Advertisement

Advertisement

Table of Contents

Summary of Contents for Hyundai HY25-2

- Page 2 Ver 2 Page 2...

-

Page 3: Table Of Contents

CONTENTS 1. SAFETY 4 – 7 2. PART LOCATIONS 3. FUEL 4. SETUP 10 – 11 5. OPERATION 12 – 13 6. MAINTENANCE 13 – 15 7. TROUBLESHOOTING 8. SPECIFICATION 9. STORAGE & TRANSPORTATION 16 – 17 10. CONTACT DETAILS 11. -

Page 4: Safety

1. SAFETY. 1.1. The operator of the machines; 1.1.1. Responsible for and has a duty of care in making sure that the machine is operated safely and in accordance with the instructions in this user manual. 1.1.2. Should never be left it in a condition which would allow an untrained or unauthorised person/s to operate this machine. - Page 5 1.2.1.2. Headaches, dizziness, nausea, breathlessness, collapsing or loss of consciousness. 1.2.2 Carbon monoxide symptoms are similar to flu, food poisoning, viral infections and simply tiredness. That’s why it’s quite common for people to mistake this very dangerous poisoning for something else. 1.2.3 To avoid Carbon monoxide poisoning DO NOT Use Petrol/Diesel powered equipment inside a home or garage even if doors and windows are open.

- Page 6 Hand protection. Protective clothing. Respiratory protective equipment should be used when in an unventilated area. 1.4.1.1. When defueling always use a propriety fuel retriever. 1.4.1.2. Always carry fuel in the correct and clearly marked container. 1.4.2. Additional safety. 1.4.2.1. Intended use is for pumping the water that is not intended for human consumption.

- Page 7 your dealer for any clarification or priority action. 1.4.3. Check the General Condition of the Pump 1.4.3.1. Look around and underneath the pump for signs of oil or gasoline leaks. 1.4.3.2. Remove any excessive dirt or debris, especially around the engine muffler, and recoil starter.

-

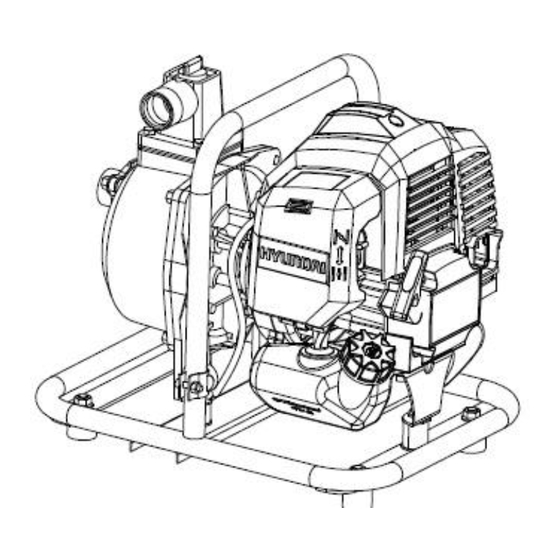

Page 8: Part Locations

2. PART LOCATIONS 1 – Carrying handle 2 – Spark plug 3 – Air filter 4 – Choke lever 5 – Recoil handle 6 – Fuel tank 7 – Resilient mount 8 – Throttle 9 – Rubber foot 10 – Pump drain 11 –... -

Page 9: Fuel

3. FUEL Petrol is highly flammable. Avoid smoking or bringing any source of ignition or naked flame near fuel, this includes tools which can cause sparks such as grinders and drills. Before re-fueling make sure the engine has been stopped and allowed to cool down. Choose an outdoor area at least 10m from fuel storage point. -

Page 10: Setup

SETUP 4.1. Pump placement. 4.1.1. For best pump performance, place the pump near the water level, and use hoses that are no longer than necessary. This will enable the pump to produce the greatest output with the least self-priming time. 4.1.2. - Page 11 4.3. Discharge hose installation. 4.3.1. Attach a hose and hose connector to the pump’s discharge port. It is best to use a short, large-diameter hose, because this will reduce fluid friction and improve pump performance. 4.3.2. A long or small-diameter hose will increase fluid friction and reduce pump output.

-

Page 12: Operation

OPERATION DO NOT operate the pump in a dry state. Operating the pump dry will destroy the pump seal. If the pump has been operated dry, stop the engine immediately, and allow the pump to cool before priming. 5.3. Priming the pump. 5.1.1. -

Page 13: Maintenance

5.3. Setting engine speed. 5.3.1. After starting the engine, move the throttle lever (1) clockwise to the HIGH position (2) and check pump output. 5.3.2. Pump output is controlled by adjusting engine speed. Moving the throttle lever in the HIGH direction (2) will increase pump output, and moving the throttle lever (anti- clockwise) in the LOW direction (3) will decrease pump output. - Page 14 6.2. Air filter. 6.2.1. Check the air filter monthly. 6.2.1.16. To remove filter press clip (1) remove cover (2) to reveal filter element (4). 6.2.1.17. Clean the element in warm soapy water as necessary. Dry completely before installing. 6.2.1.17.1. You must clean more frequently if used under very dusty conditions.

-

Page 15: Troubleshooting

The use of any spark plug other than the one designated may result in the engine failing to run correctly becoming overheated and damaged. 6.4. Fuel filter. A clogged fuel filter can cause lack of power and poor pickup. 6.4.1. Remove the fuel cap (1) and empty the remaining fuel into an approved container. -

Page 16: Specification

SPECIFICATION MODEL HY25-2 HY40-2 Single cylinder, 2 stroke, air- Single cylinder, 2 stroke, air- Engine Type cooled engine, 1E43F-B cooled engine, 1E43F-B Engine size – cc 50.8 50.8 Fuel tank capacity – ml Noise Level – dB Rated power – kw 1.56... -

Page 17: Contact Details

9.10. Transporting the machine. 9.10.1. When transporting the machine make sure that no fuel is allowed to leak out. 9.10.2. DO NOT allow the pump to come into contact with persons, animals and property. 10. CONTACT DETAILS 10.1. Postal address; Genpower Limited, Isaac Way, Pembroke Dock, Pembrokeshire,SA724RW,UK. -

Page 18: Declarations Of Conformity

11. DECLARATIONS of CONFORMITY 11.1. Genpower Ltd confirms that these Hyundai products conform to the following CE Directives; 2006/42/EC Machinery Directive 2004/108/EC EMC Directive 2000/14/EC Noise Emissions Directive 97/68/EC NRMM Emissions Directive Ver 2 Page 18... - Page 19 Ver 2 Page 19...

- Page 20 Isaac Way, London Road Pembroke Dock, UNITED KINGDOM, SA72 4RW T: +44 (0) 1646 687 880 F: +44 (0) 1646 686 198 info@hyundaipowerequipment.co.uk www.hyundaipowerequipment.co.uk...

Need help?

Do you have a question about the HY25-2 and is the answer not in the manual?

Questions and answers