Summary of Contents for Prochem PEAK

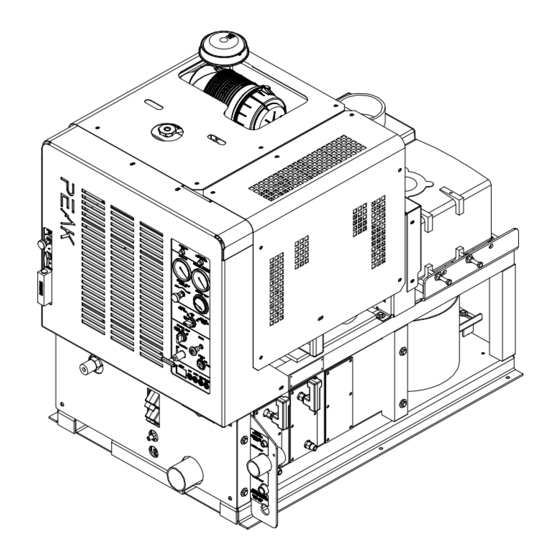

- Page 1 Operating Instructions (ENG) MODELS: PEAK Read instructions before operating the machine. 86037220 03/12/09 PRV NO. 980116...

-

Page 3: Machine Data Log/Overview

RETURNED TO YOUR DEALER. PROFESSIONAL CHEMICALS CORPORATION 325 SOUTH PRICE ROAD CHANDLER, ARIZONA 85224 Information in this document is subject to change without notice and does not represent a commitment on the part of Professional Chemicals Corporation. PEAK 86037220 02/12/07... -

Page 4: Table Of Contents

Shutdown and Daily Maintenance ....3-13 Chemical And Heat Bypass Valves..4-9 De-flooding Operations....... 3-13 Packing Nut Adjustment Freezing Protection........3-13 (Chemical Metering & Selector Valves) ..4-10 Winterizing Your Unit ........3-14 Pressure Regulator .........4-10 Removing Anti-freeze from Unit....3-15 Troubleshooting ........4-11 PEAK 86037220 02/12/07... -

Page 5: Table Of Contents

Water Tank, Dual With Demand Pump (Optional) ......5-53 Water Tank-Demand Pump (Optional) ..5-55 Auxiliary Water Tank With Pump ....5-57 Hose Reel (Optional) ........5-59 Wiring Diagram ........... 5-61 Hose Diagram ..........5-62 Warranty ............. 5-64 PEAK 86037220 02/12/07... -

Page 6: Receiving Your Unit

The dealer is also responsible for initial 9. Installation mounting plates. training of your operators and maintenance personnel in the proper operation and 10. Operation and service manual for engine, water maintenance of this unit. pump, and vacuum pump. PEAK 86037220 02/12/07... -

Page 7: How To Use This Manual

KIT INSTRUCTIONS which came with the kit. It contains replacement parts numbers needed for ordering future parts. NOTE: The number on the lower left corner of the front cover is the part number for this manual. PEAK 86037220 02/12/07... -

Page 8: Safety Instructions

Always wear hearing protection when unit is running. Always comply with local noise ordinance when operating units. PEAK 86037220 02/12/07... - Page 9 Use only ProChem supplied fuel installation kits. Ensure to use the kit specific for the truckmount model and van model being used. When traversing the vehicle floor with fuel lines, always use a bulkhead adapter. This will prevent leakage and ensure that the hose is not punctured by vehicle vibration abrasion.

-

Page 10: Hazard Intensity Level

6. DRAIN WASTE TANK INTO AN APPROVED SOURCE AND RINSE WITH CLEAN WATER. SOLUTION OUTLET With warning labels 86179290 PRV NO. 500875 (2 Warning labels required (1) Top of belt guard (1) Top of rear engine panel Warning label 86186520 PRV NO. 500769 Caution label 86186530 PRV NO. 500770 PEAK 86037220 02/12/07... -

Page 11: Technical Specifications

Recommended floor tool tip sizing not exceed a total of “.045”. Using larger jet sizes on your cleaning unit may reduce cleaning temperatures. Example: Tri-jet wand uses three 95015 jets (95° spray angle w/ 015 orifice). 015 X 3 = 045 Upholstery tool jet size: 80015 Stair tool jet size: 9502 PEAK 86037220 02/12/07... -

Page 12: Installation Requirements

5000 feet, you should order the Kohler high altitude gasoline additives. We recommend the use of clean, kit Part #48102. fresh, unleaded gasoline intended for automotive use. High octane gasoline should NOT be used with the engine on this unit. PEAK 86037220 02/12/07... -

Page 13: Components

WATER REQUIREMENTS If you require a water softener, PROCHEM has a Hard water deposits will adversely affect the model to meet your needs. Please contact your plumbing and heat exchange systems on this unit. - Page 14 3. SET ENGINE THROTTLE AT IDLE POSITION AND OPEN TEMP CONTROL VALVE, ALLOWING THE WATER TEMPERATURE TO COOL DOWN. 4. TURN OFF IGNITION SWITCH. 5. DISCONNECT ALL HOSES AND TOOLS. 6. DRAIN WASTE TANK INTO AN APPROVED SOURCE AND RINSE WITH CLEAN WATER. SOLUTION OUTLET PEAK 86037220 02/12/07...

- Page 15 7. WASTE PUMPOUT AND AUXILIARY WATER PUMP SWITCH This four-position switch is for activating the waste pumpout device. It also serves to activate the fresh water transfer pump. For turning on pumps, rotate clockwise. For turning off pumps, rotate counter clockwise. PEAK 86037220 05/22/08...

- Page 16 The valve is turned off by to the wand. The chemical check valve prevents rotating the knob clockwise and opened by chemicals from traveling up-stream into the turning the knob counter clockwise. solution system of the unit. PEAK 86037220 02/12/07...

-

Page 17: Water Pumping And Heat Transfer System

This allows the engine coolant to travel in a counter rotating direction to the cleaning water during the exchange process creating a very efficient transfer of heat out of the engine and into the cleaning solution. PEAK 86037220 02/12/07... - Page 18 OPERATION WATER PUMPING AND HEAT TRANSFER SYSTEM PEAK 86037220 02/12/07...

-

Page 19: Chemical Injection System

The chemical is picked up from the container and fed through the flow meter to the chemical pulse pump where it is pressurized. PEAK 86037220 05/22/08... -

Page 20: Vacuum System

The air is then filtered and rushes into the vacuum pump. VACUUM INLET HEATER COIL #1 HEATER COIL #2 VACUUM GAUGE LUBRICATION VACUUM SILENCER PUMP VACUUM RELIEF VALVE LEVEL SENSOR WASTE TANK STRAINER FILTER 3-10 PEAK 86037220 02/12/07... -

Page 21: Pre-Run Inspections

Connect the hose to the water supply faucet. NOTE: Never use your waste pump outlet hose as a water inlet hose. Use only clean hoses for water inlet. 2. Turn the water supply faucet on. The water will fill the water box. 3-11 PEAK 86037220 05/22/08... -

Page 22: Priming The Chemical Pump

DO NOT use a hose smaller than 5/8" I.D. NEVER use your automatic waste pump outlet hose as a water inlet hose. PEAK 86037220 05/22/08 3-12... -

Page 23: Upholstery Cleaning

3. Shut off water pump. 4. Begin de-flooding operations. 5. Under almost all conditions, the unit will sufficiently cool itself. If you find yourself operating in extreme heat, crack the bypass valve slightly to provide additional cooling. 3-13 PEAK 86037220 02/12/07... -

Page 24: Winterizing Your Unit

9. Now turn the chemical valve and flow simulator valves to the open position, making certain that the flow meter indicates flow and that all anti- freeze drains out of the chemical hose into an approved container, after 30 seconds, turn off both valves. 3-14 PEAK 86037220 05/22/08... -

Page 25: Removing Anti-Freeze From Unit

6. Open the tool valves and drain the anti-freeze local laws and regulations. Do not drain onto into an approved container until the flow is clear the ground or into storm drainage systems. and all anti-freeze is purged from the tools and hoses. 3-15 PEAK 86037220 02/12/07... -

Page 26: Maintenance

Engine 200 hrs Check radiator hoses and clamp tightness Fuel Pump 200 hrs Check hose connections Engine 200 hrs Check spark plugs for carbon deposits and proper gap Chemical Valves 200 hrs Inspect and/or adjust packing nuts PEAK 86037220 02/12/07... - Page 27 ***Change engine crankcase oil and filter after the first 50 hours ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****If using AEON PD synthetic lubricant, 4500 hours or every 2 years, whichever comes first PEAK 86037220 02/12/07...

-

Page 28: Maintenance Schedule

To keep your chemical system functioning properly, follow the chemical pump and solution outlet maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer. PEAK 86037220 02/12/07... -

Page 29: Engine

NOTE: Using less than service class SF or SG service or repair is required, contact an oil or extending oil change intervals longer than authorized Kohler Service Center. You will need recommended can cause engine damage. to provide the serial number of the engine. PEAK 86037220 02/12/07... -

Page 30: Vacuum Pump

PD will last a many times longer than a premium mineral oil. NOTE: AEON PD (Part# 86189090 PRV NO. 05-008039) is the oil which PROCHEM puts in the vacuum pump at the factory. Topping off or adding petroleum oil to synthetic oil is NOT recommended. -

Page 31: Water Pump

4. Check for pulley groove wear, clean belts and pulley grooves, check for worn belts, proper belt tension, and pulley alignment after the first 25 hours and then again at 100 hours. Check for belt ride in the groove. PEAK 86037220 02/12/07... -

Page 32: Water Pump Drive Belt

Debris can For the procedure, see the "General Service collect around the hinge of the float valve. Check Adjustments” section in this manual for details. the float valve for debris at least once a month. PEAK 86037220 02/12/07... -

Page 33: Nitrogen Accumulator

NITROGEN ACCUMULATOR ENGINE COOLANT REPLACEMENT The nitrogen accumulator is pressurized to 250 PSI Annually the coolant in the Prochem machine should and must be replaced periodically. The accumulator be replaced. This coolant is an integral part of the cannot be repaired or recharged. We recommend heating system and needs to be maintained as any replacement every 1000 hours of use. -

Page 34: Engine Speed

See the “Illustrated Parts Listing” for a parts break-down on the chemical pump. DRIVE BELTS FOR WATER PUMP AND VACUUM PUMP Use only exact replacement for system drive belts. Use only exact manufacturer and models for replacements PEAK 86037220 02/12/07... -

Page 35: Packing Nut Adjustment

(cap) (while observing the pressure gauge on the control panel) until the desired pressure is obtained. Retighten the locking nut. DO NOT loosen the adjusting body (cap) all the way (counterclockwise) or remove it while the unit is running. PEAK 86037220 02/02/08 4-10... - Page 36 Cleaning tool valve is malfunctioning. Repair or replace valve. Hose inner lining is constricted. Remove restriction or replace hose. Air leak in chemical supply line, priming Check for air leaks. Replace faulty parts. valve or metering valve. 4-11 PEAK 86037220 05/22/0807...

-

Page 37: Troubleshooting

Measure the pump volume. If the pump volume is less than normal, refer to “Loss Defective cylinder in the water pump. of Pump Volume” in the Troubleshooting section in this manual. PEAK 86037220 02/12/07 4-12... - Page 38 Oil pressure switch (located on engine), fuel shut-off solenoid Test these components. If any are (located on engine), high defective, replace. Consult the Kohler temperature switch (located on Engine Operation and Maintenance Manual. engine). 4-13 PEAK 86037220 02/12/07...

- Page 39 After inspecting waste pump to determine Pump-out circuit breaker on control new electrical connectors and the cause of the tripped circuit breaker, panel has been tripped. heat shrink. Inspect connection press the reset button. for watertight seal. 4-14 PEAK 86037220 05/22/08...

- Page 40 FRAME PEAK 86037220 01/12/08...

- Page 41 86282850 790635 TRIM, SEAL 5/8” BULB, 1.5 86282840 790634 TRIM, SEAL 5/8” BULB, 16 1000141381 86043940 791056 ASSY, RAD CLOSEOUT, PEAK NEW WAS 61410 86274000 70069 SCR, 3/8-16 X 3 HHCS GR5 86279510 87171 WASHER, 3/8 FLAT 86191570 01-000259 RECPT SNAPIN 1/4 TURNFAST...

- Page 42 FRAME PEAK 86037220 01/12/08...

- Page 43 61413 PNL, FRAME SUPPORT 86005680 57047 NUT, 1/4-20 HEX NYLOCK 86273330 00-000286 SCR, CAP 1/4-20 X 2.75 HXHD 86054350 61403 PNL, FRNT HD PEAK, PC 86186740 500887 LABEL, MAIN WAS 500784 86276100 70597 SCR, 1/4-20 X 3/4 PPHMS BLK 86279400...

- Page 44 FRAME PEAK 86037220 01/12/08...

- Page 45 FRAME SERIAL NO. PART NO. PRV NO. DESCRIPTION FROM NOTES: 86030810 61445 PANEL ASM, RT HD PEAK INCLUDES 2,3,10 86193550 00-000272 12 STUD, 1/4 TURN FAST 86193220 02-000268 12 SPLIT RING, RETAIN, 1/4 TRUN 86054560 61472 PNL, LWR FR 86179290...

-

Page 46: Side Panel

SIDE PANEL PEAK 86037220 02/12/07... - Page 47 86181360 12-800269 FTTG, BRB 1/2P X 5/8H BR 86188210 11-800354 NIP, 1/2 X 3/8 HEX BR 86179710 13-806008 DSC, 3/8F X 3/8FP 1000158501 86180700 32064 END CAP, VAC INLET, 1 1/2 86178700 19-800075 CUP, OIL FILL 1/8P PEAK 86037220 02/12/07...

-

Page 48: Chemical Control Panel

CHEMICAL CONTROL PANEL PEAK 86037220 02/12/07... - Page 49 NUT, WELL 1/4-20 HD 1000141381 86273180 00-000078 SCR, 1/4-20 X 1” HXHD GRD8 1000141381 86270330 02-000066 FLATWASHER, 1/4 1000141381 86177660 12-800065 CONN, 1/8P X 1/4T QTY WAS 2 1000141381 86195050 15-808106 VALVE, METER 1/8FP QTY WAS 1 5-10 PEAK 86037220 03/01/08...

-

Page 50: Control Panel

CONTROL PANEL 5-11 PEAK 86037220 02/02/08... - Page 51 CONTROL PANEL SERIAL NO. REF PART NO. PRV NO. DESCRIPTION FROM NOTES: 1000141381 86056010 791075 PNL, INSTR PANEL, PEAK 1000141381 86179410 791076 LBL, INSTR PANEL, PEAK 86186930 51387 LIGHT, WARNING, IDEC AP2M 86181930 36225 GAUGE, 0-1500 PSI 86181950 36227 GAUGE, VACUUM 30” HG...

-

Page 52: Engine

ENGINE SUPPLIED WITH ENGINE SUPPLIED WITH ENGINE SUPPLIED WITH ENGINE SUPPLIED WITH ENGINE 5-13 PEAK 86037220 02/12/07... - Page 53 86174950 44-802217 1 BELT, AX43 GOODYEAR MATCH 86006760 70305 2 SCR, 5/16-18 X 3/4 HHCS 86051510 790396 1 PLT, ENG MTG, PEAK 86010790 87163 2 WASHER, 3/8 SPLIT LOCK 86275190 70377 2 SCR, 3/8-16 X 1.25 HHCS SS 86005770 57119...

-

Page 54: Vacuum Blower

VACUUM BLOWER 5-15 PEAK 86037220 08/20/08... - Page 55 86189310 790571 O-RING, 2.75 X 2.938 OD VITON 86188580 790572 NIPPLE, VAC OUTL 4M TRIFLOW 86179580 43-807074 DIAPHRAM, VAC REL VLV 86311600 WASHER, VAC REL VLV #4 VAC 86273320 00-000284 SCR, CAP 7/16-14 X 4 HXHD 5-16 PEAK 86037220 08/20/08...

-

Page 56: Water Pump

WATER PUMP TO WATER BOX TO FLOWMETER TO CHEMICAL VALVE 5-17 PEAK 86037220 01/12/08... - Page 57 1000151479 WAS 42-809264 86249220 65252 PLASTIC DISC 86179550 42-809047 DIAPHRAGM, CHEM PUMP 1000151479 WAS 52-502053 86194630 65250 PULSE PUMP, TOP COVER INLET 1000151479 WAS 52-502052 86191340 65253 PULSE PUMP, BODY 1000151479 86192920 65246 SPACER RING, 303 SST 5-18 PEAK 86037220 3/12/09...

- Page 58 WATER PUMP 5-19 PEAK 86037220 02/12/07...

- Page 59 15 86186090 42-809410 1 KIT, SEAL ORDER 1 EACH 16 86181970 42-902380 1 GAUGE, OIL LEVEL 17 86181800 43-807063 1 GASKET, OIL GAUGE ORDER 1 EACH TO 18 86286260 66-950441 - KIT, VLV CAT 3CP1140, 33258 REPLACE ALL VALVES 5-20 PEAK 86037220 02/12/07...

- Page 60 VAC/HEAT EXCHANGER WITH SILENCER 5-21 PEAK 86037220 05/22/08...

- Page 61 SEAL, 5.813 DIA., GRAPH, BRAID SQ 86051480 790328 PLT, UPPER EXHAUST 86051460 790121 PLT, VAC MUFFLER MTG OPEN 86278830 02-000143 WASHER, 5/16 FLAT PLTD 86005750 57113 NUT, 5/16-18 HEX NYLOCK 86277680 70937 SCR, 1/4-20 X 1 1/4 HXHD GR8 5-22 PEAK 86037220 02/12/07...

-

Page 62: Heli-Coil Heat Exchanger

HELI-COIL HEAT EXCHANGER TO PRESSURE REGULATOR TO RADIATOR 5-23 PEAK 86037220 02/12/07... - Page 63 RECPT, SNAPIN 1/4 TURNFAST 86048290 57-520073 HE, HELI-COIL 86177560 15-808073 COCK, DRN 1/4P X 1/4 HOSE ELL 86180000 31093 ELBOW, ¾” 45° BRASS ST 86197360 31016 ELBOW, 1/4NPT STREET 86233410 81270 CLAMP, 3/4 DIA CUSHION .406 DIA PEAK 86037220 02/12/07 5-24...

-

Page 64: Solution Manifold

SOLUTION MANIFOLD TO ELBOW ON TOP OF SECOND HEAT EXCHANGER CORE TO CHEMICAL PRIME PEAK 86037220 05/22/08 5-25... - Page 65 SCREEN, CHECK VALVE 86189260 43-810053 O-RING 86189230 43-810008 O-RING 86192390 16-808223 SEAT, CHK VLV ASSY 86194250 16-808225 TEFLON SEAT 86190910 16-808226 POPPET, CHK VLV ASSY 86193260 16-808224 SPRING 86189270 43-810079 O-RING, 7/8 ID 1-1/16 OD 86176350 16-808222 PEAK 86037220 05/22/08 5-26...

-

Page 66: Water Box

WATER BOX PART OF ITEM 1 REAR TO WATER INLET PEAK 86037220 05/22/08 5-27... - Page 67 WAS 16-808217 86308950 SCR, HHSS, M5 X 20MM, SS WAS 00-000337 86309140 ARM, PIVOT-FH VALVE WAS 16-808216 86189870 16-808219 PISTON, FH VLV 86192380 16-808164 SEAT, FLOAT VLV 86024750 94028 NUT, M5 HEX NYLOCK SS WAS 57090 PEAK 86037220 12/12/08 5-28...

-

Page 68: Pressure Regulator Manifold

PRESSURE REGULATOR FROM UPPER CONNECTION ON FRONT HEATER CORE IN VAC HE ASSEMBLY FROM LOWER ELBOW ON HELICOIL ASSEMBLY TO PRESSURE GUAGE OUTER SEAT INNER SEAT STEM SPRINGS BODY 86029480 - PRV NO. 15-808081 PRESSURE REGULATOR DETAIL PEAK 86037220 02/12/07 5-29... - Page 69 ELL, 3/8P X 1/2T 45 DEG BR 86273330 00-000286 SCR, CAP 1/4-20 X 2.75 HXHD 86010780 87162 WASHER, 1/4 SPLIT LOCK PLTD 86270330 02-000066 FLATWASHER, 1/4 86187770 790901 MNFLD, PRESS EFI 86186040 16-808193 KIT, REPAIR PRESSURE REG PEAK 86037220 03/20/08 5-30...

-

Page 70: Waste Tank

WASTE TANK PEAK 86037220 02/12/07 5-31... - Page 71 86182710 790620 GSKT, PEAK WASTE TANK 86193430 14-806518 STRAINER, WST TANK 2-1/2” 86058550 790588 TNK, WST 60G PEAK, PC OPEN 1000141381 QTY WAS 2 86180340 12-800031 ELL, 1/4P X 1/4T BR 86277830 00-000072 12 SCR, 3/8-16 X 2” HXHD 86279510...

-

Page 72: Hose Accessories

HOSE ACCESSORIES 5-33 PEAK 86037220 02/12/07... - Page 73 HOSE, WATER 1/2 X 50’ 22015 86002450 COUPLER, 1/4 QD 86184520 10-805077 HOSE, HP 1/4 X 50’ 86182800 08-805155 GUARD, HOSE VINYL 56012 86005580 NIPPLE, 1/4 FPT QD 86184540 10-805122 HOSE, HP 1/4 X 50FT W/QD PEAK 86037220 02/12/07 5-34...

-

Page 74: Battery-Floor Mount

BATTERY-FLOOR MOUNT 5-35 PEAK 86037220 05/03/08... - Page 75 BOX, BATTERY, MODIFIED 86273190 00-000132 SCR, 1/4-20 X 1-1/2 HXHD 86270330 02-000066 FLATWASHER, 1/4 86010780 87162 WASHER, 1/4 SPLIT LOCK PLTD 86270770 57006 NUT, 1/4-20 HEX 86309890 BRKT, BATTERY BOX MTG 86011470 BOLT, ELEVATOR, 1/4-20 X 1 5-36 PEAK 86037220 05/03/08...

-

Page 76: Automatic Pumpout-Optional

AUTOMATIC PUMPOUT-OPTIONAL 9,12,15 5-37 PEAK 86037220 02/12/07... - Page 77 BRKT, CTR HOOD FR 86188970 52-000123 NUT, 1-3/16-12 UN HXHD 86162270 52-501993 CONN, HOSE WATER OUTL 86191380 61-951306 PUMP, HD AUTO 86174260 61-951319 ASSY, LVL SENS SHUT OFF SW 86195860 23719 CORD ASM, CNCTN SIDE 86195910 72185 SWITCH ASSEMBLY PEAK 86037220 02/12/07 5-38...

- Page 78 AUTOMATIC PUMPOUT-OPTIONAL 5-39 PEAK 86037220 05/22/08...

- Page 79 TOP, PLNGR PUMP-OUT 86176020 52-501950 BUSH, THREADED 86178810 52-502062 CVR, INLET WST PMP-OUT 86045790 56-502428 BRKT, PMP-OUT SW/CCT BRKR 86024880 52-501821 TOP, WST TNK PUMP-OUT 86174550 52-501820 BASE, WST TANK PMP-OUT 86174710 52-502063 BDY, INLET WST PMP-OUT 5-40 PEAK 86037220 05/22/08...

-

Page 80: Wand-Titanium Six Jet-Optional

WAND-TITANIUM SIX JET-OPTIONAL 5-41 PEAK 86037220 02/12/07... - Page 81 SEAT, EXTRACTOR VALVE 86183160 16-808229 HLDR, VLV STEM-EXTRACTOR VL 86189510 43-810062 O-RING, .114 ID .254OD 86189520 43-810063 O-RING, .551ID .691OD 86174500 43-810064 BACK-UP, .250DIA 86174630 52-501590 BDY, EXTRACTOR VLV 86179250 48-941462 DEC, WD HD TITANIUM OPEN 5-42 PEAK 86037220 12/27/06...

-

Page 82: Wand-Quad Jet-Optional

WAND-QUAD JET-OPTIONAL 9, 10 21, 22 19, 20 23, 23A, 23B 19, 24 5-43 PEAK 86037220 07/11/03... - Page 83 43-810062 O-RING, .144 ID .254 OD 86193200 16-808190 SPRING, EXTRCTR VLV 86174630 52-501590 BODY, EXTRCTR VLV NOT SHOWN 86179020 48-941186 DECAL, WD HD (CAST SS) NOT SHOWN 66-808169 86186160 KIT, REP-WD VLV INCLUDES PARTS 27-29 & 31-33 5-44 PEAK 86037220 02/12/07...

-

Page 84: Wand- Tri Jet- Optional

WAND- TRI JET- OPTIONAL 9, 10 19, 19A, 19B 20, 21, 22 PEAK 86037220 02/12/07 5-45... - Page 85 43-810064 BACK-UP, .250DIA 86174500 43-810062 O-RING, .114ID .254OD 86189510 16-808190 SPRING, EXTRCTR VLV 86193200 52-501590 BODY, EXTRCTR VLV 86179020 48-941166 DECAL, WD HD NOT SHOWN 86179020 NOT SHOWN 86186160 66-808169 KIT, REP-WD VLV INCLUDES PARTS 25-27 & 29-31 5-46 PEAK 86037220 02/12/07...

-

Page 86: Stair Tool-Optional

STAIR TOOL-OPTIONAL 5, 5A 9, 10 15, 15A 5-47 PEAK 86037220 02/12/07... - Page 87 86189510 43-810062 O-RING, .114 ID .254 OD 86193200 16-808190 SPRING, EXTRCTR VLV 86174630 52-501590 BODY, EXTRCTR VLV 86178970 48-941163 DECAL, STAIR TL NOT SHOWN NOT SHOWN 86186160 66-808169 KIT, REP-WD VLV INCLUDES PARTS 16-19 & 20-22 PEAK 86037220 02/12/07 5-48...

-

Page 88: Upholstery Tool-Optional

UPHOLSTERY TOOL-OPTIONAL 5-49 PEAK 86037220 02/12/07... - Page 89 HOSE, 3/16X6-1/2 (1/8P BS) 86179740 13-806030 1 D SC, 1/8MX1/8FP SST 86192070 00-000408 SCR, SET 3-32 X 1/4 SOCHD 86178980 48-941164 NOT SHOWN DECAL, UPHLST TL NOT SHOWN 86186160 66-808169 KIT, REPAIR-WAND VLV INCLUDES PARTS 20-22 & 24-26 5-50 PEAK 86037220 02/12/07...

-

Page 90: Shelf Assembly-Optional

SHELF ASSEMBLY-OPTIONAL OVERALL DIMENSION: 41-1/2" TALL 50-1/8" WIDE 57" WIDE (WITH TOOL HOLDERS) 7-7/8" DEEP DIMENSIONAL DATA 50 1/8 5-51 PEAK 86037220 02/12/07... - Page 91 86021920 56-501920 DRAWER, SHELF GRAY 86186850 46-802506 LATCH, ADJ GRIP 86183180 50-501755 HOLDER, UP TL HOSE 86183170 50-501754 HOLDER, UPHST TL 86179350 48-941152 DECAL, PROCHEM INCLUDES PARTS 6,7 & 86162440 66-945424 KIT, ADJ BRKT. MOUNTING HARDWARE 5-52 PEAK 86037220 05/22/08...

-

Page 92: Water Tank, Dual With Demand Pump-Optional

WATER TANK, DUAL WITH DEMAND PUMP-OPTIONAL TO DEMAND PUMP OVERALL DIMENSION: 32-1/2" TALL 62-5/8" WIDE 15-1/2" DEEP 5-53 PEAK 86037220 02/12/07... - Page 93 86043320 ASSY, BASE SADDLE TANK GRAY 58-500661 86030990 MOLDING, WATER TANK 11-800168 86190500 PLUG, 1/2 BRASS HXHD 50-500511 86190170 PLATE, INSTALL MT 57119 86005770 NUT, 3/8-16 HEX NYLOCK 86285190 41458 SHLR, CHEM, 10-GAL JUG NOT SHOWN 5-54 PEAK 86037220 02/12/07...

-

Page 94: Water Tank-Demand Pump-Optional

WATER TANK-DEMAND PUMP-OPTIONAL 5-55 PEAK 86037220 02/12/07... - Page 95 PUMP, WATER BOOSTER FLOJET 2 86186120 48-809423 KIT, PORT 86180210 11-800275 ELBOW, ST 3/8 BR 65240 86191390 PUMP ONLY, TM DEMAND NOT SHOWN 47449 86186030 KIT SERVICE DEMAND PMP FJ NOT SHOWN 86177060 03-000246 CLAMP, HOSE #8 SST 5-56 PEAK 86037220 02/12/07...

-

Page 96: Auxiliary Water Tank With Pump

AUXILIARY WATER TANK WITH PUMP 4X Ø.406 2X 18.7 MOUNTING DETAIL 2X 16.8 30.0 WIDE Vehicle Floor 58.6 LENGTH 30.0 TALL 5-57 PEAK 86037220 02/12/07... - Page 97 SCR, 1/4-20 X 3/4 HHCS PLTD 86010780 87162 WASHER, 1/4 SPLIT LOCK PLTD 86279510 87171 WASHER, 3/8 FLAT 86031000 790617 TANK, FRESH WATER 70GAL 86057170 790666 STRAP, WTR TNK HOLD DOWN 86177060 03-000246 CLAMP, HOSE #8 SST PEAK 86037220 09/06/07 5-58...

-

Page 98: Hose Reel-Optional

HOSE REEL-OPTIONAL OVERALL 47" TALL MOUNTING DETAIL 44-1/2" DEEP Vehicle Floor 14 15 5-59 PEAK 86037220 02/12/07... - Page 99 PLATE, INSTALL MT 86279510 87171 WASHER, 3/8 FLAT 86005770 57119 NUT, 3/8-16 HEX NYLOCK 86189850 55-501789 PIN, LOCK HOSE REEL 86175700 50-501812 BRKT, HOSE REEL LOCK 86193240 04-000302 SPRING, LOCK-LOCK PIN ASSY 86177190 04-000303 CLIP, RETAINER-LOCK PIN ASSY PEAK 86037220 02/12/07 5-60...

-

Page 100: Wiring Diagram

WIRING DIAGRAM 5-61 PEAK 86037220 02/12/07... -

Page 101: Hose Diagram

HOSE DIAGRAM PEAK 86037220 01/12/08 5-62...

Need help?

Do you have a question about the PEAK and is the answer not in the manual?

Questions and answers