Lenze 9400 Manual

L-force drives

Hide thumbs

Also See for 9400:

- Hardware manual (646 pages) ,

- Mounting instructions (206 pages) ,

- Software manual (80 pages)

Summary of Contents for Lenze 9400

- Page 1 EDS94AYAE L−force Drives .G)! Manual Translation 9400 E94AYAE − SM301 Safety module Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com...

- Page 2 0Fig. 0Tab. 0 © 2011 Lenze Automation GmbH, Hans−Lenze−Str. 1, D−31855 Aerzen No part of this documentation may be reproduced or made accessible to third parties without written consent by Lenze Auto- mation GmbH. All information given in this documentation has been selected carefully and complies with the hardware and software descri- bed.

-

Page 3: Table Of Contents

..........1.1.2 Drive−based safety with L−force | 9400 ...... -

Page 4: Table Of Contents

Safety engineering Contents Safe parameter setting ..........1.6.1 Parameter setting . -

Page 5: Safety Engineering

1.1.2 Drive−based safety with L−force | 9400 The controllers of the L−force|9400 range can be equipped with a safety module. The functional range of the safety module types varies in order to optimally implement different applications. "Drive−based safety" stands for applied safety functions, which can be used for the protection of persons working on machines. - Page 6 Terms and abbreviations of the safety engineering 1.1.3 Terms and abbreviations of the safety engineering Abbreviation Meaning 9400 Lenze servo controller Cat. Category according to EN ISO 13849−1 (formerly EN 954−1) OSSD Output Signal Switching Device, tested signal output PROFIsafe Pulse width modulation SD−In...

-

Page 7: Basics

Safety engineering Basics Important notes 1.1.4 Important notes The following pictographs and signal words are used in this documentation to indicate dangers and important information: Safety instructions Structure of safety instructions: Danger! (characterises the type and severity of danger) Note (describes the danger and gives information about how to prevent dangerous situations) Pictograph and signal word... - Page 8 Basics Safety instructions 1.1.5 Safety instructions Application as directed The safety modules SMx (E94AYAx) may only be used together with Lenze drive controllers of the L−force | 9400 (E94A...) series. Any other use shall be deemed inappropriate! Installation/commissioning Danger! Danger to life through improper installation Improper installation of the safety engineering systems can cause anuncontrolled starting action of the drives.

- Page 9 Safety engineering Basics Safety instructions Danger! When the request for the safety function is deactivated, the drive can restart automatically. The behaviour can be set via the parameter "Restart behaviour" (C15300/1/2). In the case of an automatic restart, you must provide external measures which ensure that the drive only restarts after an acknowledgement (EN 60204).

-

Page 10: Safety Instructions

Safety engineering Basics Hazard and risk analysis 1.1.6 Hazard and risk analysis This documentation can only accentuate the need for hazard analysis. The user of the integrated safety system must read up on standards and the legal situation: Before the launch of a machine, the manufacturer of the machine must conduct a hazard analysis according to Machinery Directive 2006/42/EC to determine the hazards associated with the application of the machine. - Page 11 Safety engineering Basics Overview of sensors 1.1.9 Overview of sensors Passive sensors Passive sensors are two−channel switching elements with contacts. The connecting cables and the sensor function must be monitored. The contacts must switch simultaneously (equivalently). Nevertheless, safety functions will be activated as soon as at least one channel is switched. The switches must be wired according to the closed−circuit principle.

-

Page 12: Standards

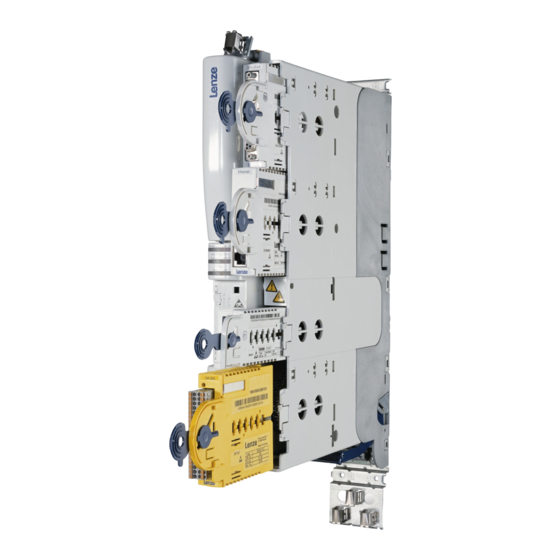

Safety engineering Device modules Slot Device modules 1.2.1 Slot The slot for the safety modules is marked in the documentation with M4. It is the lowest slot in the controller (see overview in the documentation of the controller). 1.2.1.1 Mounting E94AYAX001 1.2.1.2 Dismounting... - Page 13 Setting of the expected safety module If a safety module deviating from this setting is detected, an error (fault) is caused. The error can only be removed by mains switching. Selection list Information (Lenze setting bold) 1 SM0 2 SM100 4 SM300 5 SM301 þ...

-

Page 14: Device Modules

Safety engineering Device modules Function mode of the safety modules 1.2.2 Function mode of the safety modules C00214 The setting in C00214 must comply with the plug−in safety module type so that the controller is able to operate. Disconnecting paths The transmission of the pulse width modulation is safely disconnected by the safety module. - Page 15 Safety engineering Device modules SM301 safety module 1.2.3 SM301 safety module Validity information These instructions are valid for SM301 safety module Type E94AYAE from VA from 01.00 Identification Type ‚ ƒ „ E94YCEI003C E94AYXX001 ‚ ƒ „ Product series Version Module identification: Device module Module type: Safety module...

-

Page 16: Slot

Safety engineering Device modules SM301 safety module Application range The use of this module is permissible with standard devices of the 9400 product series from nameplate designation Type E94AxHExxxx 01.49 E94AxPExxxx 02.xx Safe position and speed detection with a resolver selected as the motor encoder and an additional position encoder is permissible with SM301 V1.3 and standard devices of the... -

Page 17: Sm301 Safety Module

Safety engineering Device modules SM301 safety module 1.2.3.1 Overview Functions Safe torque off (STO) ƒ (formerly: Safe standstill, protection against unexpected start−up) Safe stop 1 (SS1) ƒ Safe stop 2 (SS2) − see SOS ƒ Safe stop emergency (SSE) ƒ Safe operational stop (SOS) −... - Page 18 Device modules SM301 safety module Motor−encoder combinations Drive systems with Servo Drives 9400 and safety module SM301 provide speed−dependent safety functions for safe speed monitoring and/or safe relative−position monitoring. Observe permissible motor−encoder combinations during configuration. Possible speed−dependent safety functions with safety module SM301: ƒ...

- Page 19 Safety engineering Device modules SM301 safety module Compatibility Compatibility of SM301/SM300 The SM301 safety module is compatible with the SM300. The controller needs to be adapted since the safe parameter set is required. Observe the following: The GSE file can be used. ƒ...

- Page 20 Safety engineering Device modules SM301 safety module 1.2.3.3 Elements of the module SSP94SM321 Fig. 1−2 Module view Pos. Description Safety address switch (in the left part of the housing) Module switch for parameter set adoption from the memory module X82.1 X82.2 Plug−in terminal strips for input and output signals X82.3...

- Page 21 Safety engineering Device modules SM301 safety module Displays Pos. Colour State Description Drive−based safety has initialised without a fault. Drive−based safety has initialised without a fault. Internal Blinking communication to the standard device is not possible. Green Drive−based safety is in service status. (Module State) Flashing For exiting, parameterise the drive−based safety.

- Page 22 Safety engineering Device modules SM301 safety module Terminal assignment Danger! Danger to life through improper installation Improper installation of the safety engineering systems can cause anuncontrolled starting action of the drives. Possible consequences: Death or severe injuries ƒ Protective measures: Total cable length between X82 and its connected components (e.g.

- Page 23 Safety engineering Device modules SM301 safety module X82.3 Labelling Description GND clock output GND SD−In2 Sensor input SD−In2, channel B Sensor input SD−In2, channel A GND clock output GND SD−In1 Sensor input SD−In1, channel B Sensor input SD−In1, channel A Restart acknowledgement input ("Acknowledge In Stop", 1−channel, bridged to X82.4/AIS) X82.4...

- Page 24 Safety engineering Device modules SM301 safety module 1.2.3.4 Technical data 24 V supply The module and the safe output must be supplied with 24 V from safely separated power supply units. To maintain electrical isolations, separate voltage supplies are required. Detailed features of the 24−V supply Terminal Specification...

- Page 25 Safety engineering Device modules SM301 safety module 1.2.3.5 Example circuit SM301 E94AYAE X82.1 X82.2 24 V ext. ‚ X82.3 X82.4 SSP94SM360 Fig. 1−3 Wiring example E94AYAE SM301 safety module passive sensor with channel A and B higher−level safety control (active sensor) lightgrid (active sensor) 24 V ext.

- Page 26 Device modules SM301 safety module 1.2.3.6 Commissioning For commissioning and safe parameter setting, the Lenze »Engineer« PC ƒ software from version 1.4 must be used. If you select the safety module in the Project view, various tabs are available in the Operating range via which the safety module can be parameterised.

- Page 27 Test fundamentals EN 954−1, EN 60204−1, EN 50178, EN 61800−3, IEC 61508 Part 1−7 Object to be examined SM301, type E94AYAE VA1.0x of the 9400 Servo Drives series Test result The module meets the requirements according to EN 954−1, category 3.

- Page 28 EN 954−1, EN 60204−1, EN 50178, EN 61800−3, EN 61508 Part 1−7, EN ISO 13849−1, EN 62061 Object to be examined SM301, type E94AYAE VB1.1x of the 9400 Servo Drives series Test result The module meets the requirements according to EN 954−1, category 3...

- Page 29 EN 60204−1, EN 61800−3, EN 61508 Part 1−7, EN ISO 13849−1, EN 62061, EN 61800−5−2, EN 61800−5−1 Object to be examined SM301, type E94AYAE of the Servo Drives 9400 series Test result The module meets the requirements according to EN 61508, SIL 3 EN ISO 13849−1, category 3/PL e...

- Page 30 The "operation mode selector" and "enable switch" functions may only be assigned to one of the four safe inputs. Selection list Information (Lenze setting printed in bold) 0 Free assignment Safety function set in C15032 1 Emergency stop Safe stop emergency function (SSE)

- Page 31 Assignment of a safety function to a safe input. Only possible if the "free assignment" sensor function is set for the safe input in C15031. Selection list Information (Lenze setting printed in bold) 0 STO Safe torque off 1 SS1...

-

Page 32: Safe Inputs

Maximum time in which both channels of a safe input may have non−equivalent states without the safety engineering causing an error response. Setting range Information (min. value | unit | max. value) 30000 Lenze: 10, increment: 2 ms Subcodes Information C15033/1 SD-In1 discrepancy time... - Page 33 Time between the recognition of the signal change and the effective evaluation of an input signal. As a result, multiple and short signal changes due to contact bounce of the components are not taken into account. Setting range Information (min. value | unit | max. value) 100 Lenze: 0, increment: 2 ms Subcodes Information C15034/1 Input delay SD-In1...

- Page 34 Safety engineering Device modules Safe inputs SSP94SM358_1 Fig. 1−6 Contact function test − error−free input signals ‚ ƒ „ SSP94SM358_2 Fig. 1−7 Contact function test − faulty input signals A, B Safe input, channel A and channel B Internal valuation of the safe input Discrepancy monitoring Fault acknowledgement...

- Page 35 Safety engineering Device modules Safe inputs 1.2.4.2 Connection of passive sensors The safe sensor inputs I1A ... I4B are suitable for equivalently switching passive sensors. To monitor passive sensors according to EN ISO 13849−1, cat. 3, the clock outputs CLA and CLB must be wired.

- Page 36 Safety engineering Device modules Safe inputs 1.2.4.3 Connection of active sensors The safe sensor inputs I1A ... I4B are suitable for active sensors. PN−switched input signals are permissible. The line monitoring must comply with the requirements of the category 3. Drive−based safety does not provide for line monitoring.

- Page 37 Safety engineering Device modules Safe output 1.2.5 Safe output 1.2.5.1 General Via the safe output O1A/O1B information can be output to a higher−level unit (e.g. safety PLC) or external switching elements (actuators) can be controlled. The feedback output is potential−free and must be supplied separately with 24 V. The status of the safe output is controlled via two ways: ƒ...

- Page 38 Safety engineering Device modules Safe output Codes Parameter: Name: Data type: Index: C15051 SD-Out condition BITFIELD_32 9524 = 2534 Bit coded selection of the conditions for switching the safe output. Value is bit coded: Information Bit 0 STO active Safe torque off Bit 1 STO active neg.

-

Page 39: Safe Output

SD−Out logic function UNSIGNED_8 9520 = 2530 Selection of the logic operation for the switching conditions to be evaluated Selection list Information (Lenze setting bold) 0 OR 1 AND Subcodes Information C15055/1 SD−Out1 logic function þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer EDS94AYAE EN 6.0... - Page 40 Safety engineering Device modules Safe output Parameter: Name: Data type: Index: C15060 Output image BITFIELD_16 9515 = 252B Output image of the safety module feedback, shown in channels. Value is bit coded: Information Bit 0 SD-Out1 channel A Safe output 1 Bit 1 SD-Out1 channel B Bit 2 reserved Bit 15 reserved...

-

Page 41: Further Inputs

Safety engineering Device modules Further inputs 1.2.6 Further inputs AIS input The restart (when setting "acknowledged restart", (¶ 50)), after a stop function has been executed, requires an acknowledgement at AIS input: Positive signal pulse of 0.3 ... 10 s (terminal X82.3 or X82.4). ƒ... - Page 42 Safety engineering Device modules Safe speed measurement and position detection 1.2.7 Safe speed measurement and position detection For a safe speed and position detection, you must connect a safety−approved sin/cos encoder to terminal X8 (Sub−D). Alternatively, you can connect a 2−encoder system, consisting of motor encoder and position encoder from SM301 V1.3.

- Page 43 Safety engineering Device modules Safe speed measurement and position detection Note! As safe speed, the higher value which results from the comparison of the dual−channel speed information is used. The value "Tolerance − speed comparison" must be selected as low as possible. If a speed/position information fails during operation, this must be detected by the diagnostic function.

-

Page 44: Safe Speed Measurement And Position Detection

Protective measures: Prevent malfunctions by constructive measures. ƒ Use the motors and encoder systems with guaranteed features. Your Lenze ƒ contact partner helps you to find suitable systems. In the event of service, this must also be observed for the motor or the ƒ... - Page 45 Safety engineering Device modules Safe speed measurement and position detection Single−encoder concepts with resolvers Please observe during the configuration of such systems: If only one feedback system is used in connection with these safety applications, the applicable safety standard, IEC 61800−5−2 (Adjustable speed electrical power drive systems, Part 5−2: Safety requirements −...

- Page 46 "Sin/cos encoder" is used in place of the entries "Sin/cos encoder", "Absolute value encoder (Hiperface)" and "Absolute value encoder (EnDat)" of code C00422 of the standard device 9400. 2 Resolver þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer...

- Page 47 Number of increments of the sin/cos encoder used Setting range Information (min. value | unit | max. value) 16384 Lenze: 1 þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15430 Number of pole pairs of resolver...

- Page 48 9370 = 249A Selection of the stop function for emergency stop Selection list Information (Lenze setting printed in bold) 0 STO Safe torque off 1 SS1 Safe stop 1 þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer 1.3.1.2...

- Page 49 Stopping time for the SS1 and SS2 safety functions Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15306 SS1 mode...

-

Page 50: Safety Functions

Index: UNSIGNED_8 9275 = 243B C15300 Restart behaviour Behaviour for restart after functions have been cancelled Selection list Information (Lenze setting bold) 0 Acknowledged restart 1 Automatic restart Subcodes Information C15300/1 Restart - STO, SS1 C15300/2 Restart - SS2, SOS þ... - Page 51 Engineer depending on the runtime software licence. For this, the system block LS_SafetyModuleInterface must be integrated into the application. The safety module is implemented in the 9400 ServoPLC via the control configuration (SMI_SafetyModuleInterface). The control and status data of the safety module can be evaluated via the free programming and connected to further interface signals.

- Page 52 Safety engineering Safety functions Integration into the application of the controller 1.3.2.1 Control information The safety module transfers information via requested or active safety functions with the control word SMI_dwControl. The application in the standard device must evaluate the control word and execute the corresponding action. The following table shows the bit coding of the control word.

-

Page 53: Integration Into The Application Of The Controller

Safety engineering Safety functions Integration into the application of the controller Status word SMI_dnState Name Meaning Safe torque off is active. EC_STO Error stop category 0 is active (Safe Torque Off). EC_SS1 Error stop category 1 is active (Safe Stop 1). EC_SS2 Error stop category 2 is active (Safe Stop 2). -

Page 54: Safe Torque Off

Index: UNSIGNED_8 9275 = 243B C15300 Restart behaviour Behaviour for restart after functions have been cancelled Selection list Information (Lenze setting bold) 0 Acknowledged restart 1 Automatic restart Subcodes Information C15300/1 Restart - STO, SS1 C15300/2 Restart - SS2, SOS þ... - Page 55 Safety engineering Safety functions Safe torque off 1.3.3.2 Activation How to activate the function: "OFF state" at a safe input, the function of which has been assigned by parameter ƒ setting. Via a safety bus data telegram with corresponding content. ƒ...

- Page 56 Safety engineering Safety functions Safe stop 1 1.3.4 Safe stop 1 1.3.4.1 Description Safe Stop 1 / SS1 This function corresponds to a "Stop 1" according to EN 60204. The function monitors the reaching of the speed n = 0 (C15310) within an adjustable stopping time (C15305).

- Page 57 Safety engineering Safety functions Safe stop 1 SM301DIA_SS1 Input signal of the request of a safety function ON state OFF state Speed characteristic n of the motor Optional: Monitoring of the brake ramp as of SM301 V1.4 Time axis tx Action instant Monitored stopping time ––...

-

Page 58: Safe Stop 1

Stopping time for the SS1 and SS2 safety functions Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15306 SS1 mode... - Page 59 Safety engineering Safety functions Safe stop 1 1.3.4.2 Activation How to activate the function: "OFF state" at a safe input, the function of which has been assigned by parameter ƒ setting. Via a safety bus data telegram with corresponding content. ƒ...

- Page 60 Safety engineering Safety functions Safe stop 2 1.3.5 Safe stop 2 1.3.5.1 Description Safe Stop 2 / SS2 This function corresponds to a "Stop 2" according to EN 60204. This function serves to monitor the reaching of speed n = 0 within an adjustable stopping time (C15305).

- Page 61 Safety engineering Safety functions Safe stop 2 Note! The position of the motor is saved when the SOS state is entered. In the SOS state, relative position changes are added and compared to the permissible value in the parameter "Tolerance window Delta p=0". When the SOS state is quit, the maximum relative position change is displayed in code C15312.

-

Page 62: Safe Stop 2

Safety engineering Safety functions Safe stop 2 SM301DIA_SS2 Input signal of the request of a safety function ON state OFF state Speed characteristic n of the motor Speed−monitored up to SM301 V1.2 Position−monitored as of SM301 V1.3 Optional: Monitoring of the brake ramp as of SM301 V1.4 Time axis tx Action instant Monitored stopping time... - Page 63 Stopping time for the SS1 and SS2 safety functions Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15308 SS2 mode...

- Page 64 Safety engineering Safety functions Ramp monitoring SS1/SS2 1.3.6 Ramp monitoring SS1/SS2 1.3.6.1 Description From SM301 V1.4 onwards, the deceleration ramp for the stop functions SS1 and SS2 can be parameterised and monitored. If the parameterised ramp is not exceeded, the state changes to the parameterised stop function STO or SOS.

- Page 65 Stopping time for the SS1 and SS2 safety functions Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15310 Tolerance window (n=0)

-

Page 66: Ramp Monitoring Ss1/Ss2

0 % S−ramp time º 10 % deceleration 100 % S−ramp time º 30 % deceleration – In the Lenze setting of the S−ramp time, the deceleration time is 10 % of the set stopping time. EDS94AYAE EN 6.0... -

Page 67: Emergency Stop

9370 = 249A Selection of the stop function for emergency stop Selection list Information (Lenze setting printed in bold) 0 STO Safe torque off 1 SS1 Safe stop 1 þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer 1.3.7.2... - Page 68 Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer 1.3.8.2 Activation The function is activated or deactivated via the parameter value. A value > 0 activates the function, a value = 0 deactivates the function.

- Page 69 Safety engineering Safety functions Safe maximum speed 1.3.8.3 Fault analysis This consideration applies to the SMS and SLS functions. The evaluation and plausibility of the speed values is done in a cycle of 2 ms. If the defined limit values are exceeded, the parameterised error response is activated within a time slot of maximally one evaluation cycle.

-

Page 70: Safe Maximum Speed

Safety engineering Safety functions Safe maximum speed Note! In case of an error, the set limited speed will be exceeded. To assess the risk for the plant, you have to calculate the height of the maximum exceedance. Consider the following: internal response time ƒ... - Page 71 Safety engineering Safety functions Safely limited speed 1.3.9 Safely limited speed 1.3.9.1 Description Safely Limited Speed/SLS Safe Speed Monitor/SSM After the adjustable braking time (C15331/1 ... 4) has elapsed, the function monitors the compliance with the reduced speed N (C15330/1 ... 4). From SM301 V1.,1 four different speeds can be monitored (SLS1 ...

- Page 72 = 241C Safely monitored time for braking the drive to the limited speed set in C15330. Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms Subcodes Information C15331/1 SLS1: Braking time Nlim1 C15331/2 SLS2: Braking time Nlim2 (as of SM301 V1.1)

-

Page 73: Safely Limited Speed

Maximum time after an exceeded speed has been detected, after which the speed must be below the limit again. Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer 1.3.9.2 Activation How to activate the function: "OFF state"... - Page 74 Safety engineering Safety functions Safe direction 1.3.10 Safe direction 1.3.10.1 Description Safe Direction / SDI This function monitors the safe compliance with an adjustable direction of rotation. The monitoring also includes zero speed with a tolerance window. If the valid direction of rotation is not complied with, optionally SS1, SS2, or STO can be activated.

- Page 75 Safety engineering Safety functions Safe direction Note! If the SDI delay time (C15341) is parameterised greater than zero, either the "SDIxxx monitored" feedback must be evaluated (safety bus or safe output) or the risk analysis must show that the delay is not hazardous. This fact must e.g. be considered in the calculation of the safety clearance.

-

Page 76: Safe Direction

Safety engineering Safety functions Safe direction Codes Parameter: Name: Data type: Index: C15340 SDI: Monitoring − normal operation UNSIGNED_8 9235 = 2413 Setting of the monitoring of the direction of movement of the motor during normal operation Selection list Information (read only) 0 Both directions enabled (From SM301 V1.3) - Page 77 Furthermore, the set stopping time must be added to the response time until the defined operating status is reached. In the Lenze setting, the error response is set to SS1. EDS94AYAE EN 6.0...

- Page 78 Safety engineering Safety functions Safe operation mode selector 1.3.11 Safe operation mode selector 1.3.11.1 Description Operation Mode Selector / OMS The function provides a special operation of the drive. In the special operation the drive is stopped (status 2). The drive can be traversed in the special operation via an enable switch (status 3).

- Page 79 Safety engineering Safety functions Safe operation mode selector Note! If an error (e.g. a discrepancy error) occurs at a safe input to which the OMS function has been assigned, normal operation will be selected. This corresponds to the OFF state. The "ME" LED is blinking and STO is not activated.

-

Page 80: Safe Operation Mode Selector

Safety engineering Safety functions Safe operation mode selector SM301OMS01 Operating mode Normal Special Event Impact Impact State − − Request − OMS special operation via ... Change W State ‚ ... safe input Stop function ..is executed Activated monitoring functions remain active. - Page 81 Safety engineering Safety functions Safe operation mode selector 1.3.11.2 Conditions A safe input must be parameterised and interconnected as an operation mode selector. Select the operating mode for the LOW level (C15202) depending on the application. Only one operation mode selector can be connected and parameterised. The OMS bit of the safety bus must be deactivated (C15113).

- Page 82 Selection of the motion function in special operation Selection list Info (Lenze setting bold) 3 SLS1 Safely limited speed 1 (Lenze setting up to SM301 V1.3) 4 SLS2 Safely limited speed 2 (From SM301 V1.1) 5 SLS3 Safely limited speed 3 (From SM301 V1.1)

- Page 83 Safety engineering Safety functions Safe operation mode selector 1.3.11.3 Activation How to activate the function: Via a safe input which has been assigned to the function by parameterisation. In ƒ addition, the requested operating mode depends on OMS: Function at LOW level (C15202).

-

Page 84: Safe Enable Switch

The "operation mode selector" and "enable switch" functions may only be assigned to one of the four safe inputs. Selection list Information (Lenze setting printed in bold) 0 Free assignment Safety function set in C15032 1 Emergency stop Safe stop emergency function (SSE) - Page 85 Safety engineering Safety functions Cascading 1.3.13 Cascading 1.3.13.1 Description Cascading / CAS This function enables a synchronised shutdown of an entire drive system. The function can only be activated via parameter setting. For this purpose set the ƒ "CAS: cascading" parameter to "Cascading with SD−In4". With activated function: ƒ...

- Page 86 Safety engineering Safety functions Cascading SM301 SM301 SM301 E94AYAE E94AYAE E94AYAE X82.1 X82.2 X82.1 X82.2 X82.1 X82.2 24 V ext. 24 V ext. 24 V ext. X82.3 X82.4 X82.3 X82.4 X82.3 X82.4 SSP94SM365 Fig. 1−11 Wiring example E94AYAE Safety module SM301 as of V1.1 #1, #2, #n...

-

Page 87: Cascading

UNSIGNED_8 9540 = 2544 Safe cascading Selection list Information (Lenze setting bold) 0 No cascading (As of SM301 V1.1) 4 Cascading with SD−In4 þ Read access } Write access o CINH o PLC-STOP o No transfer C15036 CAS: Stop delay... -

Page 88: Safety Address

Safety engineering Safety address Safety address The safety address serves to clearly assign the safety modules of the SM301 type in systems with several drives. The address "0" is not permissible. Address switch The safety address can be set in the left part of the housing by means of the DIP switch 0. For setting the switch, use an appropriately small tool, e. - Page 89 Safety address Safety address parameterised in the safety module Setting range Information (min. value | unit | max. value) 65534 Lenze: 0 þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15112 Effective safety address UNSIGNED_16...

- Page 90 (as of SM301 V1.1) Note! A safety bus system (PROFIsafe) can only be operated via the upper module slot (MXI1) of the Servo Drive 9400. Note! The operation with PROFIsafe via PROFINET is only permissible according to the "PROFIsafe − Profile for Safety Technology" specification, version 2.x.

- Page 91 Safety engineering Safe bus interfaces PROFIsafe connection 1.5.1.2 Description Addressing In order that a data telegram reaches the correct node, an unambiguous PROFIsafe target address is required. If PROFIsafe has been selected as safety bus, the safety address is simultaneously accepted as PROFIsafe target address. This address must comply with the corresponding configuration of the safety PLC.

-

Page 92: Safe Bus Interfaces

Safety engineering Safe bus interfaces PROFIsafe connection PROFIsafe message − V2 mode (as of SM301 V1.1) Bit offset Byte offset PROFIsafe process data PROFIsafe output data/PROFIsafe input data Control byte or status byte CRC2 (Signature consists of PROFIsafe process data and PROFIsafe parameters and the consecutive number) Tab. - Page 93 Safety engineering Safe bus interfaces PROFIsafe connection Control byte For the PROFIsafe V1 mode only the indicated bits of the PROFIsafe control byte are supported: Assignment Byte − − − activate_FV − − − − Tab. 1−8 Structure of the PROFIsafe control byte in V1 mode Bit coding −...

- Page 94 Safety engineering Safe bus interfaces PROFIsafe connection Codes Parameter: Name: Data type: Index: C15113 S-Bus: Filter control data BITFIELD_32 9462 = 24F6 Bit coded selection of the active bit positions in the safety bus control data Value is bit coded: Information Bit 0 STO Safe torque off...

- Page 95 Safety engineering Safe bus interfaces PROFIsafe connection Parameter: Name: Data type: Index: C15115 S-bus: Control data display BITFIELD_32 9460 = 24F4 Display of safety bus control data after filtering via C15113 Value is bit coded: Information (From SM301 V1.2) Bit 0 STO Safe torque off Bit 1 SS1 Safe stop 1...

- Page 96 Safety engineering Safe bus interfaces PROFIsafe connection PROFIsafe input data The safety module transmits the PROFIsafe input data to the controller. This can be displayed via "Safety function status" (C15000). Bit coding of PROFIsafe input data Name Description STO active The STO function is active and the drive is safely switched to torque−free operation.

- Page 97 Safety engineering Safe bus interfaces PROFIsafe connection Status byte For the PROFIsafe V1 mode only the indicated bits of the PROFIsafe status byte are supported: Assignment Byte − − − FV_activated COM−Failure WD-Timeout COM−Failure CRC − − Tab. 1−13 Structure of the PROFIsafe status byte in V1 mode Bit coding −...

- Page 98 Safety engineering Safe bus interfaces PROFIsafe connection PROFIsafe parameters These PROFIsafe parameters and contents are supported: PROFIsafe parameters Name Description Valid contents F_Source_Add PROFIsafe source address of the safety PLC 0x01 ... 0xFFFE F_Dest_Add PROFIsafe target address of the safety module DIP switch: 0x01 ...

- Page 99 Safety engineering Safe bus interfaces PROFIsafe connection GSE file The GSE file contains all information on the configuration of the PROFIBUS system. This makes the integration easy and user−friendly. GSDML file The GSDML file contains all information on the configuration of the PROFINET system (As of SM301 V1.1).

- Page 100 1.6.1.1 Parameter setting with the Lenze »Engineer« PC software Safe parameter setting is supported by the Lenze PC software »Engineer« as of version 1.4. The parameter setting is described in the Software Manual for the SM301 safety module. Moreover, the software provides a comprehensive Online Help.

- Page 101 Safety engineering Safe parameter setting Parameter setting 1.6.1.2 Parameter set transfer from the memory module The safe parameter set transfer is supported by a safe parameter set stored in the memory module, e.g. in case of a module exchange. A valid parameter set with a corresponding module ID must be stored. ƒ...

-

Page 102: Safe Parameter Setting

The clear assignment of the safety address must be configured in the safety PLC. In drive systems without activated safety bus, individuality and correct assignment of the safety address must be checked. For this, use the Lenze »Engineer« PC software or an E94AZK... keypad. Codes... - Page 103 Safety engineering Error management Error states Error management 1.7.1 Error states Detected errors or maloperation of the drive are assigned to error statuses with definite reactions. The reaction can be co−ordinated with the complete drive via the error statuses. Error status Features System error Trouble...

- Page 104 Safety engineering Error management Logbook function in the controller 1.7.2 Logbook function in the controller Error states are saved in the logbook of the standard device. The following is entered: Type of response (e.g. trouble, warning, or information) to the event ƒ...

-

Page 105: Error Management

Safety engineering Error management Logbook function in the SM301 Parameter: Name: Data type: Index: C15892 Log time UNSIGNED_32 8683 = 21EB Time of log entry. Display area Information (min. value | unit | max. value) 4294967295 (From SM301 V1.4) Subcodes Information C15892/1 Log time n... - Page 106 Safety engineering Response times Response times In order to detect the response time to a safety function the entire system must be considered. The following is relevant: Response time of the connected sensors. ƒ Input delay of the safety inputs. ƒ...

- Page 107 Safety engineering Response times Response times of the inputs 1.8.1 Response times of the inputs Response time to an event in the sensors Time interval (Fig. 1−14) [ms] Response time of the sensors according to manufacturer information Input delay of the safe inputs C15034: 0 ...

-

Page 108: Response Times

Safety engineering Response times Response time of encoder monitoring Response time to a PROFIsafe control word (PROFIsafe output data) Time interval (Fig. 1−14) [ms] Processing time in the safety PLC must be calculated PROFIsafe cycle time according to manufacturer information Processing time in drive−based safety Safety function starts after ... - Page 109 Safety engineering Acceptance Description Acceptance 1.9.1 Description The machine manufacturer must check and prove the operability of the safety functions used. Inspector The machine manufacturer must authorise a person with expertise and knowledge of the safety functions to carry out the test. Test report The test result of every safety function must be documented and signed by the inspector.

- Page 110 Safety engineering Acceptance Periodic inspections 1.9.2 Periodic inspections The correct sequence of the safety−oriented functions must be checked in periodic inspections. The risk analysis or applicable regulations determine the time distances between the tests. The inspection interval should not exceed one year. EDS94AYAE EN 6.0 Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com...

- Page 111 This chapter contains all parameters of the SM301 safety module in numerically ascending order. Standard values are printed in bold type or with the "Lenze:" addition. ƒ The write access is marked with } if the codes can only be set via the safe ƒ...

- Page 112 Safety engineering Appendix Module internal codes Parameter: Name: Data type: Index: C15000 Status of safety functions BITFIELD_32 9575 = 2567h Bit coded status word of the safety functions Value is bit coded: Information Bit 0 STO active Safe torque off Bit 1 SS1 active Safe stop 1 Bit 2 SS2 active...

-

Page 113: Appendix

Safety engineering Appendix Module internal codes Parameter: Name: Data type: Index: C15003 Command status UNSIGNED_16 9572 = 2564 Status of the current command. In high byte the command is repeated. In low byte the status is displayed: 0x00: no command 0x01: command executed 0x02:... - Page 114 The "operation mode selector" and "enable switch" functions may only be assigned to one of the four safe inputs. Selection list Information (Lenze setting printed in bold) 0 Free assignment Safety function set in C15032 1 Emergency stop Safe stop emergency function (SSE)

- Page 115 Maximum time in which both channels of a safe input may have non−equivalent states without the safety engineering causing an error response. Setting range Information (min. value | unit | max. value) 30000 Lenze: 10, increment: 2 ms Subcodes Information C15033/1 SD-In1 discrepancy time...

- Page 116 UNSIGNED_8 9540 = 2544 Safe cascading Selection list Information (Lenze setting bold) 0 No cascading (As of SM301 V1.1) 4 Cascading with SD−In4 þ Read access } Write access o CINH o PLC-STOP o No transfer C15036 CAS: Stop delay...

- Page 117 Safety engineering Appendix Module internal codes Parameter: Name: Data type: Index: C15051 SD-Out condition BITFIELD_32 9524 = 2534 Bit coded selection of the conditions for switching the safe output. Value is bit coded: Information Bit 0 STO active Safe torque off Bit 1 STO active neg.

- Page 118 SD−Out logic function UNSIGNED_8 9520 = 2530 Selection of the logic operation for the switching conditions to be evaluated Selection list Information (Lenze setting bold) 0 OR 1 AND Subcodes Information C15055/1 SD−Out1 logic function þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer EDS94AYAE EN 6.0...

- Page 119 9475 = 2503 Configuration of the safety bus Selection list Information (Lenze setting bold) 0 No safety bus 1 PROFIsafe / PROFIBUS 2 PROFIsafe / PROFINET (As of SM301 V1.1) þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15101 Display −...

- Page 120 Safety engineering Appendix Module internal codes Parameter: Name: Data type: Index: C15113 S-Bus: Filter control data BITFIELD_32 9462 = 24F6 Bit coded selection of the active bit positions in the safety bus control data Value is bit coded: Information Bit 0 STO Safe torque off Bit 1 SS1 Safe stop 1...

- Page 121 Selection of the motion function in special operation Selection list Info (Lenze setting bold) 3 SLS1 Safely limited speed 1 (Lenze setting up to SM301 V1.3) 4 SLS2 Safely limited speed 2 (From SM301 V1.1) 5 SLS3 Safely limited speed 3 (From SM301 V1.1)

- Page 122 Stopping time for the SS1 and SS2 safety functions Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15306 SS1 mode...

- Page 123 Setting range Information (min. value | unit | max. value) 16000 Lenze: 1, deactivate: 0 þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer EDS94AYAE EN 6.0 Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com...

- Page 124 = 241C Safely monitored time for braking the drive to the limited speed set in C15330. Setting range Information (min. value | unit | max. value) 30000 Lenze: 0, increment: 2 ms Subcodes Information C15331/1 SLS1: Braking time Nlim1 C15331/2 SLS2: Braking time Nlim2 (as of SM301 V1.1)

- Page 125 SLS: Permissible direction of movement UNSIGNED_8 9242 = 241A Permissible direction of movement during SLS monitoring Selection list Information (Lenze setting printed in bold) 0 Both directions enabled 1 Positive direction enabled 2 Negative direction enabled Subcodes Information C15333/1 SLS1: Permissible direction of movement (from SM301 V1.3)

- Page 126 "Sin/cos encoder" is used in place of the entries "Sin/cos encoder", "Absolute value encoder (Hiperface)" and "Absolute value encoder (EnDat)" of code C00422 of the standard device 9400. 2 Resolver þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer...

-

Page 127: Response Time Of Encoder Monitoring

Number of increments of the sin/cos encoder used Setting range Information (min. value | unit | max. value) 16384 Lenze: 1 þ Read access } Write access o Controller inhibit o PLC-STOP o No transfer C15430 Number of pole pairs of resolver... - Page 128 1 Warning 2 Trouble þ Read access o Write access o Controller inhibit o PLC-STOP o No transfer C15801 Error history UNSIGNED_16 8774 = 2246 for Lenze service Selection list Information (read only) (As of SM301 V1.2) − − −...

- Page 129 C15822 Service code INTEGER_16 8753 = 2231 for Lenze service: Minimum differences between actual speed value and monitored ramp. Display area Information (min. value | unit | max. value) −16000 16000 The value is kept until the ramp monitoring is restarted.

- Page 130 Safety engineering Appendix Module internal codes Parameter: Name: Data type: Index: C15893 Log state BITFIELD_64 8682 = 21EA Bit 4 SS1 via SD−In SS1 was triggered via a safe input. Bit 5 SS1 via S−bus SS1 was triggered via the safety bus. Bit 6 SS1 through error SS1 was triggered through an error.

- Page 131 Safety engineering Appendix Module internal codes Parameter: Name: Data type: Index: C15893 Log state BITFIELD_64 8682 = 21EA Bit 48 FailSafeValues via control word Safe replacement values on the safety bus were activated via the control word. Bit 49 FailSafeValues through error Safe replacement values on the safety bus were activated through an error.

-

Page 132: Description

Error type/response/ Note Error number Internal Replace safety module. 1 0x01 Internal error, STO is active Consultation with Lenze is 2 0x02 Internal error, SS1 is active required. 3 0x03 Internal error, SS2 is active Communication − standard device 16 0x10 Communication error −... - Page 133 Safety engineering Appendix Module error messages Field Description Description Error type/response/ Error type/response/ Note Note Error number PROFIsafe 64 0x40 F_Dest_Add does not equal F address 65 0x41 F_Dest_Add = 0 or FFFFhex 66 0x42 F_Source_Add = 0 or FFFFhex PROFIsafe parameter 67 0x43 F_WD_Time is 0 msec...

-

Page 134: Module Error Messages

Safety engineering Appendix Module error messages Field Description Description Error type/response/ Error type/response/ Note Note Error number Safety functions 97 0x61 SS1/SS2: Stopping time exceeded Warning/STO (The drive has not reached zero speed within the stopping time.) 98 0x62 SLS1: Nlim1 exceeded Warning/response can be (The drive has exceeded the limited speed.) 99 0x63... - Page 135 Safety engineering Appendix Module error messages Field Description Description Error type/response/ Error type/response/ Note Note Error number Test functions − inputs 144 0x90 Stuck at High SD−In1, channel A Trouble/− (Short circuit (High) SD−In1: OFF state 145 0x91 Stuck at High SD−In1, channel B 146 0x92 Stuck at High SD−In2, channel A Trouble/−...

- Page 136 Safety engineering Total index 1.11 Total index effective safety address (C15112), 95 , 108 , 125 Address code, 94 Emergency stop, 67 Address switch, 94 Error, current error type (C15800), 134 Application as directed, 8 Error history (C15801), 134 Application range, 16 Error states, 109 Application, as directed, 8 Applications according to...

- Page 137 Safety category, 19 Safety engineering, 3 − safety functions, 48 Ramp monitoring SS1/SS2, 64 − with L−force | 9400, 5 Residual hazards, 9 Safety functions, 5 , 48 − safety instructions, during operation, 9 Response (n>Nlim) (C15332), 72 , 130 Safety instructions, during operation, 9 Response (n>Nmax) (C15321), 68 , 130...

-

Page 138: Total Index

Safety engineering Total index SDI:Tolerance threshold (C15342), 76 , 131 Sensors, Overview ..., 11 Terms, definitions, 6 Service code (C15805), 134 Time − RTC parameter setting (C15014), 119 Service code (C15810), 134 Time − sec. parameter setting (C15015), 119 Service code (C15821), 135 Time for parameter set creation (C15013), 119 Service code (C15822), 135 Tolerance of speed comparison (C15411), 47 , 133...

Need help?

Do you have a question about the 9400 and is the answer not in the manual?

Questions and answers