Summary of Contents for Mitsubishi MR-J4-10A

- Page 1 General-Purpose AC Servo General-Purpose Interface AC Servo MODEL MR-J4-_A(-RJ) MR-J4-_A4(-RJ) SERVO AMPLIFIER INSTRUCTION MANUAL...

-

Page 2: Safety Instructions

Safety Instructions Please read the instructions carefully before using the equipment. To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until you have read through this Instruction Manual, Installation guide, and appended documents carefully. Do not use the equipment until you have a full knowledge of the equipment, safety information and instructions. - Page 3 1. To prevent electric shock, note the following WARNING Before wiring and inspections, turn off the power and wait for 15 minutes or more until the charge lamp turns off. Then, confirm that the voltage between P+ and N- is safe with a voltage tester and others. Otherwise, an electric shock may occur.

- Page 4 3. To prevent injury, note the following CAUTION Only the voltage specified in the Instruction Manual should be applied to each terminal. Otherwise, a burst, damage, etc. may occur. Connect cables to the correct terminals. Otherwise, a burst, damage, etc. may occur. Ensure that polarity (+/-) is correct.

- Page 5 (2) Wiring CAUTION Wire the equipment correctly and securely. Otherwise, the servo motor may operate unexpectedly. Do not install a power capacitor, surge killer, or radio noise filter (FR-BIF-(H) option) on the servo amplifier output side. To avoid a malfunction, connect the wires to the correct phase terminals (U, V, and W) of the servo amplifier and servo motor.

- Page 6 CAUTION Use a noise filter, etc. to minimize the influence of electromagnetic interference. Electromagnetic interference may be given to the electronic equipment used near the servo amplifier. Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break it. Use the servo amplifier with the specified servo motor.

- Page 7 DISPOSAL OF WASTE Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and regulations. EEP-ROM life The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If the total number of the following operations exceeds 100,000, the servo amplifier may malfunction when the EEP-ROM reaches the end of its useful life.

- Page 8 «Wiring» Wires mentioned in this Instruction Manual are selected based on the ambient temperature of 40 °C. «U.S. customary units» U.S. customary units are not shown in this manual. Convert the values if necessary according to the following table. Quantity SI (metric) unit U.S.

- Page 9 MEMO A - 8...

-

Page 10: Table Of Contents

CONTENTS 1. FUNCTIONS AND CONFIGURATION 1- 1 to 1-44 1.1 Summary............................1- 1 1.2 Function block diagram........................1- 2 1.3 Servo amplifier standard specifications .................... 1- 9 1.4 Combinations of servo amplifiers and servo motors ............... 1-13 1.5 Function list............................1-14 1.6 Model designation.......................... - Page 11 3.8 Alarm occurrence timing chart ......................3-56 3.8.1 When you use the forced stop deceleration function..............3-56 3.8.2 When you do not use the forced stop deceleration function............. 3-57 3.9 Interfaces ............................3-58 3.9.1 Internal connection diagram...................... 3-58 3.9.2 Detailed explanation of interfaces..................... 3-59 3.9.3 Source I/O interfaces ........................

- Page 12 5. PARAMETERS 5- 1 to 5-58 5.1 Parameter list............................ 5- 1 5.1.1 Basic setting parameters ([Pr. PA_ _ ])..................5- 2 5.1.2 Gain/filter setting parameters ([Pr. PB_ _ ]) ................5- 3 5.1.3 Extension setting parameters ([Pr. PC_ _ ]) ................5- 5 5.1.4 I/O setting parameters ([Pr.

- Page 13 7.3.1 Vibration tough drive function....................7-23 7.3.2 Instantaneous power failure tough drive function ..............7-25 7.4 Compliance with SEMI-F47 standard ....................7-28 8. TROUBLESHOOTING 8- 1 to 8- 8 9. OUTLINE DRAWINGS 9- 1 to 9-20 9.1 Servo amplifier ..........................9- 1 9.2 Connector ............................

- Page 14 11.9 Selection example of wires ......................11-56 11.10 Molded-case circuit breakers, fuses, magnetic contactors (recommended) ......11-60 11.11 Power factor improving DC reactors................... 11-62 11.12 Power factor improving AC reactors ................... 11-66 11.13 Relays (recommended) ......................11-69 11.14 Noise reduction techniques ......................11-70 11.15 Earth-leakage current breaker ....................

- Page 15 13.3.2 External I/O signal connection example using an MR-J3-D05 safety logic unit ....13- 7 13.3.3 External I/O signal connection example using an external safety relay unit ......13- 9 13.4 Detailed description of interfaces ....................13-10 13.4.1 Sink I/O interface........................13-10 13.4.2 Source I/O interface ......................

- Page 16 15.3.5 Function..........................15-21 15.3.6 Absolute position detection system..................15-24 15.4 Characteristics ..........................15-25 15.4.1 Overload protection characteristics ..................15-25 15.4.2 Power supply capacity and generated loss ................15-26 15.4.3 Dynamic brake characteristics ....................15-27 15.4.4 Permissible load to motor mass ratio when the dynamic brake is used....... 15-28 16.

- Page 17 App. 4 Compliance with global standards ..................App.- 3 App. 5 MR-J3-D05 Safety logic unit ....................App.-19 App. 6 EC declaration of conformity ....................App.-37 App. 7 Analog monitor ........................App.-39 App. 8 Two-wire type encoder cable for HG-MR/HG-KR..............App.-43 App. 9 How to replace servo amplifier without magnetic pole detection......... App.-44...

-

Page 18: Functions And Configuration

1. FUNCTIONS AND CONFIGURATION 1.1 Summary The Mitsubishi MELSERVO-J4 series general-purpose AC servo has further higher performance and higher functions compared to the previous MELSERVO-J3 series. The MELSERVO-J4 series compatible rotary servo motor is equipped with 22-bit (4194304 pulses/rev) high- resolution absolute encoder. -

Page 19: Function Block Diagram

1. FUNCTIONS AND CONFIGURATION 1.2 Function block diagram The function block diagram of this servo is shown below. POINT The diagram shows MR-J4-_A_-RJ as an example. The MR-J4-_A_ servo amplifier does not have the CN2L connector. (1) 200 V class (a) MR-J4-500A(-RJ) or less (Note 6) Power factor improving... - Page 20 1. FUNCTIONS AND CONFIGURATION Note 1. The built-in regenerative resistor is not provided for MR-J4-10A(-RJ). 2. For 1-phase 200 V AC to 240 V AC, connect the power supply to L1 and L3. Leave L2 open. For the power supply specifications, refer to section 1.3.

- Page 21 1. FUNCTIONS AND CONFIGURATION (b) MR-J4-700A(-RJ) (Note 4) Power factor improving Regenerative DC reactor option Servo amplifier P4 (Note 2) Servo motor Dynamic Diode brake stack Relay circuit MCCB (Note 1) Current Power encoder Regene- supply rative CHARGE lamp Cooling fan Electromagnetic Control 24 V DC...

- Page 22 1. FUNCTIONS AND CONFIGURATION (c) MR-J4-11KA(-RJ)/MR-J4-15KA(-RJ)/MR-J4-22KA(-RJ) (Note 5) External regenerative (Note 4) resistor or Power factor improving regenerative option DC reactor External dynamic brake (optional) Servo amplifier Servo motor (Note 2) Diode stack Thyristor MCCB (Note 1) Current Power encoder Regene- supply rative...

- Page 23 1. FUNCTIONS AND CONFIGURATION (2) 400 V class (a) MR-J4-350A4(-RJ) or less (Note 5) Power factor Regenerative improving option DC reactor Servo amplifier Servo motor P4 (Note 3) Dynamic Diode brake Relay stack circuit MCCB (Note 1) Current Power Regene- detector supply rative...

- Page 24 1. FUNCTIONS AND CONFIGURATION (b) MR-J4-500A4(-RJ)/MR-J4-700A4(-RJ) (Note 4) Power factor Regenerative improving option DC reactor Servo amplifier Servo motor P4 (Note 2) Dynamic Diode brake stack Relay circuit MCCB (Note 1) Current Power Regene- detector supply rative Charge lamp Cooling fan Control Electromagnetic 24 V DC...

- Page 25 1. FUNCTIONS AND CONFIGURATION (c) MR-J4-11KA4(-RJ)/MR-J4-15KA4(-RJ)/MR-J4-22KA4(-RJ) (Note 5) External Power factor regenerative resistor (Note 4) improving regenerative option DC reactor External dynamic brake (optional) Servo amplifier P3 Servo motor P4 (Note 2) Diode Thyristor stack MCCB (Note 1) Current Power Regene- detector supply...

-

Page 26: Servo Amplifier Standard Specifications

External option (Note 8) Fully closed loop control Available (Note 9) Load-side encoder interface Mitsubishi high-speed serial communication (Note 10) USB: Connection to a personal computer or others (MR Configurator2-compatible) Communication function RS-422: 1:n communication (up to 32 axes) (Note 7) - Page 27 1. FUNCTIONS AND CONFIGURATION 100A 200A 350A 500A 700A 11KA 15KA 22KA Model: MR-J4- (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) LVD: EN 61800-5-1 Compliance to CE marking EMC: EN 61800-3 global standards MD: EN ISO 13849-1, EN 61800-5-2, EN 62061 UL standard UL 508C Structure (IP rating)

- Page 28 Fully closed loop control Compatible Scale measurement function Not compatible Load-side encoder interface (Note 5) Mitsubishi high-speed serial communication USB: connection to a personal computer or others (MR Configurator2-compatible) Communication function RS-422: 1 : n communication (up to 32 axes) Encoder output pulses...

- Page 29 1. FUNCTIONS AND CONFIGURATION 60A4 100A4 200A4 350A4 500A4 700A4 11KA4 15KA4 22KA4 Model: MR-J4- (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) (-RJ) LVD: EN 61800-5-1 Compliance to CE marking EMC: EN 61800-3 standards MD: EN ISO 13849-1, EN 61800-5-2, EN 62061 UL standard UL 508C Natural cooling, open...

-

Page 30: Combinations Of Servo Amplifiers And Servo Motors

(1) 200 V class Rotary servo motor HG-JR Linear servo motor Direct Servo amplifier (When the (primary side) drive motor HG-KR HG-MR HG-SR HG-UR HG-RR HG-JR maximum torque is 400%) MR-J4-10A(-RJ) MR-J4-20A(-RJ) LM-U2PAB-05M-0SS0 TM-RFM002C20 LM-U2PBB-07M-1SS0 MR-J4-40A(-RJ) LM-H3P2A-07P-BSS0 TM-RFM004C20 LM-H3P3A-12P-CSS0 LM-K2P1A-01M-2SS1 LM-U2PAD-10M-0SS0 LM-U2PAF-15M-0SS0... -

Page 31: Function List

1. FUNCTIONS AND CONFIGURATION 1.5 Function list The following table lists the functions of this servo. For details of the functions, refer to each section indicated in the detailed explanation field. Detailed Function Description explanation Section 3.2.1 Position control mode This servo is used as a position control servo. - Page 32 1. FUNCTIONS AND CONFIGURATION Detailed Function Description explanation Output signal selection The output devices including MBR (Electromagnetic brake interlock) can be assigned [Pr. PD23] to (device settings) to certain pins of the CN1 connector. [Pr. PD28] Output signal can be forced on/off independently of the servo status. Output signal (DO) forced Section 4.5.8 output...

-

Page 33: Model Designation

1. FUNCTIONS AND CONFIGURATION 1.6 Model designation (1) Rating plate The following shows an example of rating plate for explanation of each item. AC SERVO SER.S21001001 Serial number MODEL MR-J4-10A Model Capacity POWER : 100W Applicable power supply INPUT : 3AC/AC200-240V 0.9A/1.5A 50/60Hz... -

Page 34: Structure

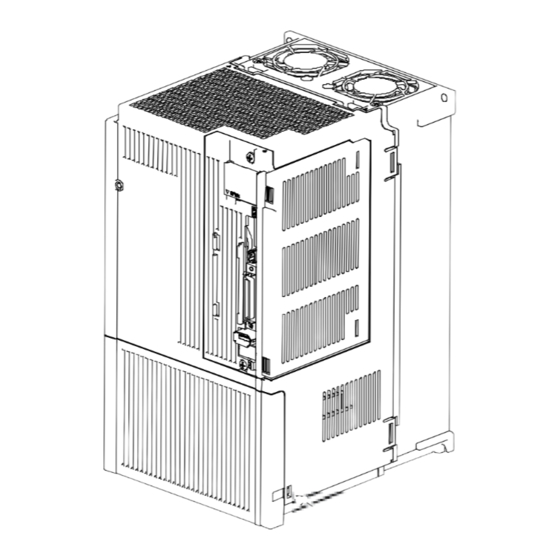

1. FUNCTIONS AND CONFIGURATION 1.7 Structure 1.7.1 Parts identification (1) 200 V class (a) MR-J4-200A(-RJ) or less Detailed Name/Application explanation Display Section 4.5 The 5-digit, 7-segment LED shows the servo status and the alarm number. Operation section Used to perform status display, diagnostic, alarm, and parameter setting operations. - Page 35 1. FUNCTIONS AND CONFIGURATION (b) MR-J4-350A(-RJ) Detailed Name/Application The broken line area is the same as explanation MR-J4-200A(-RJ) or less. Main circuit power supply connector (CNP1) Section 3.1 Section 3.3 Connect the input power supply. Section 1.6 Rating plate Servo motor power supply connector (CNP3) Connect the servo motor.

- Page 36 1. FUNCTIONS AND CONFIGURATION (c) MR-J4-500A(-RJ) POINT The servo amplifier is shown with the front cover open. The front cover cannot be removed. Detailed Name/Application The broken line area is the same as explanation MR-J4-200A(-RJ) or less. Control circuit terminal block (TE2) Used to connect the control circuit power supply.

- Page 37 1. FUNCTIONS AND CONFIGURATION (d) MR-J4-700A(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. Detailed Name/Application The broken line area is the same as explanation MR-J4-200A(-RJ) or less. Power factor improving reactor terminal block (TE3) Used to connect the DC reactor.

- Page 38 1. FUNCTIONS AND CONFIGURATION (e) MR-J4-11KA(-RJ)/MR-J4-15KA(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. Detailed Name/Application The broken line area is the same as explanation MR-J4-200A(-RJ) or less. Power factor improving reactor terminal block (TE1- Used to connect a power factor improving DC reactor and a regenerative option.

- Page 39 1. FUNCTIONS AND CONFIGURATION (f) MR-J4-22KA(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. Detailed Name/Application The broken line area is the same as explanation MR-J4-200A(-RJ) or less. Power factor improving reactor terminal block (TE1- Used to connect a power factor improving DC reactor and a regenerative option.

- Page 40 1. FUNCTIONS AND CONFIGURATION (2) 400 V class (a) For MR-J4-200A4(-RJ) or less The diagram is for MR-J4-60A4-RJ. Detailed Name/Application explanation Display The 5-digit, seven-segment LED shows the servo status and the alarm number. Operation section Used to perform status display, diagnostic, alarm, and parameter setting operations.

- Page 41 1. FUNCTIONS AND CONFIGURATION Note 1. This is for MR-J4-_A4-RJ servo amplifier. MR-J4-_A4 servo amplifier does not have CN2L connector. 2. "External encoder" is a term for linear encoder used in the linear servo system and load-side encoder used in the fully closed loop system in this manual.

- Page 42 1. FUNCTIONS AND CONFIGURATION (c) MR-J4-500A4(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. The broken line area is the same as Detailed Name/Application MR-J4-200A4(-RJ) or less. explanation Control circuit terminal block (TE2) Used to connect the control circuit power supply.

- Page 43 1. FUNCTIONS AND CONFIGURATION (d) MR-J4-700A4(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. The broken line area is the same as Detailed Name/Application MR-J4-200A4(-RJ) or less. explanation Power factor improving reactor terminal block (TE3) Used to connect the DC reactor.

- Page 44 1. FUNCTIONS AND CONFIGURATION (e) MR-J4-11KA4(-RJ)/MR-J4-15KA4(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. The broken line area is the same as Detailed Name/Application MR-J4-200A4(-RJ) or less. explanation Power factor improving reactor terminal block (TE1-2) Used to connect a power factor improving DC...

- Page 45 1. FUNCTIONS AND CONFIGURATION (f) MR-J4-22KA4(-RJ) POINT The servo amplifier is shown without the front cover. For removal of the front cover, refer to section 1.7.2. The broken line area is the same as Detailed Name/Application MR-J4-200A4(-RJ) or less. explanation Power factor improving reactor terminal block (TE1-2) Used to connect a power factor improving DC...

-

Page 46: Removal And Reinstallation Of The

1. FUNCTIONS AND CONFIGURATION 1.7.2 Removal and reinstallation of the front cover Before removing or installing the front cover, turn off the power and wait for 15 minutes or more until the charge lamp turns off. Then, confirm that the voltage CAUTION between P+ and N- is safe with a voltage tester and others. - Page 47 1. FUNCTIONS AND CONFIGURATION Reinstallation of the front cover Front cover setting tab 1) Insert the front cover setting tabs into the sockets of 2) Push down the cover, supporting at point A). the servo amplifier (2 places). Setting tab 3) Press the cover against the terminal box until the setting tabs click.

-

Page 48: Configuration Including Peripheral Equipment

1. FUNCTIONS AND CONFIGURATION 1.8 Configuration including peripheral equipment Connecting a servo motor of the wrong axis to U, V, W, or CN2 of the servo CAUTION amplifier may cause a malfunction. POINT Equipment other than the servo amplifier and servo motor are optional or recommended products. - Page 49 1. FUNCTIONS AND CONFIGURATION Note 1. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used. When not using the power factor improving DC reactor, short P3 and P4. 2.

- Page 50 1. FUNCTIONS AND CONFIGURATION (b) MR-J4-350A(-RJ) R S T (Note 2) Power supply Molded-case circuit breaker (MCCB) Personal computer MR Configurator2 (Note 3) Magnetic contactor (MC) (Note 1) Analog monitor Personal computer and other Line noise To safety relay or filter MR-J3-D05 safety (FR-BSF01)

- Page 51 1. FUNCTIONS AND CONFIGURATION (c) MR-J4-500A(-RJ) R S T (Note 2) Power supply Molded-case circuit breaker (MCCB) Personal computer MR Configurator2 (Note 3) Magnetic contactor (MC) (Note 1) Analog monitor Personal computer and other Line noise filter To safety relay or (FR-BLF) MR-J3-D05 safety logic unit...

- Page 52 1. FUNCTIONS AND CONFIGURATION (d) MR-J4-700A(-RJ) (Note 2) Power R S T supply Molded-case Personal circuit breaker (MCCB) computer MR Configurator2 (Note 3) Magnetic contactor (MC) Analog monitor (Note 1) Personal computer and other To safety relay or Line noise MR-J3-D05 safety filter logic unit...

- Page 53 1. FUNCTIONS AND CONFIGURATION (e) MR-J4-11KA(-RJ)/MR-J4-15KA(-RJ) R S T Personal (Note 2) computer Power MR Configurator2 supply Molded-case circuit breaker (MCCB) Analog monitor (Note 3) Magnetic Personal computer and other contactor (MC) To safety relay or MR-J3-D05 safety (Note 1) logic unit Line noise filter...

- Page 54 1. FUNCTIONS AND CONFIGURATION (f) MR-J4-22KA(-RJ) Personal computer MR Configurator2 R S T (Note 2) Power supply Molded-case circuit breaker (MCCB) Analog monitor Personal computer and other (Note 3) Magnetic To safety relay or contactor MR-J3-D05 safety (MC) logic unit (Note 1) Junction terminal block Line noise...

- Page 55 1. FUNCTIONS AND CONFIGURATION (2) 400 V class (a) MR-J4-200A4(-RJ) or less The diagram is for MR-J4-60A4-RJ and MR-J4-100A4-RJ. R S T Personal (Note 2) computer Power supply MR Configurator2 Molded-case circuit breaker (MCCB) Analog monitor (Note 3) Magnetic contactor Personal computer and others (MC) To safety relay or...

- Page 56 1. FUNCTIONS AND CONFIGURATION (b) MR-J4-350A4(-RJ) R S T (Note 2) Power supply Personal Molded-case computer circuit breaker MR Configurator2 (MCCB) (Note 3) Magnetic contactor (MC) Analog monitor (Note 1) Personal computer and others To safety relay or MR-J3-D05 safety logic unit Line noise filter (FR-BSF01)

- Page 57 1. FUNCTIONS AND CONFIGURATION (c) MR-J4-500A4(-RJ) R S T (Note 2) Power supply Molded-case circuit breaker (MCCB) Personal computer MR Configurator2 (Note 3) Magnetic contactor (MC) (Note 1) Power factor Analog monitor improving DC reactor Personal computer and others (FR-HEL-H) To safety relay or Line noise filter MR-J3-D05 safety...

- Page 58 1. FUNCTIONS AND CONFIGURATION (d) MR-J4-700A4(-RJ) R S T (Note 2) Power supply Personal computer Molded-case MR Configurator2 circuit breaker (MCCB) (Note 3) Analog monitor Magnetic contactor Personal computer and others (MC) To safety relay or (Note 1) MR-J3-D05 safety logic unit Line noise filter (FR-BLF)

- Page 59 1. FUNCTIONS AND CONFIGURATION (e) MR-J4-11KA4(-RJ)/MR-J4-15KA4(-RJ) Personal computer R S T MR Configurator2 (Note 2) Power supply Molded-case circuit breaker (MCCB) Analog monitor Personal computer and others (Note 3) To safety relay or Magnetic MR-J3-D05 safety contactor logic unit (MC) (Note 1) Junction terminal block Line noise filter...

- Page 60 1. FUNCTIONS AND CONFIGURATION (f) MR-J4-22KA4(-RJ) Personal computer MR Configurator2 R S T (Note 2) Power supply Molded-case circuit breaker (MCCB) Analog monitor Personal computer and others To safety relay or (Note 3) MR-J3-D05 safety Magnetic logic unit contactor (MC) (Note 1) Junction terminal block Line noise filter...

- Page 61 1. FUNCTIONS AND CONFIGURATION MEMO 1 - 44...

-

Page 62: Installation

(heat method). Additionally, disinfect and protect wood from insects before packing products. POINT When pulling out CNP1, CNP2, and CNP3 connectors of MR-J4-10A(-RJ), MR- J4-20A(-RJ), MR-J4-40A(-RJ) and MR-J4-60A(-RJ), pull out CN3 and CN8 connectors beforehand. 2 - 1... -

Page 63: Installation Direction And Clearances

2. INSTALLATION 2.1 Installation direction and clearances The equipment must be installed in the specified direction. Otherwise, it may cause a malfunction. CAUTION Leave specified clearances between the servo amplifier and the cabinet walls or other equipment. Otherwise, it may cause a malfunction. (1) Installation clearances of the servo amplifier (a) Installation of one servo amplifier Cabinet... -

Page 64: Keep Out Foreign Materials

2. INSTALLATION (b) Installation of two or more servo amplifiers POINT Close mounting is possible depending on the capacity of the servo amplifier. Refer to section 1.3 for availability of close mounting. When mounting the servo amplifiers closely, do not install the servo amplifier whose depth is larger than that of the left side servo amplifier since CNP1, CNP2, and CNP3 connectors cannot be disconnected. -

Page 65: Encoder Cable Stress

2. INSTALLATION (3) When installing the cabinet in a place where toxic gas, dirt and dust exist, conduct an air purge (force clean air into the cabinet from outside to make the internal pressure higher than the external pressure) to prevent such materials from entering the cabinet. -

Page 66: Parts Having Service Lives

2. INSTALLATION 2.5 Parts having service lives Service lives of the following parts are listed below. However, the service life vary depending or operating methods and environment. If any fault is found in the parts, they must be replaced immediately regardless of their service lives. - Page 67 2. INSTALLATION MEMO 2 - 6...

-

Page 68: Signals And Wiring

3. SIGNALS AND WIRING 3. SIGNALS AND WIRING Any person who is involved in wiring should be fully competent to do the work. Before wiring, turn off the power and wait for 15 minutes or more until the charge lamp turns off. Then, confirm that the voltage between P+ and N- is safe with a voltage tester and others. -

Page 69: Input Power Supply Circuit

3. SIGNALS AND WIRING POINT When you use a linear servo motor, replace the following left words to the right words. Load to motor inertia ratio → Load to motor mass ratio Torque → Thrust (Servo motor) speed → (Linear servo motor) speed 3.1 Input power supply circuit Always connect a magnetic contactor between the power supply and the main circuit power supply (L1, L2, and L3) of the servo amplifier, in order to configure a... -

Page 70: Class

3. SIGNALS AND WIRING 3.1.1 200 V class (1) For 3-phase 200 V AC to 240 V AC power supply of MR-J4-10A(-RJ) to MR-J4-350A(-RJ) Malfunction EMG stop switch Servo amplifier Servo motor (Note 6) MCCB CNP1 (Note 10) 3-phase CNP3... - Page 71 3. SIGNALS AND WIRING (2) For 1-phase 200 V AC to 240 V AC power supply of MR-J4-10A(-RJ) to MR-J4-70A(-RJ) POINT Connect the 1-phase 200 V AC to 240 V AC power supply to L1 and L3. One of the connecting destinations is different from MR-J3 Series Servo Amplifier's.

- Page 72 3. SIGNALS AND WIRING (3) MR-J4-500A(-RJ) Malfunction EMG stop switch Servo amplifier Servo motor (Note 6) MCCB (Note 10) 3-phase (Note 5) 200 V AC to Motor 240 V AC (Note 9) (Note 1) (Note 10) (Note 3) Encoder Encoder cable (Note 2) (Note 7) Main circuit power supply...

- Page 73 3. SIGNALS AND WIRING (4) MR-J4-700A(-RJ) Malfunction EMG stop switch Servo amplifier Servo motor (Note 6) MCCB (Note 10) 3-phase (Note 5) Built-in 200 V AC to Motor regenerative 240 V AC resistor (Note 2) (Note 9) (Note 10) (Note 3) Encoder Encoder cable (Note 1)

- Page 74 3. SIGNALS AND WIRING (5) MR-J4-11KA(-RJ)/MR-J4-15KA(-RJ)/MR-J4-22KA(-RJ) Malfunction EMG stop switch (Note 13) Cooling fan power supply (Note 14) Servo amplifier External Servo motor (Note 6) dynamic brake MCCB (optional) 3-phase (Note 10) 200 V AC to Motor 240 V AC MCCB (Note 5) (Note 9)

-

Page 75: Class

3. SIGNALS AND WIRING 3.1.2 400 V class (1) MR-J4-60A4(-RJ) to MR-J4-350A4(-RJ) Malfunction Emergency stop switch (Note 11) Step-down Servo amplifier Servo motor transformer CNP1 (Note 10) (Note 6) MCCB CNP3 (Note 5) Motor 3-phase 380 V AC to 480 V AC (Note 9) (Note 1) CNP2... - Page 76 3. SIGNALS AND WIRING (2) MR-J4-500A4(-RJ)/MR-J4-700A4(-RJ) Malfunction Emergency stop switch (Note 11) Step-down transformer Servo amplifier Servo motor (Note 6) MCCB (Note 10) 3-phase (Note 5) Built-in 380 V AC to Motor regenerative 480 V AC resistor (Note 2) (Note 9) (Note 10) (Note 3) Encoder...

- Page 77 3. SIGNALS AND WIRING (3) MR-J4-11KA4(-RJ) to MR-J4-22KA4(-RJ) Malfunction (Note 13) Cooling fan Emergency stop switch (Note 11) power supply Step-down External transformer Servo amplifier Servo motor dynamic brake (Note 6) (optional) MCCB (Note 15) 3-phase (Note 10) 380 V AC to Motor 480 V AC MCCB...

-

Page 78: I/O Signal Connection Example

3. SIGNALS AND WIRING 3.2 I/O signal connection example 3.2.1 Position control mode (1) Sink I/O interface Servo amplifier (Note 4) 24 V DC (Note 7) (Note 4) Positioning module 24 V DC QD75D (Note 7) DOCOM (Note 2) DICOM Malfunction (Note 6) CLEARCOM... - Page 79 3. SIGNALS AND WIRING Note 1. To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the protective earth (PE) of the cabinet. 2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output signals, disabling EM2 (Forced stop 2) and other protective circuits.

- Page 80 3. SIGNALS AND WIRING (2) Source I/O interface POINT For notes, refer to (1) in this section. Servo amplifier (Note 4, 14) 24 V DC (Note 7) (Note 4, 14) Positioning module 24 V DC QD75D (Note 7) DOCOM (Note 2) DICOM Malfunction (Note 6)

-

Page 81: Speed Control Mode

3. SIGNALS AND WIRING 3.2.2 Speed control mode (1) Sink I/O interface Servo amplifier (Note 7) (Note 4) 24 V DC DOCOM DOCOM (Note 2) 10 m or less Malfunction (Note 7) (Note 13) (Note 6) Main circuit power supply Zero speed Forced stop 2 (Note 3, 5) - Page 82 3. SIGNALS AND WIRING Note 1. To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the protective earth (PE) of the cabinet. 2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output signals, disabling EM2 (Forced stop 2) and other protective circuits.

- Page 83 3. SIGNALS AND WIRING (2) Source I/O interface POINT For notes, refer to (1) in this section. Servo amplifier (Note 7) (Note 4, 14) 24 V DC DOCOM DOCOM (Note 2) 10 m or less Malfunction (Note 7) (Note 13) (Note 6) Main circuit power supply Zero speed...

-

Page 84: Torque Control Mode

3. SIGNALS AND WIRING 3.2.3 Torque control mode POINT EM2 has the same function as EM1 in the torque control mode. (1) For sink I/O interface Servo amplifier (Note 6) (Note 4) 24 V DC DOCOM DOCOM (Note 2) 10 m or less Malfunction (Note 6) (Note 11) - Page 85 3. SIGNALS AND WIRING Note 1. To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the protective earth (PE) of the cabinet. 2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output signals, disabling EM2 (Forced stop 2) and other protective circuits.

- Page 86 3. SIGNALS AND WIRING (2) For source I/O interface POINT For notes, refer to (1) in this section. Servo amplifier (Note 6) (Note 4, 12) 24 V DC DOCOM DOCOM (Note 2) 10 m or less Malfunction (Note 11) (Note 6) (Note 5) Main circuit power supply Zero speed...

-

Page 87: Explanation Of Power Supply System

(application) Supply the following power to L1, L2, and L3. For 1-phase 200 V AC to 240 V AC, connect the power supply to L1 and L3. Leave L2 open. Servo amplifier MR-J4-10A(-RJ) to MR-J4-100A(-RJ) to MR-J4-60A4(-RJ) to MR-J4-70A(-RJ) MR-J4-22KA(-RJ) -

Page 88: Power-On Sequence

3. SIGNALS AND WIRING Connection target Symbol Description (application) Connect the servo amplifier power output (U, V, and W) to the servo motor power input (U, V, Servo motor U/V/W and W) directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a power output malfunction. -

Page 89: Wiring Cnp1, Cnp2, And Cnp3

For the wire sizes used for wiring, refer to section 11.9. MR-J4-500A(-RJ) or more do not have these connectors. Use the servo amplifier power connector for wiring CNP1, CNP2, and CNP3. (1) Connector (a) MR-J4-10A(-RJ) to MR-J4-100A(-RJ) Servo amplifier CNP1 CNP2 CNP3 Table 3.1 Connector and applicable wire... - Page 90 3. SIGNALS AND WIRING (c) MR-J4-60A4(-RJ) to MR-J4-350A4(-RJ) Servo amplifier (Note) CNP1 CNP2 CNP3 Note. A pin for preventing improper connection is inserted to N- of CNP1 connector. Table 3.3 Connector and applicable wire Applicable wire Stripped Manufa Connector Receptacle assembly Open tool length [mm] cturer...

- Page 91 You can also use a ferrule to connect with the connectors. The following shows references to select ferrules according to wire sizes. Ferrule model (Phoenix Contact) Crimp terminal Servo amplifier Wire size (Phoenix Contact) For one For two MR-J4-10A(-RJ) AWG16 AI1.5-10BK AI-TWIN2×1.5-10BK AWG14 AI2.5-10BU MR-J4-100A(-RJ) AWG16 AI1.5-10BK AI-TWIN2×1.5-10BK...

-

Page 92: Connectors And Pin Assignment

3. SIGNALS AND WIRING 3.4 Connectors and pin assignment POINT The pin assignment of the connectors are as viewed from the cable connector wiring section. For the STO I/O signal connector (CN8), refer to chapter 13. For the CN1 connector, securely connect the external conductive portion of the shielded cable to the ground plate and fix it to the connector shell. - Page 93 3. SIGNALS AND WIRING The servo amplifier front view shown is that of the MR-J4-20A-RJ or less. Refer to chapter 9 DIMENSIONS for the appearances and connector layouts of the other servo amplifiers. CN5 (USB connector) refer to section 11.7. CN3 (RS-422 connector) refer to chapter 14.

- Page 94 3. SIGNALS AND WIRING (Note 2) I/O signals in control modes (Note 1) Pin No. Related parameter P15R P15R P15R P15R P15R P15R -/VC VC/VLA VLA/- PP/- -/PP PG/- -/PG OPC/- -/OPC Pr. PD03/Pr. PD04 -/SP2 SP2/SP2 SP2/- Pr. PD05/Pr. PD06 PC/ST1 ST1/RS2 RS2/PC...

-

Page 95: Signal (Device) Explanations

3. SIGNALS AND WIRING 3.5 Signal (device) explanations For the I/O interfaces (symbols in I/O division column in the table), refer to section 3.9.2. In the control mode field of the table P: Position control mode, S: Speed control mode, T: Torque control mode : devices used with initial setting status, : devices used by setting [Pr. - Page 96 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division Forward rotation CN1-43 To start operation, turn on LSP and LSN. Turn it off to bring the motor to a DI-1 stroke end sudden stop and make it servo-locked. Setting [Pr.

- Page 97 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division Forward rotation CN1-18 This is used to select a servo motor torque generation directions. DI-1 selection The following shows the torque generation directions. (Note) Input device Torque generation direction Torque is not generated.

- Page 98 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division Proportion control CN1-17 Turn PC on to switch the speed amplifier from the proportional integral type DI-1 to the proportional type. If the servo motor at a stop is rotated even one pulse due to any external factor, it generates torque to compensate for a position shift.

- Page 99 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division Control switching CN1-45 «Position/speed control change mode» DI-1 Refer to Function This is used to select the control mode in the position/speed control switching mode. application (Note) Control...

- Page 100 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division ABS transfer ABSM CN1-17 This is an ABS transfer mode request device. DI-1 mode When "_ _ _ 1" is set in [Pr. PA03] and absolute position detection system by DIO is selected, CN1-17 pin will become ABSM.

- Page 101 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division Zero speed CN1-23 ZSP turns on when the servo motor speed is zero speed (50r/min) or less. DO-1 detection Zero speed can be changed with [Pr. PC17]. OFF level Forward 70 r/min...

- Page 102 3. SIGNALS AND WIRING Control Connector Device Symbol Function and application mode pin No. division During tough MTTR MTTR turns on when the instantaneous power failure tough drive operates DO-1 drive while the tough drive function selection is enabled with [Pr. PA20]. During fully CLDS CLDS turns on during fully closed loop control.

- Page 103 3. SIGNALS AND WIRING (3) Output signal Control Connector Device Symbol Function and application mode pin No. division Encoder A- CN1-4 The encoder output pulses set in [Pr. PA15] are outputted in the differential DO-2 phase pulse line driver type. CN1-5 (differential line In CCW rotation of the servo motor, the encoder B-phase pulse lags the...

-

Page 104: Detailed Explanation Of Signals

3. SIGNALS AND WIRING 3.6 Detailed explanation of signals 3.6.1 Position control mode POINT Adjust the logic of a positioning module and command pulse as follows. Q series/L series positioning module Command pulse logic setting MR-J4-_A_(-RJ) servo Signal type Q series/L series positioning amplifier module Pr. - Page 105 3. SIGNALS AND WIRING The following section explains about the case where the negative logic and the forward/reverse rotation pulse trains are set to "_ _ 1 0" in [Pr. PA13]. (ON) (ON) (ON) (OFF) (OFF) (OFF) Forward rotation pulse train (transistor) Reverse rotation pulse train (OFF)

- Page 106 3. SIGNALS AND WIRING (2) INP (In-position) INP turns on when the number of droop pulses in the deviation counter falls within the preset in-position range ([Pr. PA10]). INP may turn on continuously during a low-speed operation with a large value set as the in-position range.

- Page 107 3. SIGNALS AND WIRING (5) Torque limit If the torque limit is canceled during servo-lock, the servo motor may suddenly CAUTION rotate according to position deviation in respect to the command position. (a) Torque limit and torque By setting [Pr. PA11 Forward rotation torque limit] or [Pr. PA12 Reverse rotation torque limit], torque is always limited to the maximum value during operation.

- Page 108 3. SIGNALS AND WIRING (Note) Input device Enabled torque limit value Limit value status CCW power running/CW CW power running/CCW regeneration regeneration Pr. PA11 Pr .PA12 Pr. PA11 > Pr. PA11 Pr. PA12 Pr. PA12 Pr. PA11 < Pr. PA12 Pr.

-

Page 109: Speed Control Mode

3. SIGNALS AND WIRING 3.6.2 Speed control mode (1) Speed setting (a) Speed command and speed The servo motor is run at the speeds set in the parameters or at the speed set in the applied voltage of VC (Analog speed command). A relation between VC (Analog speed command) applied voltage and the servo motor speed is as follows. - Page 110 3. SIGNALS AND WIRING (b) SP1 (Speed selection 1), SP2 (Speed selection 2), and speed command value Select any of the speed settings by the internal speed commands 1 to 3 and by VC (Analog speed command) using SP1 (Speed selection 1) and SP2 (Speed selection 2) as follows. (Note) Input device Speed command value VC (Analog speed command)

-

Page 111: Torque Control Mode

3. SIGNALS AND WIRING 3.6.3 Torque control mode (1) Torque limit (a) Torque command and torque The following shows a relation between the applied voltage of TC (Analog torque command) and the torque by the servo motor. The maximum torque is generated at ±8 V. The speed at ±8 V can be changed with [Pr. PC13]. CCW direction Forward rotation Maximum torque... - Page 112 3. SIGNALS AND WIRING (b) Analog torque command offset Using [Pr. PC38], the offset voltage of -9999 mV to 9999 mV can be added to the TC applied voltage as follows. Maximum torque Torque [Pr. PC38] offset range -9999 mV to 9999 mV 8 (-8) TC applied voltage [V] (2) Torque limit...

- Page 113 3. SIGNALS AND WIRING Normally, connect as follows. Servo amplifier (Note) 24 V DC DICOM P15R 2 kΩ 2 kΩ Japan resistor RRS10 or equivalent Note. This diagram shows sink I/O interface. For source I/O interface, refer to section 3.9.3. (b) Speed limit value selection Select any of the speed settings by the internal speed limits 1 to 7 and by VLA (Analog speed limit) using SP1 (Speed selection 1), SP2 (Speed selection 2), and SP3 (Speed selection 3) as follows.

-

Page 114: Position/Speed Control Switching Mode

3. SIGNALS AND WIRING 3.6.4 Position/speed control switching mode Set " _ _ _ 1" in [Pr. PA01] to switch to the position/speed control switching mode. This function is not available in the absolute position detection system. (1) LOP (control switching) Use LOP (Control switching) to switch between the position control mode and the speed control mode with an external contact. - Page 115 3. SIGNALS AND WIRING (3) Speed setting in speed control mode (a) Speed command and speed The servo motor is run at the speeds set in the parameters or at the speed set in the applied voltage of VC (Analog speed command). The relation between an applied voltage of VC (Analog speed command) and servo motor speed, and the rotation direction with turning on ST1/ST2 are the same as section 3.6.2 (1) (a).

-

Page 116: Speed/Torque Control Switching Mode

3. SIGNALS AND WIRING (c) SA (Speed reached) As in section 3.6.2 (2) 3.6.5 Speed/torque control switching mode Set " _ _ _ 3" in [Pr. PA01] to switch to the speed/torque control switching mode. (1) LOP (control switching) Use LOP (Control switching) to switch between the speed control mode and the torque control mode with an external contact. - Page 117 3. SIGNALS AND WIRING Normally, connect as follows. Servo amplifier (Note) 24 V DC DICOM P15R 2 kΩ 2 kΩ Japan resistor RRS10 or equivalent Note. This diagram shows sink I/O interface. For source I/O interface, refer to section 3.9.3. (b) Speed limit value selection Select any of the speed settings by the internal speed limit 1 and by VLA (Analog speed limit) using SP1 (Speed selection 1) as follows.

-

Page 118: Torque/Position Control Switching Mode

3. SIGNALS AND WIRING 3.6.6 Torque/position control switching mode Set " _ _ _ 5" in [Pr. PA01] to switch to the torque/position control switching mode. (1) LOP (control switching) Use LOP (Control switching) to switch between the torque control mode and the position control mode with an external contact. -

Page 119: Forced Stop Deceleration Function

3. SIGNALS AND WIRING 3.7 Forced stop deceleration function POINT When alarms not related to the forced stop function occur, control of motor deceleration can not be guaranteed. (Refer to chapter 8.) In the torque control mode, the forced stop deceleration function is not available. 3.7.1 Forced stop deceleration function (SS1) When EM2 is turned off, dynamic brake will start to stop the servo motor after forced stop deceleration. - Page 120 3. SIGNALS AND WIRING (2) Timing chart POINT When LSP/LSN is turned on during a forced stop deceleration, the motor will stop depending on the setting of [Pr. PD30] as follows. [Pr. PD30] Stop system _ _ _ 0 Switching to sudden stop _ _ _ 1 Continuing forced stop deceleration When EM2 (Forced stop 2) turns off, the motor will decelerate according to [Pr.

-

Page 121: Base Circuit Shut-Off Delay Time Function

3. SIGNALS AND WIRING 3.7.2 Base circuit shut-off delay time function The base circuit shut-off delay time function is used to prevent vertical axis from dropping at a forced stop (EM2 goes off) or alarm occurrence due to delay time of the electromagnetic brake. Use [Pr. PC16] to set the delay time between completion of EM2 (Forced stop 2) or activation of MBR (Electromagnetic brake interlock) due to an alarm occurrence, and shut-off of the base circuit. -

Page 122: Vertical Axis Freefall Prevention Function

3. SIGNALS AND WIRING 3.7.3 Vertical axis freefall prevention function The vertical axis freefall prevention function avoids machine damage by pulling up the shaft slightly like the following case. When the servo motor is used for operating vertical axis, the servo motor electromagnetic brake and the base circuit shut-off delay time function avoid dropping axis at forced stop. -

Page 123: Alarm Occurrence Timing Chart

3. SIGNALS AND WIRING 3.8 Alarm occurrence timing chart When an alarm has occurred, remove its cause, make sure that the operation CAUTION signal is not being input, ensure safety, and reset the alarm before restarting operation. POINT In the torque control mode, the forced stop deceleration function is not available. To deactivate an alarm, cycle the control circuit power, push the "SET"... -

Page 124: When You Do Not Use The Forced Stop Deceleration Function

3. SIGNALS AND WIRING (2) When the forced stop deceleration function is not enabled Alarm occurrence Braking by the dynamic brake Dynamic brake + Braking by the electromagnetic brake Servo motor speed 0 r/min Base circuit (Energy supply to the servo motor) Servo amplifier No alarm Alarm No. -

Page 125: Interfaces

3. SIGNALS AND WIRING 3.9 Interfaces 3.9.1 Internal connection diagram POINT Refer to section 13.3.1 for the CN8 connector. Servo amplifier (Note 1) (Note 5) 24 V DC (Note 1) Approx. DOCOM 6.2 kΩ SON SON SON DOCOM SP2 SP2 16 INP SA PC ST1 RS2 17 TL ST2 RS1 18... -

Page 126: Detailed Explanation Of Interfaces

3. SIGNALS AND WIRING Note 1. P: Position control mode, S: Speed control mode, T: Torque control mode 2. This is for the differential line driver pulse train input. For the open-collector pulse train input, connect as follows. DOCOM 24 V DC DICOM DOCOM 3. - Page 127 3. SIGNALS AND WIRING (3) Pulse train input interface DI-2 Give a pulse train signal in the differential line driver type or open-collector type. (a) Differential line driver type 1) Interface Servo amplifier Max. input pulse frequency 4 Mpulses/s (Note 2) 10 m or less PP (NP) Approximalely...

- Page 128 3. SIGNALS AND WIRING 2) Input pulse condition tLH = tHL < 0.2 s tc > 2 s tF > 3 s (4) Encoder output pulse DO-2 (a) Open-collector type Interface Maximum sink current: 35 mA 5 V DC to 24 V DC Servo amplifier Servo amplifier Photocoupler...

- Page 129 3. SIGNALS AND WIRING 2) Output pulse Servo motor CCW rotation Time cycle (T) is determined by the settings of [Pr. PA15] and [Pr. PC19]. 400 s or more (5) Analog input Input impedance 10 kΩ to 12 kΩ Servo amplifier +15 V DC P15R Upper limit setting...

-

Page 130: Source I/O Interfaces

3. SIGNALS AND WIRING 3.9.3 Source I/O interfaces In this servo amplifier, source type I/O interfaces can be used. (1) Digital input interface DI-1 This is an input circuit whose photocoupler anode side is the input terminal. Transmit signals using source (open-collector) type transistor output, relay switch, etc. -

Page 131: Servo Motor With An Electromagnetic Brake

3. SIGNALS AND WIRING 3.10 Servo motor with an electromagnetic brake 3.10.1 Safety precautions Configure an electromagnetic brake circuit so that it is activated also by an external EMG stop switch. Contacts must be opened when ALM (Malfunction) Contacts must be opened with the or MBR (Electromagnetic brake interlock) turns off. -

Page 132: Timing Chart

3. SIGNALS AND WIRING (2) Setting (a) Enable MBR (Electromagnetic brake interlock) with [Pr. PD23] to [Pr. PD26] and [Pr. PD28]. (b) In [Pr. PC16 Electromagnetic brake sequence output], set a delay time (Tb) from MBR (Electromagnetic brake interlock) off to base circuit shut-off at a servo-off as in the timing chart in section 3.10.2 (1). - Page 133 3. SIGNALS AND WIRING (b) Forced stop 2 on/off POINT In the torque control mode, the forced stop deceleration function is not available. (Note 2) Model speed command 0 and equal to or less than zero speed Servo motor speed 0 r/min Base circuit (Energy supply to...

- Page 134 3. SIGNALS AND WIRING (e) Main circuit power supply off during control circuit power supply on POINT In the torque control mode, the forced stop deceleration function is not available. Forced stop deceleration Dynamic brake Dynamic brake The time until a voltage Servo motor speed drop is detected.

- Page 135 3. SIGNALS AND WIRING (c) Alarm occurrence The operation status during an alarm is the same as section 3.8. (d) Both main and control circuit power supplies off It is the same as (1) (d) of this section. (e) Main circuit power supply off during control circuit power supply on Dynamic brake Dynamic brake + Electromagnetic brake...

-

Page 136: Grounding

3. SIGNALS AND WIRING 3.11 Grounding Ground the servo amplifier and servo motor securely. WARNING To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo amplifier to the protective earth (PE) of the cabinet. The servo amplifier switches the power transistor on-off to supply power to the servo motor. - Page 137 3. SIGNALS AND WIRING MEMO 3 - 70...

-

Page 138: Startup

4. STARTUP 4. STARTUP Do not operate the switches with wet hands. Otherwise, it may cause an electric WARNING shock. Before starting operation, check the parameters. Improper settings may cause some machines to operate unexpectedly. The servo amplifier heat sink, regenerative resistor, servo motor, etc. may be hot while power is on or for some time after power-off. -

Page 139: Switching Power On For The First Time

4. STARTUP 4.1 Switching power on for the first time When switching power on for the first time, follow this section to make a startup. 4.1.1 Startup procedure Check whether the servo amplifier and servo motor are wired correctly using Wiring check visual inspection, DO forced output function (section 4.5.8), etc. -

Page 140: Wiring Check

4. STARTUP 4.1.2 Wiring check (1) Power supply system wiring Before switching on the main circuit and control circuit power supplies, check the following items. (a) Power supply system wiring The power supplied to the power input terminals (L1, L2, L3, L11, and L21) of the servo amplifier should satisfy the defined specifications. - Page 141 4. STARTUP (c) When option and auxiliary equipment are used 1) 200 V class a) When you use a regenerative option for 5 kW or less servo amplifiers The lead wire between P+ terminal and D terminal should not be connected. The regenerative option should be connected to P+ terminal and C terminal.

- Page 142 4. STARTUP c) When you use a brake unit and power regeneration converter for 5 kW or more servo amplifiers For 5 kW or 7 kW servo amplifiers, the lead wire of built-in regenerative resistor connected to P+ terminal and C terminal should not be connected. Brake unit, power regeneration converter should be connected to P+ terminal and N- terminal.

-

Page 143: Surrounding Environment

4. STARTUP 4.1.3 Surrounding environment (1) Cable routing (a) The wiring cables should not be stressed. (b) The encoder cable should not be used in excess of its bending life. (Refer to section 10.4.) (c) The connector of the servo motor should not be stressed. (2) Environment Signal cables and power cables are not shorted by wire offcuts, metallic dust or the like. -

Page 144: Stop

4. STARTUP 4.2.2 Stop If any of the following situations occurs, the servo amplifier suspends the running of the servo motor and brings it to a stop. Refer to section 3.10 for the servo motor with an electromagnetic brake. Operation/command Stopping condition Switch of SON (Servo-on). -

Page 145: Test Operation

4. STARTUP 4.2.3 Test operation Before starting actual operation, perform test operation to make sure that the machine operates normally. Refer to section 4.2.1 for the power on and off methods of the servo amplifier. Test operation of the servo motor In this step, confirm that the servo amplifier and servo motor operate alone in JOG operation of test normally. -

Page 146: Parameter Setting

4. STARTUP 4.2.4 Parameter setting POINT The following encoder cables are of four-wire type. When using any of these encoder cables, set [Pr. PC22] to "1 _ _ _" to select the four-wire type. Incorrect setting will result in [AL. 16 Encoder initial communication error 1]. MR-EKCBL30M-L MR-EKCBL30M-H MR-EKCBL40M-H... - Page 147 4. STARTUP Start-up sequence Fault Investigation Possible cause Reference Switch on SON Alarm occurs. Refer to chapter 8 and remove cause. Chapter 8 (Servo-on). (Note) Servo motor shaft is 1. Check the display to see if the 1. SON (Servo-on) is not input. Section not servo-locked.

- Page 148 4. STARTUP (2) How to find the cause of position shift Controller Servo amplifier Machine (a) Output pulse Servo motor counter Electronic gear [Pr.PA05], [Pr.PA06], (d) Machine stop position M [Pr.PA07], [Pr.PA21] (b) Cumulative command pulses Cause B Cause A SON (Servo-on) input LSP/LSN (Stroke end) input Encoder...

-

Page 149: Startup In Speed Control Mode

4. STARTUP 2) When P • ≠ C During operation, SON (Servo-on), LSP (Forward rotation stroke end), or LSN (Reverse rotation stroke end) was switched off; or CR (Clear) or RES (Reset) was switched on. (Cause C) 3) When C • Δℓ ≠ M Mechanical slip occurred between the servo motor and machine. -

Page 150: Test Operation

4. STARTUP 4.3.3 Test operation Before starting actual operation, perform test operation to make sure that the machine operates normally. Refer to section 4.3.1 for the power on and off methods of the servo amplifier. Test operation of the servo motor In this step, confirm that the servo amplifier and servo motor operate alone in JOG operation of test normally. -

Page 151: Parameter Setting

4. STARTUP 4.3.4 Parameter setting POINT The following encoder cables are of four-wire type. When using any of these encoder cables, set [Pr. PC22] to "1 _ _ _" to select the four-wire type. Incorrect setting will result in [AL. 16 Encoder initial communication error 1]. MR-EKCBL30M-L MR-EKCBL30M-H MR-EKCBL40M-H... - Page 152 4. STARTUP Start-up sequence Fault Investigation Possible cause Reference Switch on SON Alarm occurs. Refer to chapter 8 and remove cause. Chapter 8 (Servo-on). (Note) Servo motor shaft is 1. Check the display to see if the 1. SON (Servo-on) is not input. Section not servo-locked.

-

Page 153: Startup In Torque Control Mode

4. STARTUP 4.4 Startup in torque control mode Make a startup in accordance with section 4.1. This section provides the methods specific to the torque control mode. 4.4.1 Power on and off procedures (1) Power-on Switch power on in the following procedure. Always follow this procedure at power-on. 1) Switch off SON (Servo-on). -

Page 154: Test Operation

4. STARTUP 4.4.3 Test operation Before starting actual operation, perform test operation to make sure that the machine operates normally. Refer to section 4.4.1 for the power on and off methods of the servo amplifier. Test operation of the servo motor In this step, confirm that the servo amplifier and servo motor operate alone in JOG operation of test normally. -

Page 155: Parameter Setting

4. STARTUP 4.4.4 Parameter setting POINT The following encoder cables are of four-wire type. When using any of these encoder cables, set [Pr. PC22] to "1 _ _ _" to select the four-wire type. Incorrect setting will result in [AL. 16 Encoder initial communication error 1]. MR-EKCBL30M-L MR-EKCBL30M-H MR-EKCBL40M-H... -

Page 156: Trouble At Start-Up

4. STARTUP 4.4.6 Trouble at start-up Never adjust or change the parameter values extremely as it will make unstable CAUTION movement. POINT Using the optional MR Configurator2, you can refer to reason for rotation failure, etc. The following faults may occur at start-up. If any of such faults occurs, take the corresponding action. Start-up sequence Fault Investigation... -

Page 157: Display And Operation Sections

4. STARTUP 4.5 Display and operation sections 4.5.1 Summary The MR-J4-_A_(-RJ) servo amplifier has the display section (5-digit, 7-segment LED) and operation section (4 pushbuttons) for servo amplifier status display, alarm display, parameter setting, etc. Also, press the "MODE" and "SET" buttons at the same time for 3 s or more to switch to the one-touch tuning mode. The operation section and display data are described below. -

Page 158: Display Flowchart

4. STARTUP 4.5.2 Display flowchart Press the "MODE" button once to shift to the next display mode. Refer to section 4.5.3 and later for the description of the corresponding display mode. To refer to and set the gain/filter parameters, extension setting parameters and I/O setting parameters, enable them with [Pr. -

Page 159: Status Display Mode

4. STARTUP 4.5.3 Status display mode The servo status during operation is shown on the 5-digit, 7-segment LED display. Press the "UP" or "DOWN" button to change display data as desired. When the required data is selected, the corresponding symbol is displayed. Press the "SET" button to display that data. At only power-on, however, data appears after the symbol of the status display selected in [Pr. - Page 160 4. STARTUP (b) Fully closed loop control mode Load-side encoder information 2 (Note) Cumulative feedback pulses Unit total power consumption 2 (increment of 100 kWh) Load-side encoder cumulative feedback pulses Load-side encoder droop pulses Load-side encoder information 1 (1 pulse unit) Load-side encoder information 1 (100 pulses unit) Load-side encoder information 2...

- Page 161 4. STARTUP (c) Linear servo motor control mode/DD motor control mode Electrical angle high (Note) Cumulative feedback pulses Unit total power consumption 2 (increment of 100 kWh) Z-phase counter low Z-phase counter high Electrical angle low Electrical angle high Cumulative feedback pulses Note.

- Page 162 4. STARTUP (2) Display examples The following table shows the display examples. Displayed data Item State Servo amplifier display Forward rotation at 2500 r/min Servo motor speed Reverse rotation at 3000 r/min Reverse rotation is indicated by "- ". Load to motor inertia ratio 7.00 times 11252 rev ABS counter -12566 rev...

- Page 163 4. STARTUP (3) Status display list The following table lists the servo statuses that may be shown. Refer to appendix 8 (3) for the measurement point. Status display Symbol Unit Description Feedback pulses from the servo motor encoder are counted and displayed. The values in excess of ±99999 can be counted.

- Page 164 4. STARTUP Status display Symbol Unit Description The estimated ratio of the load inertia moment to the servo motor shaft inertia Load to motor inertia ratio Multiplier moment is displayed. Bus voltage The voltage of main circuit converter (between P+ and N-) is displayed. Encoder inside temperature °C Inside temperature of encoder etected by the encoder is displayed.

- Page 165 4. STARTUP (4) Changing the status display screen The status display item of the servo amplifier display shown at power-on can be changed by changing [Pr. PC36] settings. The item displayed in the initial status changes with the control mode as follows. Control mode Status display Position...

-

Page 166: Diagnostic Mode

4. STARTUP 4.5.4 Diagnostic mode Name Display Description Not ready Indicates that the servo amplifier is being initialized or an alarm has occurred. Sequence Ready Indicates that the servo was switched on after completion of initialization and the servo amplifier is ready to operate. Drive recorder enabled When an alarm occurs in the status, the drive recorder will operate and write the status of... - Page 167 4. STARTUP Name Display Description Indicates the system number of the software. Software version - Upper If offset voltages in the analog circuits inside and outside the servo amplifier cause the servo motor to rotate slowly at VC (Analog speed command) or VLA (Analog speed limit) of 0 V, this function automatically makes zero- adjustment of offset voltages.

-

Page 168: Alarm Mode

4. STARTUP 4.5.5 Alarm mode The current alarm, past alarm history and parameter error are displayed. The lower 2 digits on the display indicate the alarm number that has occurred or the parameter number in error. Name Display Description Indicates no occurrence of an alarm. Current alarm Indicates the occurrence of [AL. -

Page 169: Parameter Mode

4. STARTUP Functions at occurrence of an alarm (1) Any mode screen displays the current alarm. (2) Even during alarm occurrence, the other screen can be viewed by pressing the button in the operation area. At this time, the decimal point in the fourth digit remains flickering. (3) For any alarm, remove its cause and clear it in any of the following methods. - Page 170 4. STARTUP (2) Operation example (a) Parameters of 5 or less digits The following example shows the operation procedure performed after power-on to change the control mode to the speed control mode with [Pr. PA01 Operation mode]. Press "MODE" to switch to the basic setting parameter screen.

-

Page 171: External I/O Signal Display

4. STARTUP 4.5.7 External I/O signal display POINT The I/O signal settings can be changed using the I/O setting parameters [Pr. PD03] to [Pr. PD28]. The on/off states of the digital I/O signals connected to the servo amplifier can be confirmed. (1) Operation Call the display screen shown after power-on. - Page 172 4. STARTUP (a) Control modes and I/O signals Signal (Note 2) Symbols of I/O signals in control modes Connector Pin No. input/output Related parameter (Note 1) I/O Pr. PD03/Pr. PD04 -/SP2 SP2/SP2 SP2/- Pr. PD05/Pr. PD06 PC/ST1 ST1/RS2 RS2/PC Pr. PD07/Pr. PD08 TL/ST2 ST2/RS1 RS1/TL...

- Page 173 4. STARTUP (3) Display data at initial values (a) Position control mode CR (CN1-41) PC (CN1-17) RES (CN1-19) TL (CN1-18) SON (CN1-15) LOP (CN1-45) LSN (CN1-44) EM2 (CN1-42) LSP (CN1-43) Input signal Light on: on Output signals Light off: off OP (CN1-33) RD (CN1-49) ALM (CN1-48)

-

Page 174: Output Signal (Do) Forced Output

4. STARTUP 4.5.8 Output signal (DO) forced output POINT When the servo system is used in a vertical lift application, turning on MBR (Electromagnetic brake interlock) by the DO forced output after assigning it to connector CN1 will release the electromagnetic brake, causing a drop. Take drop preventive measures on the machine side. -

Page 175: Test Operation Mode

4. STARTUP 4.5.9 Test operation mode The test operation mode is designed for checking servo operation. Do not use it CAUTION for actual operation. If the servo motor operates unexpectedly, use EM2 (Forced stop 2) to stop it. POINT The test operation mode cannot be used in the absolute position detection system by DIO ([Pr. - Page 176 4. STARTUP (2) JOG operation POINT When performing JOG operation, turn on EM2, LSP and LSN. LSP and LSN can be set to automatic on by setting [Pr. PD01] to " _ C _ _ ". JOG operation can be performed when there is no command from the controller. (a) Operation The servo motor rotates while holding down the "UP"...

- Page 177 4. STARTUP (3) Positioning operation POINT MR Configurator2 is required to perform positioning operation. Turn on EM2 (forced stop 2) when performing positioning operation. Positioning operation can be performed when there is no command from a controller. (a) Operation a) Motor speed [r/min] Enter the servo motor speed into the "Motor speed"...

- Page 178 4. STARTUP f) Travel distance unit selection Select with the option buttons whether the travel distance set in c) is in the command pulse unit or in the encoder pulse unit. When the command input pulse unit is selected, the value, which is the set travel distance multiplied by the electronic gear, will be the command value.

- Page 179 4. STARTUP (4) Motor-less operation Without connecting the servo motor, output signals or status display can be provided in response to the input device as if the servo motor is actually running. This operation can be used to check the sequence of a controller or the like.

-

Page 180: Parameters

5. PARAMETERS 5. PARAMETERS Never make a drastic adjustment or change to the parameter values as doing so will make the operation unstable. CAUTION If fixed values are written in the digits of a parameter, do not change these values. Do not change parameters for manufacturer setting. - Page 181 5. PARAMETERS 5.1.1 Basic setting parameters ([Pr. PA_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PA01 *STY Operation mode 1000h PA02 *REG Regenerative option 0000h PA03 *ABS Absolute position detection system 0000h PA04 *AOP1 Function selection A-1 2000h PA05 *FBP...

-

Page 182: Gain/Filter Setting Parameters ([Pr. Pb_ _ ])

5. PARAMETERS 5.1.2 Gain/filter setting parameters ([Pr. PB_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PB01 FILT Adaptive tuning mode (adaptive filter II) 0000h PB02 VRFT Vibration suppression control tuning mode (advanced 0000h vibration suppression control II) PB03 Position command acceleration/deceleration time constant [ms]... - Page 183 5. PARAMETERS Operation Control mode mode Initial Symbol Name Unit value PB37 For manufacturer setting 1600 PB38 0.00 PB39 0.00 PB40 0.00 PB41 0000h PB42 0000h PB43 0000h PB44 0.00 PB45 CNHF Command notch filter 0000h PB46 Machine resonance suppression filter 3 4500 [Hz] PB47...

- Page 184 5. PARAMETERS 5.1.3 Extension setting parameters ([Pr. PC_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PC01 Acceleration time constant [ms] PC02 Deceleration time constant [ms] PC03 S-pattern acceleration/deceleration time constant [ms] PC04 Torque command time constant/thrust command time [ms] constant PC05...

- Page 185 5. PARAMETERS Operation Control mode mode Initial Symbol Name Unit value PC38 Analog torque command offset [mV] Analog torque limit offset PC39 Analog monitor 1 offset [mV] PC40 Analog monitor 2 offset [mV] PC41 For manufacturer setting PC42 PC43 Error excessive alarm detection level [rev]/[mm] PC44 *COP9...

- Page 186 5. PARAMETERS 5.1.4 I/O setting parameters ([Pr. PD_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PD01 *DIA1 Input signal automatic on selection 1 0000h PD02 For manufacturer setting 0000h PD03 *DI1L Input device selection 1L 0202h PD04 *DI1H Input device selection 1H...

- Page 187 5. PARAMETERS 5.1.5 Extension setting 2 parameters ([Pr. PE_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PE01 *FCT1 Fully closed loop function selection 1 0000h PE02 For manufacturer setting 0000h PE03 *FCT2 Fully closed loop function selection 2 0003h PE04 *FBN...

- Page 188 5. PARAMETERS Operation Control mode mode Initial Symbol Name Unit value PE42 For manufacturer setting PE43 PE44 0000h PE45 0000h PE46 0000h PE47 0000h PE48 0000h PE49 0000h PE50 0000h PE51 0000h PE52 0000h PE53 0000h PE54 0000h PE55 0000h PE56 0000h PE57...

- Page 189 5. PARAMETERS 5.1.6 Extension setting 3 parameters ([Pr. PF_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PF01 For manufacturer setting 0000h PF02 0000h PF03 0000h PF04 PF05 PF06 0000h PF07 PF08 PF09 *FOP5 Function selection F-5 0000h PF10 For manufacturer setting...

- Page 190 5. PARAMETERS 5.1.7 Linear servo motor/DD motor setting parameters ([Pr. PL_ _ ]) Operation Control mode mode Initial Symbol Name Unit value PL01 *LIT1 Linear servo motor/DD motor function selection 1 0301h PL02 *LIM Linear encoder resolution - Numerator 1000 [µm] PL03 *LID...

-

Page 191: Basic Setting Parameters ([Pr. Pa

5. PARAMETERS 5.2 Detailed list of parameters POINT Set a value to each "x" in the "Setting digit" columns. 5.2.1 Basic setting parameters ([Pr. PA_ _ ]) Control Initial No./symbol/ Setting Function value mode name digit [unit] PA01 _ _ _ x Control mode selection *STY Select a control mode. - Page 192 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA02 _ _ x x Regenerative option *REG Select the regenerative option. Regenerative Incorrect setting may cause the regenerative option to burn. option If a selected regenerative option is not for use with the servo amplifier, [AL. 37 Parameter error] occurs.

- Page 193 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA03 _ _ _ x Absolute position detection system selection *ABS Set this parameter when using the absolute position detection system in the position control mode. Absolute position 0: Disabled (incremental system) detection 1: Enabled (absolute position detection system by DIO)

- Page 194 5. PARAMETERS Initial No./symbol/ Setting Control Function value name digit mode [unit] PA06 Set the numerator of the electronic gear. To enable the parameter, set "Electronic gear selection" to "Electronic gear (0 _ _ _)" or "J3A electronic gear setting value compatibility mode (2 _ _ _)" in [Pr. PA21]. Electronic gear The following shows a standard of the setting range of the electronic gear.

- Page 195 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA08 _ _ _ x Gain adjustment mode selection Select the gain adjustment mode. Auto tuning 0: 2 gain adjustment mode 1 (interpolation mode) mode 1: Auto tuning mode 1 2: Auto tuning mode 2 3: Manual mode 4: 2 gain adjustment mode 2...

- Page 196 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA09 Set a response of the auto tuning. Machine characteristic Machine characteristic Auto tuning Guideline for Guideline for response Setting Setting machine machine value value Response Response resonance resonance frequency [Hz] frequency [Hz]...

- Page 197 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PA13 _ _ _ x Command input pulse train form selection *PLSS 0: Forward/reverse rotation pulse train Command 1: Signed pulse train pulse input 2: A-phase/B-phase pulse train (The servo amplifier imports input pulses after form multiplying by four.) Refer to table 5.3 for settings.

- Page 198 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA14 Select the servo motor rotation direction or linear servo motor travel direction for the input pulse train. *POL Rotation Servo motor rotation direction/ direction Setting linear servo motor travel direction selection/ value When forward rotation...

- Page 199 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PA17 When you use a linear servo motor, select its model from [Pr. PA17] and [Pr. PA18]. 0000h Set this and [Pr. PA18] at a time. *MSR Refer to the following table for settings. Servo motor series setting Parameter...

- Page 200 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA18 When you use a linear servo motor, select its model from [Pr. PA17] and [Pr. PA18]. 0000h Set this and [Pr. PA17] at a time. *MTY Refer to the table of [Pr. PA17] for settings. Servo motor type setting PA19...

- Page 201 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PA21 _ _ _ x One-touch tuning function selection *AOP3 0: Disabled Function 1: Enabled selection A-3 When the digit is "0", the one-touch tuning is not available. _ _ x _ For manufacturer setting _ x _ _ x _ _ _ Electronic gear selection...

-

Page 202: Gain/Filter Setting Parameters ([Pr. Pb

5. PARAMETERS 5.2.2 Gain/filter setting parameters ([Pr. PB_ _ ]) Initial Control No./symbol/ Setting mode Function value name digit [unit] PB01 _ _ _ x Filter tuning mode selection FILT Set the adaptive filter tuning. Adaptive Select the adjustment mode of the machine resonance suppression filter 1. Refer to tuning mode section 7.1.2 for details. - Page 203 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB04 Set the feed forward gain. When the setting is 100%, the droop pulses during operation at constant speed are nearly zero. However, sudden acceleration/deceleration will increase the overshoot. Feed forward As a guideline, when the feed forward gain setting is 100%, set 1 s or more as the gain...

- Page 204 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB09 Set the gain of the speed loop. [rad/s] Set this parameter when vibration occurs on machines of low rigidity or large backlash. Increasing the setting value will also increase the response level but will Speed loop be liable to generate vibration and/or noise.

- Page 205 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB16 Set the shape of the machine resonance suppression filter 2. NHQ2 _ _ _ x Machine resonance suppression filter 2 selection Notch shape 0: Disabled selection 2 1: Enabled _ _ x _ Notch depth selection 0: -40 dB...

- Page 206 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB18 Set the low-pass filter. 3141 [rad/s] The following shows a relation of a required parameter to this parameter. Low-pass filter setting Setting range: 100 to 18000 [Pr. PB23] [Pr.

- Page 207 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PB24 _ _ _ x Slight vibration suppression control selection *MVS Select the slight vibration suppression control. Slight 0: Disabled vibration 1: Enabled suppression To enable the slight vibration suppression control, set "Gain adjustment mode control selection"...

- Page 208 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PB31 Set the speed loop gain when the gain switching is enabled. [rad/s] VG2B When you set a value less than 20 rad/s, the value will be the same as [Pr. PB09]. Speed loop This parameter is enabled only when "Gain adjustment mode selection"...

- Page 209 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB45 Set the command notch filter. CNHF _ _ x x Command notch filter setting frequency selection Command Refer to table 5.6 for the relation of setting values to frequency. notch filter _ x _ _ Notch depth selection Refer to table 5.7 for details.

- Page 210 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB46 Set the notch frequency of the machine resonance suppression filter 3. 4500 [Hz] To enable the setting value, set "Machine resonance suppression filter 3 selection" to "Enabled (_ _ _ 1)" in [Pr. PB47]. Machine resonance suppression...

- Page 211 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB51 Set the shape of the machine resonance suppression filter 5. NHQ5 When "Robust filter selection" is "Enabled (_ _ _ 1)" in [Pr. PE41], the machine resonance suppression filter 5 is not available.

- Page 212 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB56 Set the vibration frequency for vibration suppression control 2 when the gain switching is enabled. [Hz] VRF21B When you set a value less than 0.1 Hz, the value will be the same as [Pr. PB52]. Vibration suppression This parameter will be enabled only when the following conditions are fulfilled.

-

Page 213: Extension Setting Parameters ([Pr. Pc

5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PB60 Set the model loop gain when the gain switching is enabled. [rad/s] PG1B When you set a value less than 1.0 rad/s, the value will be the same as [Pr. PB07]. Model loop This parameter will be enabled only when the following conditions are fulfilled. - Page 214 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC03 Start/stop the servo motor or linear servo motor smoothly. [ms] Set the time of the arc part for S-pattern acceleration/deceleration. S-pattern acceleration/ Speed command deceleration time constant 0 r/min (0 mm/s) Time...

- Page 215 5. PARAMETERS Control Initial No./symbol/ Setting mode Function value name digit [unit] PC06 Set the speed 2 of internal speed commands. [r/min]/ [mm/s] Internal Setting range: 0 to permissible instantaneous speed speed Set the speed 2 of internal speed limits. command 2 Internal Setting range: 0 to permissible instantaneous speed...

- Page 216 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC13 Set the output torque/thrust at the analog torque/thrust command voltage (TC = ±8 100.0 V) of +8 V on the assumption that the maximum torque/thrust is 100.0%. For example, set 50.0.

- Page 217 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC14 _ _ x x Analog monitor 1 output selection MOD1 Select a signal to output to MO1 (Analog monitor 1). Refer to appendix 8 (3) for detection point of output selection. Analog monitor 1 Refer to table 5.8 for settings.

- Page 218 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PC15 _ _ x x Analog monitor 2 output selection MOD2 Select a signal to output to MO2 (Analog monitor 2). Refer to appendix 8 (3) for detection point of output selection. Analog monitor 2 Refer to [Pr.

- Page 219 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC20 Set a station No. of the servo amplifier for RS-422 and USB communication. [Station] *SNO Always set one station to one axis of the servo amplifier. Setting one station number to two or more stations will disable a normal communication.

- Page 220 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PC24 _ _ _ x In-position range unit selection *COP3 Select a unit of in-position range. Function 0: Command input pulse unit selection C-3 1: Servo motor encoder pulse unit _ _ x _ For manufacturer setting _ x _ _ x _ _ _ Error excessive alarm level unit selection...

- Page 221 5. PARAMETERS Initial Control No./symbol/ Setting Function value mode name digit [unit] PC36 _ _ x x Status display selection at power-on *DMD Select a status display shown at power-on. Status display 00: Cumulative feedback pulses selection 01: Servo motor speed/linear servo motor speed 02: Droop pulses 03: Cumulative command pulses 04: Command pulse frequency...

- Page 222 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC37 Set the offset voltage of VC (Analog speed command). The value For example, if CCW rotation or positive direction travel is provided by switching on differs ST1 (Forward rotation start) while applying 0 V to VC, set a negative value. Analog speed depending command...

- Page 223 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC45 _ _ _ X Encoder pulse count polarity selection *COPA Select a polarity of the linear encoder or load-side encoder. Function 0: Encoder pulse increases in the servo motor CCW or positive direction. selection C-A 1: Encoder pulse decreases in the servo motor CCW or positive direction.

- Page 224 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PC54 Set the compensation amount of the vertical axis freefall prevention function. [0.0001 RSUP1 Set it per servo motor rotation amount or linear servo motor travel distance. rev]/ Vertical axis When setting a positive value, the servo motor or linear servo motor moves in the [0.01...

-

Page 225: I/O Setting Parameters ([Pr. Pd

5. PARAMETERS 5.2.4 I/O setting parameters ([Pr. PD_ _ ]) Initial Control No./symbol/ Setting mode Function value name digit [unit] PD01 Select input devices to turn on them automatically. *DIA1 _ _ _ x _ _ _ x (BIN): For manufacturer setting Input signal (HEX) _ _ x _ (BIN): For manufacturer setting... - Page 226 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PD03 Any input device can be assigned to the CN1-15 pin. *DI1L _ _ x x Position control mode - Device selection Input device Refer to table 5.9. selection 1L x x _ _ Speed control mode - Device selection...

- Page 227 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PD07 Any input device can be assigned to the CN1-17 pin. *DI3L When "_ _ _ 1" is set in [Pr. PA03] and absolute position detection system by DIO is selected, the CN1-17 pin will become ABSM (ABS transfer mode).

- Page 228 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PD19 Any input device can be assigned to the CN1-44 pin. *DI9L _ _ x x Position control mode - Device selection Input device Refer to table 5.9 in [Pr. PD03] for settings. selection 9L x x _ _ Speed control mode - Device selection...

- Page 229 5. PARAMETERS Control Initial No./symbol/ Setting Function value mode name digit [unit] PD24 _ _ x x Device selection *DO2 Any output device can be assigned to the CN1-23 pin. Output device When "Enabled (absolute position detection system by DIO) (_ _ _ 1)" is selected in selection 2 [Pr.