Table of Contents

Advertisement

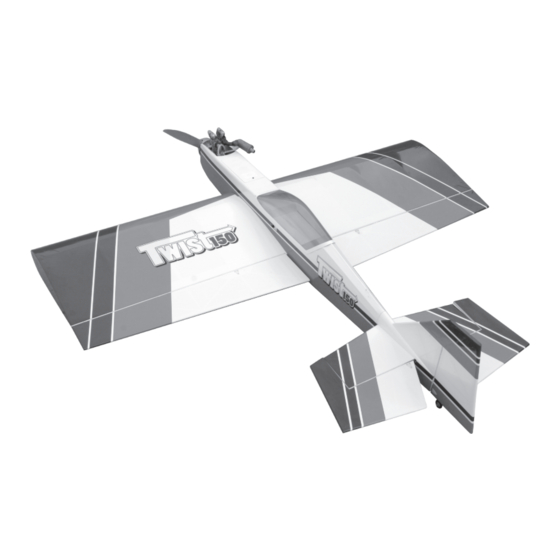

Twist 150 ARF

Specifications

Wingspan. . ....................................61.in.(1549.5mm)

Wing.Area.........................1224.sq.in.(78.96.sq.dm)

Assembly mAnuAl

Length. . .........................................59.in.(1498.5mm)

Weight. . ...............................8.5–10.lb.(3.8kg–4.5kg)

Engine. . ................................. . 1 .25–1.80.Four-Stroke

.......................................................... 26cc.Gasoline

Advertisement

Table of Contents

Summary of Contents for Hangar 9 twist 150 ARF

- Page 1 Twist 150 ARF Assembly mAnuAl Specifications Wingspan........61.in.(1549.5mm) Length...........59.in.(1498.5mm) Wing.Area......1224.sq.in.(78.96.sq.dm) Weight.........8.5–10.lb.(3.8kg–4.5kg) Engine........1 .25–1.80.Four-Stroke ............26cc.Gasoline...

-

Page 2: Table Of Contents

Table of Contents Contents.of.Kit..............3 UltraCote.Covering.Colors.. -

Page 3: Contents.of.kit

Contents of Kit Replacement Parts A.. HAN4526. Wing.Set B.. HAN4527. Fuselage C.. HAN4528. Tail.Set D.. HAN4529. . L anding.Gear.without. Wheels E.. HAN4530. Painted.Canopy F.. HAN4534. Wheel.Pant.Set Items not shown HAN4531. Pushrod.Set HAN4532. Decal.Set HAN4533. Tail.Wheel.Set UltraCote Covering Colors ® •.Midnight.Blue. HANU885. -

Page 4: Field.equipment.required

Field Equipment Required •.3 ".Spinner.(TRU3252B.or.TRU3262B120). •.Propeller.(17.x.6,.APC17060.recommended) •.Fuel. •.Long.Reach.Glow.Plug.Wrench.(HAN2510) •.Metered.Glow.Driver.w/Ni-Cd.&.Charger.(HAN7101). •.2-Cycle.Sport.Plug.(HAN3001) •.4-Cycle.Super.Plug.(HAN3011). •.2-Cycle.Super.Plug.(HAN3006) •.Manual.Fuel.Pump.(HAN118) Optional Field Equipment •.12V.7Ah.Sealed.Battery.(HAN102). •.PowerPro™.12V.Starter.(HAN161) Required Tools and Adhesives Tools •.Square. . •.Hobby.knife •.Phillips.screwdriver. •.Adjustable.wrench •.Drill. •.Felt-tipped.pen •.Ruler •.. D rill.bit:.1/16".(1.5mm),.5/64".(2mm),.5/32".(4mm),. 11/64".(4.5mm) Adhesives •.Thin.CA.(PAAPT08). •.30-minute.epoxy.(HAN8002) •.CA.remover/debonder.(PAAPT16). •.Pacer.Z-42.Threadlock.(PAAPT42) •.Canopy.glue.(PAAPT56) -

Page 5: Date.of.purchase.warranty.period

Warranty Period Exclusive.Warranty-.Horizon.Hobby,.Inc.,.(Horizon).warranties.that.the.Products.purchased.(the."Product").will.be.free. from.defects.in.materials.and.workmanship.at.the.date.of.purchase.by.the.Purchaser. Limited Warranty (a).This.warranty.is.limited.to.the.original.Purchaser.("Purchaser").and.is.not.transferable..REPAIR.OR.REPLACEMENT. AS.PROVIDED.UNDER.THIS.WARRANTY.IS.THE.EXCLUSIVE.REMEDY.OF.THE.PURCHASER..This.warranty.covers.only. those.Products.purchased.from.an.authorized.Horizon.dealer..Third.party.transactions.are.not.covered.by.this.warranty.. Proof.of.purchase.is.required.for.warranty.claims..Further,.Horizon.reserves.the.right.to.change.or.modify.this.warranty. without.notice.and.disclaims.all.other.warranties,.express.or.implied.. (b).Limitations-.HORIZON.MAKES.NO.WARRANTY.OR.REPRESENTATION,.EXPRESS.OR.IMPLIED,.ABOUT.NON- INFRINGEMENT,.MERCHANTABILITY.OR.FITNESS.FOR.A.PARTICULAR.PURPOSE.OF.THE.PRODUCT..THE.. PURCHASER.ACKNOWLEDGES.THAT.THEY.ALONE.HAVE.DETERMINED.THAT.THE.PRODUCT.WILL.SUITABLY.MEET. THE.REQUIREMENTS.OF.THE.PURCHASER’S.INTENDED.USE.. (c).Purchaser.Remedy-.Horizon's.sole.obligation.hereunder.shall.be.that.Horizon.will,.at.its.option,.(i).repair.or.(ii). replace,.any.Product.determined.by.Horizon.to.be.defective..In.the.event.of.a.defect,.these.are.the.Purchaser's.exclusive. remedies..Horizon.reserves.the.right.to.inspect.any.and.all.equipment.involved.in.a.warranty.claim..Repair.or.replacement. decisions.are.at.the.sole.discretion.of.Horizon..This.warranty.does.not.cover.cosmetic.damage.or.damage.due.to.acts.of. God,.accident,.misuse,.abuse,.negligence,.commercial.use,.or.modification.of.or.to.any.part.of.the.Product..This.warranty. does.not.cover.damage.due.to.improper.installation,.operation,.maintenance,.or.attempted.repair.by.anyone.other.than. Horizon..Return.of.any.goods.by.Purchaser.must.be.approved.in.writing.by.Horizon.before.shipment. Damage Limits HORIZON.SHALL.NOT.BE.LIABLE.FOR.SPECIAL,.INDIRECT.OR.CONSEQUENTIAL.DAMAGES,.LOSS.OF.PROFITS.OR. PRODUCTION.OR.COMMERCIAL.LOSS.IN.ANY.WAY.CONNECTED.WITH.THE.PRODUCT,.WHETHER.SUCH.CLAIM. IS.BASED.IN.CONTRACT,.WARRANTY,.NEGLIGENCE,.OR.STRICT.LIABILITY..Further,.in.no.event.shall.the.liability.of. Horizon.exceed.the.individual.price.of.the.Product.on.which.liability.is.asserted..As.Horizon.has.no.control.over.use,. setup,.final.assembly,.modification.or.misuse,.no.liability.shall.be.assumed.nor.accepted.for.any.resulting.damage.or. injury..By.the.act.of.use,.setup.or.assembly,.the.user.accepts.all.resulting.liability. If.you.as.the.Purchaser.or.user.are.not.prepared.to.accept.the.liability.associated.with.the.use.of.this.Product,.you.are. advised.to.return.this.Product.immediately.in.new.and.unused.condition.to.the.place.of.purchase. Law:.These.Terms.are.governed.by.Illinois.law.(without.regard.to.conflict.of.law.principals). Safety Precautions This.is.a.sophisticated.hobby.Product.and.not.a.toy..It.must.be.operated.with.caution.and.common.sense.and.requires. some.basic.mechanical.ability..Failure.to.operate.this.Product.in.a.safe.and.responsible.manner.could.result.in.injury.. or.damage.to.the.Product.or.other.property..This.Product.is.not.intended.for.use.by.children.without.direct.adult. supervision..The.Product.manual.contains.instructions.for.safety,.operation.and.maintenance..It.is.essential.to.read.. and.follow.all.the.instructions.and.warnings.in.the.manual,.prior.to.assembly,.setup.or.use,.in.order.to.operate.correctly. and.avoid.damage.or.injury. -

Page 6: Questions,.Assistance,.And.repairs

Questions, Assistance, and Repairs Your.local.hobby.store.and/or.place.of.purchase.cannot.provide.warranty.support.or.repair..Once.assembly,.setup.or. use.of.the.Product.has.been.started,.you.must.contact.Horizon.directly..This.will.enable.Horizon.to.better.answer.your. questions.and.service.you.in.the.event.that.you.may.need.any.assistance..For.questions.or.assistance,.please.direct.your. email.to.productsupport@horizonhobby.com,.or.call.877.504.0233.toll.free.to.speak.to.a.service.technician. Inspection or Repairs If.this.Product.needs.to.be.inspected.or.repaired,.please.call.for.a.Return.Merchandise.Authorization.(RMA)..Pack.. the.Product.securely.using.a.shipping.carton..Please.note.that.original.boxes.may.be.included,.but.are.not.designed.. to.withstand.the.rigors.of.shipping.without.additional.protection..Ship.via.a.carrier.that.provides.tracking.and.insurance. for.lost.or.damaged.parcels,.as.Horizon is not responsible for merchandise until it arrives and is accepted at our facility..A.Service.Repair.Request.is.available.at.www.horizonhobby.com.on.the.“Support”.tab..If.you.do.not.. have.internet.access,.please.include.a.letter.with.your.complete.name,.street.address,.email.address.and.phone.number. where.you.can.be.reached.during.business.days,.your.RMA.number,.a.list.of.the.included.items,.method.of.payment.. for.any.non-warranty.expenses.and.a.brief.summary.of.the.problem..Your.original.sales.receipt.must.also.be.included.. for.warranty.consideration..Be.sure.your.name,.address,.and.RMA.number.are.clearly.written.on.the.outside.of.the. shipping.carton. Warranty Inspection and Repairs To receive warranty service, you must include your original sales receipt.verifying.the.proof-of-purchase. date..Provided.warranty.conditions.have.been.met,.your.Product.will.be.repaired.or.replaced.free.of.charge..Repair.or. -

Page 7: Safety,.Precautions,.And.warnings

Safety, Precautions, and Warnings This.model.is.controlled.by.a.radio.signal.that.is.subject.to.interference.from.many.sources.outside.your.control..This. interference.can.cause.momentary.loss.of.control.so.it.is.advisable.to.always.keep.a.safe.distance.in.all.directions.around. your.model,.as.this.margin.will.help.to.avoid.collisions.or.injury. •.Always.operate.your.model.in.an.open.area.away.from.cars,.traffic,.or.people. •.Avoid.operating.your.model.in.the.street.where.injury.or.damage.can.occur. •.Never.operate.the.model.into.the.street.or.populated.areas.for.any.reason. •.Never.operate.your.model.with.low.transmitter.batteries. •.. C arefully.follow.the.directions.and.warnings.for.this.and.any.optional.support.equipment.(chargers,.rechargeable. battery.packs,.etc.).that.you.use. •.Keep.all.chemicals,.small.parts.and.anything.electrical.out.of.the.reach.of.children. •.. M oisture.causes.damage.to.electronics..Avoid.water.exposure.to.all.equipment.not.specifically.designed.and.protected. for.this.purpose. Before Starting Assembly Before.beginning.the.assembly.of.the.Twist.150,.remove.each.part.from.its.bag.for.inspection..Closely.inspect.. the.fuselage,.wing.panels,.rudder,.and.stabilizer.for.damage..If.you.find.any.damaged.or.missing.parts,.contact.the.. place.of.purchase. If.you.find.any.wrinkles.in.the.covering,.use.a.heat.gun.or.sealing.iron.to.remove.them..Use.caution.while.working.around. areas.where.the.colors.overlap.to.prevent.separating.the.colors. HAN101 – Sealing Iron HAN100 – Heat Gun HAN141 – Sealing Iron HAN150 –... -

Page 8: Section.1:.Aileron.installation

Section 1: Aileron Installation Required Parts .Step 2 •.Wing.panel.w/ailerons Use.a.1/16".(1.5mm).drill.bit.to.drill.a.hole.in.the.center. •.Servo.w/hardware.(2) of.each.hinge.location.in.both.the.wing.and.aileron..This. creates.a.tunnel.that.the.CA.can.pass.through.allowing.the. •.Servo.extension,.9".(228mm).(2) CA.to.penetrate.further.into.the.hinge. •.Pre-assembled.3 ".(89mm).aileron.linkage.(2) Required Tools and Adhesives •.Drill. •.Thin.CA •.Drill.bit:.1/16".(1.5mm),.3/32".(2.5mm) •.T-pins. •.Phillips.screwdriver •.Long.servo.arm. •.Rotary.tool •.CA.hinge.(8) .Step 1 Locate.four.CA.hinges..Place.a.T-pin.in.the.center.of.. the.hinges. Note:.Using.a.rotary.tool.and.1/16".(1.5mm). drill.bit.will.make.the.perfect.hole.as.it. removes.the.excess.wood.fibers.from.the.hole. ... - Page 9 Section 1: Aileron Installation .Step 4 .Step 6 Slide.the.aileron.and.wing.together..The.gap.between.the. Firmly.grasp.the.wing.and.aileron.and.gently.pull.on.the. aileron.and.wing.should.be.approximately.1/64".(.4mm).. aileron.to.ensure.the.hinges.are.secure.and.cannot.be. Align.the.end.of.the.aileron.to.the.wing..Also.check.that. pulled.apart..Use.caution.when.gripping.the.wing.and. the.aileron.can.move.freely.and.not.bind.at.the.wing.root. aileron.to.avoid.crushing.the.structure. Note:.Do.not.use.CA.accelerator.during. .Step 7 the.hinging.process..The.CA.must.be. Flex.each.aileron.up.and.down.a.number.of.times.to.. allowed.to.soak.into.the.hinge.to.provide. break.in.the.hinges. the.best.bond..Using.accelerator.will.not. provide.enough.time.for.this.process. .Step 5 Remove.the.T-pins.from.the.hinges..Flex.the.aileron.and. apply.Thin.CA.to.each.hinge..Make.sure.the.hinge.is.fully. saturated.with.CA..Use.a.paper.towel.and.CA.remover/ debonder.to.clean.up.any.excess.CA.from.the.wing.and/or. aileron..Make.sure.to.apply.CA.to.both.the.top.and.bottom. of.the.hinge.

- Page 10 Section 1: Aileron Installation .Step 8 .Step 10 Prepare.an.aileron.servo.by.installing.the.grommets. Place.the.servo.into.the.opening.with.the.servo.. and.brass.eyelets.provided.with.the.servo..Secure. output.towards.the.leading.edge.of.the.wing..Use.a. a.9".(228mm).servo.extension.to.the.servo.using.a. felt-tipped.pen.to.mark.the.locations.for.the.four.servo. commercially.available.connector.or.with.string.or. mounting.screws. unwaxed.dental.floss. .Step 11 .Step 9 Remove.the.servo.and.drill.the.locations.for.the.servo. Tie.the.string.that.exits.the.servo.opening.to.the.servo. mounting.screws.using.a.1/16".(1.5mm).drill.bit... extension..Use.the.string.to.pull.the.servo.lead.through. Apply.a.few.drops.of.thin.CA.to.each.hole.to.harden.the. the.wing..Use.a.piece.of.tape.to.keep.the.extension.from. wood,.which.will.help.in.preventing.the.screws.from. falling.back.into.the.wing. damaging.the.wood.

- Page 11 Section 1: Aileron Installation .Step 12 .Step 14 Secure.the.servo.using.the.screws.provided.with.the. Attach.the.clevis.to.the.control.horn..With.the.radio.system. servo..Remove.the.stock.servo.horn.and.install.a.long. on.and.the.aileron.trim.and.stick.centered,.check.that.the. servo.arm.in.its.place..Remove.the.side.of.the.arm.that. aileron.is.centered.when.viewed.from.the.wing.tip..Adjust. does.not.align.with.the.control.horn. the.length.of.the.linkage.if.necessary. .Step 13 Enlarge.the.outer.hole.of.the.servo.arm.using.a.3/32". (2.5mm).drill.bit..Remove.the.pushrod.keeper.from.the. linkage.and.slide.the.bend.to.the.servo.arm..Secure.the. pushrod.to.the.servo.arm.by.replacing.the.pushrod.keeper. .Step 15 Use.tape.on.the.servo.lead.to.prevent.it.from.falling.back. into.the.wing. .Step 16 Repeat.Steps.1.through.15.for.the.remaining.aileron.servo.

-

Page 12: Section.2:.Landing.gear.and.tail.installation

Section 2: Landing Gear and Tail Installation Required Parts .Step 2 •.Landing.gear.w/wheels. •.Fuselage Attach.the.wheel.pants.using.four.4-40.x.1/2".socket.head. •.1".(25mm).tail.wheel. •.Rudder.assembly screws.and.four.#4.washers. •.Stabilizer.assembly. •.4-40.locknut.(3) •#4.washer.(7). •#8.washer.(3) •.5/64".wheel.collar. •.4-40.setscrew •.4-40.x.1/2".socket.head.screw.(4) •.8-32.x.3/4".machine.screw.(3) •.Pre-assembled.5 ".(134mm).rudder.linkage •.Pre-assembled.4 ".(124mm).elevator.linkage Required Tools and Adhesives •.Servo.w/hardware.(2). •.Long.servo.arm.(2) •.Adjustable.wrench. •.Threadlock •.18".(458mm).servo.extension •.24".(610mm).servo.extension ... - Page 13 Section 2: Landing Gear and Tail Installation .Step 4 .Step 6 Slide.the.rudder/stabilizer.onto.the.fuselage..Guide.the. Secure.the.tail.wheel.into.position.using.the.5/64".wheel. threaded.rods.through.the.stabilizer.saddle.then.through. collar.and.the.4-40.setscrew..Use.threadlock.on.the. the.holes.in.the.bottom.of.the.fuselage. setscrew.to.prevent.it.from.vibrating.loose. .Step 5 .Step 7 Secure.the.tail.assembly.to.the.fuselage.using.three.. Attach.a.24".(610mm).servo.extension.to.the.rudder.servo.. #4.washers.and.three.4-40.locknuts..Do.not.over-tighten. Center.the.servo.using.the.radio.and.install.a.long.servo. the.nuts.and.crush.the.fuselage. arm.onto.the.servo..Use.the.photo.to.determine.which. arm.to.trim.off,.as.it.will.hit.the.elevator.if.left.in.place.. Mount.the.rudder.servo.into.the.fuselage.using.the.same. procedure.as.the.aileron.servo.

- Page 14 Section 2: Landing Gear and Tail Installation .Step 8 .Step 9 Install.the.pre-assembled.5 ".(134mm).rudder.linkage.. Repeat.Steps.7.and.8.to.install.the.elevator.servo.and. With.the.radio.on,.adjust.the.length.of.the.linkage.so.the. linkage..Use.a.18".(458mm).servo.extension.and.the.. rudder.is.centered. ".(124mm).elevator.linkage.when.installing.the. elevator.servo.

-

Page 15: Section.3A:.four-Stroke.engine.installation

Section 3A: Four-Stroke Engine Installation Required Parts .Step 2 •#8.washer.(4) Use.a.5/32".(4mm).drill.bit.to.drill.the.holes.in.the.. •.Rubber.band.(2) engine.mount. •.Pushrod.connector •.8-32.locknut.(4) •.8-32.x.1 ".screw.(4) •.20".(508mm).throttle.pushrod •.3 ".(83mm).spinner.w/hardware •.Pushrod.connector.backplate •.3mm.x.5mm.machine.screw Required Tools and Adhesives •.Servo.w/hardware. •.Ruler •.Drill. •.Phillips.screwdriver •.Hobby.knife Hint:.Remove.the.mounts.and.use. •.Drill.bit:.5/64".(2mm),.5/32".(4mm) a.drill.press.to.get.the.holes.in.the. mount.perpendicular.to.the.mount. .Step 1 Position.the.engine.on.the.engine.mount.so.the.drive. ... - Page 16 Section 3A: Four-Stroke Engine Installation .Step 4 .Step 7 Slide.the.20".(508mm).throttle.pushrod.into.the.pushrod. Attach.the.lines.from.the.fuel.tank.to.the.engine..The.. tube.and.attach.the.clevis.to.the.carburetor.arm. line.marked."vent".will.attach.to.the.muffler,.and.the. remaining.line.connects.to.the.carburetor. .Step 5 Install.the.muffler.onto.your.engine.using.the.instructions. provided.with.the.engine.as.a.guide. Note:.Plan.on.installing.a.needle.valve. extension..It.will.be.necessary.to.use.a. rotary.tool.to.provide.clearance.between. .Step 6 the.extension.and.side.of.the.fuselage. Install.a.propeller.and.spinner.onto.your.engine... Consult.the.instructions.provided.with.your.engine.. .Step 8 for.further.details. Place.the.fuselage.hatch.into.position.and.secure.it.using. the.4-40.x.1/2".socket.head.screw.

- Page 17 Section 3A: Four-Stroke Engine Installation .Step 9 .Step 11 Install.the.throttle.servo.into.the.fuselage..Use.the.opening. Use.the.radio.to.move.the.throttle.to.the.low.setting.. closest.to.the.pushrod..Turn.on.the.radio.system.and. using.the.stick.and.trim..Move.the.pushrod.so.the. center.the.throttle.stick.and.trim..Position.the.servo.horn. carburetor.is.closed..Secure.the.pushrod.wire.using.a. onto.the.servo.so.the.horn.is.perpendicular.to.the.servo. 3mm.x.5mm.machine.screw. centerline. .Step 12 .Step 10 Check.that.the.throttle.operates.from.the.radio.without. Remove.the.servo.horn.and.attach.the.pushrod.connector. binding.at.low.and.high.throttle..Use.the.ATV.setting.. to.the.throttle.servo.arm.using.the.connector.backplate.. of.the.radio.or.change.the.position.of.the.clevis.at.the. You.will.need.to.enlarge.the.hole.in.the.servo.arm.using.a. carburetor.or.the.pushrod.connector.at.the.servo.to. 5/64".(2mm).drill.bit. eliminate.any.binding.

-

Page 18: Section.3B:.gasoline.engine.installation

Section 3B: Gasoline Engine Installation Required Parts Note:.You.will.need.to.install.gas. compatible.fuel.lines.and.prepare. •#8.washer.(4) the.metal.fuel.tubing.as.follows. •.Rubber.band.(2) •.Pushrod.connector .Step 2 •.8-32.locknut.(4) Remove.the.stopper.from.the.fuel.tank.using.a.Phillips. •.8-32.x.1 ".screw.(4) screwdriver..Remove.the.fuel.lines.from.the.stopper.and. •.20".(508mm).throttle.pushrod set.them.aside..Prepare.the.tubing.by.placing.a.drop.of. •.3 ".(83mm).spinner.w/hardware solder.on.the.ends.of.the.brass.tubing.as.shown..This. •.Pushrod.connector.backplate will.keep.the.fuel.line.from.slipping.off.the.tube.when. •.3mm.x.5mm.machine.screw combined.with.the.following.steps. Required Tools and Adhesives •.Servo.w/hardware. •.Ruler •.Drill. •.Phillips.screwdriver •.Hobby.knife. •.Rotary.tool •.Sanding.drum •.Drill.bit:.5/64".(2mm),.5/32".(4mm) Note:.Installing.the.Evolution... - Page 19 Section 3B: Gasoline Engine Installation .Step 4 .Step 6 Carefully.insert.the.stopper.assembly.into.the.fuel.tank.. Position.the.engine.on.the.engine.mount.so.the.drive. Note.the.position.of.the.vent.tube;.it.must.be.up.at.the.top. washer.is.roughly.1/8".(3mm).forward.of.the.sides.of.the. portion.of.the.fuel.tank.to.function.properly..Tighten.the. fuselage..Mark.the.location.of.the.engine.mounting.bolts. M3.x.20.screw.carefully—do.not.over-tighten. using.a.felt-tipped.pen. Note:.The.engine.must.be.far.enough. .Step 5 forward.so.when.the.propeller.and.spinner. Use.a.rotary.tool.to.remove.material.from.the.inside.of.the. are.installed,.they.don't.bind.on.the.front. engine.mount.to.fit.your.particular.engine. of.the.fuselage..A.quick.check.is.to.slip.the. spinner.backplate.on.and.check.for.clearance. .Step 7 Use.a.5/32".(4mm).drill.bit.to.drill.the.holes.in.the.. engine.mount. Hint:.Remove.the.mounts.and.use. a.drill.press.to.get.the.holes.in.the. mount.perpendicular.to.the.mount.

- Page 20 Section 3B: Gasoline Engine Installation .Step 8 .Step 10 Use.a.1".hole.saw.or.rotary.tool.to.make.a.hole.in.the. Install.the.fuel.tank.back.inside.the.fuselage. firewall.that.will.be.below.the.fuel.tank. .Step 11 Attach.any.necessary.items.to.the.engine.using.the. instructions.provided.with.the.engine..Mount.the.engine. to.the.mount.using.four.8-32.x.1 ".screws,.four.#8. washers.and.four.8-32.locknuts. .Step 9 Use.plywood.to.create.a.shelf.inside.the.fuselage.to.mount. the.ignition.and.battery.for.your.engine..Make.sure.the. ignition.is.secure.to.the.plate,.and.the.plate.is.secure. inside.the.fuselage..Route.any.necessary.connections. through.the.1".hole.made.in.the.firewall.in.Step.7..Install. a.Switch.Harness.(JRPA004).in.the.fuselage.opposite.the. side.the.radio.switch.will.be.mounted.to. .Step 12 Slide.the.20".(508mm).throttle.pushrod.into.the.pushrod. tube.and.attach.the.clevis.to.the.carburetor.arm. Note:.Make.sure.your.ingition.system. with.battery.will.not.interfere.with. the.fuel.tank..Place.the.battery.back. in.the.fuselage.if.necessary.

- Page 21 Section 3B: Gasoline Engine Installation .Step 13 .Step 15 Install.the.muffler.onto.your.engine.using.the.instructions. Attach.the.line.from.the.fuel.tank.to.the.engine..Route.. provided.with.the.engine.as.a.guide. the.vent.line.from.the.fuel.tank.behind.the.engine.and.. to.the.bottom.of.the.fuselage..Remove.the.fuel.fitting.. from.the.muffler.and.replace.it.with.an.8-32.x.1/4".. screw.to.seal.the.hole. Note:.You.will.need.to.use.a.rotary.tool.to. remove.some.material.from.the.fuselage. side.to.provide.clearance.for.the.muffler. .Step 16 .Step 14 Place.the.fuselage.hatch.into.position.and.secure.it.using. the.4-40.x.1/2".socket.head.screw. Install.a.propeller.and.spinner.onto.your.engine... Consult.the.instructions.provided.with.your.engine.. for.further.details.

- Page 22 Section 3B: Gasoline Engine Installation .Step 16 .Step 18 Install.the.throttle.servo.into.the.fuselage..Use.the.opening. Use.the.radio.to.move.the.throttle.to.the.mid-point. closest.to.the.pushrod..Turn.on.the.radio.system.and. setting.using.the.stick.and.trim..Move.the.pushrod.so.the. center.the.throttle.stick.and.trim..Position.the.servo.horn. carburetor.is.at.mid-point..This.installation.method.will. onto.the.servo.so.the.horn.is.perpendicular.to.the.servo. provide.for.a.more.linear.throttle.response..Secure.the. centerline. pushrod.wire.using.a.3mm.x.5mm.machine.screw. .Step 17 .Step 19 Remove.the.servo.horn.and.attach.the.pushrod.connector. Check.that.the.throttle.operates.from.the.radio.without. to.the.throttle.servo.arm.using.the.connector.backplate.. binding.at.low.and.high.throttle..Use.the.ATV.setting.. You.will.need.to.enlarge.the.hole.in.the.servo.arm.using.a. of.the.radio.or.change.the.position.of.the.clevis.at.the. 5/64".(2mm).drill.bit. carburetor.or.the.pushrod.connector.at.the.servo.to. eliminate.any.binding.

-

Page 23: Section.4:.Final.assembly

Section 4: Final Assembly Required Parts .Step 2 •.Fuselage. •.Wing Place.the.remaining.flat.foam.over.the.receiver.and. •.1/4-20.x.1 ".nylon.bolt.(2) receiver.battery..Slide.the.radio.plate.into.position.. and.secure.it.using.a.4-40.X.1/2".socket.head.screw.. •.Canopy and.#4.washer. Required Tools and Adhesives •.Canopy.glue. •.Flat.screwdriver •.Felt-tipped.pen. •.Masking.tape •.1/4".foam .Step 1 Place.a.flat.piece.of.foam.into.the.fuselage,.followed.by. the.shaped.radio.foam..Plug.the.servos.and.extensions. into.their.proper.location.in.the.receiver..Route.the.receiver. antenna.wire.through.the.tube.on.the.right-hand.side.of. the.fuselage.to.the.tail..Place.the.receiver.and.receiver. battery.into.the.foam. .Step 3 Remove.the.covering.from.the.opening.on.the.left.side. of.the.fuselage.for.the.switch.harness..Install.the.harness. - Page 24 Section 4: Final Assembly .Step 5 .Step 7 Position.the.canopy.onto.the.fuselage..Use.a.felt-tipped. Use.canopy.glue.to.secure.the.canopy.to.the.fuselage... pen.to.trace.the.outline.of.the.canopy.onto.the.fuselage. Use.masking.tape.to.hold.the.canopy.in.position.until.. the.glue.fully.cures. .Step 6 .Step 8 Use.sandpaper.to.lightly.sand.inside.the.line.drawn.on.the. fuselage..Also.sand.the.inside.of.the.canopy.where.it.will. Attach.the.wing.to.the.fuselage.using.two.1/4-20.x.1 ". rest.on.the.fuselage. nylon.bolts.

-

Page 25: Control.throws

Control Throws The.amount.of.control.throw.should.be.adjusted.as.closely. Rudder.Low.Rate. ".(89mm).(30º).right/left as.possible.using.mechanical.means,.rather.than.making. Rudder.High.Rate. 5".(127mm).(45º).right/left large.changes.electronically.at.the.radio..By.moving. Note:.Rudder.throw.is.measured. the.position.of.the.clevis.at.the.control.horn.toward.the. at.the.bottom.of.the.rudder. outermost.hole,.you.will.decrease.the.amount.of.control. throw.of.the.control.surface:.moving.it.toward.the.control. Once.the.control.throws.have.been.set,.slide.the.clevis. surface.will.increase.the.amount.of.throw;.moving.the. retainers.over.the.clevis.to.prevent.them.from.opening. pushrod.wire.at.the.servo.arm.will.have.the.opposite. during.flight. effect..Moving.it.closer.to.center.will.decrease.throw,. and.away.from.center.will.increase.throw..Work.with.a. combination.of.the.two.to.achieve.the.closest.or.exact. control.throws.listed. Aileron.Low.Rate. ".(35mm).(13º).up/down Aileron.High.Rate. 3".(76mm).(30º).up/down Note:.Aileron.throw.is.measured.at. the.trailing.edge.tip.of.the.aileron. Elevator.Low.Rate. ".(38mm).(15º).up/down Elevator.High.Rate. ".(89mm).(40º).up/down Note:.Elevator.throw.is.measured.at.the. inboard.trailing.edge.of.the.elevator. Recommended Center of Gravity (CG) An.important.part.of.preparing.the.aircraft.for.flight.is. -

Page 26: Pre-Flight

Pre-Flight Charge.both.the.transmitter.and.receiver.pack.for.your. Check.the.radio.installation.and.make.sure.all.the.. airplane..Use.the.recommended.charger.supplied.with. control.surfaces.are.moving.correctly.(i.e..the.correct. your.particular.radio.system,.following.the.instructions. direction.and.with.the.recommended.throws)..Test.run.. provided.with.the.radio..In.most.cases,.the.radio.should. the.engine.and.make.sure.it.transitions.smoothly.from.. be.charged.the.night.before.going.out.flying. idle.to.full.throttle.and.back..Also.ensure.the.engine.is. tuned.according.to.the.manufacturer’s.instructions,.. and.it.will.run.consistently.and.constantly.at.full.throttle. when.adjusted. Check.all.the.control.horns,.servo.horns.and.clevises.to. make.sure.they.are.secure.and.in.good.condition..Replace. any.items.that.would.be.considered.questionable..Failure. of.any.of.these.components.in.flight.would.mean.the.loss. of.your.aircraft. Adjusting the Engine .Step 1 .Step 3 Completely.read.the.instructions.included.with.your. Before.you.fly,.be.sure.that.your.engine.idles.reliably,. engine.and.follow.the.recommended.break-in.procedure. transitions.and.runs.at.all.throttle.settings..Only.when.this. is.achieved.should.any.plane.be.considered.ready.. .Step 2 for.flight. At.the.field,.adjust.the.engine.to.a.slightly.rich.setting.at. full.throttle.and.adjust.the.idle.and.low-speed.needle.so. that.a.consistent.idle.is.achieved. Range Test Your Radio start.the.engine..With.the.model.securely.anchored,.check Before.each.flying.session,.be.sure.to.range.check.your... -

Page 27: Maintaining.your.twist.150.Arf

Maintaining Your Twist 150 ARF The.following.is.a.check.list.that.you.should.follow.. Checking the Control Horns every.time.you.have.completed.a.flying.session.with.. Inspect.the.control.horns.to.make.sure.they.have.not. your.Twist ™ .150..Doing.so.will.keep.your.aircraft.. crushed.the.wood.of.the.control.surface..If.so,.remove.the. in.the.best.flying.condition. control.horn.screws.to.remove.the.control.horn..Place.2–3. drops.of.thin.CA.into.each.of.the.screw.holes..In.addition,. Clean Up use.a.T-pin.to.poke.small.holes.in.the.covering.in.the.area. If.you.are.flying.with.a.glow.engine.you.will.want.to.clean. where.the.control.horn.mounts,.then.saturate.the.area.with. your.Twist.150.before.loading.it.into.your.vehicle.to.head. thin.CA..This.will.harden.the.wood.and.give.the.control. home..Use.a.cleaner.such.as.Windex.or.409.and.a.paper. horns.a.solid.surface.to.be.mounted.to. towel.to.wipe.down.the.exterior.of.your.plane,.removing. Checking the Wheel Collars the.fuel.residue..Remember.a.clean.plane.will.last.longer. since.the.fuel.won’t.be.allowed.to.soak.into.any.exposed. Check.the.setscrews.on.the.main.and.tail.wheel.wheel. wood. collars.to.make.sure.they.are.not.loose..Use.a.1.5mm.. hex.wrench.to.tighten.the.setscrews..It.is.suggested.if.. Checking the Propeller they.loosen.frequently.to.remove.them,.apply.threadlock.. -

Page 28: Glossary.of.terms

Glossary of Terms •.. A ilerons:..Each.side.of.this.airplane.has.a.hinged. •.. P itch Axis:.The.horizontal.plane.on.which.the. control.surface.(aileron),.located.on.the.trailing.edge.of. airplane’s.nose.is.raised.or.lowered..By.moving.the. the.wing..Move.the.aileron.stick.on.the.transmitter.left,. elevator,.you.can.raise.the.airplane’s.nose.above.the. the.left.aileron.moves.up.and.the.right.aileron.moves. pitch.axis.(climb).or.lower.it.below.the.pitch.axis.(dive). down..Moving.the.left.aileron.up.causes.more.drag.and. •.. P ushrod:.The.rigid.mechanism.that.transfers. less.lift,.causing.the.left.wing.to.drop.down..When.the. movement.from.the.servo.to.the.control.surface. right.aileron.moves.down,.more.lift.is.created,.causing. •.. R oll Axis:.The.horizontal.plane.on.which.the.airplane’s. the.right.wing.to.rise..This.interaction.causes.the. wings.are.raised.or.lowered..By.adjusting.the.ailerons,. airplane.to.turn.or.roll.to.the.left..Perform.the.opposite. you.can.drop.a.wing.tip.below.the.roll.axis.and.cause. actions,.and.the.airplane.will.roll.to.the.right. the.airplane.to.bank.or.roll. •.. C levis:.The.clevis.connects.the.wire.end.of.the.pushrod. •.. R udder:.The.hinged.control.surface.on.the.vertical. to.the.control.horn.of.the.control.surface..Being.a.small. stabilizer.that.controls.the.airplane’s.yaw..Moving.the. -

Page 29: Building.and.flying.notes

Building and Flying Notes... -

Page 30: 2006.Official.ama.national.model.aircraft.safety.code

2007 Official AMA National Model Aircraft Safety Code GENERAL 7).I.will.not.operate.models.with.pyrotechnics.(any. device.that.explodes,.burns,.or.propels.a.projectile. 1).I.will.not.fly.my.model.aircraft.in.sanctioned. of.any.kind).including,.but.not.limited.to,.rockets,. events,.air.shows.or.model.flying.demonstrations.until. explosive.bombs.dropped.from.models,.smoke. it.has.been.proven.to.be.airworthy.by.having.been. bombs,.all.explosive.gases.(such.as.hydrogen-filled. previously,.successfully.flight.tested. balloons),.or.ground.mounted.devices.launching.a. 2).I.will.not.fly.my.model.higher.than.approximately. projectile..The.only.exceptions.permitted.are.rockets. 400.feet.within.3.miles.of.an.airport.without.notifying. flown.in.accordance.with.the.National.Model.Rocketry. the.airport.operator..I.will.give.right-of-way.and.avoid. Safety.Code.or.those.permanently.attached.(as.per. flying.in.the.proximity.of.full-scale.aircraft..Where. JATO.use);.also.those.items.authorized.for.Air.Show. necessary,.an.observer.shall.be.utilized.to.supervise. Team.use.as.defined.by.AST.Advisory.Committee. flying.to.avoid.having.models.fly.in.the.proximity.of. (document.available.from.AMA.HQ)..In.any.case,. full-scale.aircraft. models.using.rocket.motors.as.a.primary.means.of. 3).Where.established,.I.will.abide.by.the.safety.rules. propulsion.are.limited.to.a.maximum.weight.of.3.3. for.the.flying.site.I.use,.and.I.will.not.willfully.and. pounds.and.a.G.series.motor..(A.model.aircraft.is. deliberately.fly.my.models.in.a.careless,.reckless.and/ defined.as.an.aircraft.with.or.without.engine,.not.able. or.dangerous.manner. to.carry.a.human.being.) 4).The.maximum.takeoff.weight.of.a.model.is.55. - Page 31 2007 Official AMA National Model Aircraft Safety Code 5).Flying.sites.separated.by.three.miles.or.more. Organized RC Racing Event are.considered.safe.from.site-to.site.interference,. 10).An.RC.racing.event,.whether.or.not.an.AMA.Rule. even.when.both.sites.use.the.same.frequencies..Any. Book.event,.is.one.in.which.model.aircraft.compete. circumstances.under.three.miles.separation.require. in.flight.over.a.prescribed.course.with.the.objective.of. a.frequency.management.arrangement,.which.may. finishing.the.course.faster.to.determine.the.winner. be.either.an.allocation.of.specific.frequencies.for. A..In.every.organized.racing.event.in.which. each.site.or.testing.to.determine.that.freedom.from. contestants,.callers.and.officials.are.on.the.course: interference.exists..Allocation.plans.or.interference. 1..All.officials,.callers.and.contestants.must.properly. test.reports.shall.be.signed.by.the.parties.involved. wear.helmets,.which.are.OSHA,.DOT,.ANSI,.SNELL.or. and.provided.to.AMA.Headquarters..Documents.of. NOCSAE.approved.or.comparable.standard.while.on. agreement.and.reports.may.exist.between.(1).two. the.racecourse. or.more.AMA.Chartered.Clubs,.(2).AMA.clubs.and. 2..All.officials.will.be.off.the.course.except.for.the. individual.AMA.members.not.associated.with.AMA. starter.and.their.assistant. Clubs,.or.(3).two.or.more.individual.AMA.members. 3.”On.the.course”.is.defined.to.mean.any.area.beyond. 6).For.Combat,.distance.between.combat.engagement. the.pilot/staging.area.where.actual.flying.takes.place.

- Page 32 ©.2007.Horizon.Hobby,.Inc.. 4105.Fieldstone.Road. Champaign,.Illinois.61822. (877).504-0233. horizonhobby.com 9512...

Need help?

Do you have a question about the twist 150 ARF and is the answer not in the manual?

Questions and answers