Table of Contents

Advertisement

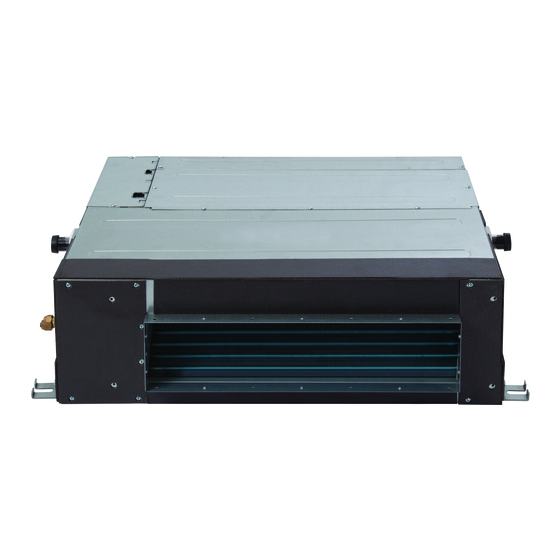

40MB*D

Ducted Ductless System

Sizes 09 to 48

TABLE OF CONTENTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIMENSIONS/CLEARANCES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY CONSIDERATIONS

Installing, starting up, and servicing air−conditioning equipment

can be hazardous due to system pressures, electrical components,

and equipment location (roofs, elevated structures, etc.).

Only trained, qualified installers and service mechanics should

install, start−up, and service this equipment.

Untrained personnel can perform basic maintenance functions such

as cleaning coils. All other operations should be performed by

trained service personnel.

When working on the equipment, observe precautions in the literature

and on tags, stickers, and labels attached to the equipment.

Follow all safety codes. Wear safety glasses and work gloves. Keep

quenching cloth and fire extinguisher nearby when brazing. Use

care in handling, rigging, and setting bulky equipment.

Read this manual thoroughly and follow all warnings or cautions

included in literature and attached to the unit. Consult local building

codes and National Electrical Code (NEC) for special requirements.

Recognize safety information. This is the safety−alert symbol

When you see this symbol on the unit and in instructions or manuals,

be alert to the potential for personal injury. Understand these signal

words: DANGER, WARNING, and CAUTION.

Service Manual

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

These words are used with the safety−alert symbol. DANGER

identifies the most serious hazards which will result in severe personal

PAGE

injury or death. WARNING signifies hazards which could result in

1

personal injury or death. CAUTION is used to identify unsafe

1

practices which may result in minor personal injury or product and

2

property damage. NOTE is used to highlight suggestions which will

3

result in enhanced installation, reliability, or operation.

4−5

!

6

6

ELECTRICAL SHOCK HAZARD

7

Failure to follow this warning could result in personal

8

injury or death.

13

Before installing, modifying, or servicing system, the

13

main electrical disconnect switch must be in the OFF

14

position. There may be more than 1 disconnect switch.

18

Lock out and tag switch with a suitable warning label.

35

39

!

!

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not bury more than 36 in. (914 mm) of refrigerant pipe

! !

.

in the ground. If any section of pipe is buried, there must be

a 6 in. (152 mm) vertical rise to the valve connections on

the outdoor units. If more than the recommended length is

buried, refrigerant may migrate to the cooler buried section

during extended periods of system shutdown. This causes

refrigerant slugging and could possibly damage the

compressor at start−up.

INTRODUCTION

This service manual provides the necessary information to service,

repair, and maintain the indoor units. Section 2 of this manual has an

appendix with data required to perform troubleshooting. Use the Table

of Contents to locate a desired topic.

WARNING

WARNING

EXPLOSION HAZARD

Failure to follow this warning could

result in death, serious personal injury,

and/or property damage.

Never use air or gases containing

oxygen for leak testing or operating

refrigerant compressors. Pressurized

mixtures of air or gases containing

oxygen can lead to an explosion.

CAUTION

Advertisement

Table of Contents

Summary of Contents for Carrier 40MBQB09D-3

-

Page 1: Table Of Contents

40MB*D Ducted Ductless System Sizes 09 to 48 Service Manual TABLE OF CONTENTS These words are used with the safety−alert symbol. DANGER identifies the most serious hazards which will result in severe personal PAGE injury or death. WARNING signifies hazards which could result in SAFETY CONSIDERATIONS . -

Page 2: Model Serial Number Nomenclatures

MODEL SERIAL NUMBER NOMENCLATURES Table 1—Unit Sizes SYSTEM TONS VOLTAGE/PH/HZ INDOOR MODEL 40MBQB09D--3 40MBQB12D--3 40MBQB18D--3 208-230/1/60 40MBQB24D--3 40MBQB36D--3 40MBQB48D--3 INDOOR UNIT 40 = FAN COIL UNIT VOLTAGE 3 = 208/230-1-60 MB = MODEL SYSTEM TYPE Q = HEAT PUMP B = ALL SIZES NOT USED NOMINAL CAPACITY 09 - 3/4 TON... -

Page 3: Specifications

SPECIFICATIONS Table 2—Specifications SIZE System Indoor Model 40MBQB09D--3 40MBQB12D--3 40MBQB18D--3 40MBQB24D--3 40MBQB36D--3 40MBQB48D--3 Voltage, Phase, V/Ph/Hz 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60 Cycle Electrical Power Supply Indoor unit powered from outdoor unit 0.51 0.51 0.62 0.62 0.73 Wireless Remote Controller Standard Standard Standard... - Page 4 DIMENSIONS air inlet from rear side Air filter 4-install hanger Liquid side Ø 0.98(25) Gas side Drain pipe Ø 0.98(25) Drain pipe Test mouth & Test cover 0.98(25) Drain connecting pipe ( for pump ) Outside Air Intake Electric control box Air filter air inlet from bottom side Fig.

- Page 5 CLEARANCES Fig. 2 – Indoor Unit Clearance Table 4—Indoor Unit Clearance Capacity (Kbtu) 27.56 in. (70cm) 8.27 in. (21cm) 11.81 in. (30cm) 27.56 in. (70cm) 8.27 in. (21cm) 11.81 in. (30cm) 36.22 in. (92cm) 8.27 in. (21cm) 11.81 in. (30cm) 36.22 in.

-

Page 6: Electrical Data

ELECTRICAL DATA Table 5—Electrical Data MAX FUSE UNIT SIZE INDOOR FAN CB AMP V-PH-HZ 1.03 0.07 1.03 0.07 Refer to outdoor unit installation instructions – 0.83 0.12 Indoor unit powered by the outdoor unit 208-230/1/60 0.83 0.12 1.263 2.23 0.32 LEGEND FLA −... -

Page 7: Connection Diagram

CONNECTION DIAGRAM Fig. 3 – Connection Diagram Notes: 1. Do not use thermostat wire for any connection between indoor and outdoor units. 2. All connections between indoor and outdoor units must be as shown. The connections are sensitive to polarity and will result in a fault code. -

Page 8: Wiring Diagrams

WIRING DIAGRAMS Fig. 4 – Wiring Diagram Sizes 09 − 12 Table 6—Wiring Diagram Sizes 09 − 12 INDOOR UNIT CODE PART NAME Input: 230VAC High voltage Connection of the terminal Input: 230VAC High voltage Connection of the terminal CN3/CN26 Output: 0V Connection of the earth Output: 0-5VDC Connection of the Water level switch Output: 5VDC Connection of the Room and Pipe temperature... - Page 9 WIRING DIAGRAMS (CONT) Fig. 5 – Wiring Diagram Size 18 Table 7—Wiring Diagram Sizes 18 INDOOR UNIT CODE PART NAME Input: 230VAC High voltage Connection of the terminal Input: 230VAC High voltage Connection of the terminal CN3/CN26 Output: 0V Connection of the earth Output: 0-5VDC Connection of the Water level switch Output: 5VDC Connection of the Room and Pipe temperature CN8/CN18...

- Page 10 WIRING DIAGRAMS (CONT) Fig. 6 – Wiring Diagram Size 24 Table 8—Wiring Diagram Sizes 24 INDOOR UNIT CODE PART NAME Input: 230VAC High voltage Connection of the terminal Input: 230VAC High voltage Connection of the terminal CN3/CN26 Output: 0V Connection of the earth Output: 0-5VDC Connection of the Water level switch Output: 5VDC Connection of the Room and Pipe temperature CN8/CN18...

- Page 11 WIRING DIAGRAMS (CONT) Fig. 7 – Wiring Diagram Size 36 Table 9—Wiring Diagram Sizes 36 INDOOR UNIT CODE PART NAME Input: 230VAC High voltage Connection of the terminal Input: 230VAC High voltage Connection of the terminal Output: 0V Connection of the earth Output: 0-5VDC Connection of the Water level switch Output: 5VDC Connection of the Room and Pipe temperature Output: 5VDC Connection of the Outer Pipe temperature...

- Page 12 WIRING DIAGRAMS (CONT) Fig. 8 – Wiring Diagram Size 48 Table 10—Wiring Diagram Sizes 48 CODE PART NAME Indoor Unit Input: 230VAC High voltage Connection of the terminal Input: 230VAC High voltage Connection of the terminal Output: 0V Connection of the earth Output: 0-5VDC Connection of the Water level switch Output: 5VDC Connection of the Room and Pipe temperature Output: 5VDC Connection of the Outer Pipe temperature...

-

Page 13: Refrigeration Cycle Diagram

REFRIGERATION CYCLE DIAGRAM Fig. 9 – Refrigerant Cycle Diagram REFRIGERANT LINES General refrigerant line sizing: 1 The outdoor units are shipped with a full charge of R410A 4 Both lines must be insulated. Use a minimum of 1/2−in. refrigerant. All charges, line sizing, and capacities are based on (12.7 mm) thick insulation. -

Page 14: System Evacuation And Charging

Deep Vacuum Method SYSTEM EVACUATION AND The deep vacuum method requires a vacuum pump capable of CHARGING pulling a vacuum of 500 microns and a vacuum gage capable of accurately measuring this vacuum depth. The deep vacuum method CAUTION is the most positive way of assuring a system is free of air and liquid water. -

Page 15: Main Protection

COOLING Mode Main Protection Indoor Fan Running Rules Fan Speed is Out of Control In the COOLING mode, the indoor fan runs all the time and the When the indoor fan speed remains too low (lower than 300RPM) speed can be selected as high, medium, low and auto. When the for 50s, the indoor fan will shut off and restarts 30 sec later, if setting temperature is reached, if the compressor stops running, the protection occurred 3 times when the fan motor restarts... - Page 16 HEATING Mode Evaporator Coil Temperature Protection Indoor Fan Running Rules When the compressor is on, the indoor fan can be set to high/med/low/auto/mute. When the indoor unit coil temperature is low, the anti−cold air function starts and the indoor fan motor runs at a low speed and the speed can not be changed.

- Page 17 Evaporator Anti−Freezing Protection Refrigerant Leakage Detection The evaporator anti−freezing protection condenser high With this new technology, the display area displays “EC” when the temperature protection and outdoor unit frequency limit are active outdoor unit detects a refrigerant leak. This function is only active and the same as that in the COOLING mode.

-

Page 18: Troubleshooting

Problems may occur that are not covered by a diagnostic code, but TROUBLESHOOTING are covered by the diagnostic flow charts. These problems are This section provides the required flow charts to troubleshoot typical air conditioning mechanical or electrical issues that can be problems that may arise. - Page 19 Indoor Unit Diagnostic Guide Table 11—Indoor Unit Error Display Operation Lamp Timer Lamp Display LED Status ☆ Indoor unit EEPROM error 1 time ☆ 2 times Communication malfunction between indoor and outdoor units ☆4 times Indoor fan speed has been out of control ☆5 times Indoor room temperature sensor T1 open circuit or short circuit ☆6 times...

-

Page 20: Diagnosis And Solution

DIAGNOSIS AND SOLUTION EEPROM error diagnosis and solution (E0/F4) Error Code E0/F4 Malfunction decision conditions Indoor or outdoor PCB main chip does not receive feedback from EEPROM chip. Installation mistake Supposed causes PCB faulty Troubleshooting: Fig. 23 – Troubleshooting Fig. 24 – Indoor PCB Fig. - Page 21 DIAGNOSIS AND SOLUTION (CONT) Communication malfunction between indoor and outdoor units diagnosis and solution (E1) Error Code Indoor unit does not receive the feedback from outdoor unit during 110 seconds and this Malfunction decision conditions condition happens four times continuously. Wiring mistake Supposed causes Indoor or outdoor PCB faulty...

- Page 22 DIAGNOSIS AND SOLUTION (CONT) Remark: Use a multimeter to test the DC voltage between L2 port and S port of outdoor unit. The red probe of the multimeter connects with L2 port while the black pin is for S port. When the system is running normal, the voltage will move alternately between -50V to 50V.

- Page 23 DIAGNOSIS AND SOLUTION (CONT) Fan speed is out of control diagnosis and solution (E3) Error Code When the indoor fan speed keeps too low (300RPM) for certain time, the unit stops and Malfunction decision conditions the LED displays the failure. Wiring mistake Fan assembly faulty Supposed causes...

- Page 24 Index 1: 1 Indoor DC fan motor (control chip is inside fan motor) Power on and when the unit is in standby, measure the voltage of pin1−pin3, pin4−pin3 in fan motor connector. If the value of the voltage is not in the range showing in below table, the PCB must have problems and need to be replaced. Fig.

- Page 25 DIAGNOSIS AND SOLUTION (CONT) Open circuit or short circuit of temperature sensor diagnosis and solution (E4/E5/F1/F2/F3) Error Code E4/E5/F1/F2/F3 If the sampling voltage is lower than 0.06V or higher than 4.94V, the LED displays the Malfunction decision conditions failure. Wiring mistake Supposed causes Sensor faulty Replace the sensor...

- Page 26 DIAGNOSIS AND SOLUTION (CONT) Refrigerant Leakage Detection diagnosis and solution (EC) Error Code Define the evaporator coil temp.T2 of the compressor just starts running as Tcool. In the beginning 5 minutes after the compressor starts up, if T2 35 Tcool 35_F does not keep Malfunction decision conditions continuous 4 seconds and this situation happens 3 times, the display area will show “EC”...

- Page 27 DIAGNOSIS AND SOLUTION (CONT) Water−level alarm malfunction diagnosis and solution Error Code Malfunction decision conditions If the sampling voltage is not 5V, the LED will display the failure. Wiring mistake Water-level switch faulty Supposed causes Water pump faulty Indoor PCB faulty Fig.

- Page 28 DIAGNOSIS AND SOLUTION (CONT) IPM malfunction or IGBT over−strong current protection diagnosis and solution (P0) Error Code When the voltage signal that IPM send to compressor drive chip is abnormal, the display Malfunction decision conditions LED shows “P0” and AC turns off. Wiring mistake;...

- Page 29 DIAGNOSIS AND SOLUTION (CONT) Fig. 36 – P−U Fig. 37 – P−V...

- Page 30 DIAGNOSIS AND SOLUTION (CONT) Fig. 38 – P−W Fig. 39 – P−N...

- Page 31 DIAGNOSIS AND SOLUTION (CONT) Over voltage or too low voltage protection diagnosis and solution (P1) Error Code An abnormal voltage rise or drop is detected by checking the specified voltage detection Malfunction decision conditions circuit. Power supply problems Supposed causes System leakage or block PCB faulty Stop the unit...

- Page 32 DIAGNOSIS AND SOLUTION (CONT) High temperature protection of compressor top diagnosis and solution (P2) Error Code Malfunction decision conditions If the sampling voltage is not 5V, the LED displays the failure. Power supply problems Supposed causes System leakage or block PCB faulty Check the air flow system Clear up the air inlet and outlet or the heat...

- Page 33 DIAGNOSIS AND SOLUTION (CONT) Inverter compressor drive error diagnosis and solution (P4) Error Code An abnormal inverter compressor drive is detected by a special detection circuit, Malfunction decision conditions including communication signal detection, voltage detection, compressor rotation speed signal detection. Wiring mistake;...

- Page 34 APPENDIX 1 Table 13— Temperature Sensor Resistance Value Table for T1,T2,T3,T4 (t−−K) K Ohm K Ohm K Ohm K Ohm 115.266 12.6431 2.35774 0.62973 108.146 12.0561 2.27249 0.61148 101.517 11.5 2.19073 0.59386 96.3423 10.9731 2.11241 0.57683 89.5865 10.4736 2.03732 0.56038 84.219 1.96532 0.54448...

-

Page 35: Appendix 2

APPENDIX 2 Table 14— Temperature Sensor Resistance Value Table for T5 (t−−K) K Ohm K Ohm K Ohm K Ohm 542.7 68.66 13.59 3.702 511.9 65.62 13.11 3.595 62.73 12.65 3.492 455.9 59.98 12.21 3.392 430.5 57.37 11.79 3.296 406.7 54.89 11.38 3.203... - Page 36 IPM Continuity Check Turn off the power, let the large capacity electrolytic capacitors discharge completely, and dismount the IPM. Use a digital tester to measure the resistance between P and UVWN; UVW and N. Table 16— IPM Continuity Check Digital Tester Normal Resistance value Digital Tester Normal Resistance Value...

- Page 37 Heating Chart Table 18—Heating Chart Outdoor Temperature _F/_C Indoor temp. 57 (13.89) 47 (8.33) 37 (2.78) 27 (-2.78) 17 (-8.33) 30.3 28.5 25.3 22.8 20.8 32.5 30.0 26.6 25.4 23.3 33.8 31.5 27.8 26.3 24.9 3.03 2.85 2.53 2.28 2.08 3.25 3.00 2.66...

- Page 38 DISASSEMBLY INSTRUCTIONS NOTE: This section is for reference only. The images may differ slightly from your actual unit. Parts name Procedures Remarks Remove the 1) Unscrew the screws and remove the electronic electronic control box cover. control box Four screws 2) Disconnect the fan motor Room temperature sensor plug and...

-

Page 39: Disassembly Instructions

DISASSEMBLY INSTRUCTIONS (CONT) 4 Move the display board Move the display board according to the arrow’s direction to disassemble. Remove the Remove the electronic Repeat step 1 of No. 1 control box cover. 2 Remove all the plugs or connectors connected to the PCB and remove the ground wire after removing the screw. - Page 40 DISASSEMBLY INSTRUCTIONS (CONT) Remove 1 Unscrew the securing screws to remove the rear the fan cover board. motor Rear cover board 5 screws 2 Unscrew the securing screws to remove the rear Rear beam beam. Total of 4 screws at the left and right sides Cut off the fastening Remove the room belt to remove the...

- Page 41 DISASSEMBLY INSTRUCTIONS (CONT) Remove the 1) Remove the rear cover Repeat step1 of No.5 water board. collector 2) Unscrew the screws to 4 screws assembly remove the water collector assembly. 3 screws 3 screws 3 screws Water collector assembly Remove the 1) Remove the water Repeat step No.6 evaporator...

- Page 42 1 screw Catalog No: 40MBD-01SM Copyright 2017 Carrier Corp. D 7310 W. Morris St. D Indianapolis, IN 46231 Edition Date: 01/17 Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations. Replaces: NEW...

Need help?

Do you have a question about the 40MBQB09D-3 and is the answer not in the manual?

Questions and answers