Wasp DELTA 2040 Use And Maintenance Manual

Hide thumbs

Also See for DELTA 2040:

- Manual of use and maintenance (79 pages) ,

- Manual of use and maintenance (85 pages) ,

- Use and maintenance manual (56 pages)

Summary of Contents for Wasp DELTA 2040

- Page 1 USE and MAINTENANCE MANUAL DELTA 2040/4070 3D PRINTER WASProject Viale Zaganelli, 26 48024 Massa Lombarda (RA) (ITALIA) tel. +39 0545 82966 http://www.wasproject.it/ e-mail: info@wasproject.it...

- Page 2 USE and MAINTENANCE MANUAL Dear Customer, WASP First of all thank you for choosing a 3D printer. WASP is an industrial landmark for printers and 3D printing systems. WASP products guarantee great reliability and safety. WASP All components of 3D printers are designed and produced to ensure the best perfor- mances at all times.

-

Page 3: Table Of Contents

USE and MAINTENANCE MANUAL GENERAL CONTENTS INFORMATIVE LETTER....................4 WARRANTY.........................6 INTRODUCTION TO OUR COMPANY................7 TRANSPORT..................8 TRANSPORT IN CARDBOARD BOX..............8 C ON T EN T................9 UNPACKING.. -

Page 4: Informative Letter

Although the main features of the machine described in this manual are not subject to change, CSP srl (WASP) reserves the right to change any part, detail and accessory it deems neces- sary to improve the printer or for manufacturing or commercial requirements, at any time and without being obliged to update this manual immediately. - Page 5 WASP printers are NOT manufactured to work in environments with danger of explosion and at high fi re risk. In case of damages or uncorrect operating, the printers must not be used until they have been repaired.

-

Page 6: Warranty

USE and MAINTENANCE MANUAL Warranty WASP 3D printer has a 24 month warranty from the date written on the last page of this manual for private customers and a 12 month warranty for companies or workers with VAT number, unless otherwise stated in writing. -

Page 7: Introduction To Our Company

Massimo and his team. WASP is CSP, Centro Sviluppo Progetti, is university, is research, is passion. These elements are perfectly integrated and combined together in order to work for Makers research and innovation. -

Page 8: Transport

USE and MAINTENANCE MANUAL 1.0 Transport To transport the 3D printer only the method below can be used. Make sure the means of transport and the lifting device can bear the weight of the machine with its packaging (about 25 Kg): + Transport in cardboard box. -

Page 9: C On T En T

USE and MAINTENANCE MANUAL 1.2 Content Standard Delta 2040 printer is supplied with use manual, SD card, power cable with schuko plug, glass surface, reel support. SD card Use manual Glass surface Lacquer For deliveries in Italy Schuko plug Reel support... -

Page 10: Labelling Data

USE and MAINTENANCE MANUAL 2.0 Labelling data The manufacturer's identifi cation and EC standard 2006/42/EC conformity plate (see picture 2) is on the internal upper part of the printer. The plate must not be removed at all, even if the printer is resold. Always refer to the serial number (written on the plate itself) when contacting the manufacturer. -

Page 11: Printer Description

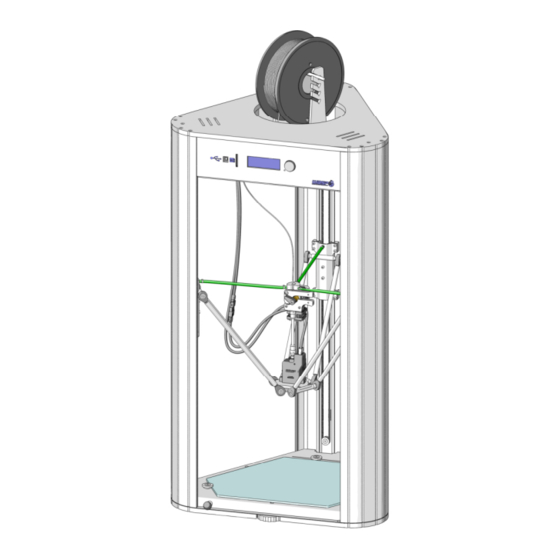

USE and MAINTENANCE MANUAL 2.1 Description of the 3D printer The printer is provided with an heated extruder mounted on a delta robot structure, a working surface and a reel unit. The material is unrolled from the reel and led towards the heated nozzle, where it melts and drips through a nozzle which leaves extra-small quantities of material on the working surface. -

Page 12: Technical Features

The heated surface and the complete protection carter ensure a homogeneous and constant temperature. Furthermore WASP Delta printers can start again the production of a piece from the moment it had stopped for any reasons. The printer can be connected to a computer or a SD card can be inserted in order to allow working with the printer completely disconnected from the computer. -

Page 13: Field Of Application

WARNING Read the instructions carefully as written on page 18. 2.4 Optional equipment / spare parts The printers are supplied with many options. For any information about them apply to WASP and to the dealer. Optional equipment: - 0.7mm - 0.9 mm extruder nozzle... -

Page 14: Dimensions And Positioning

USE and MAINTENANCE MANUAL 2.5 Dimensions and positioning The printer dimensions, in millimeters, are indicated in picture 4. Picture 4 OTHER FEATURES: MINIMUM LIGHT FOR WORKING OPERATIONS MAXIMUM NOISE: db (A) 60 dB* * Noise tests have been carried out in compliance with Standard UNI EN ISO 11202:2010. ** Maximum height varies according to the used reel dimensions. -

Page 15: General Safety Rules

Do not modify or add any devices to the electric system, without written authorization or upon WASP technical intervention, which describes the change made. Do not use the printer for a purpose other than the one for which it is intended, specifi ed in the use and maintenance manual. -

Page 16: Check Of The Purchased Product

USE and MAINTENANCE MANUAL 3.1 Check on the purchased product Before using the printer make sure it has not been damaged during transport or storage. Check also that all the ordered optional elements and all the standard components are inside the packa- ging. -

Page 17: Use

USE and MAINTENANCE MANUAL 4.0 Use The printer is supplied with a small display and a menu navigation button, which are placed on the upper part of the printer. With reference to picture 5, button "1" is available for menu navigation, display "2", SD card "3" and USB port of type B "4"... - Page 18 USE and MAINTENANCE MANUAL LARGE-SIZE REEL PLACEMENT In order to place reels with diameter larger than 200mm or higher than 100mm, install the external support supplied with the machine. Insert support brackets "A" into seats "B" on plate "C" (see picture 8). Then insert reel "D"...

- Page 19 USE and MAINTENANCE MANUAL FILAMENT LOADING In the printer side with the seat for the fi lament reel, a small transparent tefl on tube "A" is located. Insert the fi lament and push it until it goes out from the lower part.

- Page 20 USE and MAINTENANCE MANUAL PRINT TEST Printing objects is really easy and does not require any particular precautions. The settings described below can be followed also once and the maintenance can be checked after a con- siderable time. Spray some lacquer provided with the printer on the glass surface. In case of deliveries abroad use the stick glue supplied with the printer.

- Page 21 USE and MAINTENANCE MANUAL Before carrying out a print, make sure that the bed is on 0 level. In order to put the bed on 0 level: Push the button next to the display. In the menu which appears on the display select Prepare by turning the button and pushing it.

-

Page 22: Ordinary And Preventive Maintenance

A suitable maintenance is very important for a longer duration of the printer in very good wor- king and effi ciency conditions and it ensures safety from a functional point of view. The design and the materials used to manufacture WASP machines reduce maintenance interventions to a minimum. -

Page 23: Printer Documentation And Files

1 - From website http://217.133.65.215:8080/ you can access the "RESERVED AREA" and then click the icon "ENTER". 2 - Enter Username: guestwasp and Password: wasp in the Home Page. 3 - Then click the icon to enter the folder where you will fi nd all the fi les available for download. -

Page 24: Putting Out Of Service

USE and MAINTENANCE MANUAL 6.0 Putting out of service If the printer is not to be used for a certain period, carry out the following operations: Clean the printer by removing any residues or scraps. Cover the equipment with a waterproof tarpaulin. Keep the equipment in a dry place. - Page 25 EC DECLARATION OF CONFORMITY FOR MACHINERY Manufacturer: CSP SRL- Viale Zaganelli, 26 Massa Lombarda (RA) ltaly Machine description and identification: DeltaWASP 2040 DeltaWASP 4070 Modelling 3D printer for deposition of melted material. Model D2040/D4070 Serial number The machine complies with all the relevant requirements: with particolar reference to CEl EN 60335-1 Electromagnetic Compatibility Directive 2004/108/CE, Low Voltage Directive 2006/95/CE contained in the Directive 2006/42/CE...

Need help?

Do you have a question about the DELTA 2040 and is the answer not in the manual?

Questions and answers