Table of Contents

Advertisement

Operating Manual

Micropump mp6/mp6-pp

and Controller

Sold in North America by:

Servoflo Corporation

75 Allen Street Lexington, MA 02421

Tel: 781-862-9572

Last update: 15.05.2013

www.servoflo.com / info@servoflo.com

Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany

www.micro-components.com, microComponents@bartels-mikrotechnik.de

Tel: +49-231-9742-500, Fax: +49-231-9742-501

Advertisement

Table of Contents

Summary of Contents for Bartels Mikrotechnik mp6

- Page 1 Operating Manual Micropump mp6/mp6-pp and Controller Sold in North America by: Servoflo Corporation 75 Allen Street Lexington, MA 02421 Tel: 781-862-9572 Last update: 15.05.2013 www.servoflo.com / info@servoflo.com Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501...

-

Page 2: Table Of Contents

3.1 Technical specifications mp6 ......................... 6 3.2 Technical specifications mp6-pp ......................7 3.3 Typical flow characteristics mp6 and mp6-pp ..................8 3.4 Final inspection .............................. 8 4. Operating the micropump ......................10 4.1 Connecting the micropump ........................10 4.1.1 Connecting the mp6/mp6-pp to the cable ................11 4.2 Cleaning the system ........................... - Page 3 5.6 Operation via USB port (after installation of the drivers) ............. 20 6.1 Technical specifications mp6-OEM ....................... 22 6.2 Typical flow characteristics mp6......................22 6.3 Connecting the mp6 to the mp6-OEM controller ................23 6.4 Typical schematics ............................23 6.4.1 Fixed pump rate ..........................23 6.4.2 Pump rate set by external components ..................

-

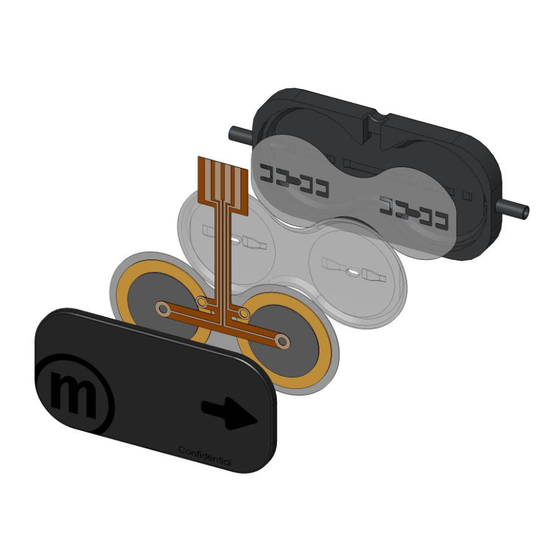

Page 4: General

CE markings have been affixed to the devices. 1.2 Description of functions The micropumps have been developed for the transport of gases or liquids. The mp-x controller, the mp6-a controller, mp6-OEM and mp6-EVA controller have been developed for operating one mp6 or one mp6-pp. -

Page 5: Proper Use

The micropump is intended for pumping liquids or gases with varying flow rates controlled by the electronics. The mp-x, the mp6-a, mp6-OEM and mp6-EVA controllers are intended for operating one mp6 or one mp6-pp. Any other use of the micropump or controller unit is deemed improper. -

Page 6: Technical Specifications

Conditions: DI water, room temperature, settings mp-x: 100 Hz, 250 V, SRS. Can be changed to IP44. The mp6 is not stable against concentrated alcoholic solutions as MeOH or EtOH. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de... -

Page 7: Technical Specifications Mp6-Pp

Conditions: suction pressure < 10 mbar, DI water, settings mp-x: 100 Hz, 250 V, SRS, the max. flow rate will be reached after a few minutes of operation time. Can be changed to IP44. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... -

Page 8: Typical Flow Characteristics Mp6 And Mp6-Pp

3.3 Typical flow characteristics mp6 and mp6-pp The flow rate of the pumps shows a linear dependency on the back pressure. At 0 mbar back pressure the maximum pump rate can be achieved and at the maximum back pressure the flow rate is decreased to 0 ml/min. - Page 9 Specifications mp6 Flowrate [ml/min]: min. 5.95 typ. 7.0 max. 8.05 Backpressure [mbar]: min. 510 typ. 600 max. 690 Specifications mp6-air (mp-x; 250Vpp, SRS-Signal, 300 Hz) Flowrate [ml/min]: min. 15.3 typ. 18.0 max. 20.7 Backpressure [mbar]: min. 85 typ. 100 max. 115...

-

Page 10: Operating The Micropump

Please connect suitable tubes to the inlet and outlet. The tubing should have an inner diameter of ~1.3 mm for the mp6 and ~1 mm for the mp6-pp. The micropump has to be connected to a suitable controller as described in the next sections. -

Page 11: Connecting The Mp6/Mp6-Pp To The Cable

The mp6/mp6-pp pump can be connected via a standard electrical connector manufactured by Molex. The layout of the connector and pin assignment of the mp6/mp6-pp is as shown below. Each piezo (P1 / P2) has a single lead for the negative (-P1/-P2) and the positive (+P1/+P2) supply voltage. -

Page 12: Cleaning The System

The pump can be washed with water, alcohol (iso-propanol) or if necessary with weak acid by pumping or by flushing with the help of a syringe. !! Only use the syringe pulling from the outlet in pumping direction!! Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... -

Page 13: Typical Operation Parameters

4.3 Typical operation parameters 4.3.1 mp6 4.3.1.1 Medium: Dl water The flow curves present typical flow data, results may differ under varying operation conditions. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... -

Page 14: Medium: Air

4.3.2 mp6-pp 4.3.2.1 Medium: Dl water The flow curves present typical flow data, results may differ under varying operation conditions. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... - Page 15 95-105 V 4 Hz 2 ml/min 250 V 30 Hz As a general guideline the amplitude should be kept as high as possible while varying the frequency. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501...

-

Page 16: The Mp-X Controller

7.5 x 16 x 20 cm³ Weight approx. 800 g Pumping media liquids or gases mp6: 7 ml/min (SRS, 250V, 100 Hz) Max. flow water mp6-pp: 5 ml/min (SRS, 250V, 100 Hz) Controlling parameters amplitude, frequency, signal form Amplitude range 0 –... -

Page 17: Electrical Signal Form

5.2 Electrical signal form SRS: Rectangular: Sine: Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... -

Page 18: Connecting The Pump To The Mp-X

Two connectors for the mp5 One connector for the mp6 Please note that it is only possible to connect either one mp6/mp6-pp or a maximum of two mp5 to the mp-x otherwise a maximum voltage drop is possible! Step 1: Plug the micropump control cable into the corresponding micropump connector. -

Page 19: Operation Of The Mp-X

Do not unplug the micropump before switching off the controller. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... -

Page 20: Installation Of The Drivers "Usb Micropump Control" And "Usb Serial Port

COM-Port, like the Hyperterminal as shown below. As the Hyperterminal is not available in Windows 7 anymore, other free terminal programs are recommended like PuTTY for example http://www.putty.org/ Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501... - Page 21 On request we can send a package of LabView-Routines as an example of implementation. We do however not offer a complete software environment for the use of the mp-x controller. Development of specific software routines can be offered on request. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501...

-

Page 22: Technical Specifications Mp6-Oem

In order to locate Pin 1, please refer to the following figure. Looking onto the mp6-OEM from the top with the black encapsulation on the left side, Pin 1 is in the lower left. The pin is as well marked by a small white spot. -

Page 23: Connecting The Mp6 To The Mp6-Oem Controller

6.4 Typical schematics 6.4.1 Fixed pump rate The mp6-OEM can drive the mp6/mp6-pp without the need of external components. In this case the pumps frequency and amplitude is fixed determined by internal components to 235 V and 100 Hz. Schematic 1: Fixed amplitude of 235 V and fixed frequency of 100 Hz ±10 % with internal components. - Page 24 Typical capacitor values are shown in the following table 6.1. For frequencies that are lower than 20 Hz, an external frequency signal needs to be applied as described in chapter 6.4.3. Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501...

-

Page 25: Pump Rate Control Via Microcontroller

6.4.3 Pump rate control via microcontroller To control the mp6-OEM with a microcontroller, an external clock with four times the desired frequency connected to the CLOCK pin can directly set the output frequency. In this case the pump frequency can be decreased down to the single Hz range. -

Page 26: Electrical Characteristics

If the noise generated by the pump is critical a series resistor of 2-10 kΩ in the P1+ and the P2+ line between the mp6-OEM and the pump will help. There is no limit for the resistor value but it will decrease the maximum pump performance. -

Page 27: The Mp6-Eva Evaluation Board

7.1 Safety notice The mp6-OEM generates voltages of up to 250 V peak to peak. All parts of the mp6-EVA evaluation board can carry voltages in this range. Therefore the board should only be used by qualified personal. Although the output power of the module is very low, proper insulation according to the application conditions needs to be considered by the customer. -

Page 28: Operation

To operate a pump with the evaluation board, the following steps are necessary: 1) Connect the mp6/mp6-pp pump to the board according to the description in chapter 4.1.1. Due to the orientation of the connector, the pump needs to be inserted with its metallic contacts upwards. -

Page 29: Operation Voltage Setting With Jumper J3

Pin 1 (Vcc) and Pin2 (GND) of CON 1 7.5 Connecting the pump via CON2 If the mp6/mp6-pp micropump shall not be connected directly to the PCB with the Molex connector CON 3, an extension cable can be soldered to the connector CON 2. -

Page 30: Passive Check Valve Mp-Cv

When the micropump is switched off, a back flow of the pumping medium, depending on a differential pressure between in- and outlet is possible. In order to impede a back flow Bartels Mikrotechnik offers a passive check valve integrated in stainless steel. -

Page 31: Trouble Shooting

- Tubing is too long = shorten tubing - Tubing diameter is too small = use appropriate tubing with an inner diameter of 1.3 mm for the mp6 and 1 mm for the mp6-pp - Back pressure is too high = reduce pressure or lower outlet... - Page 32 Germany www.bartels-mikrotechnik.de www.micro-components.com microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500 Fax: +49-231-9742-501 Sold in North America by: Servoflo Corporation 75 Allen Street Lexington, MA 02421 Tel: 781-862-9572 www.servoflo.com / info@servoflo.com Bartels Mikrotechnik GmbH, Otto-Hahn-Str. 15, 44227 Dortmund, Germany www.micro-components.com, microComponents@bartels-mikrotechnik.de Tel: +49-231-9742-500, Fax: +49-231-9742-501...

Need help?

Do you have a question about the mp6 and is the answer not in the manual?

Questions and answers