Table of Contents

Advertisement

Quick Links

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 1,2

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Unit Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

PREINSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-12

Rigging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Suspended Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Service Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

External Vibration Isolators. . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-35

Base Rail Split . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Mixing Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Variable Frequency Drive (VFD) . . . . . . . . . . . . . . . . . . . . . . . 16

Install Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install Sheaves on Motor and Fan Shafts . . . . . . . . . . . . . 16

Install V-Belts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Water and Steam Coil Piping Recommendations . . . . . 19

Coil Freeze-Up Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Refrigerant Piping, Direct Expansion (DX) Coils . . . . . . 24

Electric Heaters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Discharge Modification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35,36

Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36-46

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Fan Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Coil Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Winter Shutdown (Chilled Water Coil Only) . . . . . . . . . . . 36

Field-Installed Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Coil Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Changing Coil Hand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Fan Shaft Bearing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Fan and Shaft Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fan Sled Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

METRIC CONVERSION CHART . . . . . . . . . . . . . . . . . . . . . . . 47

SAFETY CONSIDERATIONS

Air-handling equipment is designed to provide safe and

reliable service when operated within design specifications. To

avoid injury to personnel and damage to equipment or property

when operating this equipment, use good judgment and follow

safe practices as outlined below.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53390016-01

Printed in U.S.A.

Installation, Start-Up and

Service Instructions

Page

Form 39L-7SI

39LA,LB,LC,LD,LF,LG,LH03-25

Indoor Air-Handling Units

NEVER enter an enclosed fan cabinet or reach into a unit

while the fan is running.

LOCK OPEN AND TAG the fan motor power disconnect

switch before working on a fan. Take fuses with you and

note removal on tag. Electric shock can cause personal

injury or death.

LOCK OPEN AND TAG the electric heat coil power dis-

connect switch before working on or near heaters.

CHECK the assembly and component weights to be sure

that the rigging equipment can handle them safely. Note

also, the centers of gravity and any specific rigging

instructions.

CHECK for adequate ventilation so that fumes will not

migrate through ductwork to occupied spaces when weld-

ing or cutting inside air-handling unit cabinet or plenum.

WHEN STEAM CLEANING COILS be sure that the area

is clear of personnel.

DO NOT attempt to handle access covers and removable

panels on outdoor units when winds are strong or gusting

until you have sufficient help to control them. Make sure

panels are properly secured while repairs are being made to

a unit.

DO NOT remove access panel fasteners until fan is com-

pletely stopped. Pressure developed by a moving fan can

cause excessive force against the panel which can injure

personnel.

DO NOT work on dampers until their operators are

disconnected.

BE SURE that fans are properly grounded before working

on them.

Pg 1

DANGER

WARNING

816

3-14

Replaces: 39L-6SI

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Carrier 39LH

-

Page 1: Table Of Contents

39LA,LB,LC,LD,LF,LG,LH03-25 Indoor Air-Handling Units Installation, Start-Up and Service Instructions CONTENTS DANGER Page SAFETY CONSIDERATIONS ......1,2 NEVER enter an enclosed fan cabinet or reach into a unit INTRODUCTION . -

Page 2: Introduction

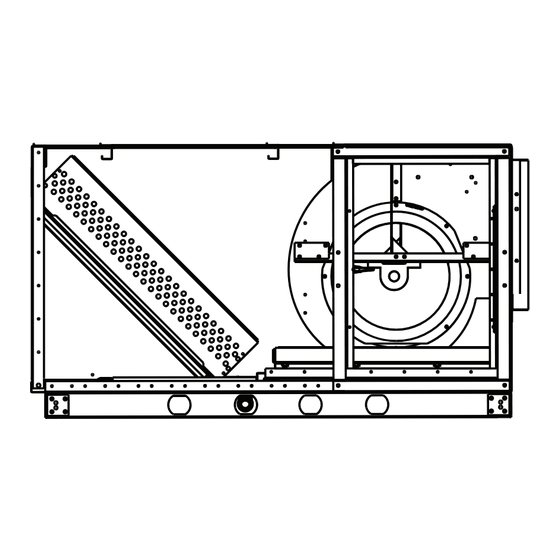

See Fig. 1-9 for unit identification. repairs cannot be completed. Failure to follow these proce- dures may result in damage to equipment. 39LA 39LC 39LG 39LB HORIZONTAL DRAW-THRU 39LD 39LH 39LF a39-4440 VERTICAL DRAW-THRU Fig. 1 — Unit Identification... - Page 3 39L – 39L Special Order Air Handler Insulation/Suspension Package/Hand Side Model Fan Discharge – Motor Frequency Fan Speed Unit Size Motor HP – Type – Voltage Base Unit Coil Description Base Unit Coil Coil Type and Arrangement Preheat Coil a39-4441 Draw-Thru Options Fig.

- Page 4 B V 1 28N – Coil Model Number Hand – Right Hand Coil Type – Left Hand B – Hot Water – Non-ferrous Coil Orientation V – Vertical Rows Tube Size (Copper) A – 0 .016 Std. H-Pin B – 0 .025 Std. H-Pin Circuiting Fin Material Fins Per Inch...

- Page 5 28L – Coil Model Number Coil Type [ Blank] Z – Steam Distributing Tube (1 in. OD) [ Blank] Coil Position Rows Circuiting Tube Size (Copper) 3 – 1 in. OD x 0.030 Wall Fin Material Fins Per Inch Casing Material C –...

- Page 7 SMALL FACE AREA LARGE FACE AREA a39-4447 39LD – VERTICAL COOLING 39LF – VERTICAL COOLING/HEATING 39LG – FAN ONLY 39LH – VERTICAL HEATING LARGE FACE AREA SMALL FACE AREA SMALL FACE AREA ACCESSORY SECTIONS 9 FILTER MIXING BOX FILTER MIXING BOX...

- Page 8 25.2 29.1 29.1 29.1 37.0 40.9 40.9 48.8 39LG 21.3 25.2 29.1 29.1 29.1 37.0 40.9 40.9 48.8 39LH ACCESSORIES Unit Size Height (in.) 24.3 28.2 32.1 32.1 32.1 40.0 43.9 43.9 43.9 Width (in.) 37.9 45.8 49.7 57.6 65.1 65.1...

-

Page 9: Preinstallation

Figure 12 shows overhead suspen- PREINSTALLATION Suspended Units — sion of unit using optional factory-supplied suspension 1. Check items received against packing list. Notify Carrier channels. of any discrepancy. Each support channel consists of 2 pieces, the smaller of 2. Refer to Fig. 10 for service area requirements. - Page 10 NOTE: Dimensions are in inches, ( ) are in mm. DIMENSIONS (mm) DIMENSIONS (ft-in.) SIZE SIZE 39LA 39LB 39LC 39LA 39LB 39LC 1- 7 2- 3 1162 1159 1-11 2- 3 1262 1259 2- 3 2- 3 1462 1459 2- 3 2- 3 1653 1659...

- Page 11 Table 2 — Additional Component Weights UNIT SIZE TYPICAL DRY COIL WEIGHTS (lb) Large Face Area Cooling Coils, -in. OD (Chilled Water & DX)* 4-Row 6-Row Small Face Area Cooling Coils, -in. OD (Chilled Water & DX)* 4-Row 6-Row 8-Row Hot Water Coils, -in.

- Page 12 SPREADER NOTE: Lift in one piece. Use slings and spreader bars at each lifting bracket. a39-4449 LIFTING BRACKET Fig. 11 — Unit Rigging Details VIBRATION ISOLATORS (FIELD SUPPLIED) MOUNT UNIT TO SUSPENSION CHANNELS SUSPENSION ROD THROUGH / IN. DIAM. HOLES (FIELD SUPPLIED) PROVIDED IN LIFTING BRACKET SUSPENSION CHANNEL...

-

Page 13: Installation

After rejoining the split sections, fully tighten all AB in.- INSTALLATION in. screws on the flanges and the AB in. screws on the A base rail split between the primary Base Rail Split — flanges. See Fig. 16. coil/fan section and the accessory sections is optional. If this option has ben selected, the 39L unit will arrive at the job site assembled as one piece. -

Page 14: Mixing Box

Mixing Box DAMPER ACTUATORS — The 39L mixing boxes are sup- plied with low leak dampers and blade and edge seals. Damper operating torques are shown in Table 3. The actuator and mounting brackets are field supplied and may be mounted inside or outside the unit. A typical inside mounting bracket is shown in Fig. - Page 15 Table 4 — Recommended Actuators ROUND DAMPER AREA MAXIMUM ACCESSORY SHAFT (sq ft) MAXIMUM ACTUATOR VOLTAGE TIMING TORQUE WIRE PACKAGE SIZE STROKE PART NO. (50/60 Hz) (sec) (in.-lb) LENGTH MIN-MAX (degrees) Parallel Opposed (ft) (in.) 33AMACTDMP133 HF27BJ035* 0.750-1.050 33AMACTGV-133 HF27BJ033 0.375-0.625 <...

-

Page 16: Condensate Drain

Install Sheaves on Motor and Fan Shafts — DIFFERENTIAL Factory-supplied drives are prealigned and tensioned, however, Carrier recommends that you check the belt tension and align- ment before starting the unit. Always check the drive align- ment after adjusting belt tension. -

Page 17: Install V-Belts

Fig. 21 — Determining Sheave-Shaft Overhang assembly. For this reason, substitution of motor sheave is preferable for final speed adjustment. When installing or replacing belts, al- Install V-Belts — ways use a complete set of new belts. Mixing old and new belts will result in the premature wear or breakage of the newer belts. - Page 18 Tension Measurement Procedure tensioned at this value to allow for expected tension loss. “New Belt” tensions should be used at initial installation 1. Measure the belt span (see Fig. 23). and after job start or 1 to 3 minutes of operation. Used 2.

-

Page 19: Water And Steam Coil Piping Recommendations

Do not use the coil connections to support piping. When tightening coil connections, use a REPLACEMENT PARTS backup wrench on the nozzles. Piping practices are outlined in the Carrier System Design BEARINGS Manual, Part 3, Piping Design. See Tables 6-7 for circuiting data. DRIVE ________________________ WATER COILS —... - Page 20 For vacuum return systems, the vacuum breaking check valve would be piped into the condensate line between the trap and the gate valve instead of open to the atmosphere. Figure 27 illustrates the typical piping at the end of every steam supply main.

- Page 21 Table 7 — Chilled Water Coil Circuiting Data LARGE FACE AREA (39LA, 39LD) UNIT SIZE COIL Face Area (sq ft) CIRCUIT TYPE 3.63 5.90 7.90 9.54 11.18 Connection Connection Connection Connection Connection Circuits Size Circuits Size Circuits Size Circuits Size Circuits Size —...

-

Page 22: Coil Freeze-Up Protection

INNER DISTRIBUTING TUBE STEAM COILS — The NOTE: IDT coils must be installed with the tubes draining inner distributing tube (IDT) steam coil used in the Carrier 39L toward the header end of the coil. Carrier's IDT steam coils air-handling units has an inner tube pierced to facilitate the dis- are pitched toward the header end as installed in the unit. - Page 23 NOTES: 1. Flange or union is located to facilitate coil removal. 2. Flash trap may be used if pressure differential between steam and condensate return exceeds 5 psi. 3. When a bypass with control is required. 4. Dirt leg may be replaced with a strainer. If so, tee on drop can be replaced by a reducing ell.

-

Page 24: Refrigerant Piping, Direct Expansion (Dx) Coils

Refrigerant Piping, Direct-Expansion (DX) Direct-expansion coils are divided into Coils (Fig. 31) — 2 or 4 splits depending upon the unit size and coil circuiting. See Table 9 for coil circuiting data. Each split requires its own distributor nozzle, expansion valve, and suction piping. Suction connections are on the air entering side when the coil is proper- ly installed. - Page 25 Refer to Carrier System Design Manual, Part 3, and size re- maining suction line to compressor for a pressure drop equiva- lent to 2.0 F. This will provide a total suction line header pres- sure drop equivalent to approximately 2.5 F.

- Page 26 Table 9 — Direct Expansion Coil Circuiting Data LARGE FACE AREA (39LA, 39LD) UNIT SIZE CIRCUITING TYPE Half Full Half Full Half Full Half Full Half Full CFM AT 550 FPM 1996 3245 4345 5247 6149 FACE AREA (sq ft) 3.63 5.90 7.90...

- Page 27 Table 9 — Direct Expansion Coil Circuiting Data (cont) SMALL FACE AREA (39LB, 39LC, 39LF) UNIT SIZE CIRCUITING TYPE Half Full Half Full Half Full Half Full Half Full CFM AT 550 FPM 1496 2596 3619 4372 5126 FACE AREA (sq ft) 2.72 4.72 6.58...

- Page 28 Table 10 — Distributor Part Numbers SPORLAN PART NO. CONNECTION NOZZLE OD (in.) TUBES Sporlan Carrier Type Size 1112-2- EA07NC261 1112-3- EA07FC027 1112-4- EA07NC262 0.88 to 12 1112-5- EA07NC263 1112-6- EA07NC264 1113-7- EA07HC207 1113-8- EA07HC208 1115-8- EA07KC240 1115-9- EA07KC241 1.12...

- Page 29 UNLOADING CONSIDERATIONS — Direct expansion SPECIAL PIPING WITH 4 SPLITS PER COIL coils can have two intertwined refrigerant circuits. In addition, Manifolding for 2-Face Splits — Refer to Fig. 38 and exter- quarter, half, full and double circuiting configurations are of- nally manifold as follows: fered to allow optimum system performance and oil return at 1.

- Page 30 TXV — Thermostatic Expansion Valve Fig. 38 — Face Split Coil Manifolding (Typical) TXV — Thermostatic Expansion Valve Fig. 39 — Row Split Coil Manifolding (Typical)

-

Page 31: Electric Heaters

multi-stage heaters, wire stage no. 1 so that it is first stage on, Electric heaters may be factory in- Electric Heaters — last stage off. Connect thermostats as required. stalled or drop shipped to the jobsite and field installed. The heater can only be installed in the preheat-electric section. - Page 32 NOTE: All wiring must be copper and must conform to the NEC (National Electrical Code). Fig. 41 — Typical Electric Heater Wiring Schematic...

- Page 33 Table 12 — Electric Heater Data 208/3/60 VOLTS 240/3/60 VOLTS 480/3/60 VOLTS 380/3/50 VOLTS NOMINAL UNIT HEATER NO. OF HEATER TEMP COIL FACE SIZE AREA CONTROL COIL RISE Total Total Total Total VELOCITY MCA† Sub- MOCP MCA† Sub- MOCP MCA† Sub- MOCP MCA†...

-

Page 34: Discharge Modification

skilled mechanic) to any standard hand and discharge without Table 13 — Field Wiring for Incoming Conductors any additional parts. (NOTE: This does not apply to a model Sized for 125% of Heater Load change conversion.) All mounting holes are prepunched. LOAD AMPS* LOAD AMPS* WIRE SIZE... -

Page 35: Start-Up

LEGEND THF — Top Horizontal Front THR — Top Horizontal Rear UBF — Upblast Front UBR — Upblast Rear Fig. 43 — Fan Discharge Positions, Sizes 21 and 25 START-UP Make a walkway inside unit components to Check List — protect insulation. -

Page 36: Service

6. Check fan speed with a strobe-type tachometer or use the DX Coil — Charge refrigerant. Also refer to condensing unit following formula: Obtain the motor rpm from the fan service and installation instructions. Refrigerant operating motor nameplate and read sheave pitch diameters marked charge for unit coil is shown in Table 2. -

Page 37: Field-Installed Coils

5. Open service valve and circulate solution for 15 minutes; install the coil with the downstream bottom of the coil attached then check its strength. to the upright mounting flange as shown in Fig. 45. Adjust the coil and then attach the top coil baffle to the top flange 6. - Page 38 SIDE HAIRPIN TOP COIL SIDE HEADER SEE TOP BAFFLE BAFFLE BAFLE FLANGE DETAIL BOTTOM MOUNTING FLANGE BOTTOM COIL BAFFLE TOP FLANGE DETAIL Fig. 46 — Field-Installed Coils (39LA and LD only) LEGEND 1 — Accessory Side Panel 8 — Condensate Baffle 2 —...

- Page 39 VERTICAL UNIT SLANT COIL REMOVAL (39LD 6. Remove screws from inside baffle (item 14). Leave baffle Units) attached to left side panel (Item 16). NOTE: Item numbers are in Fig. 48. 7. Remove left side panel (Item 16). 1. Refer to Fig. 10 for service area clearance. NOTE: Support of fan section may be required after re- moval of side panels (Items 7 and 16).

- Page 40 HORIZONTAL OR VERTICAL UNIT — DUAL COIL 4. Remove side panel(s) (Item 6). REMOVAL (39LA,39LD units — size 25) — (NOTE: Item NOTE: Vertical units may require support of fan section numbers are in Fig. 49 unless otherwise indicated.) after removal of side panels. 1.

-

Page 41: Changing Coil Hand

Hydronic versions are counterflow circuited for full gravity draining when installed level. Vertical Unit, 39LF and 39LH — Through fan access door (Item 2, Fig. 48), remove screws (Item 3, Fig. 48) Correct installation will result in the typical bottom inlet on holding angle (Item 4, Fig. -

Page 42: Filters

There are additional precautions and control strategies, as found in various catalogues and in the ASHRAE Fundamentals Handbook and in the Carrier System Design Guide — Piping Section, when the entering-air temperature to the coil falls be-... -

Page 43: Fan Shaft Bearing Removal

b. Add a few drops of oil after cleanup of shaft end. Fan Shaft Bearing Removal 1. Lock open and tag electrical disconnect. CAUTION 2. Enter through fan section access door or remove panels as required. It should not be necessary to drive a new bearing onto 3. - Page 44 SIZE 21 16” 20” 25” 25” 25” SIZE 25 20” 25” 16” 16” 20” 20” Fig. 52 — Filter Arrangement, 2-in. and 4-in. Flat...

-

Page 45: Fan And Shaft Removal

Fig. 53 — Fan Shaft and Bearing Removal – .001 Carrier-specified parts are recommended. Lubrication MOTORS — Lubricate in accordance with nameplate at- tached to motor or with manufacturer’s recommendations included with motor. -

Page 46: Fan Sled Disassembly

Fan Sled Disassembly — units (39LD, 39 LF, or 39LH), it may be necessary to remove the fan sled (Fig. 55) from the unit and break it down into smaller components. a39-4458 Fig. 57 — Remove All Panels a39-4456 Fig. -

Page 47: Metric Conversion Chart

METRIC CONVERSION CHART... - Page 48 © Carrier Corporation 2014 Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations. Catalog No. 04-53390016-01 Printed in U.S.A. Form 39L-7SI Pg 48 3-14 Replaces: 39L-6SI...

Need help?

Do you have a question about the 39LH and is the answer not in the manual?

Questions and answers