Summary of Contents for Phoenix Contact IB IL SYS PRO UM E

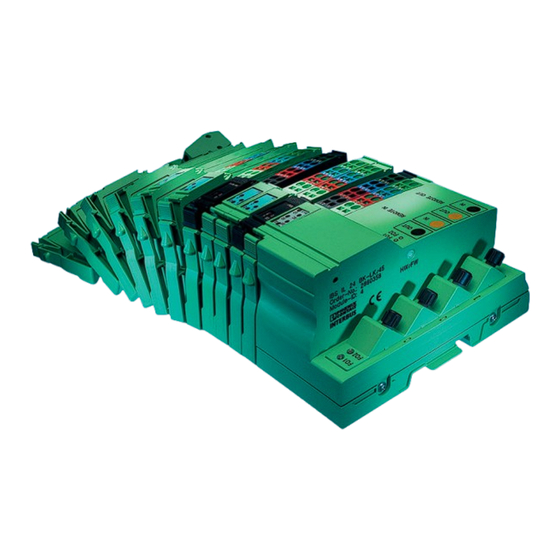

- Page 1 AUTOMATION User Manual IB IL SYS PRO UM E Order No.: 2743048 Configuring and installing the INTERBUS Inline product range...

- Page 3 AUTOMATION User Manual Configuring and installing the INTERBUS Inline product range 07/2008 Designation: IB IL SYS PRO UM E Revision: Order No.: 2743048 This user manual is valid for: Inline Modular IO automation terminals for the INTERBUS bus system 5520_en_03...

- Page 4 Phoenix Contact accepts no liability for erroneous handling or damage to products from Phoenix Contact or third-party products resulting from disregard of information contained in this manual.

- Page 5 The receipt of technical documentation (in particular data sheets, installation instructions, manuals, etc.) does not constitute any further duty on the part of Phoenix Contact to furnish information on alterations to products and/or technical documentation. Any other agreement shall only apply if expressly confirmed in writing by Phoenix Contact.

- Page 6 Phoenix Contact. Violators are liable for damages. Phoenix Contact reserves all rights in the case of patent award or listing of a registered design. Third-party products are always named without reference to patent rights. The existence of such rights shall not be excluded.

-

Page 7: Table Of Contents

Connecting I/O devices ..................5-2 Diagnostic and status indicators ....................6-1 Diagnostic indicators on bus couplers ..............6-2 Indicators on terminals with remote bus branch..........6-4 Diagnostic indicators FO1 to FO3...............6-5 Indicators on other terminals ................6-7 Error localization....................6-7 5520_en_03 PHOENIX CONTACT... - Page 8 IB IL SYS PRO UM E Configuration, installation, and startup of an Inline system (example)........7-1 Task........................7-2 Selecting the required I/O terminals..............7-2 7.2.1 Inline station devices ................7-2 7.2.2 System limits ..................7-4 Selecting accessories..................7-7 7.3.1 Power supplies ...................7-7 7.3.2 Connectors ..................

-

Page 9: Documentation Landscape For Inline Modular Io On Interbus

This data sheet contains technical data, installation guidelines, and assembly specifications for fiber optics. In addition, it also contains notes on power measurement and optical diagnostics, as well as a checklist for complete installation and a fiber optic measured value protocol. 5520_en_03 PHOENIX CONTACT... -

Page 10: Inline

Examples and tips User manuals (system or special terminal) The IB IL SYS PRO UM E user manual describes Inline Modular IO in association with the INTERBUS bus system. It provides information about all the bus-specific properties. The additional user manuals describe a special Inline terminal (e.g., counter terminal, positioning terminal). - Page 11 A package slip contains key information for the electrical installation of an Inline terminal or group of Inline terminals. This includes, for example: – Short description – Safety notes – Mounting/removal – Terminal point assignment – Local diagnostic and status indicators 5520_en_03 PHOENIX CONTACT...

- Page 12 IB IL SYS PRO UM E PHOENIX CONTACT 5520_en_03...

-

Page 13: Integration Of Inline Into The Interbus System

The forward and return lines run in one bus cable. From the installation point of view, INTERBUS has a tree structure, as only one cable is led from one device to the next. 5520_en_03 PHOENIX CONTACT... -

Page 14: Example Topology Of An Interbus System

IB IL SYS PRO UM E Example topology of an INTERBUS system MRESET FAIL RUN / PROG 10/100 INLINE CONTRO L ILC 370 PN 2TX-IB Ord. No.: 2876915 RESET RB IN RB OUT xxxxxxx (Seriennr .) RDY / RUN FAIL... - Page 15 Integration of Inline into the INTERBUS system Control technology Control technology from Phoenix Contact offers comprehensive networking options with INTERBUS. All control systems are suitable for central or distributed use. Basic tasks of control technology: – Transferring output data to the output modules –...

- Page 16 IB IL SYS PRO UM E Tasks of the bus coupler: – Coupling the remote bus and local bus – Supplying the I/O modules with communications power – Refreshing the data signal (repeater function) – Electrical isolation of the bus segments –...

-

Page 17: Inline, An Interbus Product Group

– Automatic creation of isolated groups, potential circuits, and data circuits – The amount of costly parallel wiring is reduced Within a station, potential and data routing can be carried out without additional wiring. 5520_en_03 PHOENIX CONTACT... -

Page 18: Example Of An Inline System

IB IL SYS PRO UM E 2.3.2 Example of an Inline system RB-T 230 PWR IN 230 DI1 230 DI1 230 DI1 230 DI1 230 DI1 Incomung remote bus Remote bus branch Outgoing remote bus Fieldline Modular M8 devices 3 3 3... -

Page 19: System Requirements

For configuration, parameterization, and visualization of the system, CMD software Version 4.40 or later is available for standard controller boards. PC WorX software Version 1.30 or later is available for use with a Field Controller or Remote Field Controller. 5520_en_03 PHOENIX CONTACT... -

Page 20: Product Description

IB IL SYS PRO UM E 2.3.4 Product description Within the Inline product range, automation terminals are available for I/O functions, special functions, control functions, and power-level terminals. Automation terminals consist of an electronics base and one or more connectors for connecting the I/O or power supply. -

Page 21: Inline Terminals Specifically For Interbus

An Inline bus coupler forms the head of an Inline station. It connects the Inline station to the INTERBUS remote bus. An Inline bus coupler provides the communications power U for the connected devices and the supply voltage for the connected analog terminals U from the supply voltage U 5520_en_03 PHOENIX CONTACT... - Page 22 IB IL SYS PRO UM E Number of devices The maximum number of devices that can be connected to a bus coupler is determined by the following parameters: The maximum number of devices in INTERBUS is limited to 512. Up to 63 devices can be connected to an Inline bus coupler.

- Page 23 The incoming and outgoing remote bus interface potentials are isolated from one another Incoming/outgoing and from the rest of the station electronics. remote bus Electrical isolation: FE and FE capacitive represent two individual isolated groups. FE/FE capacitive 5520_en_03 PHOENIX CONTACT...

- Page 24 IB IL SYS PRO UM E Electrical isolation: Other forms of electrical isolation depend on how the supply voltages are provided. Other The bus coupler supply U and the I/O supply U are supplied from separate power supply units: Figure 3-2...

- Page 25 Area for functional earth ground (FE) capacitive Area for functional earth ground (FE) Area for the bus coupler supply U from which the communications power U and analog terminal supply U are generated not isolated from the I/O voltages U and U 5520_en_03 PHOENIX CONTACT...

- Page 26 IB IL SYS PRO UM E Electrical isolation: The isolation of the I/O circuit of a digital terminal from the communications power is only Digital terminal ensured if U and U are provided from separate power supply units. Electrical isolation:...

-

Page 27: Terminal With Remote Bus Branch

-L K R B -L R B -L 5520A203 5520C074 5520A204 IBS IL 24 RB-T-PAC IBS IL 24 RK-LK IBS IL 24 BK RB-LK-PAC Figure 3-5 Terminals with remote bus branch 5520_en_03 PHOENIX CONTACT... -

Page 28: Interface Recognition

IB IL SYS PRO UM E RB-T Incoming remote bus Outgoing Remote bus branch remote bus 5520B123 Figure 3-6 Example topology with remote bus branch 3.1.2 Interface recognition The protocol chip of the bus coupler, control terminal or terminal with remote bus branch detects whether an additional remote bus device (terminal with remote bus branch) or a local bus device (e.g., I/O terminal) is installed. -

Page 29: Control Terminals

Power, segment, and accessory terminals – I/O terminals – Power-level terminals – Servo amplifiers – Safety terminals – Programmable terminals (control terminals) – Branch terminals For an overview of all the available terminals, please refer to the Phoenix Contact "AUTOMATION" catalog. 5520_en_03 PHOENIX CONTACT... -

Page 30: Typical Structure Of An Inline Station

IB IL SYS PRO UM E Typical structure of an Inline station Figure 3-8 Example station with power-level terminals and 24 V DC terminals The example Inline station shown in Figure 3-8 consists of the following elements: End clamps Bus coupler or control terminal Power-level terminals Terminals for the 24 V DC area (e.g., I/O terminal) -

Page 31: Electrical Potential And Data Routing

(see IL SYS INST UM E). Which supply voltages can also be supplied at the bus coupler depends on the bus coupler itself. For additional information, please refer to the terminal-specific data sheets. 5520_en_03 PHOENIX CONTACT... -

Page 32: Example Of A Circuit Diagram

IB IL SYS PRO UM E 4.1.2 Example of a circuit diagram S1.1 S1.2 S2.1 S2.2 INTERBUS 7,5 V 24 V INTERBUS 5520D109 Figure 4-1 Potential routing within an Inline station The illustrated Inline station is a typical example. It shows the supply and provision of different voltages and their forwarding via potential jumpers. - Page 33 S2.1 is tapped from the main voltage at this terminal. Segment S2.2 The segment voltage U is provided at the IB IL 24 SEG-PAC segment terminal via a switch. Output terminals installed here can therefore be switched externally. 5520_en_03 PHOENIX CONTACT...

-

Page 34: Electrical Potential And Data Routing

IB IL SYS PRO UM E Examples of errors and their effects: In this example structure, a short circuit in segment S1.2 would not affect the terminals in other segments. The fuse in the IB IL 24 SEG/F-PAC segment terminal means that only segment S1.2 is switched off. -

Page 35: Mounting/Removing Inline Terminals And Connecting Cables

The bus coupler supplies the module electronics of the connected terminals with communications power (U ), which is generated from the bus coupler supply voltage (e.g., U ). If this supply voltage is disconnected, the bus stops. 5520_en_03 PHOENIX CONTACT... -

Page 36: Connecting The Bus

IB IL SYS PRO UM E The supply voltage to the sensors and actuators (U ) should be installed and protected independently of the bus coupler supply (U ). In this way INTERBUS continues to run even if some I/O devices are switched off. -

Page 37: Diagnostic And Status Indicators

(see "Diagnostic indicators FO1 to FO3" on page 6-5). For information about the diagnostic and status indicators on a specific terminal, please refer to the terminal-specific data sheet. 5520_en_03 PHOENIX CONTACT... -

Page 38: Diagnostic Indicators On Bus Couplers

IB IL SYS PRO UM E Diagnostic indicators on bus couplers Figure 6-1 Indicators on bus couplers (e.g., IBS IL 24 BK-T/U-PAC and IBS IL 24 BK-LK-PAC) The following states can be read on bus couplers: BA (1) Green LED... - Page 39 Incoming fiber optic path OK or not used Yellow LED Status of the outgoing fiber optic path Outgoing fiber optic path not OK System reserve reached in controlled operation Off: Outgoing fiber optic path OK or not used 5520_en_03 PHOENIX CONTACT...

-

Page 40: Indicators On Terminals With Remote Bus Branch

IB IL SYS PRO UM E Indicators on terminals with remote bus branch Figure 6-2 Indicators on the IBS IL 24 RB-T-PAC terminal Diagnostics The following states can be read on terminals with remote bus branch: D (1) Green LED... -

Page 41: Diagnostic Indicators Fo1 To Fo3

For the branching interface of an Inline terminal with remote bus branch, the same applies as for the "standard" outgoing interface. The FO3 LED then indicates that the forward path of the branching interface is affected. 5520_en_03 PHOENIX CONTACT... - Page 42 IB IL SYS PRO UM E Figure 6-3 Example of diagnostics using indicators at outgoing interfaces PHOENIX CONTACT 5520_en_03...

-

Page 43: Indicators On Other Terminals

IB IL 24 PWR IN-PAC power terminals are not numbered because they are not bus devices and therefore do not have indicators for error diagnostics. When the system is operating correctly, the green LEDs on the bus coupler and the other terminals remain lit (Figure 6-5, detail A). 5520_en_03 PHOENIX CONTACT... - Page 44 IB IL SYS PRO UM E Figure 6-5 shows a station with possible error states. It shows that errors have been detected at terminal 5 or that terminal 4 has failed, and shows the behavior of the diagnostic indicators on the adjacent terminals.

-

Page 45: Configuration, Installation, And Startup Of An Inline System (Example)

Mount and install all terminals according to the instructions in the IL SYS INST UM E user manual. • Switch on the supply voltage of the control or computer system. • Switch on the supply voltages of the Inline station. The initialization of the bus system now begins. 5520_en_03 PHOENIX CONTACT... -

Page 46: Task

IB IL SYS PRO UM E Task Example project You want to acquire signals from twelve digital 4-wire sensors each with 50 mA current consumption at 24 V in one system. You want a short-circuit-proof initiator supply, diagnostics via the bus, and easy operation in the event of an error. - Page 47 Requirements met? Possible terminals Temperature Rate of change 2 channels range 0°C to 120°C ... TEMP 2 RTD -200°C to +850°C 1 x TEMP 2 RTD ... TEMP 2 UTH > +850°C High (not required) (not required) 5520_en_03 PHOENIX CONTACT...

-

Page 48: System Limits

IB IL SYS PRO UM E Task point 5: Switch 1 motor up to 1 kW Requirements met? Possible terminals Mechanical/electronic 1 channel ... ELR ... Electronic (not required) ... MLR ... Mechanical 7.2.2 System limits When configuring an Inline station, you must take into consideration the system data of INTERBUS and an Inline station. - Page 49 Based on the information regarding the order of the Inline terminals provided in the IL SYS INST UM E user manual, the order of the listed terminals is as follows, for example: 1.2 A 0.16 A 0.4 A 0.1 A 0.1 A 5520_en_03 PHOENIX CONTACT...

- Page 50 IB IL SYS PRO UM E If this terminal arrangement is to be maintained, an additional power terminal is required: 1.2 A 0.16 A 0.4 A 0.1 A 0.1 A 7.16 A 0.6 A In addition to the terminals listed, a bus coupler (IBS IL 24 BK-T/U-PAC) and a power terminal (e.g., IB IL 24 PWR IN-PAC) are also required.

-

Page 51: Selecting Accessories

If you want to set up various electrically isolated areas within an Inline station, you must use additional power terminals that are supplied from separate power supply units. A selection of suitable power supply units can be found in the Phoenix Contact "INTERFACE" catalog. -

Page 52: Connectors

Inline station to keep it from moving from side to side. Depending on the mounting position, Phoenix Contact recommends CLIPFIX 35-5 end clamps (mounting on a horizontal DIN rail; snapped on without tools) or E/AL-NS 35 end clamps (mounting on a vertical DIN rail;... -

Page 53: Installing An Inline Station

Also refer to the terminal-specific data sheets for the individual terminals (e.g., for the connection of sensors/actuators). Example project Figure 7-1 shows the structure of the Inline station for the example project. PWR IN PWR IN DO2-2A DO2-2A DO2-2A SEG-ELF 2RTD 5520C119 Figure 7-1 Typical structure of an Inline station 5520_en_03 PHOENIX CONTACT... -

Page 54: Connecting The Bus Coupler

IB IL SYS PRO UM E Connecting the bus coupler The INTERBUS remote bus and the supply voltages are connected to the bus coupler. The terminal point assignment is listed in the data sheet for the bus coupler. The following is just a brief overview. -

Page 55: Software Configuration For Interbus

From the planning phase through to system servicing, our software solutions guide you through every stage of the value added chain of an automation solution. The software tools from Phoenix Contact are perfectly designed to work together, have a modular design, and are based on international standards, which means that even complex applications can be implemented easily. - Page 56 IB IL SYS PRO UM E 7-12 PHOENIX CONTACT 5520_en_03...

-

Page 57: Technical Data And Ordering Data

50 m, maximum (polymer fiber) 300 m, maximum (HCS fiber) 3000 m, maximum (glass fiber) Between two installation remote bus devices 50 m, maximum (copper) Between a bus coupler and installation remote bus device 50 m, maximum (copper) 5520_en_03 PHOENIX CONTACT... -

Page 58: Technical Data For Inline Modular Io On Interbus

IB IL SYS PRO UM E Technical data for Inline Modular IO on INTERBUS For all technical data that generally applies to Inline, please refer to the IL SYS INST UM E user manual. This section only lists data that applies specifically for use on INTERBUS. -

Page 59: Ordering Data

DB GB IB IL DEVICE LIST – – The documentation listed above and all terminal-specific documentation can be downloaded in the download area for the corresponding Inline terminal at www.download.phoenixcontact.com. Make sure you always use the latest documentation. 5520_en_03 PHOENIX CONTACT... - Page 60 IB IL SYS PRO UM E PHOENIX CONTACT 5520_en_03...

-

Page 61: A Examples And Tips

You can configure the station using the DB GB IB IL DEVICE LIST data sheet. This document is available on the Internet at www.download.phoenixcontact.com. Another option is to use the "AX Sales" configuration tool from Phoenix Contact. This is also available on the Internet at www.download.phoenixcontact.com. -

Page 62: A 1.2 Voltage Failure Diagnostics

IB IL SYS PRO UM E A 1.2 Voltage failure diagnostics There are various ways to diagnose a voltage failure: PF on the controller board A peripheral fault (PF) on the controller board is triggered by: – The bus coupler if the main or segment voltage on the bus coupler fails –... -

Page 63: A 2 Voltage Concept Using The Example Of A Station With An Ibs Il 24 Bk-T/U-Pac

(point A). If ground (GND) of the bus coupler supply voltage were also connected to functional earth ground, electrical isolation would be lost. Electrically isolated areas within the station in Figure A-1: Bus logic of the station I/O (outputs) I/O (inputs) 5520_en_03 PHOENIX CONTACT... - Page 64 IB IL SYS PRO UM E Figure A-1 Creating electrical isolation In the bus coupler, the power terminal, and the segment terminal, the electronics has a capacitive connection to FE. For notes on the electrical isolation of the individual terminals, please refer to Section 3.

-

Page 65: Example Of A Plant

Example of a plant Example of a plant Figure A-2 Example plant Plant control Removal of material from area 1 Press Punching machine Removal of material from area 2 5520_en_03 PHOENIX CONTACT... - Page 66 IB IL SYS PRO UM E Welding robot Material area 3 1, 7, 8 Inline stations 3, 4, 10 Inline stations with power-level terminals 2, 6 Motor starter Fieldline Modular modules Robot controller Emergency stop switch Figure A-2 is a schematic diagram of a plant, which is controlled by a PC.

-

Page 67: A 4 Temperature Response Of The Terminals

Examples for calculating these values can be found in the IL SYS INST UM E user manual. Explanation of abbreviations and symbols For an explanation of the abbreviations and symbols used in basic circuit diagrams, please refer to the IL SYS INST UM E user manual. 5520_en_03 PHOENIX CONTACT... - Page 68 IB IL SYS PRO UM E PHOENIX CONTACT 5520_en_03...

-

Page 69: B Index

Peripheral fault (PF) ........... A-2 End plate..............3-2 Potential routing ............4-4 Error Power dissipation Diagnostics............6-1 Electronics ............A-7 Localization ............6-7 Housing..............A-7 EX ZONE 2 ..............1-3 Working point ............A-7 Example project ............7-9 Power supply, example project ........7-7 5520_en_03 PHOENIX CONTACT... - Page 70 IB IL SYS PRO UM E Remote bus..............2-4 Remote bus branch.............2-4 Safety-related segment circuit........1-3 Software, addressing ..........7-11 Status indicators See also Diagnostic and status indicators System data ..............8-2 System requirements ..........2-7 Temperature response..........A-7 Terminals with remote bus branch ......3-7 In association with IBS IL 24 BK-LK-PAC ....3-7...

Need help?

Do you have a question about the IB IL SYS PRO UM E and is the answer not in the manual?

Questions and answers