Summary of Contents for Shark Pressure Washers SMT-354037E

- Page 1 OPERATOR'S MAN U AL MODEL # ORDER # SMT-354037E 1.103-841.0 To locate your local Shark Commercial Pressure Washer Dealer nearest you, visit www.sharkpw.com 10/26/16 9.800-504.0-D...

-

Page 2: Table Of Contents

TABLE OF CONTENTS Important Trailer Safety Information What to Check and How to Check Important Safety Information 10-12 Component Identifi cations Accessory Assembly Instructions Assembly Instructions Installation Operating Instructions Detergents & General Cleaning Techniques Shut Down & Clean-up Procedures Storage Troubleshooting 20-21 Maintenance Charts... - Page 3 TABLE OF CONTENTS Notice This trailer is equipped to meet applicable U.S. Federal safety standards. Check local and state requirements regarding brakes and any additional equipment that may be required. Any modifi cations or additions including load-equalizing hitches, without written factory consent: usage in an abnormal manner including overloading voids all manufacturers’...

-

Page 4: Important Trailer Safety Information

IMPORTANT TRAILER SAFETY INFORMATION Referencing the Utility Trailer in this Understanding Tire Pressure and Load Manual Limits All references to the trailer or component parts to Tire infl ation pressure is the level of air in the tire that provides it with the load-carrying capacity and affects either left or right are made with the assumption that the overall performance of the trailer. - Page 5 IMPORTANT TRAILER SAFETY INFORMATION Tire Size Tow Vehicles To maintain the trailer's carrying capacity and safety, WARNING: Serious injury or property damage can purchase only the same size tires as what were originally result if the total weight of your loaded trailer exceeds supplied on the trailer.

- Page 6 IMPORTANT TRAILER SAFETY INFORMATION Hitch Coupler Troubleshooting Safety Chains If the coupler becomes damaged it must be repaired Listed in the chart below are the different class sizes or replaced before towing. When the coupler is placed of safety chains and the rated load each chain must be on the ball, the latch should close fi...

- Page 7 IMPORTANT TRAILER SAFETY INFORMATION Shown below is an example of the tire label that is placed on your trailer showing the items just discussed above. Once you have familiarized yourself with the information supplied on the ex ample tire label and VIN tag, check the tire size and capacity of your trailer as shown on the VIN tag on your trailer.

-

Page 8: Important Trailer Safety Information

IMPORTANT TRAILER SAFETY INFORMATION Caster Operations Trailer Brake Operations This trailer has a caster for manual transporting while using the pressure washer and to keep the WARNING: To avoid injury, the trailer brake must trailer tongue off the ground when not trailering. be set when operating the pressure washer or when not in use. -

Page 9: What To Check And How To Check

WHAT TO CHECK AND HOW TO CHECK WHAT TO CHECK AND HOW TO CHECK Tire Pressure Tires Proper air pressure for your tires is printed on the Before mounting tires onto wheels make certain that sidewall. Check pressure while tires are cold. Do not the rim size and contour is approved for the tire as raise or lower pressure to meet load. -

Page 10: Important Safety Information

IMPORTANT PRESSURE WASHER SAFETY INFORMATION Thank you for purchasing a Shark Pressure Washer. We reserve the right to make changes DANGER: Keep wand, hose, and DANGER at any time without incurring any obligation. water spray away from electric wiring or fatal electric shock Owner/User Responsibility: may result. - Page 11 IMPORTANT PRESSURE WASHER SAFETY INFORMATION WARNING: High pressure de- WARNING: High pressure spray WARNING WARNING veloped by these machines can cause paint chips or other will cause personal injury particles to become airborne and fl y at high speeds. To avoid or equipment damage.

- Page 12 IMPORTANT SAFETY INFORMATION 20. Do not operate this machine when fatigued or under CHECKLIST the infl uence of alcohol, prescription medications, or drugs. Before Every Trip: Follow the maintenance instructions • Tire pressure and tire condition specifi ed in the manual. •...

-

Page 13: Component Identification

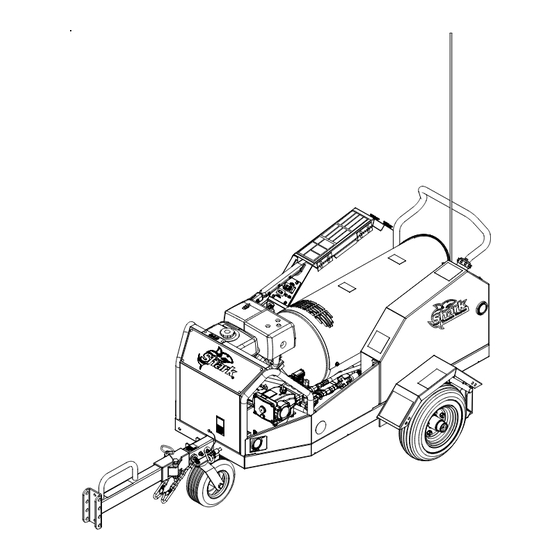

COMPONENT IDENTIFICATION Hose and Wand Storage Diesel Tank Gasoline Tank Discharge Manifold and Temperature Switch VIN Plate Hitch Channel Pump & Unloader Valve Control Panel Chemical Injector (Optional) Wand Nozzle Quick Coupler Spray Gun Battery Box High Pressure Trigger Water Inlet Outlet Safety Chains High Pressure Hose... -

Page 14: Accessory Assembly Instructions

ACCESSORY ASSEMBLY INSTRUCTIONS Handle Installation Safety Rod installation Handle Washer Bolt Align the 4 holes in the handle with the holes in the back plate, install the fasteners and washers supplied. (See Hose Box and Fuel Tank pages for fastener part numbers.) Slide the rod through both holes in the tabs. -

Page 15: Assembly Instructions

ASSEMBLY INSTRUCTIONS High Pressure Inlet Hose Connector Detergent Discharge Injector Nipple (Option) Safety Detergent Latch 98005040-6 Hose 98005040-4 98005040-5 STEP 1: Attach a 5/8" garden hose STEP 2: Attach high pressure hose STEP 3: Attach wand to spray to inlet connector. Minimum fl ow to discharge nipple using quick gun using tefl... -

Page 16: Installation

INSTALLATION Place machine in a convenient location providing am ple Placement: support, draining and room for maintenance. Do not locate near any combustible material. Keep all This machine is intended for outdoor use. Ma chine fl am ma ble material at least 20 feet away. must be stored indoors when not in use. -

Page 17: Operating Instructions

OPERATING INSTRUCTIONS 98005040-10 STEP 1: Turn water on. STEP 2: Grip spray gun handle se cure ly and pull trigger. Then turn variable pressure control handle counterclockwise. Nozzle Quick Coupler 98005040-13 Trigger STEP 3: Before installing noz- Safety Latch zle, turn on water supply and run machine, allowing water to flush through the system until clear. - Page 18 DETERGENTS & GENERAL OPERATING TECHNIQUES tures. When the water reaches this tem per a ture, the WARNING: Some de ter gents WARNING pump pro tec tor engages and cools the pump by dis- may be harm ful if in haled or in- charg ing the warm water onto the ground.

-

Page 19: Storage

SHUTTING DOWN AND CLEAN-UP 98005040-20 98005040-19 98015040-18 STEP 1: Re move detergent suc tion STEP 2: Turn burner switch off and STEP 3: Turn off water supply. tube from container and insert into continue spray ing wa ter, allowing 1 gallon of fresh water. Turn vari able the water to cool. -

Page 20: Troubleshooting

TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION LOW OPERATING Faulty pressure gauge Install new gauge. PRESSURE Insuffi cient water supply Use larger garden hose; clean fi lter washer at water inlet. Old, worn or incorrect spray Match nozzle number to machine and/or replace nozzle with new nozzle. - Page 21 TROUBLESHOOTING PROBLEM POSSIBLE CAUSE SOLUTION Improper fuel or water in fuel Drain fuel tank and replace with proper fuel. LOW WATER TEMPERATURE Low fuel pressure Increase fuel pressure. Weak fuel pump Check fuel pump temperature. Replace pump if needed. Fuel fi lter partially clogged Replace as needed.

-

Page 22: Maintenance Charts

MAINTENANCE CHARTS This pressure washer was produced with the best available materials and quality craftsmanship. However, you as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative main te nance procedures will assist in preserving the performance of your equipment. Contact your Pressure Wash ers dealer for main te nance. -

Page 23: Oil Change Record

TRAILER MAINTENANCE TRAILER MAINTENANCE SCHEDULE 6 Months 12 Months Item Function Required 3 Months or 3,000 Miles or 6,000 or 12,000 Miles Miles Hub/Drum Check for abnormal wear and scoring Wheel Bearings Inspect for corrosion or wear; & Cups clean and repack Seals Inspect for leakage;... -

Page 24: Preventative Maintenance

PREVENTATIVE MAINTENANCE During winter months, when temperatures drop be low 1. Use clean fuel — kerosene, No. 1 home heating 32°F, pro tect ing your machine against freezing is nec- fuel or diesel fuel. Clean or replace fuel fi lter every es sary. - Page 25 MAINTENANCE Fuel: KNA Oil Burner Use clean fuel oil that is not contaminated with water Burner Air Adjustment: The oil burner on this machine and debris. Replace fuel fi lter and drain tank every 100 is preset for operation at altitudes below 500 feet. If hours of operation.

- Page 26 MAINTENANCE Coil Reinstallation: KNA Burner Air Adjustment Reinstall by reversing the above steps 5 through 1. Reference Numbers NOTE: The 12 VDC burner systems can draw as much as 18 amps. For such motors to run prop- erly, the battery and engine charging system must be kept in good condition, and the engine must run fast enough to adequately charge the battery.

- Page 27 MAINTENANCE D. Bearing Adjustment HUB INSPECTION REMOVAL- Feel and Drag Method REPLACEMENT AND Tighten slotted nut until hub drags slightly whe rotated. ADJUSTMENTS (Rotating the hub while tightening the nut seats the bearing.) Loosen the slotted nut 1/6 turn (1 hex) to A.

- Page 28 www.sharkpw.com Shark SMT • # 9.800-504.0 • Printed in U.S.A. or Mexico...

Need help?

Do you have a question about the SMT-354037E and is the answer not in the manual?

Questions and answers