Table of Contents

Advertisement

Operation

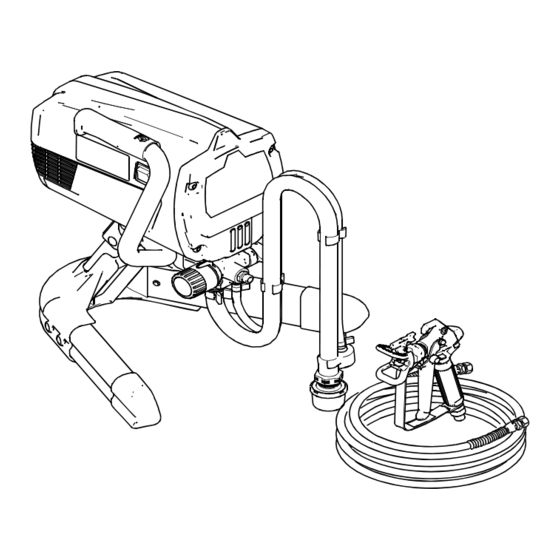

Tradeworks

Tradeworks

- For portable spray applications of architectural paints and coatings -

(Specifications, page 10.)

IMPORTANT SAFETY INSTRUCTIONS.

Read all warnings and instructions in this

manual and related manuals. Be familiar

with the controls and the proper usage of

the equipment. Save these instructions. See

page 10 for model and series information

including dispense rate, recommended

hose length, guns, and maximum working

pressure.

Tradeworks Project Painter

Model: 826610

™

Project Painter,

™

150 and Tradeworks

™

FIRE AND EXPLOSION HAZARD

•

Use only non-flammable or water-based materi-

als, or non-flammable paint thinners. Do not use

materials having flash points lower than 100°F

(38°C). This includes, but is not limited to, ace-

tone, xylene, toluene, and naphtha. For more

information about your material, request Safety

Data Sheet (SDS) from the supplier.

•

Spraying flammable or combustible materials in

a factory or fixed location must comply with

NFPA 33 and OSHA 1910.94(c) requirements in

the USA and with all similar local regulations in

other countries.

Tradeworks 150

Model: 826620

Visit our website:

http://tradeworkssprayers.com

313381L

170

Tradeworks 170

Model: 826630

ti12937a

EN

Advertisement

Table of Contents

Need help?

Do you have a question about the Tradeworks 150 and is the answer not in the manual?

Questions and answers