Table of Contents

Advertisement

Quick Links

Registration code

Collection: APCX1

Tab:

38

Printed matter N°

2950 0892 00 EN

2950 0892 00

1998 - 05

1998 – 05

Instruction Manual

for Portable Compressors

XA(S)175 Dd

Instruction manual for portable compressors

Instructieboek voor transportabele compressoren

Manuel d'instructions pour compresseurs mobiles

Bedienungsanleitung fŸr fahrbare Kompressoren

Libro de instrucciones para compresores transportables

Instruktionsbok fšr transportabla kompressorer

Istruzioni per l'uso di compressori mobili

Bruksanvisning for mobil kompressorer

Instruktionsbog til mobile kompressorer

BÈ‚Ï›Ô Ô‰ËÁÈÒÓ ÁÈ· ÊÔÚËÙÔ‡˜ Û˘Ì ÈÂÛÙ¤˜

Manual de instru•›es para compressores port‡teis

SiirrettŠvien kompressorin ohjekirja

Parts list Ð Onderdelenlijst Ð Liste de pi•ces Ð Ersatzteilliste Ð

Lista de las partes Ð Reservdelsfšrteckning Ð Listino parti di

ricambio Ð Deleliste Ð Reservedelsliste Ð K·Ù¿ÏÔÁÔ˜

EÍ·ÚÙËÌ¿ÙˆÓ Ð Lista de pe•as Ð Osaluettelo

GlossaryÐ Woordenlijst Ð Glossaire Ð Glossar Ð Glosario Ð

Ordlista Ð Glossario Ð Ordliste Ð Ordliste Ð °ÏˆÛÛ·ÚÈÔ Ð

Gloss‡rio Ð Sanasto

......................................................................................................................

and Parts List

.............................................................

.............................................

............................................

..............................................

................................................

..................................................................

.....................................................................

....................................................................

..................................................................

......................................

...............................................................................

.....................................................

ATLAS COPCO – PORTABLE AIR DIVISION

B-2630 AARTSELAAR BELGIUM

PAGE

3

35

67

99

131

........................

163

195

227

259

291

323

355

387

485

Advertisement

Table of Contents

Summary of Contents for Atlas Copco XAS 175 Dd

-

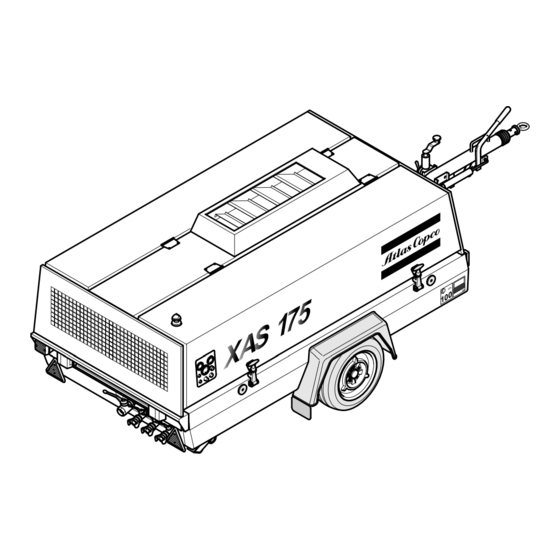

Page 1: Instruction Manual

Ordlista Ð Glossario Ð Ordliste Ð Ordliste Ð °ÏˆÛÛ·ÚÈÔ Ð Gloss‡rio Ð Sanasto ........................Registration code Collection: APCX1 Tab: Printed matter N° ATLAS COPCO – PORTABLE AIR DIVISION 2950 0892 00 EN 2950 0892 00 B-2630 AARTSELAAR BELGIUM 1998 - 05 1998 – 05... - Page 2 XA(S)175 Dd...

-

Page 3: Table Of Contents

NSTRUCTION ANUAL Congratulations on the purchase of your XA(S)175 Dd compressor. It is a solid, safe and reliable machine, built according to the latest technology. Follow the instructions in this booklet and we guarantee you years of troublefree operation. Please read the following instructions carefully before starting to use your machine. - Page 4 XA(S)175 Dd ONTENTS ONTENTS 4. Maintenance ...................... 6. Problem solving .................... Use of service paks ..............Problem solving chart .............. Preventive maintenance schedule Alternator precautions .............. for the compressor ..............Lubrication oils ................Oil level check 7. Available options ..................................

-

Page 5: Safety Precautions For Portable Compressors

In addition, a warning sign bearing a legend such as „work in progress; do The policy of Atlas Copco is to provide the users of their equipment with safe, reliable and not start“ shall be attached to the starting equipment. On engine-driven units the efficient products. -

Page 6: Safety During Use And Operation

Never play with compressed air. Never apply it to your skin or direct an air stream at AFETY DURING USE AND OPERATION people. Never use it to clean dirt from your clothes. When using it to clean down equipment, do so with extreme caution and use eye protection. To lift a unit, all loose or pivoting parts, e.g. -

Page 7: Tool Applications Safety

Support the towbar and the axle(s) securely if working underneath the unit or when PECIFIC SAFETY PRECAUTIONS removing a wheel. Do not rely on jacks. Batteries Make sure that no tools, loose parts or rags are left in or on the unit. The electrolyte in batteries is a sulphuric acid solution which is fatal if it hits your 10 Before clearing the unit for use after maintenance or overhaul, check that operating eyes, and which can cause burns if it contacts your skin. -

Page 8: Safety Valve

Draining of condensate shall be performed regularly when vessel is in use. 11 For maximum safety and efficiency of the lifting apparatus all lifting members shall be applied as near to perpendicular as possible. If required, a lifting beam shall be Installation, design and connections should not be changed. -

Page 9: Leading Particulars

NSTRUCTION ANUAL LEADING PARTICULARS – Regulation ESCRIPTION OF SAFETY PICTOGRAMS USED IN THIS MANUAL The compressor is provided with a continuous regulating system and a blow-down valve. The valve is closed during operation by outlet pressure of the compressor element and This symbol draws your attention to dangerous opens by air receiver pressure when the compressor is situations. -

Page 10: Markings And Information Labels

Dangerous exhaust. Warning ! Danger, heat flat. Part under pressure. Electrocution hazard. Do not stand on outlet valves. Atlas Copco compressor oil. Start-Stop indication of switch. PAROIL M PAROIL Atlas Copco engine oil. Do not run the motor with open doors. -

Page 11: Main Parts

NSTRUCTION ANUAL ARTS °C Fig.2.2 Main parts of XA(S)175 Dd (adjustable towbar, brakes and roadsignalisation are options) Air filter (for engine and compressor) Filler cap, fuel tank Oil level gauge Air receiver Fuel filter Regulating valve Air outlet valves Filler plug, compressor oil Speed regulator Compressor element Fuel tank... - Page 12 XA(S)175 Dd PEED REGULATING AND UNLOADING SYSTEM Min. Max. DETAIL SEE DETAIL Fig. 2.3 Speed regulating and unloading system Air filter (for engine and Filler plug, compressor oil Safety valve compressor) Flow restrictor, oil scavenging line Air/oil temperature gauge Air receiver Loading valve Throttle valve Air outlet valves...

-

Page 13: Air Flow

NSTRUCTION ANUAL . 2.3) IR FLOW The system comprises: The oil filter by-pass valve opens when the pressure drop over the filter is above normal because of a clogged filter. The oil Air filter then by-passes the filter without being filtered. For this reason, AR/OS Air receiver/oil separator the oil filter must be replaced at regular intervals (see section... -

Page 14: Electrical System

XA(S)175 Dd LECTRICAL SYSTEM 2.8.1 C IRCUIT DIAGRAM The compressor is equipped with a negative earthed system. 12V DC X1:1 – X1:7 X1:5 X1:3 X1:8 X1:4 X1:2 X1:6 14 14 18 18 Fig. 2.4 Circuit diagram (Nr. 2920 1184 00) Engine fuel level sensor/shut-down switch Starter motor Suppressor... -

Page 15: Description

NSTRUCTION ANUAL 2.8.2 D ESCRIPTION Operation of the electric circuit Engine safety shut-down 1. Closing ON/OFF switch (S1) supplies voltage to: 1. If engine oil pressure shut-down switch (S5) or compressor temperature shut-down switch (S7) opens, relay (K1) will – charging indicator lamp (H1), which lights up be de-energised, breaking contact (30-87) and making –... -

Page 16: Operating Instructions

XA(S)175 Dd OPERATING INSTRUCTIONS ARKING TOWING AND LIFTING INSTRUCTIONS Safety precautions When parking a compressor, secure nose wheel (1) to support the compressor in a level position. Apply parking brake (2). The operator is expected to apply all relevant Place the compressor as level as possible; however, it can be safety precautions, including those mentioned on operated temporarily in an out-of-level position not exceeding the inside of the cover of this book. -

Page 17: Lifting Instructions

NSTRUCTION ANUAL 3.1.3 L IFTING INSTRUCTIONS EFORE STARTING If the compressor is to be connected to a common compressed air system, fit an appropiate check valve between compressor outlet and air system. Observe the right mounting position/direction! 1. Before initial start-up, prepare battery for operation if not already done. -

Page 18: Starting/Stopping

XA(S)175 Dd TARTING TOPPING To start the compressor: 1 Move ON/OFF switch (S1) to ”I” and check that alternator charging indicator lamp (H1) and alarm lamp (H6) are alight. 2 Press and keep override/start switch (S2) depressed to override the shut-down circuit and to engage the starter motor. -

Page 19: During Operation

NSTRUCTION ANUAL Fault situations and protective devices: URING OPERATION – The starter motor is protected against prolonged starting or against attempts to start when the group is already The doors must be closed during operation and running. may be opened for short periods only. –... -

Page 20: Maintenance

When servicing, replace all disengaged packings, e.g. Order Service Paks at your local Atlas Copco dealer. gaskets, O-rings, washers. For engine maintenance refer to Engine Operation Manual. The maintenance schedule has to be seen as a guideline for units operating in a duty environment typical to compressor applications. -

Page 21: Lubrication Oils

ANUAL UBRICATION OILS IL LEVEL CHECK It is strongly recommended to use Atlas Copco branded Never mix oils of different brands or types lubrication oils for both compressor and engine. Use only non-toxic oils where there is a risk of... -

Page 22: Oil And Oil Filter Change

Keep the compressor oil cooler (1) clean to maintain the cooling efficiency. In this case, contact Atlas Copco. 1 Run the compressor until warm. Close the outlet valve(s) Remove any dirt from the cooler with a fibre brush. -

Page 23: Battery Care

4.10 C OMPRESSOR ELEMENT OVERHAUL When a compressor element is due for overhaul, it is recommended to have it done by Atlas Copco. This 4.7.3 R ECHARGING A BATTERY guarantees the use of genuine parts and correct tools with care and precision. -

Page 24: Adjustments And Servicing Procedures

XA(S)175 Dd ADJUSTMENTS AND SERVICING PROCEDURES DJUSTMENT OF THE REGULATING VALVE Min. Max. DETAIL SEE DETAIL Fig. 5.1 Speed regulating and unloading system Air filter (for engine and Filler plug, compressor oil Safety valve compressor) Flow restrictor, oil scavenging line Air/oil temperature gauge Air receiver Loading valve... -

Page 25: Air Filter Engine/Compressor

The piston rod of the speed regulator should then be in its full-in position and piston (4) rest The Atlas Copco air filters are specially designed against its stop in the regulator. for the application. The use of non-genuine air filters may lead to severe damage of engine 5. -

Page 26: Replacing The Air Filter Element

XA(S)175 Dd 5.2.4 R EPLACING THE AIR FILTER ELEMENT UEL SYSTEM 1. Release the snap clips (7) and remove the dust trap (6). Clean the trap. 2. Remove retaining nut (5) and withdraw the element (3) from housing (1). If the element is to be serviced for immediate re-use, reinstall the dust trap to protect the air intake system while cleaning the element. -

Page 27: Brake (= Option) Adjustment

NSTRUCTION ANUAL 3. Apply the hand brake lever several times and repeat the RAKE OPTION ADJUSTMENT adjustment. Tighten the nuts with their lock nuts (Fig. 5.6, 2). Remove the jack and the blocks. Before jacking up the compressor, connect it to 4. -

Page 28: Problem Solving

XA(S)175 Dd PROBLEM SOLVING LTERNATOR PRECAUTIONS ROBLEM SOLVING CHART 1. Never reverse the polarity of the battery or the alternator. The chart helps to solve mechanical and electrical problems. 2. Never disconnect any alternator or battery connections It is assumed that the engine is in good condition and that while the engine is running. - Page 29 NSTRUCTION ANUAL Problem Possible faults Corrective actions 5. Starter motor cranks a. Switch (S2) defective. a. See remedy 4b. engine when depressing b. Fuel solenoid (Y1) defective. b. Check solenoid and its valve; correct or (S2), but engine does not replace as necessary.

- Page 30 Bleeder valve (BV) leaking. i. Remove and inspect. Replace, if necessary. j. Compressor element (CE) out of order. j. Consult an Atlas Copco Service representative. a. Regulating valve (RV) incorrectly set or a. Adjust working pressure, see section 5.1.

- Page 31 NSTRUCTION ANUAL Problem Possible faults Corrective actions 16. Compressor loaded a. Loading valve/switch (LV/S4) stuck in a. Remove and dismantle. automatically to full loaded position. Correct if necessary. capacity after starting. b. Air intake throttle valve (TV) stuck in open b.

-

Page 32: Available Options

The XA(S)175 Dd can be delivered with following options: Type: EURO ASME Towbar: Adjustable with brakes Fixed with brakes Support (without undercarriage) Towing eyes: Atlas Copco Ball NATO Towbar support: Jockey wheel Road signalisation: Full Semi Air quality equipment: Aftercooler + water separator... -

Page 33: Technical Specifications

NSTRUCTION ANUAL TECHNICAL SPECIFICATIONS ORQUE VALUES OMPRESSOR ENGINE SPECIFICATIONS 8.1.1 F OR GENERAL APPLICATIONS Compressor type XA(S)175 Dd The following tables list the recommended torques applied for general applications Reference conditions at assembly of the compressor. 1. Absolute inlet pressure 2. -

Page 34: Conversion List Of Si Units Into British Units

1 Nm 0.738 lbf.ft t °F 32 + (1.8 x t °C) MADE BY ATLAS COPCO AIRPOWER n.v. WILRIJK, BELGIUM t °C (t °F - 32)/1.8 1615 6945 00 – A temperature difference of 1 °C = a temperature difference of 1.8 °F...

Need help?

Do you have a question about the XAS 175 Dd and is the answer not in the manual?

Questions and answers

ขออนุญาติเเอดมิน สอบถามหน่อยครับ พอดีเครื่องลมผมปิดวาล์วลมเเล้วเครื่องดับไปเลยนี้น่าจะเกี่ยวกับอะไร ผมลองปรับลมลงดูก็เหมือนเดิม ปั๊มหัวฉีดก็ไปเช็คเเล้วก็ยังเป็นเหมือนเดิมไม่ทราบว่าเกิดปัญหาเกี่ยวกับอะไร