Subscribe to Our Youtube Channel

Summary of Contents for Larius NOVA 45:1

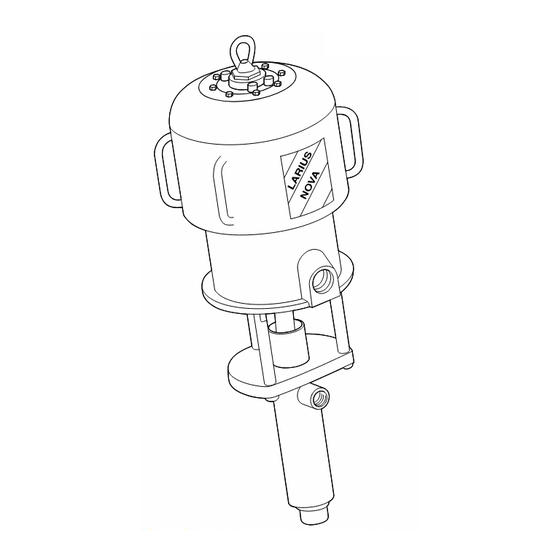

- Page 1 AIRLESS PNEUMATIC PUMP II 2 G c IIB T6 P A I N T S P R A Y I N G E Q U I P M E N T ENGLISH...

- Page 2 Due to a constant product improvement programme, the factory reserves the right to modify technical details mentioned in this manual without prior notice. This manual is to be considered as an English language translation of the original manual in Italian. The manufacturer shall bear no responsibility for any damages or inconveniences that may arise due to the incorrect translation of the instructions contained within the original manual in Italian.

-

Page 3: Table Of Contents

ONLY USE THIS MACHINE FOR USAGE SPECIFICALLY MENTIONED IN THIS MANUAL. Thank you for choosing a LARIUS S.R.L. product. As well as the product purchased, you will receive a range of support services enabling you to achieve the results desired,... -

Page 4: Aworking Principle

NOVA 45:1/60:1 WORKING PRINCIPLE NOVA pump 45:1 (or 60:1) is a pneumatic pump to be used in So doing the pump sucks the fluid and pushes it to the outlet. The ratio 45:1 (o 60:1) means that the outlet pressure of fluid is the high pressure painting without air (Airless) or for transferring 45 (o 60) times higher than the pump feed air pressure. - Page 5 NOVA 45:1/60:1 L/MIN L/MIN 4000 4800 3500 4000 3000 4200 3000 3600 3200 2400 2500 3000 2400 1800 2000 2400 1500 1800 1600 1200 1000 1200 L/MIN L/MIN PUMP DELIVERY PUMP DELIVERY 7 bar (100 psi) 5 bar (70 psi)

-

Page 6: Cdescription Of The Equipment

NOVA 45:1/60:1 DESCRIPTION OF THE EQUIPMENT ANTI-FREEZE SYSTEM POS. POS. Description Description Pump feed air inlet Fluid inlet Pneumatic motor Fluid pumping group Material outlet Eyebolt for pump transport... -

Page 7: Dtransport And Unpacking

Unpack the machine and verify if there has been PERLY. any damage due to transportation. In case of damage, call immediately LARIUS and the Shipping Agent. All the notices about possible damage or • ALWAYS FOLLOW THE INSTRUCTIONS ABOUT SAFETY anomalies must arrive timely within 8 days at least from AND THE REGULATIONS IN FORCE. -

Page 8: Conditions Of Guarantee

NOVA 45:1/60:1 CONNECTION BETWEEN PUMP, FLEXIBLE HOSE AND SPRAY GUN BEFORE USING THE EQUIPMENT. • ALWAYS USE THE FLEXIBLE HOSE SUPPLIED WITH STANDARD KIT. THE USE OF ANY ACCESSORIES OR TAKE PROPER SAFETY MEASURES FOR THE PROTECTION TOOLING OTHER THAN THOSE RECOMMENDED IN OF HEARING IN CASE OF WORK NEAR THE PLANT. -

Page 9: Gsetting-Up

(it is suggested complete with condensate filter and lubricator). The outlet pressure of the material is 45 times (NOVA 45:1) or 60 times (NOVA 60:1) the inlet pressure of the pump feed air. Therefore, it is extre- mely important to adjust the value of the feed air pressure. -

Page 10: Icleaning At The End Of The Work

NOVA 45:1/60:1 CLEANING AT THE END OF THE WORK By "cleaning at the end of the work" is meant the cleaning to carry • Now, stop the air supply to the pump and drain the residual out in case of use with a different product or if a long period of pressure. -

Page 11: Mproblems And Solutions

DESCRIPTION FOR EXPLOSIVE AREAS These safety instructions refer to the installation, use and main- tenance procedures for NOVA series LARIUS pneumatic piston NOVA series LARIUS pneumatic piston pumps pumps for decanting. These pumps are designed for use in poten- are group II mechanical devices for use in the tially explosive areas where gas or vapours are present. - Page 12 NOVA 45:1/60:1 TECHNICAL FEATURES The main characteristics of NOVA series pneumatic piston pumps are indicated in the table below: Input Ø Air Ø Material Ø Material Ø Max working Max capacity Ratio pressure intake intake outlet pressure 20:1 3 ÷ 6 bar CG 3/4"...

- Page 13 Technical file c/o: INERIS (0080) All the operations, installation and service, must be carried out by qualified operators. Calolziocorte- LC Signature (LARIUS) EXAMPLE OF INSTALLATION The diagram illustrates a typical installation example of a LARIUS pneumatic piston pump for decanting.

-

Page 14: Odisassembly Of The Pneumatic Motor

NOVA 45:1/60:1 DISASSEMBLY OF THE PNEUMATIC MOTOR Always close the compressed air supply and • Turn counterclockwise the screws (N8) [take care of the release the pressure in the plant before disas- washers (N9)] and extract the mount (N7) together with the sembling the pneumatic motor of the pump. - Page 15 NOVA 45:1/60:1 • Pull upwards the seat (N17) so as to take out the valves (N18) and the springs (N19) (clean and/or replace the worn parts). • Unscrew the lock nut (N20) [take care of the washer (N21)] by keeping the bush (N22) blocked using a key.

- Page 16 NOVA 45:1/60:1 • Turn counterclockwise the trip rod bearing (N30) [take care of the washer (N31)] and check the seal inside the screw (N30) is undamaged. • Take out the screws (N32) [take care of the washers (N33)] and remove carefully the cylinder (N34) (do not bend it during extraction in order to avoid that motor piston may damage the internal surface of the cylinder).

- Page 17 NOVA 45:1/60:1 • Check the gas ring inside the support (N39) is undama- ged. • Check the gasket (N40) is undamaged and correctly positio- ned. • Coat the inner walls of the cylinder (N41) with a thin layer of vaseline grease.

- Page 18 NOVA 45:1/60:1 • Insert the springs (N54) and the valves (N55) into the seat (N53). Position the seat on the pump support and lay the manifold (N56) on the seat [do not forget the gasket (N57)]. • Fasten the manifold with screws (do not tighten) ensuring it is perfectly parallel to the other manifold and the distance between them is 46 mm (see illustration).

-

Page 19: Pdisassembly Of The Pumping Group

NOVA 45:1/60:1 DISASSEMBLY OF THE PUMPING GROUP Always close the compressed air supply and • Unscrew the coupling sleeve so as to disconnect the pumping release the pressure in the plant before disas- group from the motor. sembling the pumping group. If the product being used is toxic, it is suggested to follow the cleaning •... - Page 20 NOVA 45:1/60:1 • Remove the split pin (O3), loosen the nut (O4) and unscrew the tie rod from the piston rod. • Unscrew the packing nut (O5). Tie rod • Unscrew the suction valve. Clean and/or replace its parts, if...

- Page 21 NOVA 45:1/60:1 It is possible to increase the suction valve ball stroke placing the stop ball pin (O6) on the upper holes of the suction valve. This modification is suggested in case of very viscous products. The same operation can be performed on the piston rod.

-

Page 22: Qexploded View For Stainless Steel

NOVA 45:1/60:1 EXPLODED VIEW FOR STAINLESS STEEL PUMPING GROUP WARNING: always indicate code and quantity for each part required. -

Page 23: Pumping Group

Reduction M-F 98214 Pumping group housing 98232 Suction pipe fitting 98126 Filter fitting 98231 Elbow M-F 1" GAS" *Pumping group repair kit for stainless steel NOVA 45:1 Ref. 40071 Pos. Code Description Pos. Code Description 98201 Complete pumping group for NOVA... -

Page 24: Rexploded View For Motor Group

NOVA 45:1/60:1 EXPLODED VIEW FOR MOTOR GROUP WARNING: always indicate code and quantity for each part required. - Page 25 NOVA 45:1/60:1 Pos. Code Description Pos. Code Description 95062 Screw 95070 Manifold 95063 Washer 95072 Manifold gasket 95064 Covering 95096 Washer 95065 Screw 95068 Screw 95066 Washer 95067 Plug 3/4" conical GAS 95061 Eyebolt 95090 Fitting 95109 Support 95089 Elbow 3/4" GAS...

-

Page 26: Sexploded View For Carbon Steel

NOVA 45:1/60:1 EXPLODED VIEW FOR CARBON STEEL PUMPING GROUP WARNING: always indicate code and quantity for each part required. -

Page 27: Pumping Group

Pumping group housing 95031 Elbow M-F 95126 Filter fitting 95032 Suction pipe fitting 95016 Gasket 96099 Bush *Pumping group repair kit for carbon steel NOVA 45:1 Ref. 40070 Pos. Code Description Pos. Code Description 95500 Complete pumping group for 98208 Sleeve... - Page 28 NOVA 45:1/60:1 EXPLODED VIEW FOR HIGH PRESSURE FILTER WARNING: always indicate code and quantity for each part required.

-

Page 29: Filter

NOVA 45:1/60:1 Nova 45:1/60:1 Pos. Code Description Pos. Code Description 95200 Complete line filter 95207 Intermediate fitting 95201 Filter base 95208 Ring nut 95202 O-ring 95209 O-ring 98303 Sieve fitting 96115 Filter container 95204 Dowel 95230 Fitting 3/8" - 3/8"... -

Page 30: Ucomplete Handtruck

NOVA 45:1/60:1 COMPLETE HANDTRUCK Pos. Code Description 95150 Complete handtruck 95154 Wheels... -

Page 31: Vair Group Complete

NOVA 45:1/60:1 AIR GROUP COMPLETE Pos. Code Description Pos. Code Description 95145 Air group complete 95313 Reduction 1" -3/4" Male Female 95031 Elbow Male Female 1" -MF92 95318 Rapid coupling 8x17 95090 Adapter 3/4 (NGE 3/4) 95319 Rapid coupling male da 1/4"... -

Page 32: Z Accessories

NOVA 45:1/60:1 ACCESSORIES Code 11250: AT 250 1/4" Code 11000: AT 300 1/4" Code 11180: L91X 1/4" Code 11200: AT 250 M16x1,5 Code 11090: AT 300 M16x1,5 Code 11120: L91X M16x1,5 FILTER Code 95218: SIEVE 30M FITTING WITH MANOMETER PISTON GUNSTOCK FILTERS... - Page 33 NOVA 45:1/60:1 Nozzles code 07-20 19-60 29-80 07-40 21-20 31-40 09-20 21-40 31-60 09-40 21-60 31-80 11-20 23-20 33-40 FAST-CLEAN 11-40 23-40 33-60 13-20 23-60 33-80 13-40 25-20 39-40 13-60 25-40 39-60 25-60 39-80 15-20 15-40 27-20 43-40 15-60 27-40...

- Page 34 NOVA 45:1/60:1 EXTENTION Code 153: cm 30 Code 154: cm 40 Code 155: cm 60 Code 156: cm 100 Code 95055: SUCTION SYSTEM Code 98055: SUCTION SYSTEM inox Code 95200: LINE FILTER Code 98300: LINE FILTER inox ANTISTATIC HOSE 3/16" - M16x1,5 HIGH PRESSURE HOSE 3/8"...

- Page 35 L’innovazione. Quella vera. PAINT SPRAYING EQUIPMENT...

- Page 36 VEGA AIRLESS Art.-Nr. 91500 VEGA MISTLESS Art.-Nr. 91400 MAnuFACTuRER: 23801 CALOLZIOCORTE - LECCO - ITALY - Via Stoppani, 21 Tel. (39) 0341/62.11.52 - Fax (39) 0341/62.12.43 E-mail: larius@larius.com - Internet http://www.larius.com DIRECT LINE CUSTOMERS TECHNICAL SERVICE Tel. (39) 0341/621256 Fax (39) 0341/621234...

Need help?

Do you have a question about the NOVA 45:1 and is the answer not in the manual?

Questions and answers