Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Duplo DP-63P

- Page 1 DP-63P Instruction Manual Ver.1 DP-43SH/63SH DP-43SH/63SH Correct operation and periodic maintenance are essential for ensuring safe use of this machine. Thoroughly read this manual before using this machine. DUPLO CORPORATION Store this manual so that it can be retrieved whenever needed.

-

Page 2: Introduction

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Introduction Thank you for your purchase of the Duprinter DP-43SH/63SH. -

Page 3: Function Quick Reference

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Function Quick Reference The following is a quick reference to the functions of the DP-43SH/63SH printer. - Page 4 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Function Quick Reference Text/Photograph/Text and Photograph/Finelettering Print Modes ..

- Page 5 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Function Quick Reference Multiple Printing ..

- Page 6 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Function Quick Reference Changing Print Quantity per Document ..

-

Page 7: Table Of Contents

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Contents Introduction ......................... - Page 8 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Contents Chapter 3 Printing With Various Function...

- Page 9 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Contents Chapter 5 Replacing Consumables...

-

Page 10: Notes On Safety (Please Read And Observe)

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) Safety Precautions Various symbols and pictures are used in this manual and on the stickers affixed to the machine. - Page 11 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) WARNING Do not modify the machine.

- Page 12 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) CAUTION Before moving the machine, remove the power plug from the outlet.

-

Page 13: Warning Sticker

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) Warning Sticker Keep the WARNING and CAUTION stickers clean at all times. - Page 14 ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) WARNING Do NOT touch the drum or rollers...

-

Page 15: Positioning The Machine

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) Positioning the Machine Installing the machine on a flat, stable surface. -

Page 16: Maintenance

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) Maintenance Clean the exterior of the machine as described below. -

Page 17: Printing And Duplicating Cautions

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) Printing and Duplicating Cautions There are restrictions on what you may print on this printer. -

Page 18: Conventions Used In This Manual

○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Notes on Safety (Please Read and Observe) Conventions Used in This Manual Each page of descriptions in this manual of how to operate the DP-43SH/63SH is set up as follows. - Page 20 Chapter Before Using This Machine This chapter contains essential information such as the names of the machine parts, the names and functions of keys, etc., on the control panel, and the sizes of documents and printing papers that you can use. Please be sure to read this chapter carefully before attempting to use the printer.

-

Page 21: System Setup

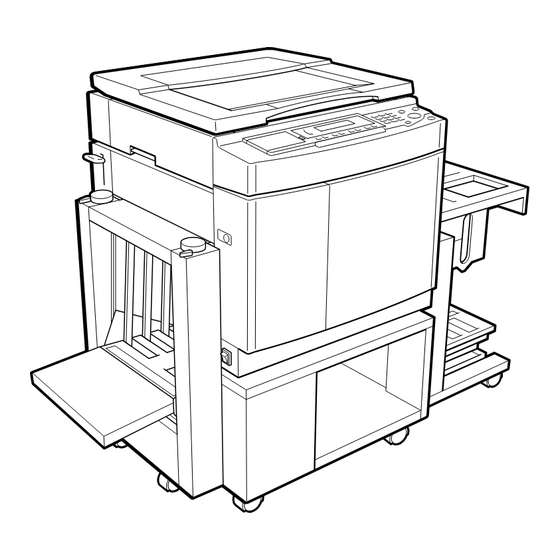

System Setup The machine and its optional equipment are set up as follows: Duplo Direct Print System Key card counter Tape cluster Documents prepared on a personal computer can be printed on this machine. The IPC board and PC interface kit are required to connect this machine to a personal computer. -

Page 22: Part Names And Their Functions

Part Names and Their Functions Printer Appearance Reference Name Function page Document cover Keeps the document in contact with the document glass plate. The machine automatically detects the size of the document when you close the document cover. Panel cover Open to operate the keys inside the panel. - Page 23 Part Names and Their Functions DP-43SH Lever Lever Press the lever to separate the Lift the lever to release the Master set switch thermal head from the roller. Use scanner unit lock. Press when installing a the lever when necessary to new master.

- Page 24 Part Names and Their Functions Master ejection core Reference Name Function page Lever Press to open the master ejection box. JOG switch Press and hold to rotate the drum for a set time. Use to remove paper jams, etc.. Print tray switch Press to lower the print tray.

-

Page 25: Control Panel

Part Names and Their Functions Control Panel AUTO 2 in 1 See “Keys Inside Panel Cover” on page 24. Reference Name Function page “ZOOM” key Adjusts the zoom factor in 1% increments. “AUTO ZOOM” key Turns the auto zoom function ON. LCD panel Displays the number of prints and other settings. - Page 26 Part Names and Their Functions x94% !7 !6 Reference Name Function page “CLEAR” key Clears the display to “0”. Clears the number of prints only. Printing speed indicator lamp The lamp for the specified printing speed lights. “PRINTING SPEED ADJUSTMENT” keys The printing speed is adjusted with these keys.

-

Page 27: Lcd Panel

Part Names and Their Functions LCD Panel 1 0 0 % AUTOA 4 x94% Reference Name Function page Prints per page Displays the icon for the selected number of prints per page (multi- ple printing). Zoom ratio Displays the selected zoom (enlargement/reduction) ratio. 41, 50 Paper size Displays the selected paper size. -

Page 28: Book Shadow Eraser" Mode

Part Names and Their Functions Reference Name Function page “CONFIDENTIAL” key Selects Confidential Mode. Prints cannot be made unless a plate is made. Confidential safeguard indicator lamp Lights when the confidential safeguard mode is ON. “SPECIAL FUNCTION” key Allows use of special functions. Special function indicator lamp Lights when special functions are in use. -

Page 29: Turning Power On/Off

Turning Power ON/OFF This section describes the operating sequence from turning ON the power switch until the printer is ready to make prints, and how to turn OFF the printer power. Turning ON Printer Power ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Connect the power cable to the printer and a wall outlet. -

Page 30: Turning Off Printer Power

Turning Power ON/OFF Turning OFF Printer Power ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Switch the power switch to the “... -

Page 31: Key Card Counter [Available Only With Key Card Counter Installed]

Turning Power ON/OFF Key Card Counter Available only with Key Card Counter installed With the key card counter installed, you can control the platemaking and print quantities per person or per department, etc. See the Instruction Manual for the Key Card Counter for details. Inserting a key card When you turn on the power, the icon shown at right is displayed if no key card has been inserted in the key card... -

Page 32: Document/Printing Paper Specification

Document/Printing Paper Specification Acceptable Documents Document glass plate • Weight : Sheet documents, books, etc, not exceeding 10kg. • Size : 297mm x 432mm max. Acceptable Printing Paper • Document thickness : 50g/m to 105g/m (15 to 28lb bond) • Document size : A3 to A5 size (A5 in landscape mode: A5R cannot be used.) ST to 11x17-in. -

Page 33: How Platemaking And Printing Is Performed

How Platemaking and Printing is Performed The machine performs two processes: platemaking and printing. Platemaking In the “platemaking” process, the old master on the drum is removed while the thermal head creates the scanned image on the new master and transfers it onto the drum. Master roll Master ejection box Drum unit... - Page 34 Chapter Printing Using Basic Functions This chapter describes how to make prints using the basic functions, including how to load the document, set zoom ratio, etc. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Basic Printmaking ....................

-

Page 35: Basic Printmaking

Basic Printmaking This section describes how to make prints using the basic functions. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Turn ON the power. - Page 36 Basic Printmaking ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Select the zoom ratio.

- Page 37 Basic Printmaking ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (PRINT) key. The feed tray rises so that the top of the paper stack is the height of the feed ring.

-

Page 38: Loading And Replacing Paper

Loading and Replacing Paper This section describes how to load the printer with paper. You can load approximately 3,000 sheets in this printer. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Adjust the side guides to the size of paper. -

Page 39: Loading Documents

Loading Documents Positioning the Document The document can be loaded in the “portrait” or “landscape” position. IMPORTANT • A4, B5, and A5-size documents can be loaded in the “portrait” or “landscape” position. • Use the landscape position when enlarging or reducing from standard-size documents to standard-size paper, such as A4 to A3. -

Page 40: Loading Document On Document Glass Plate

Loading Documents Loading Document on Document Glass Plate Use the platen glass when copying from books, thick documents, or thin documents. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Gently open the document cover. -

Page 41: Loading Document In Adf [Available Only When Adf Is Installed]

Loading Documents Loading Document in ADF Available only when ADF is installed Load documents that consist of a series of sheets to be printed in the ADF. When one or more documents are loaded in the ADF, platemaking and printing are automatically repeated until the document tray is empty. IMPORTANT •... -

Page 42: Enlarging/Reducing From Standard-Size Document To Standard-Size Paper

Enlarging/Reducing from Standard-Size Document to Standard-Size Paper You can enlarge or reduce a standard-size document onto standard-size printing paper. The following zoom ratios are available when enlarging or reducing a standard-size document onto standard-size printing paper. Enlargements You can enlarge a standard-size document onto standard-size paper using the following zoom ratios: European paper sizes A3 Printout A4 →... -

Page 43: 141% A4>A3

Enlarging/Reducing from Standard-Size Document to Standard-Size Paper ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (PRINT SIZE) key to highlight the desired zoom ratio. -

Page 44: Selecting Printing Paper Size

Selecting Printing Paper Size Press (PAPER SIZE) key to select a paper size. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (PAPER SIZE) key. - Page 45 Selecting Printing Paper Size ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ IMPORTANT Select this size of paper •...

-

Page 46: Print Output

Print Output This section describes how to remove the printed pages from the machine when installed. Output to Print Tray Normally, the printed paper is output to the print tray. The print tray cover has both length and width guides. This section describes how the width and length guides operate, and how to remove the printed pages from the print tray. - Page 47 Print Output ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ If the output tray is quite full, press the print tray switch to lower the print tray.

-

Page 48: Main Unit

Print Output ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Grasp the print tray handles and push the print tray gently in the grooves until it is against the main unit. -

Page 50: Printing With Various Function

Chapter Printing With Various Function This chapter describes how to make prints using the various printer functions. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Enlargement and Reduction ................ -

Page 51: Enlargement And Reduction

Enlargement and Reduction You can enlarge or reduce the size of the copy to the desired size. 94% Reduction (a a a a a page 50) You can make a copy that is just slightly smaller than the original document. A4 Document A4 Printout (94%) -

Page 52: Auto Zoom

Enlargement and Reduction ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Proceed with steps 1 to 4 of the sequence described in “... - Page 53 Enlargement and Reduction ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Select a paper size.

-

Page 54: Settings Are Reset To Standard Mode

Enlargement and Reduction ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ IMPORTANT: •... -

Page 55: 1%-Step Enlargement And Reduction

Enlargement and Reduction 1%-Step Enlargement and Reduction You can set a zoom ratio between 50% and 499% in 1% steps. IMPORTANT • Select “1%-Step Enlargement and Reduction” before starting platemaking. • You cannot select “94% Reduction” at the same time as “1%-Step Enlargement and Reduc- tion”. -

Page 56: Adjusting Darkness

Adjusting Darkness If the test print made after platemaking is too light, adjust the print darkness. If you cannot adjust the print darkness sufficiently to give a satisfactory print, adjust the plate darkness. IMPORTANT • You can print immediately after adjusting the print darkness. •... -

Page 57: Adjusting Print Darkness

Adjusting Darkness Adjusting Print Darkness You can adjust print darkness in three steps. To make the print darker, select “DARKER” (increased ink transfer amount). To make the print lighter, select “LIGHTER” (reduced ink transfer amount). ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Check that printing is not in progress. -

Page 58: Printing Photographs And Color Documents

Printing Photographs and Color Documents You can adjust the print quality to match the quality of the document (text or photos). You can also enhance text and lines, or process non-screened photographs. Text/Photograph/Text and Photograph Mode (a a a a a page 57) In this mode, the print quality is adjusted to match the document. -

Page 59: Fine Text/Screen Mode

Printing Photographs and Color Documents IMPORTANT • Select “Text/Photograph/Text and Photograph Mode” before starting platemaking. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Proceed with steps 1 to 4 of the sequence described in “Basic Printmaking”... - Page 60 Printing Photographs and Color Documents ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Proceed with steps 1 to 4 of the sequence described in “Basic Printmaking”...

-

Page 61: Photo Dark Mode

Printing Photographs and Color Documents Photo Dark Mode This mode reproduces gradations in dark areas of photographs in detail. IMPORTANT • Select “Photo Dark Mode” before starting platemaking. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Proceed with steps 1 to 4 of the sequence described in “Basic Printmaking”... -

Page 62: Book Shadow Eraser Mode

Book Shadow Eraser Mode Prints book documents without shadows This mode erases the shadows caused by the book binding when printing an open spread from a book or other folded document. It also erases the shadow around the periphery of the document. Printout With shadow eraser Document... -

Page 63: Book Shadow Eraser Mode

Book Shadow Eraser Mode ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (BOOK SHADOW ERASER) key. The Book shadow eraser mode indicator lamp lights and a book icon is displayed on the LCD panel. -

Page 64: Multiple Printing On One Page

Multiple Printing on One Page This mode allows you to print 2, 4, or 8 copies of the document on one page. Multiple Printing (a a a a a page 63) This mode prints multiple copies of the document on one page. 2 images 4 images Document... - Page 65 Multiple Printing on One Page • Copying A4 to A3 (2 prints on one page) and A4 to A3 (4 prints per page) Portrait Placement A3, LDG A3, LDG Landscape Placement Zoom ratio: Zoom ratio: 100% IMPORTANT • Select “Multiple Printing” before starting platemaking. •...

-

Page 66: 2-In-1 Layout

Multiple Printing on One Page 2-in-1 Layout Available only with ADF installed 2 in 1 Two-in-one (2-in 1) mode allows you to print two small documents on one page and also easily print for creating booklets that will be saddle stitched. When you use 2-in-1 mode, the layout is as follows: Printout1 Printout2... - Page 67 Multiple Printing on One Page ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (MULTIPLE PRINTING) key to select “2-in-1”...

-

Page 68: Saving Settings

Saving Settings MEMORY You can save and retrieve two sets of settings for platemaking and printing. The settings are stored in memory even when the power is turned OFF. Tips The following settings are saved: • Number of prints (including sets) •... - Page 69 Saving Settings ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (SAVE) key. “SAVE?” is displayed on the LCD panel. 2 in 1 ○...

-

Page 70: Retrieving Settings

Saving Settings Retrieving Settings ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Load paper. -

Page 71: Sectional Printing

Sectional Printing You can print the specified number of sets of prints in each set. Sectional Printing (a a a a a page 70) The machine stops after each set of prints. 1st set 2nd set 3rd set 5 copies x 2 sets 3 copies x 4 sets 2 copies x 5 sets Document... -

Page 72: Continue Page

Sectional Printing ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Proceed with steps 1 to 5 of the sequence described in “Basic Printmaking”... - Page 73 Sectional Printing ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Use the keypad to enter the number of sets. Example: 3 sets •...

-

Page 74: Sectional Printing (Changing Print Quantity Per Document)

Sectional Printing Sectional Printing (changing print quantity per document) You can change the number of prints made from each document. You can separate the number of prints for up to 15 documents. IMPORTANT • Select “Sectional Printing” before starting platemaking. ○... - Page 75 Sectional Printing ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press key. The current set is displayed to the left of the number of prints.

- Page 76 Sectional Printing ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Repeat steps 3 to 6.

-

Page 77: Dividing Sections With Tape [Available Only With Tape Cluster Device]

Sectional Printing Dividing Sections with Tape Available only with Tape Cluster Device Only the specified number of sets is printed with the specified number of prints taken as one set. Paper tape is inserted when printing of each set is completed. You can enter up to 15 groups of number of prints x number of sets. -

Page 78: Miscellaneous Functions

Chapter Miscellaneous Functions This chapter describes miscellaneous functions such as the confidential safeguard function, and the print speed and print position adjustments. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Confidential Safeguard Function .............. -

Page 79: Confidential Safeguard Function

Confidential Safeguard Function The confidential safeguard function, which prevents printing unless platemaking has been completed, is a simple means of prohibiting others from printing sensitive documents. IMPORTANT • When the Confidential Safeguard function is ON, printing cannot be performed with (PRINT) or (TEST PRINT) keys. -

Page 80: Total Counter Display Function

Total Counter Display Function This function displays the total numbers of prints and plates on the LCD panel. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Check that the machine is not printing. -

Page 81: Print Speed Adjustment Function

Print Speed Adjustment Function SPEED The print speed can be adjusted in 5 steps between 45 pages per minute and 120 pages per minute. The default setting when the power is turned ON is about 80 pages per minute. Tips •... -

Page 82: Printing Position Adjustment Function

Printing Position Adjustment Function After platemaking has finished, you can fine-tune the position of the image (in the vertical direction) within ±1.5cm. • You can adjust the printing position while the machine is printing. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press “PRINTING POSITION AUTO... -

Page 83: Special Functions

Special Functions Fine Start “Startup Time Setting” This function allows you to specify whether or not fine-start mode is used (The default setting is “OFF”). This printer employs a mechanism that forces ink out from inside the drum. The Fine Start Mode automatically checks the time elapsed since the printer was last used and the room temperature, and then selects the optimal operational settings to ensure the first page is printed clearly and vividly. - Page 84 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (AUTO ZOOM) key. AUTO AUTO The “FINE START MODE Screen”...

- Page 85 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (ZOOM) keys to highlight the de- sired mode.

-

Page 86: Fine Start "Operation At Next Platemaking

Special Functions Fine Start “Operation at Next Platemaking” This setting forces the machine to operate once under maximum conditions the first time a plate is made after the drum is replaced, regardless of the elapsed time. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Open the panel cover. - Page 87 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (AUTO ZOOM) key. AUTO AUTO The “FINE START MODE Screen”...

- Page 88 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (ZOOM) keys to highlight 2.ON ENABLED IN NEXT OPERAT 1.OFF...

-

Page 89: Auto Clear

Special Functions Auto Clear This function automatically clears the display (settings) on the control panel when the machine is not operated for a specified period of time. (The same thing happens when the power is turned ON, or (CLEAR) key is pressed.) The specified time period can be set for OFF, 3 minutes, 10 minutes, or 15 minutes. - Page 90 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (AUTO ZOOM) key. AUTO AUTO The “AUTO CLEAR MODE Screen”...

-

Page 91: Preprint

Special Functions Preprint This function disables counting for a specified number of prints following the start of a printing operation. For example, if you set the Preprint mode to three (3) pages, the count function ignores the first three pages printed, and starts counting from the fourth printed page. - Page 92 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (AUTO ZOOM) key. AUTO AUTO The “PREPRINT MODE Screen”...

-

Page 93: Print Number Input Mode

Special Functions Print Number Input Mode This function switches from the normal “Number of Groups Input Mode” to the “Number of Pages Per Document Input Mode.” The default settings is “Number of Groups Input Mode.” The Number of Groups Input Mode prints out all sets input (number of pages * number of groups) as a single document. - Page 94 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (AUTO ZOOM) key. AUTO AUTO The “PRINT NUMBER INPUT MODE Screen”...

-

Page 95: Change Initial Settings

Special Functions Change Initial Settings This function allows you to change the paper selection setting when the power is turned ON or the “ALL CLEAR” key is pressed. You can also specify that the contents of memory 1 are retrieved. (The default setting is “AUTO”.) ○... - Page 96 Special Functions ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (AUTO ZOOM) key. AUTO AUTO The “CHANGE INITIAL SETTING Screen”...

-

Page 97: On-Line Print Function [Available Only With Interface Kit Installed]

On-Line Print Function Available Only With Interface Kit Installed This function allows you to make prints of documents directly from on-line data from personal computers. IMPORTANT • The IPC board and PC interface kit are required to connect this machine to a personal computer. - Page 98 Chapter Replacing Consumables This chapter describes how to supply paper, ink pack, and other consumables. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Replacing the Ink Pack ..................

-

Page 99: Replacing The Ink Pack

Replacing the Ink Pack The message “CHANGE INK” is displayed on the LCD panel when the remaining ink is low. Replace the ink pack using the following procedure. CHANGEoINK XXXXXXXXXXXXXXXX IMPORTANT • Only use ink packs designed for this machine. ○... - Page 100 Replacing the Ink Pack ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Remove the cap from a new ink pack. Ink pack IMPORTANT •...

- Page 101 Replacing the Ink Pack ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Front cover Close the front cover. ○...

-

Page 102: Replacing The Master Roll

Replacing the Master Roll The message “CHANGE MASTER” is displayed on the LCD panel when the master roll is used up. Replace the master roll using the following procedure. CHANGEoMASTER XXXXXXXXXXXXXXXX IMPORTANT • Only use a master roll designed for use in this machine. DP-43SH ○... - Page 103 Replacing the Master Roll ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Remove the master holder from the master roll. Holder ○...

- Page 104 Replacing the Master Roll ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Yellow label Pull out the master and insert the arrow on the yellow label until it contacts the roller.

-

Page 105: Dp-63Sh

Replacing the Master Roll DP-63SH ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Lever Scanner unit Raise the lever. - Page 106 Replacing the Master Roll ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Remove arrow label, pull out the blue sheet. ○...

- Page 107 Replacing the Master Roll ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Gently close the scanner unit and press it down until it locks.

-

Page 108: Replacing The Master Ejection Core

Replacing the Master Ejection Core The message “CHANGE MASTER EJECTION CORE” is displayed on the LCD panel when the master ejection core is full. Remove the master ejection core using the following procedure: CHANGEoMASTER EJECTIONoCORE IMPORTANT • Use only a master ejection core designed for use in this machine. ○... - Page 109 Replacing the Master Ejection Core ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Holding the edges of the master ejection core, pull out the core and discard it.

-

Page 110: Replacing The Drum Unit

Replacing the Drum Unit Removing the Drum Unit ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press and hold the JOG switch until the drum JOG switch comes to a stop with a beep. -

Page 111: Installing The Drum Unit

Replacing the Drum Unit When the message “NO DRUM” is displayed on the LCD panel, use the following procedure to replace the drum. NOoDRUM XXXXXXXXXXXXXXXX Installing the Drum Unit ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Hold the drum level and place the drum guide roller onto the rail in the machine. - Page 112 Replacing the Drum Unit ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Lever Lift the drum securing lever toward you while pressing the drum in.

- Page 114 Chapter Troubleshooting This chapter describes how to remove paper jams and what to do when error messages are displayed. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Power Does Not Turn ON .................

-

Page 115: Power Does Not Turn On

Power Does Not Turn ON If the power does not turn ON, check the following. THE MACHINE DOESN'T TURN ON. IS POWER PLUG INSERTED? Insert the power plug securely. IS POWER SWITCH ON? Turn the power switch ON. Please contact your service person. -

Page 116: Platemaking/Printing Is Not Possible

Platemaking/Printing is Not Possible If platemaking/printing is not possible, check the following. IS THERE A MESSAGE DISPLAYED ON ERROR DISPLAY PANEL? See "Error Messages" on page 110. Please contact your service person. -

Page 117: Error Messages

Error Messages Error messages are displayed as text and illustrations. Message Countermeasure There is no paper in the feed tray. Load the feed tray with printing paper. ADDoPAPER XXXXXXXXXXXXXXXX There is no ink. Replace the old ink pack with a new one. (a For details, see page 98, “Replacing the Ink Pack”.) CHANGEoINK XXXXXXXXXXXXXXXX... - Page 118 Error Messages Message Countermeasure The scanner unit is open. Close the scanner unit. TOPoCOVERoOPEN A paper jam has occurred in the feed tray. Remove the jammed paper. (For details, see page 122, “When ‘PAPER JAM’ is displayed (Feed Tray)”.) PAPERoJAM Paper jam at print tray sensor.

- Page 119 Error Messages Message Countermeasure There is an old master on the drum. Remove all the masters from the drum. (a For details, see page 127, “When ‘PLATE EJECTION ERROR’ is Displayed”.) PLATEoEJECTION ERRORXXXXXXXX There is an error during master setting. Open the top cover and remove the master that is left in the plate feeder.

- Page 120 Error Messages Message Countermeasure Cannot read key card. Please reinsert the card. RE-INSERToCARD XXXXXXXXXXXXXXXX Key card reading is in progress. Please wait. NOWoREADINGoCARD PLEASEoWAIT You have inserted an unusable card. Check the card for dirt and scratches, then reinsert the card. For details, see the Key Card Counter Instruction Manual.

-

Page 121: Supplying Or Changing Paper While Printing

Supplying or Changing Paper While Printing If Paper Runs Out During Printing ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ If paper runs out during printing, printing stops and the message “ADD PAPER”... -

Page 122: Changing Paper Selection

Supplying or Changing Paper While Printing ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (PRINT) key. -

Page 123: Paper Jams

Paper Jams When “PAPER JAM” is displayed (Feed Tray) When a paper jam occurs in the feed tray, the message “PAPER JAM” is displayed on the LCD. Follow the procedure below to remove the jammed paper. PAPERoJAM ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Temporarily remove all non-jammed paper from the feed tray. -

Page 124: When "Paper Jam" Is Displayed (Print Tray)

Paper Jams ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Load paper. (See page 37, “Loading and Replacing Paper.”) ○... -

Page 125: Paper Adhering To Drum

Paper Jams ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Remove the jammed paper. Press the JOG switch to eject the partially printed paper. JOG switch ○... - Page 126 Paper Jams ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Paper edge Press the JOG switch to find the edge of the paper, then stop the drum at the position shown in the diagram.

- Page 127 Paper Jams ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Close the master ejection box, pressing it until it locks.

-

Page 128: When "Plate Ejection Error" Is Displayed

When “PLATE EJECTION ERROR” is Displayed When and old master remains on the drum, “PLATE EJECTION ERROR” is displayed on the LCD panel. Remove it by following the procedure below. PLATEoEJECTION ERROR ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press the lever to open the master ejection box. - Page 129 When “PLATE EJECTION ERROR” is Displayed ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Lift the lever toward you. Master clamp The master clamp opens and the edge of the master will be Lever...

- Page 130 When “PLATE EJECTION ERROR” is Displayed ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Press (STOP) key.

-

Page 131: When "Master Setting Error" Is Displayed

When “MASTER SETTING ERROR” is Displayed The message “MASTER SETTING ERROR” is displayed on the LCD panel. Remove the master and remake the plate by following the procedure below. MASTERoSETTING ERROR ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Lever Raise the top cover release lever to open the Scanner unit... - Page 132 When “MASTER SETTING ERROR” is Displayed ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Check that the error message is deleted.

-

Page 133: When "Set Master Roll Properly" Is Displayed

When “SET MASTER ROLL PROPERLY” is Displayed The message “SET MASTER ROLL PROPERLY” is displayed on the LCD panel. Remove the master and remake the plate by following the procedure below. SEToMASTERoROLL PROPERLY ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Lever Raise the top cover release lever to open the Scanner unit... - Page 134 When “SET MASTER ROLL PROERLY” is Displayed ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Master cover Close the master cover.

-

Page 136: Chapter 7 Specifications And Maintenance

Chapter Specifications and Maintenance This chapter lists the machine specifications and describes maintenance, etc. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Specifications .................... -

Page 137: Specifications

Specifications Product name/model No. Duprinter DP-43SH Duprinter DP-63SH Model Floor model Platemaking method Thermal digital platemaking Platemaking time 17 seconds (A3, same size) 25 seconds (A4, same size) Resolution 15.7dpm (400dpi) 23.6dpm (600dpi) Scanning method Fixed document Printing method Stencil printing Document type Sheet, book (10kg max.) Document size... - Page 138 Specifications Product name/model No. Duprinter DP-43SH Duprinter DP-63SH Power source 120 VAC model 120VAC 60 Hz, 2.7 A 230 VAC model 230VAC 50 Hz, 1.7 A Size 1414mm (W) x 671mm (D) x 1048mm (H) Weight 182kg 185kg Operating temperature 10°C to 30°C PC interface kit The printer driver must be installed in the PC.

-

Page 140: Appendix

Appendix This section contains an index and quick reference diagrams for basic operations. ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Index ........................ -

Page 141: Index

..............22 Key pad ............... 24 drum unit ..........20, 22, 32, 109 Keys Inside Panel Cover ..........26 Duplo Direct Print System .......... 20 Lateral Placement ............38 Enlargement and Reduction........50 LCD panel ............24, 26 Enlargements .............. - Page 142 Index PRINT key ..............24 Print Number Input Mode .......... 92 Maintenance ............... 16 Print Output ..............45 master ............... 128 PRINT SIZE key ..........25, 41 master clamp ............. 128 Print Speed Adjustment Function ....... 80 master ejection box ........23, 32, 107 print tray ............

- Page 143 Index Tape Cluster ............20, 72 TEST PRINT key ..........24, 78 TEXT/PHOTOGRAPH key ......... 25, 58 Text/Photograph/Text and Photograph Mode ..... 57 Thermal head .............. 32 Top blow fan ............... 32 Total Counter Display Function ......... 79 total number of plates ..........79 transport roller ............

-

Page 144: Quick Operation Guide

Quick Operation Guide ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ ○ Turn ON the power. - Page 146 M3-Y1021...

Need help?

Do you have a question about the DP-63P and is the answer not in the manual?

Questions and answers