Table of Contents

Advertisement

Quick Links

Everest

Mobile Cleaning Unit

Operating Instructions (ENG)

MODELS:

EVEREST 650

HIGH PRESSURE

EVEREST 650

LOW PRESSURE

EVEREST 408

HIGH PRESSURE

EVEREST 408

LOW PRESSURE

EVEREST 650 E-IDLE™

HIGH PRESSURE

EVEREST 650 E-IDLE™

LOW PRESSURE

EVEREST 408 E-IDLE™

HIGH PRESSURE

EVEREST 408 E-IDLE™

LOW PRESSURE

From Serial Number (Ref No1*)

*See Serial Number Page in spare

parts list or call manufacturer

86411100-B

1.001-145.0

1.001-146.0

1.001-151.0

1.001-152.0

1.001-158.0

1.001-159.0

1.001-160.0

1.001-161.0

03/24/17

Advertisement

Table of Contents

Summary of Contents for Prochem EVEREST 650

- Page 1 HIGH PRESSURE 1.001-145.0 EVEREST 650 LOW PRESSURE 1.001-146.0 EVEREST 408 HIGH PRESSURE 1.001-151.0 EVEREST 408 LOW PRESSURE 1.001-152.0 EVEREST 650 E-IDLE™ HIGH PRESSURE 1.001-158.0 EVEREST 650 E-IDLE™ LOW PRESSURE 1.001-159.0 EVEREST 408 E-IDLE™ HIGH PRESSURE 1.001-160.0 EVEREST 408 E-IDLE™ LOW PRESSURE 1.001-161.0...

-

Page 3: Machine Data Label

PROCHEM.IF Warranty Registration Thank you for purchasing a Prochem Legend Group product. Warranty registration is quick and easy. Your registration will allow us to serve you better over the lifetime of the product. To register your product go to : http://www.prochem.com/WarrantyRegistration.aspx... -

Page 4: Table Of Contents

Winterizing Your Unit ..... . . 42 Removing Anti-freeze From The Unit ..43 86411100 Manual Operators - Everest E-Idle Prochem... - Page 5 Pressure Regulators ......53 Troubleshooting ......54 86411100 Manual Operators - Everest E-Idle Prochem...

-

Page 6: Receiving Your Unit

8. 50 ft. water supply hose with quick connect. from manufacturer. 9. Installation bolting kit. 10. Installation mounting plates. 11. Operation and service manuals for engine, solution pump, and vacuum pump. 12. Hose clamps for vacuum hoses. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 7: How To Use This Manual

It contains replacement parts side approximately where shown. numbers needed for ordering future parts. NOTE: The part number for this manual is in the lower right corner of the cover page. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 8: Safety

Keep sparks, open flames, and other sources of ignition away from the battery at all times. Keep batteries out of the reach of children. Remove all jewelry when servicing batteries. 86411100 Manual Operators - Everest E-Idle Prochem... - Page 9 Do not modify this unit in any manner. Improper modification can cause severe personal injury or fatality. CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. READ AND SAVE THESE INSTRUCTIONS 86411100 Manual Operators - Everest E-Idle Prochem...

- Page 10 à l'écart des étincelles, de la flamme nue et de toute autre source d'inflammation en tout temps. Garder les batteries hors de la portée des enfants. Enlever tous les bijoux au moment de procéder à l'entretien des batteries. 86411100 Manual Operators - Everest E-Idle Prochem...

- Page 11 AVERTISSEMENT EN VERTU DE LA PROPOSITION 65 DE L'ÉTAT DE LA CALIFORNIE : L'échappement du moteur de ce produit contient des agents chimiques connus, dans l'État de la Californie, comme pouvant causer le cancer, des anomalies congénitales ou d'autres problèmes liés à la reproduction. CONSERVER CES INSTRUCTIONS 86411100 Manual Operators - Everest E-Idle Prochem...

-

Page 12: Hazard Intensity Level

In Flammable or Explosive areas. In areas with possible falling objects. WHEN SERVICING MACHINE: Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use Prochem approved replacement parts. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 13: Degrés De Risques En Cas De Danger

LORS DE L’ENTRETIEN DE LA MACHINE: Éviter les parties amovibles. Ne pas porter de vêtements amples, tels que des vestes, des chemises ou des vêtements avec manches lors de l’utilisation de la machine. Utiliser les pièces détachées homologuées. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 14: Safety Labels

Front Lower Panel Decal Caution Label (Lower Pressure) 86186510 86410060 Front Lower Panel Decal (High Pressure) 86410070 Caution Tag 86186500 Warning Label 86412290 Warning Label 86412300 Warning Label Caution Label 86186520 86012220 86411100 Manual Operators - Everest E-Idle Prochem... - Page 15 Notes 86411100 Manual Operators - Everest E-Idle Prochem...

-

Page 16: Installation

Electric or hydraulic brakes should be provided, and a strict compliance with any State and Federal vehicle laws must be maintained. 3. The vehicle tires should have a load rating above the combined vehicle and unit weight. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 17: Lifting Unit Onto Vehicle

NOTE: For individuals who wish to make an screws and tighten them until console and waste engineering layout prior to positioning unit, refer to tank are firmly secured to vehicle floor. “Dimensional Data” illustrations for waste tank and console dimensions. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 18: Layout With 100 Gallon Waste Tank

6 5 8 " 1 1 2 " 1'-9 1 2 " 5'-6 1 2 " 3'-11 1 8 " 3'-4 3 4 " 2'-8 1 2 " 3'-2 1 16 " 4'-5 13 16 " 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 19: Waste Tank To Console Connection

4. Do not connect the power cords to the truckmount console wiring harness until installation is complete. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 20: Van Bulkhead Installation

CLAMPS AT THIS CONNECTION. HOSEBARB FUEL HOSE LOCTITE BULKHEAD ADAPTER TO CONSOLE BULKHEAD GASKET 5/8" DIA HOLE VEHICLE FLOOR BULKHEAD GASKET BULKHEAD NUT HOSEBARB FUEL HOSE FROM FUEL PRESSURE REGULATOR HOSE MOUNTING CLAMPS USE AS NEEDED 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 21: Fuel Supply & Return Line Installation

1/4" RETURN HOSE FROM VEHICLE FUEL SUPPLY FUEL FLOW ELECTRICAL FUEL PUMP ASSEMBLY FUEL FILTER ELECTRICAL CORDS 5/16" SUPPLY HOSE BUSHINGS BULKHEAD CONNECTOR 5/16" SUPPLY HOSE FRONT OF VAN HOSE MOUNTING CLAMP USE AS NEEDED 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 22: Battery Connection

TOUJOURS déconnecter d’ABORD la borne négative (-). 1. Attach the red positive (+) battery cable from the console starter solenoid to the positive (+) terminal on the battery and tighten the holding nut. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 23: Technical Specifications

(Model 408 & HP 408) Console weight (with waste tank & waste tank accessories) 1300 lbs (Model 650 & HP 650) Torque Values Engine pulley 360 inch lbs 30 foot/lbs Vacuum pump hub 300 inch/lbs 25 foot/lbs 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 24: Water Requirements

NOT covered under If you require a water softener, your dealer has a model the warranty. to meet your needs. Please contact your nearest distributor for information, price, and availability. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 25: Fuel Requirements

This unit is not compatible with E-85 optimum results with this unit, we recommend using the fuel. PROCHEM line of chemicals. For information on using the cleaning compounds, refer to the PROCHEM Engine Oil Requirements chemical manual. -

Page 26: Emission Control Information

When referring to an engine for assistance from your labels are located on the valve cover of the engine near dealer, Prochem, or ZPP please identify your engine by the oil fill cap, and on the side of the catalytic converter. -

Page 27: Trouble Codes

P0183 Gasoline Fuel Temp High Voltage P0217 ECT higher than engine shutdown threshold P0219 Engine Over speed Condition P0221 TPS1 voltage higher than TPS2 voltage P0222 Throttle Position Signal 2 low voltage 520251 86411100 Manual Operators - Everest E-Idle Prochem... - Page 28 5V Reference #2 voltage low 1080 P0653 5V Reference #2 voltage high 1080 P0685 Power relay coil open 1485 P0686 Power relay short to GND 1485 P0687 Power relay short to 12V 1485 86411100 Manual Operators - Everest E-Idle Prochem...

- Page 29 CPS = Crank Position Sensor MIL = Malfunction Indicator Light MAP = Manifold Absolute Pressure TPS1 = Throttle Position Sensor Pcode= Powertrain Code EGO = Exhaust Gas Oxygen ECT = Engine Coolant Temperature 86411100 Manual Operators - Everest E-Idle Prochem...

-

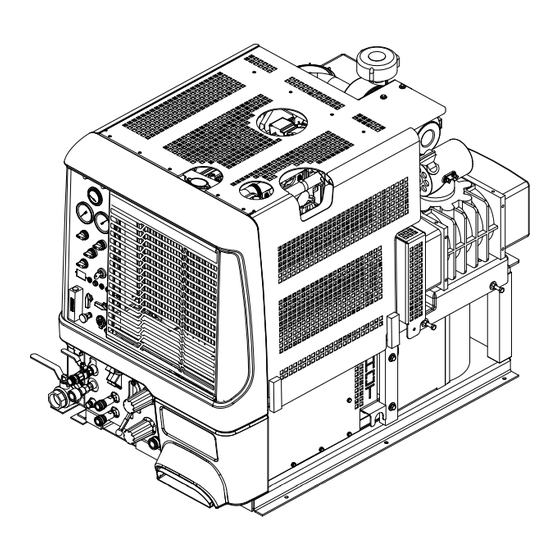

Page 30: Components

Operations Components UPPER CONTROL PANEL FILTER BOX LOWER CONTROL PANEL LOWER CONTROL PANEL 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 31: Lower Control Panel

This lever directs hot engine and blower exhaust (This valve must be maintained in accordance with gases through or around the heat exchangers. this manuals maintenance table.) 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 32: Upper Control Panel

Operations Upper Control Panel 86411100 Manual Operators - Everest E-Idle Prochem... - Page 33 When machine is running let off the switch and engine will continue to run. To turn power off, rotate key counter clockwise to stop position, engine will then stop. 86411100 Manual Operators - Everest E-Idle Prochem...

-

Page 34: Filter Box

Filter Box 1. Vacuum Inlets The vacuum inlets serve as the connecting point for vacuum hoses. 2. Waste Tank Drain This allows the waste tank to be emptied. Must be closed for operation. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 35: Water Pumping And Heat Transfer System

86411100 Manual Operators - Everest E-Idle Prochem... - Page 36 Operations 86411100 Manual Operators - Everest E-Idle Prochem...

- Page 37 Operations 86411100 Manual Operators - Everest E-Idle Prochem...

-

Page 38: Chemical Injection System

HOT WATER SOLUTION OUTLET FLOW SETUP MANIFOLD VALVE WASTE TANK CHEMICAL METERING CHECK VALVE VALVE CHEMICAL SELECTOR VALVE CHEMICAL PUMP CHECK VALVE FLOWMETER CHEMICAL CONTAINER CHEMICAL FLOW INLET CHEMICAL PRIME STRAINER SOLUTION FLOW 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 39: Vacuum System

The air is then filtered and rushes into the vacuum pump. VACUUM SYSTEMS EXHAUST OUTLET VACUUM INLET HEATER COIL #1 HEATER COIL #2 PRE-FILTER BOX HEATER COIL #3 VACUUM PUMP SILENCER WASTE TANK FILTER 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 40: Pre-Run Inspection / Setup

NOTE: Never use your waste pump outlet hose as a water inlet hose. Use only clean hoses for water inlet. 2. Turn the water supply faucet on. The water will fill the water box. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 41: Priming The Chemical Pump

Always dispose of waste empty the waste tank before proceeding. If in accordance with Local, State, and Federal laws. shutdown occurs due to foam created by chemicals used, add Prochem defoamer. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 42: Upholstery Cleaning

à haute pression Prochem. possible, contact medical personnel immediately. Prochem offre une lance à double cylindre. This machine is to be used by trained cleaning Contacter votre revendeur Prochem pour des professionals only. -

Page 43: Operation

Les appareils avec des réservoirs d'eau auxiliaires doivent être entreposés dans un local 7. Operate under normal low-pressure instruction or chauffé lorsqu'ils ne sont pas utilisés. follow normal shutdown procedures. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 44: Winterizing Your Unit

8. Turn the solution pump switch OFF. Attach the winterizing loop hose with attachment (P/N 86260700) to the bottom solution outlet connection and the water inlet connection. Turn the solution pump switch ON. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 45: Removing Anti-Freeze From The Unit

Lors de l'élimination de l'antigel usé, respecter toutes les lois et tous les règlements locaux. Ne pas vider sur le sol ou dans des réseaux de collecte des eaux pluviales. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 46: Service Schedule

200 hrs Check radiator hoses and clamp tightness Fuel Pump 200 hrs Check hose connections and wire connections Chemical Valves 200 hrs Inspect and/or adjust packing nuts Engine 250 hrs Service air cleaner elements* 86411100 Manual Operators - Everest E-Idle Prochem... - Page 47 ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****If using AEON PD-XD synthetic lubricant, 1500 hours or every 2 years, whichever comes first. ****** Replace after 2 years or 2000 hours, whichever comes first. 86411100 Manual Operators - Everest E-Idle Prochem...

-

Page 48: Key Checkpoints

To keep your chemical system functioning properly, follow the chemical pump and solution outlet maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 49: Engine

15W-50 and 20W-50. NOTE: Using less than service class SH oil or extending oil change intervals longer than recommended can cause engine damage. Engine oil capacity is approximately 3.5 quarts (3.3Liters) including filter. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 50: Vacuum Pump

5. Vacuum pump lubrication is vital to performance of NOTE: AEON PD-XD is the oil that PROCHEM puts the pump. Failure to follow the maintenance in the vacuum pump at the factory. Topping off or... -

Page 51: Vacuum Pump Drive Belts

5. Check for pulley groove wear, clean belts and pulley grooves, check for worn belts, proper belt tension, and pulley alignment after the first 25 hours and then again at 100 hours. Check for belt ride in the groove. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 52: Solution Pump Drive Belt

The strainer basket located inside the pre-filter box should be removed and cleaned whenever it is full of 5. Reassemble as shown in Parts Section - Solution debris. This should be done at the end of each job. Outlet. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 53: Check Valve (Outlet)

Re-install radiator cap. these requirements. Pressure wash hoses must be rated at 4000 PSI. Shutdown unit. Check radiator overflow bottle. Add coolant to proper "cold" level. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 54: General Service Adjustments

5/16" Allen wrench. DO NOT over-tighten seat. NOTE: Improper seating of the check valve poppet, damaged spring or o-rings will cause poor operation of the chemical system. 6. Lubricate the o-rings with o-ring lubricant and rein- stall. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 55: Packing Nut Adjustment For Chemical Valves

2. If the pressure regulator requires adjustment, turn the adjusting knob (while observing the pressure gauge on the control panel) until the desired pressure is obtained. 86411100 Manual Operators - Everest E-Idle Prochem... -

Page 56: Troubleshooting

Defective quick-connect on one or more of Replace defective quick-connect(s) on high the high-pressure hoses. pressure hose(s). Cleaning tool valve is malfunctioning. Repair or replace valve. Hose inner lining is constricted. Remove restriction or replace hose. 86411100 Manual Operators - Everest E-Idle Prochem... - Page 57 Internal leak in chemical valve causing Tighten valve packing nut (see "General Service continual flow through prime tube returning Adjustments" section in this manual). Replace to waste tank. valve, if necessary. Flow setup valve open. Close valve. 86411100 Manual Operators - Everest E-Idle Prochem...

- Page 58 Maintenance Manual. DO NOT restart the down, due to insufficient oil pressure. engine until the cause is determined and corrected. No ignition in the engine or engine is Refer to the ZPP416 Engine Operation and malfunctioning. Maintenance Manual. 86411100 Manual Operators - Everest E-Idle Prochem...

- Page 59 Loose connection of vacuum line Reconnect vacuum hoses. Tear in vacuum hose. Replace vacuum hose. All wiring connections are done, vacuum line is Bad or faulty PCB. Replace PCB. connected and the E-Idle™ does not function. 86411100 Manual Operators - Everest E-Idle Prochem...

Need help?

Do you have a question about the EVEREST 650 and is the answer not in the manual?

Questions and answers