Connecting To A Separately Powered Radio

R/C Operation Connecting to a Separately Powered Radio This wiring option must be used when the controller is used with a RC receiver that is powered by its own separate battery. The red wire in the loop must be cut so that the 5V out from the controller does not flow to the radio, and so that the battery that is connected to the controller does not inject power into the controller. -

Page 107: Reception Watchdog

Reception Watchdog ond indicates the minimum joystick position and 2.0 milliseconds indicates the maximum joystick position. When the joystick is in the center position, the pulse should be 1.5ms. Note that the real pulse-length to joystick-position numbers that are generated by your R/C radio may be different than the ideal 1.0ms to 2.0ms discussed above. -

Page 108: R/C Transmitter/Receiver Quality Considerations

R/C Operation Similarly, if the pulse train is lost while the motors were enabled, the controller will wait a short preset amount of time before it disables the motors. If the pulses reappear during that time, the controller continues without any breaks. If the communication is confirmed to be lost, the “no ctrl”... -

Page 109: Command Control Curves

Command Control Curves The deadband is measured as a percentage of total normal joystick travel. For example, a 16% deadband means that the first 16% of joystick motion in either direction will have no effect on the motors. TABLE 17 . Selectable deadband values Deadband Parameter Value d = 0 d = 1... -

Page 110: Activating The Accessory Outputs

R/C Operation Left/Right Tuning Adjustment When operating in mixed mode with one motor on each side of the robot, it may happen that one motor is spinning faster than the other one at identically applied power, causing the vehicle to pull to the left or to the right. To compensate for this, the AX1500 can be made to give one side up to 10% more power than the other at the same settings. -

Page 111: Data Logging In R/C Mode

Data Logging in R/C Mode Output C is a buffered output capable of driving a 2A device at up to 24V. Details on how to wire this output to user accessories can be found at “Connecting Sensors and Actuators to Input/Outputs”... - Page 112 R/C Operation To read the output string while operating the controller with the R/C radio, you must mod- ify the R/C cable to add an RS232 output wire and connector that will be connected to the PC’s communication port. Figure 74 and below shows the wiring diagram of the modified R/C cable for connection to a PC.

-

Page 113: Section 12 Analog Control And Operation

Mode Description Analog Control SECTION 12 and Operation This section describes how the motors may be operated using analog voltage commands. Mode Description The AX1500 can be configured to use a 0 to 5V analog voltage, typically produced using a potentiometer, to control each of its two motor channels. -

Page 114: Connector I/O Pin Assignment (Analog Mode)

Analog Control and Operation Connector I/O Pin Assignment (Analog Mode) When used in the Analog mode, the pins on the controller’s DB15 connector are mapped as described in the table below TABLE 18. DB15 Connector pin assignment in Analog mode Number Signal Output C... -

Page 115: Connecting To A Voltage Source

Connecting to a Voltage Source Connecting to a Voltage Source The analog inputs expect a DC voltage of 0 to 5V which can be sourced by any custom cir- cuitry (potentiometer, Digital to Analog converter). The controller considers 2.5V to be the zero position (Motor Off). 0V is the maximum reverse command and +5V is the maximum forward command. -

Page 116: Selecting The Potentiometer Value

Analog Control and Operation FIGURE 76. Potentiometer connection wiring diagram The controller includes two 47K ohm resistors pulling the input to a mid-voltage point of 2.5V. When configured in the Analog Input mode, this will cause the motors to be at the Off state if the controller is powered with nothing connected to its analog inputs. -

Page 117: Analog Deadband Adjustment

Analog Deadband Adjustment Voltage at Input 10K Pot FIGURE 77 . Effect of the controller’s internal resistors on various potentiometers Analog Deadband Adjustment The controller may be configured so that some amount of potentiometer or joystick travel off its center position is required before the motors activate. The deadband parameter can be one of 8 values, ranging from 0 to 7 , which translate into a deadband of 0% to 16%. -

Page 118: Data Logging In Analog Mode

Analog Control and Operation TABLE 19. Analog deadband parameters and their effects Parameter Value 3 (default) Important Notice Some analog joysticks do not cause the potentiometer to reach either extreme. This may cause the analog voltage range to be above 0V and below 5V when the stick is moved to the extreme, and therefore the controller will not be able to deliver full for- ward or reverse power. - Page 119 Data Logging in Analog Mode Data in Analog and R/C Modes” on page 176). It may also be stored in a PDA that can be placed in the mobile robot. The string and data format is described in “Analog and R/C Modes Data Logging String For- mat”...

- Page 120 Analog Control and Operation AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 121: Section 13 Serial (Rs-232) Controls And Operation

Use and benefits of RS232 Serial (RS-232) SECTION 13 Controls and Operation This section describes the communication settings and the commands accepted by the AX1500 in the RS232 mode of operations. This information is useful if you plan to write your own controlling software on a PC or microcomputer. -

Page 122: Connector I/O Pin Assignment (Rs232 Mode)

Serial (RS-232) Controls and Operation Connector I/O Pin Assignment (RS232 Mode) FIGURE 1. Pin locations on the controller’s 15-pin connector When used in the RS232 mode, the pins on the controller’s DB15 connector are mapped as described in the table below TABLE 20. -

Page 123: Extending The Rs232 Cable

Cable configuration Cable configuration The RS232 connection requires the special cabling as described in the figure below. The 9- pin female connector plugs into the PC (or other microcontroller). The 15-pin male connec- tor plugs into the AX1500. It is critical that you do not confuse the connector’s pin numbering. The pin numbers on the drawing are based on viewing the connectors from the front (facing the sockets or pins). -

Page 124: Establishing Manual Communication With A Pc

To save time and avoid errors, a hyperterm configuration file is automatically installed in your PC’s Start button menu when the Roboteq’s Roborun utility is installed (See “Down- loading and Installing the Utility” on page 161). The configuration file is set to use the AX1500 Motor Controller User’s Manual... -

Page 125: Rs232 Communication With The Encoder Module

In all cases, immediately after reset or power up, the controller will output a short identity message followed by a software revision number and software revision date as follows: Roboteq v1.9b 06/01/07 The letter below the prompt message is a code that provides information on the hardware and can be ignored. -

Page 126: Data Logging String In R/C Or Analog Mode

Serial (RS-232) Controls and Operation FIGURE 83. Hyperterm session showing power up messages from both MCUs After this information is sent, the Encoder’s MCU will “listen” for approximately 100ms and will enter the In System Programming mode (ISP) if the letter “Z” is sent to it. While in the ISP mode, new software can be loaded into the Encoder’s MCU via the controller’s main serial port. -

Page 127: Commands Acknowledge And Error Messages

Commands Acknowledge and Error Messages RS232 Mode if default If the controller is configured in RS232 mode, it will automatically be in the RS232 mode upon reset or power up. In this case, the “OK” message is sent automatically, indicating that the controller is ready to accept commands through its serial port. -

Page 128: Controller Commands And Queries

Serial (RS-232) Controls and Operation RS-232 Watchdog For applications demanding the highest operating safety, the controller may be configured to automatically stop the motors (but otherwise remain fully active) if it fails to receive a character on its RS232 port for more than 1 seconds. The controller will also send a “W”... -

Page 129: Set Motor Command Value

Controller Commands and Queries TABLE 21. Controller’s basic Commands and Queries Command Type Description ?m or ?M Query Read Heatsink Temperature ?e or ?E Query Read Battery and Internal Voltage ?i or ?I Query Read Digital Inputs ?k or ?K Query Quick read of Encoder Speed or Position if present Set Motor Command Value... -

Page 130: Query Amps From Battery To Each Motor Channel

Serial (RS-232) Controls and Operation Query Power Applied to Motors Description: This query will cause the controller to return the actual amount of power that is being applied to the motors at that time. The number is a hexadecimal number ranging from 0 to +127 (0 to 7F in Hexadecimal). -

Page 131: Query Heatsink Temperatures

Figure 34 on page 64 shows this correlation. Sample conversion software code is available from Roboteq upon request. The values are unsigned Hexadecimal numbers ranging from 0 to 255. The lowest read value represents the highest temperature. -

Page 132: Query Digital Inputs

Serial (RS-232) Controls and Operation ages: the first is the Main Battery voltage present at the thick red and black wires. The sec- ond is the internal 12V supply needed for the controller’s microcomputer and MOSFET drivers. The values are unsigned Hexadecimal numbers ranging from 0 to 255. To convert these numbers into a voltage figure, use the formulas described in “Internal Voltage Moni- toring Sensors”... -

Page 133: Accessing & Changing Configuration Parameter In Flash

Accessing & Changing Configuration Parameter in Flash Reply: None. Controller will reset and display prompt message Accessing & Changing Configuration Parameter in Flash It is possible to use RS232 commands to examine and change the controller’s parameters stored in Flash. These commands will appear cryptic and difficult to use for manual param- eter setting. -

Page 134: Flash Configuration Parameters List

Serial (RS-232) Controls and Operation Syntax: Reply: Table 22 below lists the complete set of configuration parameters that may be accessed and changed using RS232 commands. Flash Configuration Parameters List TABLE 22. Configuration parameters in Flash Location AX1500 Motor Controller User’s Manual + Success, changed parameters are now active - if error Description... -

Page 135: Input Control Mode

Accessing & Changing Configuration Parameter in Flash TABLE 22. Configuration parameters in Flash Location Description Joystick Max 2 MS Joystick Max 2 LS Amps Calibration Parameter 1 Amps Calibration Parameter 2 These parameters are stored in the controller’s Flash memory and are not intended to be changed at runtime. -

Page 136: Amps Limit

Serial (RS-232) Controls and Operation This parameters selects the various open loop and closed loop operating modes as well as the feedback method. Definition Motor Control Mode Reserved Ch1 Feedback type Ch2 Feedback type Amps Limit Address: Access: Effective: This parameter configures the controller’s Amps limit. Note that this limits the amps flow- ing out of the power supply. -

Page 137: Input Switches Function

Accessing & Changing Configuration Parameter in Flash Acceleration Address: Access: Read/Write Effective: After Reset or ^FF This parameter configures the rate at which the controller internally changes the command value from the one it was to the one just received. Definition 0 = very slow 1 = slow... -

Page 138: Exponentiation On Channel 1 And Channel 2

Serial (RS-232) Controls and Operation Definition Input E Input F RC Joystick or Analog Deadband Address: Access: Effective: This parameter configures the amount of joystick or potentiometer motion can take place around the center position without power being applied to the motors. Definition Values are for Joystick deadband 0 = no deadband... -

Page 139: Default Encoder Time Base 1 And 2

Accessing & Changing Configuration Parameter in Flash This parameter configures the transfer curve that is applied the input command. Definition (0) = Linear (no exponentiation - default) 1 = strong exponential 2 = normal exponential 3 = normal logarithmic 4 = strong logarithmic Left/Right Adjust Address: Access:... -

Page 140: Default Encoder Distance Divider

Serial (RS-232) Controls and Operation Default Encoder Distance Divider Address: Access: Effective: This parameters is the Encoder’s Distance Divider that is loaded after the controller is reset or powered on. The Encoder Distance Divider can be changed at Runtime using separate commands (see page 142). -

Page 141: Reading & Changing Operating Parameters At Runtime

Reading & Changing Operating Parameters at Runtime ^1C - Joystick Max 2 MS ^1D - Joystick Max 2 LS Effective: Instantly These parameters are the Gains values that are loaded after the controller is reset or pow- ered on. These Gains apply to both channels. Gains can be changed at Runtime, and values can be different for each channel using separate commands (see page 142). -

Page 142: Operating Modes Registers

Serial (RS-232) Controls and Operation TABLE 23. Runtime R/W Parameters list Location Important Notice: Do not write in the locations marked as Read Only. Doing so my cause Controller malfunction. Operating Modes Registers Address: Access: Effective: Modifying the bits in the Operating Mode registers will change the controller’s operating modes on-the fly. -

Page 143: Controller Status Register

Reading & Changing Operating Parameters at Runtime ^86 - I2 ^87 - D2 Access: Read/Write Effective: Instantly The Proportional, Integral and Derivative gain for each channel can be read and changed on- the-fly. This function also provides a mean for setting different PID values for each channel. Actual Gain value is the value contained in the register divided by 8. -

Page 144: Controller Identification Register

Serial (RS-232) Controls and Operation TABLE 25. Controller Status Register Definition Controller Identification Register Address: Access: Effective: This register may be used to query the Controller’s model and some of its optional hard- ware configurations. TABLE 26. Controller Identification Register Definition Current Amps Limit Registers Address: Access:... -

Page 145: Set/Reset Encoder Counters And Destination Registers

RS232 Encoder Command Set RS232 Encoder Command Set When present, the Encoder module responds to a dedicated set of commands and que- ries. The serial port setting and basic command format is identical to this for all other functions of the controller as described in “Serial (RS-232) Controls and Operation” on page 121. Read Encoder Counter Description: Read the value of the Encoder counter(s). -

Page 146: Read Speed

While resetting is a single step command, setting the counters to a non-zero value requires two steps: 1- load a 4 byte buffer (32-bit) with the desired value. 2- Transfer the buffer’s content to the counter(s). Loading the buffer can be done using the commands described in “Read / Modify Encoder Module Registers and Parameters”... -

Page 147: Read Encoder Limit Switch Status

RS232 Encoder Command Set Read Distance Description: This query will cause the controller to return the distance between the current position and the value in the destination register. The values are signed Hexadecimal numbers ranging from -127 to +127 . The -127 value represents the relative distance according to the formu- las described in “Using the Encoder to Track Position”... -

Page 148: Read / Modify Encoder Module Registers And Parameters

Reply: Where: The relationship between the value of n and the switch status is shown in the table below. Extracting the status of a given switch from this number is easily accomplished in software using masking. TABLE 27 . Reported value and switch status relationship n Value Note that the 0 and 1 levels represent a Closed Switch and Open Switch status, respec- tively. - Page 149 RS232 Encoder Command Set Example: Read value of parameter at address hex 84 Controller replies, value is 01 Modify parameter Syntax: *mm nn Reply: + if command was executed successfully - if error Where mm= parameter address nn= new parameter value Examples: *84 03 Store 03 into parameter at address hex 84...

-

Page 150: Register Description

Encoder Hardware ID code Address: Returns a 4-bit number identifying the encoder module hardware version and the status of two on-board jumpers. For Roboteq use only. Switch Status Address: Returns a 4 bit number (4 least significant bits of the byte), each representing the state of one of the limit switches when installed. -

Page 151: Destination Register 1 And 2

Register Description These two registers contain either the measured speed or the measured distance. Whether speed or distance information is returned depends on the settings contained in the Mode register described at. This information is returned using the ?p query (see “Query Analog Inputs”... -

Page 152: Encoder Threshold

These two 32-bit (4-bytes) registers are used to store the desired destination when the controller is used in position mode. These registers should always be set using the mailbox mechanism described above. See “Using the Encoder to Track Position” on page 77 for a complete description of the position mode. -

Page 153: Encoder Testing And Setting Using The Pc Utility

Counter Read Data Format Counter Read Data Format When receiving a counter read query, the encoder module will output the value of its 32-bit counter. If all 32-bit are sent, this would require 8 ASCII digits to represent the value. A 32-bit counter can store over 2 billion counts in each direction. - Page 154 AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 155: Automatic Switching From Rs232 To Rc Mode

Automatic Switching from RS232 to RC Mode Automatic Switching from RS232 to RC Mode In many computer controlled applications, it may be useful to allow the controller to switch back to the RC mode. This would typically allow a user to take over the control of a robotic vehicle upon computer problem. -

Page 156: Analog And R/C Modes Data Logging String Format

Controller is on, Radio is turned Off (or Radio On with RC ch3 Off) Note: Wait 5 seconds for the capacitor to discharge before attempting to switch to RC mode if doing this repeatedly. Controller will not reset otherwise. Analog and R/C Modes Data Logging String Format When the controller is configured in R/C or Analog mode, it will automatically and continu- ously send a string of ASCII characters on the RS232 output. -

Page 157: Decimal To Hexadecimal Conversion Table

Decimal to Hexadecimal Conversion Table logging purposes. This cable has a 15-pin male connector and 3 15-pin connectors. The Front View FIGURE 86. ASCII string sent by the controller while in R/C or Analog mode male connector plugs into the controller. The application cable that would normally plug into the controller may now be plugged into one of the adapter’s female connector 2. - Page 158 TABLE 30. 0 to +127 signed or unsigned decimal to hexadecimal conversion table TABLE 31. +128 to 255 unsigned and -1 to -128 signed decimal to hexadecimal conversion table UDec -128 -127 -126 -125 -124 -123 -122 AX1500 Motor Controller User’s Manual UDec UDec UDec...

- Page 159 Decimal to Hexadecimal Conversion Table TABLE 31. +128 to 255 unsigned and -1 to -128 signed decimal to hexadecimal conversion table UDec UDec -121 -120 -119 -118 -117 -116 -115 -114 -113 -112 -111 -110 -109 -108 -107 -106 -105 -104 -103 -102...

- Page 160 AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 161: Section 14 Using The Roborun Configuration Utility

Configuration Utility A PC-based Configuration Utility is available, free of charge, from Roboteq. This pro- gram makes configuring and operating the AX1500 much more intuitive by using pull-down menus, buttons and sliders. The utility can also be used to update the controller’s software in the field as described in “Updating the Controller’s Soft-... -

Page 162: Connecting The Controller To The Pc

Leave VMot unconnected unless you want to exercise the Motors. AX1500 Motor Controller User’s Manual • after the installation is complete, run the program from your Start Menu > Programs > Roboteq • to read the current parameters stored in the controller and display them on the computer •... -

Page 163: Roborun Frame, Tab And Menu Descriptions

1- Program Revision Number This is the revision and date of the Roborun utility. It is recommended that you always ver- ify that you have the latest revision of the utility from Roboteq’s web site at www.roboteq.com 2- Controller and Communication Link Information This frame will automatically be updated with an indication that a free communication port was found and opened by the utility. -

Page 164: Loading, Changing Controller Parameters

Using the Roborun Configuration Utility This is the program’s main frame and includes several types of tabs, each of which has sev- eral buttons, menus and other User Interface objects. These tabs and the functions they contain are described in detail in the following sections. Navigate from one set of commands to another by clicking on the desired tab. -

Page 165: Control Settings

Loading, Changing Controller Parameters When starting Roborun, this screen is filled with the default values. If the controller is con- nected to your PC, Roborun will automatically detect it and ask you if you wish to read its settings. The controller’s setting in the PC at can be read any other time by pressing the “Load from Controller”... -

Page 166: Power Settings

Using the Roborun Configuration Utility 4- Emergency Stop or Invert Switch Select This pull down menu allows the selection of the controller’s response to changes on the optional switch input: Emergency Stop, Invert Commands, or no action. See “Emergency Stop using External Switch” on page 49 and “Inverted Operation” on page 49. 5- Effect of Digital Inputs This pull down menu allows the selection of the controller’s response to changes on either of the two digital inputs. -

Page 167: Analog Or R/C Specific Settings

Loading, Changing Controller Parameters accelerate a motor from idle to maximum speed. See “Programmable Acceleration” on page 45. Analog or R/C Specific Settings FIGURE 92. Power settings screen The screen shown in Figure 92 slightly changes in function of whether or not the Analog Input mode is selected. -

Page 168: Encoder Setting And Testing

Using the Roborun Configuration Utility Closed Loop Parameters FIGURE 93. Closed Loop parameter setting screen The screen shown in Figure 93 is used to set the Proportional, Integral and Differential gains needed for the PID algorithm. These PID gains are loaded after reset and apply to both channels. -

Page 169: Encoder Module Parameters Setting

Encoder Setting and Testing FIGURE 94. Encoder setup and test screen on Roborun With this utility, the following actions can be accomplished: • Set and program the Encoder module’s parameters in EEPROM • Activate the motors in each direction at variable speed •... -

Page 170: Exercising The Motors

Using the Roborun Configuration Utility The Time Base parameter is used to compute the speed measured by the module. The measured speed is a relative number ranging from 0 to +/-127 . The relationship between this relative speed number and the actual RPM is based on the Time Base value and the Encoder’s Pulses Per Revolution (PPR) value (see “Using the Encoder to Measure Speed”... - Page 171 Running the Motors FIGURE 95. Motor exercising and monitoring screen 1- Run/Stop Button This button will cause the PC to send the run commands to the controller and will update the screen with measurements received from the controller. When the program is running, the button’s caption changes to “Stop” . Pressing it again will stop the motors and halt the exchange of data between the PC and the controller.

- Page 172 Using the Roborun Configuration Utility case the power level will be the one needed to keep the Amps within the limit. Note that the display value is not signed and thus does not provide rotation direction information. The Ana fields contain the analog input values that are measured and reported by the con- troller.

-

Page 173: Logging Data To Disk

Running the Motors 7- Data Logging and Timer A timer is provided to keep track of time while running the motors. An additional set of but- tons and displays are provided to operate a data logger. The data logger is fully described in the section that follows. -

Page 174: Connecting A Joystick

Using the Roborun Configuration Utility TABLE 32. Logged parameters order, type and definition Parameter Header Power1 Power2 Ana 1, Speed 1, Pos 1 or Temp 1 or Volt 1 Ana 2, Speed 2, Pos 2 Temp 2 or Volt 2 Amps1 Amps2 FET Temp1... - Page 175 Using the Console cannot be established (e.g. “Controller not found” , no response to command changes, communication errors, ...etc.). The Roborun utility will let you exercise and monitor the motors, sensors and actuators using a computer. This feature is particularly useful during development as you will be able to visualize, in real-time, the robot’s Amps consumption and other vital statistics during actual operating conditions.

-

Page 176: Operating The Ax1500 Over A Wired Or Wireless Lan

Using the Roborun Configuration Utility 4- Send Reset String Clicking this button while the controller is in RS232 mode, will cause the reset string to be sent to the controller. 5- Send 10 Carriage Returns Clicking this button will cause Roborun to send ten consecutive “Carriage Return” charac- ter. - Page 177 Operating the AX1500 over a Wired or Wireless LAN To operate over the network, two computers are required, as show in Figure 97 below. The top computer is connected to the controller via its COM port. Both computers are con- nected to a TCP/IP network.

-

Page 178: Updating The Controller's Software

Using the Roborun Configuration Utility Updating the Controller’s Software The AX1500’s operating software can be easily upgraded after it has left the factory. This feature makes it possible to add new features and enhance existing ones from time to time. Important Warning Updating the controller will cause all its parameters to reset to their default condi- tions. -

Page 179: Creating Customized Object Files

Select the latest official controller firmware issued by Roboteq. Select the profile file that was created and saved earlier. Select a revision letter. This letter will be added at the end of Roboteq’s own version identity number. Click on the Create button and save the new customized object file. - Page 180 Using the Roborun Configuration Utility Install the new object file in the controller using the Roborun utility. AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

-

Page 181: Section 15 Mechanical Specifications

Mechanical Dimensions Mechanical SECTION 15 Specifications This section details the mechanical characteristics of the AX1500 controller. Mechanical Dimensions The AX1500 is delivered as an assembled and tested Printed Circuit Board. The board includes connectors for direct connection to the Optical Encoders and to the Radio, Joy- stick or microcomputer on one side. -

Page 182: Mounting Considerations

Mechanical Specifications 4.20" (106.7mm) FIGURE 101. AX1500 top view and dimensions Mounting Considerations The AX1500’s heatsink is located at the bottom of the board. This requires therefore that the board be mounted with spacers that are at minimum 0.6” (15mm). FIGURE 102. -

Page 183: Attaching The Controller Directly To A Chassis

Attaching the Controller Directly to a Chassis board against a vertical surface as shown in the figure below will ensure a better natural convection flow and is, therefore, recommended. FIGURE 103. Mount the controller against a vertical surface to maximize convection flow For high current applications, it is possible that the controller may heat up faster and to a higher temperature than can be dissipated by the using natural convection alone. -

Page 184: Precautions To Observe

Mechanical Specifications Note that the back of the PCB has large copper areas exposed just under the power MOS Board Thermal Pad Metal Interposer Metal Chassis Spacer FIGURE 104. Mount the controller without heatsink against a chassis area. It is critical that the interposer either is insulated (example: anodized aluminum) or a layer of thermal conducting - but electrically insulating - pad is used. -

Page 185: Wire Dimensions

Wire Dimensions Wire Dimensions The AX1500 uses screw terminals for the power connections to the batteries and motors. These connectors are rated to support the controller’s maximum specified current. It is rec- ommended that you use AWG12 wire for all power connections to ground, batteries and motors. - Page 186 Mechanical Specifications AX1500 Motor Controller User’s Manual Version 1.9b. June 1, 2007...

Need help?

Do you have a question about the Dual Channel Digital Motor Controller AX1500 and is the answer not in the manual?

Questions and answers