Garmin G300 Installation Manual

Pilot gps

Hide thumbs

Also See for G300:

- Pilot's manual (296 pages) ,

- User manual (22 pages) ,

- Pilot's manual (9 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Garmin G300

- Page 1 G300 Installation Manual 190-00921-01 March, 2009 Revision A...

- Page 2 Garmin. Garmin hereby grants permission to download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and...

- Page 3 NOTE Unless otherwise noted all installation guidance, requirements, and instructions apply to both the one-display and two-display G300 system. NOTE References to the GDU 37X throughout this manual apply equally to the GDU 370 and GDU 375 except where specifically noted.

-

Page 4: Table Of Contents

GSU 73/GMU 44 Interconnect Harness Fabrication Instructions............3-5 Mounting Instructions ........................3-6 Continued Airworthiness .........................3-6 GSU 73.............................4-1 Equipment Description........................4-1 Electrical Specifications........................4-2 Environmental Specifications ......................4-3 Installation Requirements.........................4-3 Installation Considerations.......................4-4 Mounting Requirements........................4-6 Unit Installation..........................4-7 Continued Airworthiness .........................4-7 Page ii G300 Installation Manual – Table of Contents Revision A 190-00921-01... - Page 5 10.4 GSU 73 – Air Data Troubleshooting....................10-7 10.5 Troubleshooting On-board the Aircraft..................10-10 10.6 GSU Page .............................10-11 Return to Service Information......................11-1 11.1 GDU 37X ............................11-1 11.2 GSU 73............................11-1 11.3 GMU 44 ............................11-2 G300 Installation Manual – Table of Contents Page iii 190-00921-01 Revision A...

- Page 6 10-5 No Info for TAS & OAT........................10-7 10-6 Airspeed and Altitude Failure Indications ..................10-7 10-7 Attitude, Heading, Air Data, and Engine/Airframe Failure ............10-9 10-8 CONFIG GSU Page ........................10-11 Page iv G300 Installation Manual – Table of Contents Revision A 190-00921-01...

- Page 7 GMU 44 Part Numbers ........................3-2 GMU 44 Accessories ........................3-2 Required Distance from Magnetic Disturbances................3-3 Parts Needed for GMU 44 Installation.....................3-5 GMU 44 Connector Kit, (011-00871-00) Contents, Reference Figure B-2.4........3-5 G300 Installation Manual – Table of Contents Page v 190-00921-01 Revision A...

- Page 8 Post-Installation Calibration Procedure Summary ................9-4 Magnetometer Interference Test Sequence Example..............9-23 10-1 GSU 73 AHRS Operating Mode Table..................10-3 10-2 GSU 73 AHRS Pitch/Bank Limitations for Cold Start While Airborne ........10-3 Page vi G300 Installation Manual – Table of Contents Revision A 190-00921-01...

- Page 9 Garmin retains the exclusive right to repair or replace the unit or software or offer a full refund of the purchase price at its sole discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

- Page 10 Garmin retains the exclusive right to repair or replace the unit or software or offer a full refund of the purchase price at its sole discretion. SUCH REMEDY SHALL BE YOUR SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF WARRANTY.

-

Page 11: G300 Installation Overview

If the unit is damaged, notify the carrier and file a claim. To justify a claim, save the original shipping container and all packing materials. Do not return the unit to Garmin until the carrier has authorized the claim. -

Page 12: System Overview

This design greatly eases troubleshooting and maintenance of the G300 system. A failure or problem can be isolated to a particular LRU, which can be replaced quickly and easily. Each LRU has a particular function, or set of functions, that contributes to the system’s operation. -

Page 13: General G300 Lru Specifications

1.4 General G300 LRU Specifications 1.4.1 Garmin LRU Part Numbers Table 1-1. G300 LRU Part Numbers Assembly Part Unit Only Part Number Number GDU 370 011-01747-10 010-00667-10 GDU 375 011-01747-30 010-00667-30 GMU 44 011-00870-00 010-00296-00 GSU 73 011-01817-00 010-00691-00 1.4.2 Power Specifications All LRUs are capable of operating at either 14 or 28 VDC. -

Page 14: Mounting

FAA AC 43.13-1B and AC 43.13-2A. 1.5 Mounting Refer to Section 2 through Section 6 for specific mounting instructions for each component of the G300, and to Appendix A for Outline & Installation Drawings. It may be necessary to mount the GSU 73 and/or the GMU44 remotely due to spacing/accessibility concerns, or due to weight/balance requirements. -

Page 15: Wiring/Cabling Considerations

Check that there is ample space for the cabling and mating connectors. Avoid sharp bends in cabling and routing near aircraft control cables. Cabling for the G300 should not be routed near components or cabling which are sources of electrical noise. Route the GPS antenna cable as far as possible away from all COM transceivers and antenna cables. -

Page 16: Pin Contact And Crimp Tools Part Numbers

Jackscrew kit) NOTES 1. Insertion/Extraction tools from ITT Cannon are all plastic; others are plastic with metal tip. 2. Non-Garmin part numbers shown are not maintained by Garmin and consequently are subject to change without notice. 1.6.2 Cable Location Considerations Use cable meeting the applicable aviation regulation for the interconnect wiring. -

Page 17: Coaxial Cable Installation

Connector kits include backshell assemblies. The backshell assembly houses the configuration module and a thermocouple reference junction (if applicable). Garmin’s backshell connectors give the installer the ability to quickly and easily terminate shield grounds at the backshell housing. The instructions... -

Page 18: Antenna Considerations

Locate the GDU 37X as far as possible from all COM antennas. If a COM antenna is found to be the problem, a 1.57542 GHz notch filter (Garmin P/N 330-00067-00) may be installed in the VHF COM coax, as close to the COM as possible. -

Page 19: Gdu 37X

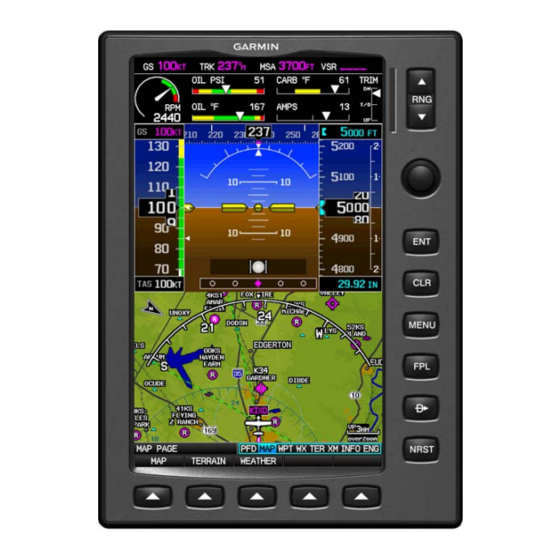

The display is mounted flush to the aircraft instrument panel using four #6 screws. A GDU 37X is available in two models, GDU 370 and GDU 375. The GDU 370 is a Garmin Display Unit with a VFR WAAS-GPS receiver. The GDU 375 provides these same features plus an XM receiver. -

Page 20: Electrical Specifications

Update Rate 5/second, continuous Positional Accuracy <10 meters Velocity Accuracy 0.05 meter/sec steady state Antenna power supply Voltage (4.5 to 5.0), current (50 mA max) Max Input Signal 40dB Page 2-2 G300 Installation Manual – GDU 37X Revision A 190-00921-01... -

Page 21: Environmental Specifications

Contact, Sckt, D-Sub, Crimp, Size 20 336-00094-00 2.4.2 Additional Equipment Required A 3/32” hex drive tool is required to secure the GDU 37X to the panel as described in Section 2.7 Unit Installation. G300 Installation Manual – GDU 37X Page 2-3 190-00921-01 Revision A... -

Page 22: Installation Considerations

Connector kits include backshell assemblies. The backshell assembly houses the configuration module (if applicable). Garmin’s backshell connectors give the installer the ability to quickly and easily terminate shield grounds at the backshell housing. The instructions needed to install the Jackscrew Backshell (190- 00313-11), and Configuration Module (190-00313-10) can be downloaded from the Dealer portion of the Garmin website www.garmin.com. -

Page 23: Equipment Description

Figure 3-1. GMU 44 Unit View 3.1 Equipment Description The Garmin GMU 44 Magnetometer is a remote mounted device that interfaces with a Garmin GSU 73 to provide flight attitude and heading data for flight instrumentation. An Attitude and Heading Reference System combines the functions of a Vertical Gyro and a Directional Gyro to provide measurement of Roll, Pitch and Heading angles. -

Page 24: Environmental Specifications

115-00481-00 3.5 Installation Considerations The following guidelines describe proper mechanical installation of the Garmin GMU 44 Magnetometer. The guidelines include requirements for proper location selection in the aircraft, requirements for supporting structure and mechanical alignment and restriction on nearby equipment. -

Page 25: Required Distance From Magnetic Disturbances

The heading offset procedure is described in Section 9.3.4. It is strongly preferred that the GMU 44 alignment is within 0.5° of the aircraft longitudinal axis, rather than using the heading offset procedure. G300 Installation Manual – GMU 44 Page 3-3 190-00921-01 Revision A... - Page 26 GMU 44. Electrically isolating the light assembly should not be used as an alternative to item 1 above, unless the isolated light assembly has been analyzed for adequate protection against direct attachment of lighting. Refer to Appendix B.2 for outline and installation drawings. Page 3-4 G300 Installation Manual – GMU 44 Revision A 190-00921-01...

-

Page 27: Gsu 73/Gmu 44 Interconnect Harness Fabrication Instructions

Table 3-7. GMU 44 Connector Kit (011-00871-00) Contents, Reference Figure B-2.4 Item Garmin P/N Quantity Figure B-2.4 Ref Screw,6-32x.250,PHP,BR,w/Nyl 211-60037-08 Conn,Circular,Female,9 Ckt 330-00360-00 Backshell,Circular,Kit,SS 330-90005-01 Cont,Sckt,Mil Crp,Size 20 336-00022-00 G300 Installation Manual – GMU 44 Page 3-5 190-00921-01 Revision A... -

Page 28: Section 3 3-1 –

If the GMU 44 is ever removed, the anti-rotation properties of the mounting screws must be restored. This may be done by replacing the screws with new Garmin PN 211-60037-08. If original screws must be re-used, coat screw threads with Loctite 242 (blue) thread-locking compound, Garmin PN 291-00023-02, or equivalent. -

Page 29: Equipment Description

Garmin GSU 73 Sensor Unit is not a TSO-certified product and has received no FAA approval or endorsement. The GSU 73 is intended to be used as a part of the G300, and it is not suitable for certified configurations. - Page 30 4.2 Electrical Specifications Table 4-1. GSU 73 Supply Specifications Characteristic Specification Input Voltage Range 9-29 Vdc Power Input 1.75 Amp @ 14 Vdc (Max) 0.80 Amp @ 28 Vdc (Max) Page 4-2 G300 Installation Manual – GSU 73 Revision A 190-00921-01...

-

Page 31: Installation Requirements

Table 4-4. Contents of P731 Connector Kit (011-01818-00) Item Garmin P/N Quantity Sub-Assy,Backshell w/Hdw,Jackscrew 011-01855-03 Connector ,Hi Dens, D-Sub, Mil Crimp 62ck 330-00185-62 Contact Pin, Mil Crimp, Size 22D 336-00021-00 G300 Installation Manual – GSU 73 Page 4-3 190-00921-01 Revision A... -

Page 32: Installation Considerations

Connector kits include backshell assemblies. The backshell assembly houses the configuration module and a thermocouple reference junction (if applicable). Garmin’s backshell connectors give the installer the ability to quickly and easily terminate shield grounds at the backshell housing. The instructions... -

Page 33: Gsu 73 Air Hose Fitting Locations

3. Use care to avoid getting fluids or particles anywhere within the pitot and static lines connected to the GSU 73. The installer must fabricate any additional mounting equipment needed. Use outline and installation drawings in Appendix B.3 for reference. G300 Installation Manual – GSU 73 Page 4-5 190-00921-01 Revision A... - Page 34 Do not mount the GSU 73 in an enclosed area, it should be mounted in a location that provides adequate airflow to comply with the maximum outer case temperature listed in Section 4.3. Page 4-6 G300 Installation Manual – GSU 73 Revision A 190-00921-01...

-

Page 35: Unit Installation

The GSU 73 utilizes an Earth magnetic field model which is updated once every five years. The update is expected to be available from Garmin by July 1 of each of the following years: 2010, 2015, and every five years thereafter, so long as the GSU 73 remains a Garmin –supported product. Otherwise maintenance of the GSU 73 is ‘on condition’... -

Page 36: Section 4 4-1 –

This page intentionally left blank Page 4-8 G300 Installation Manual – GSU 73 Revision A 190-00921-01... - Page 37 Figure 5-1. GTP 59 5.1 Equipment Description The Garmin GTP 59 is an outside mounted temperature probe that provides raw air temperature data. The temperature input device is a three-wire temperature probe interface. OAT Power Out and OAT High are connected internally at the OAT probe.

- Page 38 5.2.2 Environmental Qualification Form Refer to the GTP 59 Environmental Qualification Form (Garmin P/N 005-00191-97) for a complete list of environmental characteristics. 5.3 Installation Considerations 5.3.1 GTP 59 Icing The GTP 59 OAT probe has no icing protection. If ice accumulates on the GTP 59 OAT probe, its accuracy is unknown.

- Page 39 10. Wrap the cable bundle with Silicone Fusion Tape (GPN: 249-00114-00 or a similar) at the point where the backshell strain relief and cast housing contact the cable bundle. The smooth side of the backshell strain relief should contact the tape. G300 Installation Manual – GTP 59 Page 5-3 190-00921-01...

-

Page 40: Section 5 5-1 –

Refer to Figure B-4.1 GTP 59 O.A.T. Probe Wiring Detail for wiring and mounting instructions. 5.5 Continued Airworthiness Maintenance of the GTP 59 is “on condition” only. Periodic maintenance of the GTP 59 is not required. Page 5-4 G300 Installation Manual – GTP 59 Revision A 190-00921-01... -

Page 41: Antennas

Antennas Connect the GPS antenna to the PFD unit only. The G300 is software configured to use only GPS signals input to the PFD, other GPS inputs are not currently configured for use. 6.1 Antenna Mounting Location The GPS antenna is a key element in the overall system performance and integrity for a GPS navigation system. -

Page 42: Recommended Antenna Placement

Figure 6-1 below shows the recommended placement of antennas. Figure 6-1. Recommended Antenna Placement Page 6-2 G300 Installation Manual – Antennas Revision A 190-00921-01... -

Page 43: Antenna Doubler/Backing Plate

The bottom of the antenna does not need to make contact with the ground plane (i.e. the surface may be painted). The antenna will capacitively couple to the ground plane beneath the paint or aircraft cover. G300 Installation Manual – Antennas Page 6-3 190-00921-01... -

Page 44: Section 6 6-1 –

This page intentionally left blank Page 6-4 G300 Installation Manual – Antennas Revision A 190-00921-01... -

Page 45: Non-G300 Lru Interfaces

Non-G300 LRU Interfaces SL40 The G300 system can load communication frequencies to the SL40 via an RS-232 interface which is output from the GDU 375. 7.1.1 Installation Requirements Refer to the SL40 Installation Manual (P/N 560-0956-03) for detailed information regarding the SL40 installation. -

Page 46: Gtx 327

Conn Plate w/hex, GTX327 125-00032-04 Screw, 4-40x.187, PHP, SS/P, w/NYL 211-60234-06 Wshr, Flat, Non-Std, SS, ID.449 212-20014-00 Snap Ring, Ext, 7/16" 232-00013-01 Spring,Washer, .620 234-10002-00 BNC, Male/Female, Snap Ring 330-00326-00 Page 7-2 G300 Installation Manual – Non-G300 LRU Interfaces Revision A 190-00921-01... -

Page 47: Software, Configuration, Databases, And Xm Activation

1. Turn on the unit in configuration mode. 2. Use the FMS Joystick to select the CONFIG MAIN page (if needed). 3. Note the displayed software version. G300 Installation Manual – Software, Configuration, Databases ,and XM Activation Page 8-1 190-00921-01... - Page 48 4. Press the ENT key to highlight the database information. 5. Use the FMS Joystick to scroll down as needed to display the audio database information. Page 8-2 G300 Installation Manual – Software, Configuration, Databases, and XM Activation Revision A 190-00921-01...

-

Page 49: Software Loading Procedure

Do the following steps to place files for software and configuration loading in the appropriate location on the SD card: 1. Place the “gupdate.gcd” file in the “Garmin” folder, or use the provided software update application. 2. Copy all configuration .ini files to the “/Garmin/config” folder 8.3.1... - Page 50 3. After pressing the UPDATE SW softkey a confirmation will be requested. Press the ENT Key to begin updating the GSU software. 4. Allow the software load to complete. Page 8-4 G300 Installation Manual – Software, Configuration, Databases, and XM Activation Revision A 190-00921-01...

- Page 51 6. An unsuccessful update is indicated by an UPDATE FAILED message. Attempt the load again, or reload GDU software and then attempt to load the GSU software again. G300 Installation Manual – Software, Configuration, Databases ,and XM Activation Page 8-5...

-

Page 52: Configuration Procedure

3. Use the FMS Joystick to select Yes (if not already selected) to load the C162 Baseline Configuration, and press the ENT Key. 4. Ensure that a green checkmark appears beside the configuration description to indicate a successful load. Page 8-6 G300 Installation Manual – Software, Configuration, Databases, and XM Activation Revision A 190-00921-01... -

Page 53: Garmin Database Updates

3. Upon turn-on, a screen appears which lists the databases on the SD card. A green checkbox indicates that the database already installed on the G300 is up to date, an empty checkbox indicates that the database on the SD card is more current and should be installed. -

Page 54: Available Databases

The Jeppesen aviation database (NavData) is updated on a 28-day cycle. Terrain, Airport Terrain, and Obstacle G300 topography, terrain, airport terrain, and obstacle data are updated every 56 days. The terrain and airport terrain database is updated less often, and on an irregular basis. -

Page 55: Xm Activation Instructions (Gdu 375 Only)

3. Hook up the aircraft to external power if available. The complete activation process may take 45- 60 minutes or more, depending on the demand on the XM activation system. 4. Power on the avionics and allow the G300 to power up. Do not power cycle the units during the activation process. -

Page 56: Section 8 8-1 –

This page intentionally left blank Page 8-10 G300 Installation Manual – Software, Configuration, Databases, and XM Activation Revision A 190-00921-01... -

Page 57: Post-Installation Checkout And Calibration Procedures

9. Post-Installation Checkout and Calibration Procedures The checkout procedures in this section are recommended to be performed after installing the G300, the calibration procedures are required to be performed after installing the G300. It is assumed that the person performing these checks is familiar with the aircraft, has a working knowledge of typical avionics systems, and has experience using the test equipment defined in this section. -

Page 58: Required Test Equipment

1. Power on unit and use the FMS Joystick to select the Info Page. 2. Verify that the GPS receiver is functional and able to calculate its present position. Page 9-2 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01... - Page 59 1. Power on unit and use the FMS Joystick to select the XM Page. 2. Verify that the XM receiver is functioning correctly as indicated by the green signal strength bars. See Section 8.6 for XM Activation Instructions if needed. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-3 190-00921-01...

-

Page 60: Post-Installation Calibration Procedure Summary

12 months by all aircraft manufacturers on a minimum of one production aircraft for every airframe type or model equipped with the G300 system. Page 9-4 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01... - Page 61 Wiring or grounding changes associated with a device located in the same wing as the GMU 44 is a good example of such a change. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-5 190-00921-01...

- Page 62 8. Use the FMS Joystick to highlight the Calibrate button at the bottom of the display, press the ENT Key to begin the calibration. Page 9-6 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

- Page 63 10. After a few minutes the calibration will finish and a Done button will appear at the bottom of the display, ensure that a CALIBRATION SUCCESSFUL message appears at the bottom of the display, press the ENT Key to return to the GSU Status Page. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-7 190-00921-01...

- Page 64 GPS repeater to produce positive status indications. 5. Use the FMS Joystick to select PITCH/ROLL OFFSET. 6. Use the FMS Joystick to highlight the Calibrate button, press the ENT Key. Page 9-8 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

- Page 65 9. After a few minutes the calibration will finish and a Done button will appear at the bottom of the display, ensure that a CALIBRATION SUCCESSFUL message appears at the bottom of the display, press the ENT Key to return to the GSU Status Page. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-9 190-00921-01...

-

Page 66: Aircraft Alignment

1. Enter configuration mode by holding down the left-hand softkey while powering on the GDU 37X (if needed). 2. Use the FMS Joystick to select the GSU Page (if needed). Page 9-10 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01... - Page 67 5. On the GSU Status Page, use the FMS Joystick to select MAGNETOMER. 6. Use the FMS Joystick to highlight the Calibrate button, press the ENT Key. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-11 190-00921-01...

- Page 68 30° (±5°) turn increments of the aircraft by using the compass rose radials. Dwelling at these 30° increments for the time recommended by the PFD should result in successful calibration. Page 9-12 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

- Page 69 12. When the calibration is finished, a Done button will appear at the bottom of the display, ensure that a CALIBRATION SUCCESSFUL message appears at the bottom of the display, press the ENT Key to return to the GSU Status Page. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-13 190-00921-01...

- Page 70 GSU 73 units must be communicating with the GDU 37X, and the GPS antenna must have clear view of the sky or a GPS repeater to produce positive status indications. Page 9-14 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

- Page 71 Maneuver the aircraft with the longitudinal axis aligned with the desired heading line of the compass rose. 10. Repeat the preceding steps 3, 4, and 5 until a Calibration OK message is displayed. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-15 190-00921-01...

- Page 72 CALIBRATION SUCCESSFUL message appears at the bottom of the display, press the ENT Key to return to the GSU Status Page. Page 9-16 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

- Page 73 GPS repeater to produce positive status indications. 5. Use the FMS Joystick to select ENGINE RUN-UP TEST. 6. Use the FMS Joystick to highlight the Calibrate button, press the ENT Key. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-17 190-00921-01...

- Page 74 Mounting of GSU 73 at a location that is subject to severe vibrations (example; close to an engine mount.) d) Mounting screws and other hardware for GSU 73 and/or GMU 44 not firmly attached. Page 9-18 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

- Page 75 ENGINE RUN-UP TEST PASSED message appears at the bottom of the display, press the ENT Key to return to the GSU Status Page. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-19...

- Page 76 GRS 77 AHRS. Calibration Procedures A through D are not required prior to this execution of this procedure. NOTE Garmin recommends this test be performed at least once every 12 months by all aircraft manufacturers on a minimum of one production aircraft for every airframe type or model equipped with the G300 system.

- Page 77 6. Use the FMS Joystick to highlight the Calibrate button, press the ENT Key. 7. Ensure that the aircraft has been properly prepared per the on-screen instructions. See Table 9-2 for a sample test sequence. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-21 190-00921-01...

- Page 78 MAG INTERFERENCE TEST PASSED message appears at the bottom of the display, press the ENT Key to return to the GSU Status Page. Page 9-22 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01...

-

Page 79: Magnetometer Interference Test Sequence Example

1) New equipment is installed in close proximity to the GMU 44 magnetometer. 2) An existing or new electronic device has become grounded through the aircraft structure instead of via the proper ground wire in a twisted shielded pair. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-23 190-00921-01... - Page 80 Magnetometer Calibration Procedure. A G300-equipped airplane can be used to evaluate a candidate site for magnetic disturbances and determine whether it is a suitable location to perform the magnetometer calibration procedure. The magnetometer calibration procedure itself contains the logic to simultaneously survey the location for magnetic cleanliness while it is computing the magnetometer calibration parameters.

- Page 81 A site that is used repeatedly to perform the Magnetometer Calibration Procedure should be re-evaluated every 12 months, and after any significant construction or placement of magnetic objects (above or below ground) within 50 meters of the location. G300 Installation Manual – Post Installation Checkout and Calibration Procedures Page 9-25 190-00921-01...

-

Page 82: Section 9 9-1 –

This page intentionally left blank Page 9-26 G300 Installation Manual – Post Installation Checkout and Calibration Procedures Revision A 190-00921-01... -

Page 83: Troubleshooting

In this section the term ‘Red-X’ refers to a red “X” that appears on different areas of the display to indicate the failure of that particular function. Refer to the G300 Pilot’s Guide (190-00921-00) for a complete listing of System Status Messages. For troubleshooting information in addition to that found in this section, contact Garmin Aviation Product Support at US Toll Free Number 1-888-606-5482, or US 1-913-397-8200. -

Page 84: Gmu 44

If the GMU 44 heading is not present on the GDU 37X, there may be a problem with the RS-232 line between the GSU 73 and GMU 44. Troubleshoot any possible wiring/connector issues before replacing either unit. Page 10-2 G300 Installation Manual –Troubleshooting Revision A 190-00921-01... -

Page 85: Gsu 73

Degrees Primary ± 20.0 ± 5.0 Reversion No GPS ± 10.0 ± 5.0 Reversion No Mag ± 10.0 ± 5.0 Reversion No Mag, No Air ± 10.0 ± 5.0 G300 Installation Manual - Troubleshooting Page 10-3 190-00921-01 Revision A... - Page 86 • AHRS extended operation in no-GPS mode 8. Did the onset of the problem occur shortly after a software upload to one or more of the G300 LRU’s, or shortly after a repeat of the magnetometer calibration procedure? 9. Was a cell phone on in the aircraft at the time? 10.

- Page 87 Figure 10-2 – Attitude, Air Data, and Engine/Airframe Fail Indication (Reversionary or Split-Screen PFD) Figure 10-3 – Attitude Fail Indication (PFD) G300 Installation Manual - Troubleshooting Page 10-5 190-00921-01 Revision A...

-

Page 88: Ahrs Align Message (Pfd)

3. There is not sufficient or valid sensor information being provided to the GSU 73 for it to compute valid attitude information. Table 10-2 summarizes the inputs the GSU needs to provide Attitude and Heading information. Page 10-6 G300 Installation Manual –Troubleshooting Revision A 190-00921-01... -

Page 89: Gsu 73 -Air Data Troubleshooting

4. If the problem persists, replace the GSU 73 with a known good unit If the Airspeed and/or Altitude is failed and shows a Red-X condition as shown in Figure 10-6: Figure 10-6 – Airspeed and Altitude Failure Indications G300 Installation Manual - Troubleshooting Page 10-7 190-00921-01... - Page 90 9. If the AMP indication Red-X’d, check the Alternator Shunt for correct resistance. Refer to the Cessna Aircraft Manual. 10. If the Trim Indication is Red-X’d. check the Elevator Trim Pot Sensor and wiring. Page 10-8 G300 Installation Manual –Troubleshooting Revision A 190-00921-01...

-

Page 91: Attitude, Heading, Air Data, And Engine/Airframe Failure

Figure 10-7 – Attitude, Heading, Air Data, and Engine/Airframe Failure (Reversionary or Split-Screen PFD) G300 Installation Manual - Troubleshooting Page 10-9 190-00921-01 Revision A... -

Page 92: Troubleshooting On-Board The Aircraft

A Garmin Field Service Engineer may ask the technician to download the fault logs to a PC (via the USB port on the GSU 73) and email the logs back to Garmin to help determine if the problem is in the GSU 73 or in the aircraft. -

Page 93: Gsu Page

(Section 9). The GMU 44 and GSU 73 units must be communicating with the GDU 37X, and the GPS antenna must have clear view of the sky to produce positive status indications. Figure 10-8 – CONFIG GSU Page G300 Installation Manual - Troubleshooting Page 10-11 190-00921-01 Revision A... -

Page 94: Section 10 10-1 –

This page intentionally left blank Page 10-12 G300 Installation Manual –Troubleshooting Revision A 190-00921-01... -

Page 95: Return To Service Information

NavData, terrain, and obstacle databases. If the correct software version is not installed, update the displays to the current G300 system software available on the web. No configuration is required as a long as the configuration module is still operational. Continue to Section 11.2. -

Page 96: Gmu 44

(Section 8.2) is required. If the correct software version is not installed, load the GMU 44 software contained in the G300 system software which is loaded to the displays (Section 8). Following a successful magnetometer calibration, and software verification the Return to Service Procedure is complete. -

Page 97: Appendix A: G300 Pinouts

CDU SYSTEM ID PROGRAM* 3 28V LIGHTING BUS HI SIGNAL GROUND CAN BUS TERMINATION RS-232 IN 3 RS-232 OUT 2 AIRCRAFT POWER 2 AIRCRAFT POWER 1 * Indicates Active Low G300 Installation Manual – Pinouts Page A-1 190-00921-01 Revision A... - Page 98 Open PFD1 Open Ground Open Open PFD2 Open Open Ground* Open REVERSIONARY Open Open Open Ground SIMULATOR *All display modes can be manually placed in reversion by grounding Pin 25 Page A-2 G300 Installation Manual – Pinouts Revision A 190-00921-01...

- Page 99 The GDU 37X display and keys can be configured to track 28 VDC or 14 VDC lighting busses using these inputs. Pin Name Connector 14V LIGHTING BUS HI P3701 28V LIGHTING BUS HI P3701 G300 Installation Manual – Pinouts Page A-3 190-00921-01 Revision A...

- Page 100 P3701 The left and right common pins (pins 2 and 20) may be tied together or only one may be used. It is not necessary to use both common pins. Page A-4 G300 Installation Manual – Pinouts Revision A 190-00921-01...

-

Page 101: A-2 View Of J441 Connector Looking At Rear Of Unit

The RS-232 outputs conform to EIA/TIA-232C with an output voltage swing of at least ±5 V when driving a standard RS-232 load. Pin Name Connector GPS 1 RS-232 IN P441 A.2.3.2 RS-485 Pin Name Connector RS-485 OUT A P441 RS-485 OUT B P441 G300 Installation Manual – Pinouts Page A-5 190-00921-01 Revision A... -

Page 102: A-3 Rear View Of Connector End Plate

CAN BUS HI CAN BUS LO DISCRETE IN* 1 DISCRETE IN* 2 DISCRETE IN* 3 DISCRETE IN* 4 DISCRETE OUT* 1 DISCRETE OUT* 2 MAGNETOMETER RS-232 OUT * Indicates Active Low Page A-6 G300 Installation Manual – Pinouts Revision A 190-00921-01... - Page 103 SIGNAL GROUND SPARE SPARE SPARE AIRCRAFT POWER 1 SPARE AIRCRAFT POWER 2 SPARE SPARE SPARE SIGNAL GROUND SIGNAL GROUND SPARE SPARE SPARE SIGNAL GROUND POWER GROUND SIGNAL GROUND POWER GROUND SPARE G300 Installation Manual – Pinouts Page A-7 190-00921-01 Revision A...

- Page 104 ANALOG IN 19 HI ANALOG IN 6 HI ANALOG IN 12 HI OAT PROBE IN LO FREQUENCY COUNTER IN* 3 SIGNAL GROUND FREQUENCY COUNTER IN* 4 CONFIG MODULE DATA * Indicates Active Low Page A-8 G300 Installation Manual – Pinouts Revision A 190-00921-01...

- Page 105 TRANSDUCER POWER OUT LO (GROUND) +5 VDC TRANSDUCER POWER OUT RESERVED (FUEL SENSOR PULL-UP 2 (ANALOG IN 15)) RESERVED (FUEL SENSOR PULL-UP 1 (ANALOG IN 14)) CONFIG MODULE GROUND * Indicates Active Low G300 Installation Manual – Pinouts Page A-9 190-00921-01 Revision A...

- Page 106 High: 8 VDC < Vin < 36 VDC, OR Rin > 100k ohm (inactive) Connector Pin Name P731 GSU SYSTEM ID PROGRAM* 1 P731 GSU SYSTEM ID PROGRAM* 2 * Indicates Active Low Page A-10 G300 Installation Manual – Pinouts Revision A 190-00921-01...

- Page 107 The RS-232 outputs conform to EIA Standard RS-232C with an output voltage swing of at least ±5V when driving a standard RS-232 load. Connector Pin Name P731 MAGNETOMETER RS-232 OUT P731 RS-232 IN 2 P731 RS-232 OUT 2 P731 RS-232 IN 3 P731 RS-232 OUT 3 G300 Installation Manual – Pinouts Page A-11 190-00921-01 Revision A...

- Page 108 High: 8 VDC < Vin < 36 VDC, OR Rin> 100k ohms (inactive) Connector Pin Name P731 DISCRETE IN* 1 P731 DISCRETE IN* 2 P731 DISCRETE IN* 3 P731 DISCRETE IN* 4 * Indicates Active Low Page A-12 G300 Installation Manual – Pinouts Revision A 190-00921-01...

- Page 109 A.3.7 Analog Input Configuration Some analog inputs are multi-purpose capable and have several configuration options. These inputs are configured automatically at power on by a configuration file stored in the G300. The following table summarizes the configuration options. Configurable Parameter...

- Page 110 ANALOG IN 19 HI P732 ANALOG IN 19 LO P732 ANALOG IN 20 HI P732 ANALOG IN 20 LO P732 ANALOG IN 21 HI P732 ANALOG IN 21 LO continued Page A-14 G300 Installation Manual – Pinouts Revision A 190-00921-01...

- Page 111 GTP 59 is a Resistive Temperature Device (RTD). Refer to Figure C-1 for the temperature probe interconnect. Connector Pin Name P732 OAT PROBE IN HI P732 OAT PROBE POWER OUT P732 OAT PROBE IN LO G300 Installation Manual – Pinouts Page A-15 190-00921-01 Revision A...

- Page 112 FREQUENCY COUNTER IN* 4 1 Hz 100 KHz A.3.10 Fuel Select Outputs Connector Pin Name RESERVED (FUEL SENSOR PULL-UP 2 P732 (ANALOG IN 15)) RESERVED (FUEL SENSOR PULL-UP 1 P732 (ANALOG IN 14)) Page A-16 G300 Installation Manual – Pinouts Revision A 190-00921-01...

-

Page 113: B.1 Outline & Installation Drawings-Gdu 37X

48.7 75.8 6.04 3.41 15.0 153.4 86.7 1.08 27.5 NOTES: DIMENSIONS: INCHES[MM] DIMENSIONS ARE SHOWN FOR REFERENCE ONLY. Figure B-1.1 GDU 37X Outline Drawing G300 Installation Manual – Outline & Installation Drawings Page B-1 (Page B-2 blank) 190-00921-01 Revision A... -

Page 114: B-1.2 Gdu 37X Panel Cutout Drawing

1.24 31.5 CONNECTOR KIT 011-01921-00 2X 3.58 4X 45 91.1 3.67 93.1 GDU 37x UNIT 011-01747-( ) Figure B-1.2 GDU 37X Panel Cutout Drawing G300 Installation Manual – Outline & Installation Drawings Page B-3 (Page B-4 blank) 190-00921-01 Revision A... -

Page 115: B-2.1 Gmu 44 Mounting Rack

SEE SECTIONS 2 AND 3 FOR SPECIFIC AIRCRAFT MOUNTING INSTRUCTIONS OF THE GRS 77 AHRS AND GMU 44 MAGNETOMETER UNIT. FOLLOW "FORWARD" AND "TOP" INDICATIONS ON UNIT AND RACK. Figure B-2.1 GMU 44 Mounting Rack G300 Installation Manual – Outline & Installation Drawings Page B-5 (Page B-6 blank) 190-00921-01 Revision A... - Page 116 RACK .3 8 NOTES: DIMENSIONS IN INCHES [mm] AIRCRAFT MOUNTING SURFACE 2.10 53.34 1.84 46.61 2.38 60.33 Figure B-2.2. GMU 44 Top Mounted Installation G300 Installation Manual – Outline & Installation Drawings Page B-7 (Page B-8 blank) 190-00921-01 Revision A...

-

Page 117: B-2.3 Gmu 44 Bottom Mounted Installation

HEAD BRASS SCREWS .3 8 0.24 [6.1] MAX THREAD LENGTH WITHOUT CLEARANCE HOLES 2.23 56.52 2.38 60.33 Figure B-2.3 GMU 44 Bottom Mounted Installation G300 Installation Manual – Outline & Installation Drawings Page B-9 (Page B-10 blank) 190-00921-01 Revision A... -

Page 118: B-2.4 Gmu 44 Wiring Detail

APPENDIX B.2 OUTLINE AND INSTALLATION DRAWINGS-GMU 44 NOTE: 1. BUBBLE NUMBERS IN THIS DRAWING REFER TO REFERENCE NUMBERS LISTED IN TABLES 3-6 AND 3-7. Figure B-2.4 GMU 44 Wiring Detail G300 Installation Manual – Outline & Installation Drawings Page B-11 (Page B-12 blank) 190-00921-01 Revision A... -

Page 119: B-3.1 Gsu 73 Outline Drawing

MOUNTING HOLES FOR #10 PAN HEAD OR HEX HEAD FASTENERS. CENTER OF GRAVITY LOCATION INCLUDES UNIT WITH CONNECTOR KITS. Figure B-3.1 GSU 73 Outline Drawing G300 Installation Manual – Outline & Installation Drawings Page B-13 (Page B-14 blank) 190-00921-01 Revision A... -

Page 120: B-4.1 Gtp 59 O.a.t. Probe Wiring Detail

6. SHIELD OF CABLE ELECTRICALLY CONNECTED TO 16 AWG WIRE. 7. BUBBLE NUMBERS IN THIS DRAWING REFER TO REFERENCE NUMBERS LISTED IN TABLE 5-3. Figure B-4.1 GTP 59 O.A.T. Probe Wiring Detail G300 Installation Manual – Outline & Installation Drawings Page B-15 (Page B-16 blank) 190-00921-01...

Need help?

Do you have a question about the G300 and is the answer not in the manual?

Questions and answers