Summary of Contents for BIANCHI VENDING BVM 901 LEISA

- Page 1 USE AND MAINTENANCE MANUAL CERT. N° 9105 BNVD UNI EN ISO 9001: 2000 CERT. N° 9191 BNVN UNI EN ISO 14001:2004...

-

Page 3: Declaration Of Conformity

DECLARATION OF CONFORMITY La BIANCHI VENDING GROUP S.p.A. Corso Africa, 9 - 24040 Zingonia di VERDELLINO (BG) Italia hereby declares under its own liability that the family of automatic vending machines - model: “BVM 901 LEIsa” is complying with the safety measures foreseen by the directives: Low Voltage Directive EEC 73/23 ⇒... - Page 4 Bianchi Vending Group S.p.A. dichiara che: dal 1° luglio 2006 qualsiasi prodotto di Bianchi Vending Group S.p.A. immesso sul mercato in Europa è conforme alla Direttiva RoHS, e quindi non contiene concentrazioni che superino i...

-

Page 5: Maintenance Technician

BEFORE USING THE MACHINE, READ THIS MANUAL CAREFULLY FOR ITS CORRECT USE IN ACCOR- DANCE WITH THE CURRENT SAFETY STANDARDS. ATTENTION: Important safety indications READ the instruction manual machine carefully before using the machine For any service or maintenance switch off the machine ATTENTION: machine switched on ATTENTION: hot parts in contact! CAUTION! Parts in motion... - Page 6 Keys at the disposal of the MAINTENAN- CE and INSTALLATION technicians Tools necessary for undertaking interven- tions on the automatic dispenser. SOCKET SPANNERS n° 5,5 n° 7 n° 8 n° 10 n° 20 n° 22 SPANNERS (fork type) n° 7 n°...

-

Page 7: General Instructions

PREMISE INDEX PREMISE Important notices 1.1 Important notices This automatic distributor has been designed and constructed in 1.2 General Instructions full accordance with current safety regulations and is therefore safe for those who follow the ordinary filling and cleaning instructions TECHNICAL CHARACTERISTICS as indicated in this manual. DESCRIPTION OF THE MACHINE’S TECHNICAL The user must not under any circumstances remove the CHARACTERISTICS guards that require a tool for removal. - Page 8 – It is however Bianchi Vending Group S.p.A. faculty, when deemed opportune and for valid motives, to adjourn the ma- nuals already present on the market, sending to their customers adjournment sheets that must be kept in the original manual.

-

Page 9: Technical Characteristics

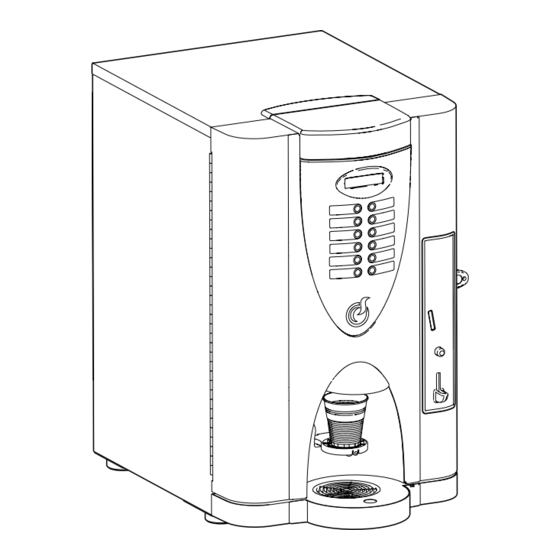

TECHNICAL CHARACTERISTICS mm 640 Height (A) CONTAINER CAPACITY mm 395 Width (B) Coffee bean container kg 0,8 mm 580 Depth (C) Single instant powder con- 1,75 lt. kg 31,5 Weight tainer Power Supply V 230 - V110 Double instant powder con- 3,5 lt. - Page 10 GENERAL TECHNICAL DESCRIPTIONS 3.1 Machine description (Fig.3.1) 7 Instant boiler 8 Dispensing chamber 3.1.1 Espresso version 9 Keyboard 1 Coffee group and grinder 10 Master board 2 Container units for soluble drinks 11 Coffee grounds container 3 Coffee bean container 12 Self-feeding tank 4 Coin mechanism 13 Keyboard cards...

- Page 11 The distributor is exclusively for the dispensing of drinks, pre- by the mod. BVM 901 LEIsa Distributor. pared mixing food substances with water (by infusion as far as concerns coffee).

- Page 12 CUP AND SPOON COLLECTION The mod. BVM 901 LEIsa automatic distributor does not feature an automatic cup and spoon distributor. The user shall therefore independently see to obtaining them via...

- Page 13 INSTANT DRINKS According to the type drink requested and to the distributor mo- del, several of the various processes described here below can be activated. – The solenoid valve fixed to the espresso boiler is engaged in order to deliver the required quantity of water into the mixer (fig.3.7). – The pump that dispenses the quantity of programmed water is activated and is controlled by an appropriate electronic device.

- Page 14 ESPRESSO COFFEE This process only occurs for the versions provided with an express coffee group. – the grinder is activated until it reaches the dose of ground coffee set by the doser (Fig.3.11) – the doser electromagnet is activated , causing the opening of the door and consequent fall of the coffee into the brew chamber –...

- Page 15 4.0 MOVING AN AUTOMATIC VENDING MACHINE Moving and transport (Fig.4.1) The distributor must be shifted by 2 people (Fig.4.1). Avoid : – lifting the distributor with ropes or presses – dragging the distributor – upset or lay down the distributor during transport –...

- Page 16 – remove the key from the drink dispensing chamber (Fig.4.3) – open the door of the distributor and remove the adhesive tape from the components listed here below: coin mechanism cover / keyboard cards product containers The packing material must not be left accessible to others, as it is a potential environmental pollution sources.

- Page 17 Always disconnect the POWER CABLE before objects, keep a minimum safety distance of 30 cm. maintenance or cleaning interventions. Bianchi Vending group S.p.A. declines all responsibility for in- ABSOLUTELY DO NOT INTERVENE ON THE MA- conveniences due to the non observance of the above mentioned CHINE AND DO NOT REMOVE ANY PROTECTION BEFORE installation norms.

- Page 18 Connection to the main water supply kit (optional) Before proceeding with the connection of the distributor to the water main supply verify the following water characteristics: – that it is drinkable (eventually through an laboratory’s analysis certification) – it has a pressure comprised between 0.5 and 6.5 bar ( if this should not be the case, use a pump or a water pressure, reducer according to the case).

- Page 19 – The sockets that are not compatible with that of the machine must be replaced. (Fig.6.9). – The use of extension, adapters and/ or multiple plugs is forbid- den. Bianchi Vending Group S.p.A. declines all responsibility for damages deriving for the complete or partial failure to observe these warnings. Fig. 6.9 The power supply cables are to be replaced by skilled personnel.

- Page 20 6.6 Installation 6.6.1 Filling the water circuit The appliance undertakes automatic filling of the water supply circuit. The sequence: Machine starting up. First self installation mode. At the first machine start up will be performed a self installtion. At first machine start-up, the system will perform an auto-instal- lation run that will also fill-up the espresso boiler with 300cc. - At the end of said auto-installation and fill-up, the system will request entry of the date. Fig. 6.12 – at the end of the water filling (Fig.6.13), effect a cleaning cycle of the mixer group so as to fill all the circuits and remove even- tual residues from the boiler.

- Page 21 6.6.2 Cleaning of the parts in contact with food substances With distributor switched on effect a cleaning of the mixers pressing the buttons according to what is described in the service functions so as to eliminate any dirt from the coffee boiler and the instant boiler.

- Page 22 – remove all the powder chutes, water funnels, mixing bowls and whippers and silicone tubes and dip these parts also in the prepared solution (Fig.6.17) – with a cloth soaked with the solution clean the whipper assembly base (Fig.6.18) – the parts must soak in the solution for the time indicated on the solutions’...

- Page 23 Product container loading (with machine off) 6.7.1 Loading containers Filling is possible keeping the containers inserted, and by raising the upper flap of the distributor (Fig. 6.20) or by extracting each container. For granulated coffee in particular it is necessary to close the closure plat before extracting the container.(Fig.6.21). –...

- Page 24 7.0 SOFTWARE INSTRUCTIONS STANDARD MODE PUSHBUTTON PANEL The pushbuttons provided are meant for: Key 1: Selection 1 Key 2: Selection 2 Key 3: Selection 3 Key 4: Selection 4 Key 5: Selection 5 Key 6: Selection 6 Key 7: Selection 7 Key 8: Selection 8 Key 9: Selection 9 Key 10: Selection 10...

- Page 25 ACCESS MENU 1. BLOCKING ALARMS Code Out of order In these circumstances, the machine is 00000 Alarm blocked. It will be possible to access the A password entry code is requested to access the programming maintenance or the programming mode. menu for the special functions management.

- Page 26 MENU 5 (PRE-SELECTIONS) Customer number Sets the V.M. customer number 00000 The entry data allowed here is: 0 to Txx pre-selec Select the Txx key for which the 65535. tions key pre-selection programming is required. The entry data allowed here is: 1 to12. Language Sets the V.M.

- Page 27 MENU 6 (DOSES) # Ev.sol. ¤ P×× Sets the soluble powders on time ¤ (1 to 3) 00.0 s onT associated with the electro valve. With P×× Doses Selects the drink to be programmed. going from P1 to P24. # stands for the order Drink P×× With P×× going from P1 to P24. of the electro valve number, i.e.: 1, 2 (*).

- Page 28 Max. coin credit Sets the maximum coin credit enabled. MENU 11 (PRICES) 000.00 The entry data allowed here is: 0 to 65535 and display depends on the decimal point. Price ×× For price setting. Characters ××× Visible only if the MDB protocol has been set. 001.00 specify the number of the price amount being programmed, that can go from price 1 to 50.

- Page 29 MENU 16 (PREVENTIVE ACTION) MENU 17.3 (RESERVE) Enab.Powd.Res. Enables instant powder decounter reserve Water treatment unit Water treatment unit decounter management. 00000 Decremented at every dispensing Entry data allowed: No or Yes. cycle requiring the supply of water. Entry data allowed: 0-65535 Enab.BeansRes.

- Page 30 MENU 18.1 (SET HOURS AND MINUTES) Sets hours/minutes Changes the clock chip time. 1:40 The format provided is: hours:minutes. The hours go from 0 to 23 and the minutes go from 0 to 59. MENU 18.2 (DATE) Date Changes the clock chip date. We 23/11/05 The format provided is: weekday dd/mm/yy.

- Page 31 MAINTENANCE Key 1: Alarms scroll-down 2nd level function Key 2: Alarm reset Alarm reset Key 3: Test run complete Key 4: Only water test Key 5: Mixer test Key 6: Group movements Key 7: View total selections MDB tube filling Key 8: Cleaning MDB tube emptying Key 9:...

- Page 32 9.0 MAINTENANCE AND INACTIVITY 9.1.3 Daily cleaning recommended The objective is that to avoid the creation of bacteria in the food Cleaning and Loading zone areas. So as to guarantee the correct functioning of the distribu- For all cleaning operations follow the instructions indicated tor during time it is necessary to effect some operations in paragraph 9.1.1.

- Page 33 – silicone water dispensing tubes. – dispensing chamber (Fig. 9.4) – coffee funnel and chute (Fig. 9.5) Before effecting the re-assembly operations clean all the elements carefully. – remove all coffee powder residue; the unit can be removed from its housing to make the task easier (Fig. 9.6) Fig.9.4 Fig.9.5 Fig.9.6...

- Page 34 9.1.5 Product loading When necessary provide for the loading of the products and/or consumption materials of the automatic vending machine. For these operations please refer to the operations described under chapter 6.0 (first installation). 9.2 Recommended maintenance TIME / No.of COUN TYPE OF INTERVENTION 20000 COUN OR EVERY DAY EVERY WEEK...

- Page 35 9.2.3 Coffee group maintenance Monthly extraction of the unit and thorough rinsing in hot water is recommended. The necessary requirement for this operation is that the coffee unit is in idle position. Then detach the pipe indicated in Fig. 9.10, unscrew knob A, rotate lever B (Fig.

- Page 36 9.3 Regulations 9.3.1 Dosage and grinding regulations The distributor is supplied regulated with standard values and i.e.: – TEMPERATURE of the coffee in the cup of about 78°C for 38 cc of dispensed product – TEMPERATURE of the instant products in the of about 73°C –...

- Page 37 11.0 ALARMS AND WARNINGS 10.0 DISMANTLEMENT Proceed with the emptying of the products and of the water as SYSTEM-STORED ALARMS described in the previous paragraph. EBI translator unit Translator unit alarm. This alarm is displayed For the dismantlement we advise to disassemble the machine if the translator unit time-out expires during dividing the parts according to their composition (plastic, metal relative exit cycle.

- Page 38 Seals Seals decounter not blocking warning. Occurs SYSTEM-STORED WARNINGS if the seals decounter is null. The alarm war- EDT_1 Grinder þ Grinder warning. This warning occurs when ning is auto-resetting therefore it will reset grinder operations last longer than the itself immediately as soon as the decounter maximum programmed time.

- Page 39 ATTIVAZIONE GARANZIA Si prega il Gentile Cliente di ritornare via fax o e-mail la presente scheda (S.R.I.) alla Bianchi Vending Group S.p.A. dopo aver ultimato le operazioni d’installazione del distributore in caso di buon fine dell'installazione. In caso di problematiche, utilizzare il presente modulo per segnalare alla Bianchi la problematica e richiedere pezzi di ricambio in garanzia.

- Page 41 SCHEDA RICHIESTA RICAMBI IN GARANZIA Si prega il Gentile Cliente di ritornare via fax o e-mail la presente scheda alla Bianchi Vending Group S.p.A. per la richiesta dei pezzi di ricambio in garanzia, descrivendo il dettaglio delle anomalie riscontrate sulla macchina. La Bianchi Vending Group S.p.A.

- Page 50 Cod. 11116621 - Ediz. 10/2009...

Need help?

Do you have a question about the BVM 901 LEISA and is the answer not in the manual?

Questions and answers