Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for MTU 16 V 4000 M63L

-

Page 1: Operating Instructions

Operating Instructions Diesel engine 16 V 4000 M63L MS150067/02E... - Page 2 This Publication is protected by copyright and may not be used in any way whether in whole or in part without the prior written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution, translation, mi- crofilming and storage or processing on electronic systems including data bases and online services.

- Page 3 Commissioning Note...

-

Page 5: Table Of Contents

Table of Contents 1 Safety 4 Maintenance 1.1 Important provisions for all products 4.1 Maintenance task reference table [QL1] 1.2 Personnel and organizational requirements 1.3 Transport 5 Troubleshooting 1.4 Safety regulations for maintenance and 5.1 Troubleshooting repair work 5.2 Fuel treatment system – Troubleshooting 1.5 Fire prevention and environmental 5.3 Engine governor ADEC (ECU 7) fault protection, fluids and lubricants, auxiliary... -

Page 6: Table Of Contents

7 Appendix A analysis 6.15.8 Engine coolant filter – Replacement 7.1 Abbreviations 6.15.9 Preheating unit 7.2 MTU contact persons/service partners 6.15.10 Preheater – Overhaul 6.15.11 Preheater – Function and leak-tightness check 8 Appendix B 6.16 Raw Water Pump with Connections 6.16.1 Raw water pump –... -

Page 7: Important Provisions For All Products

• With fluids and lubricants approved by the manufacturer in accordance with the (→ Fluids and Lubri- cants Specifications of the manufacturer) • With spare parts approved by the manufacturer in accordance with the (→ Spare Parts Catalog/MTU contact/Service partner) •... -

Page 8: Personnel And Organizational Requirements

1.2 Personnel and organizational requirements Organizational measures of the operator This manual must be issued to all personnel involved in operation, maintenance, repair or transporta- tion. Keep this manual handy in the vicinity of the product such that it is accessible to operating, mainte- nance, repair and transport personnel at all times. -

Page 9: Transport

Place the engine only on an even, firm surface. Ensure appropriate consistency and load-bearing capacity of the ground or support surface. Never place an engine on the oil pan, unless expressively authorized by MTU on a case-to-case basis to do so. -

Page 10: Safety Regulations For Maintenance And Repair Work

1.4 Safety regulations for maintenance and repair work Safety regulations prior to maintenance and repair work Have maintenance or repair work carried out by qualified and authorized personnel only. Allow the product to cool down to below 50°C before starting maintenance work (risk of explosion of oil vapors, fluids and lubricants, risk of burning). - Page 11 Ensure particular cleanness during maintenance and repair work on the product. After completion of maintenance and repair work, make sure that no unattached parts are in/on the product (e.g. cloths and cable ties). Safety regulations after completion of maintenance and repair work Before barring, make sure that nobody is standing in the danger zone of the product.

- Page 12 Working on electrical and electronic assemblies Always obtain the permission of the person in charge before commencing maintenance and repair work or switching off any part of the electronic system required to do so. De-energize the appropriate areas prior to working on assemblies. Do not damage cabling during removal work.

-

Page 13: Protection, Fluids And Lubricants, Auxiliary Materials

The latest version can be found on the website on the "Technical Info" or "Spare Parts and Service" tabs at http://www.mtu-online.com. Consumable fluids and materials may also be hazardous or toxic. When using fluids, lubricants, consum- ables and other chemical substances, follow the safety regulations that apply to the product. -

Page 14: Compressed Air

Lead • Adopt suitable measures to avoid the formation of lead dust. • Switch on extraction system. • When working with lead or pastes that contain lead, avoid direct contact with the skin. Do not inhale lead vapors. • Wash hands after contact with lead or lead-containing substances. Compressed air Observe special safety precautions when working with compressed air: •... -

Page 15: Standards For Safety Notices In The Text

1.6 Standards for safety notices in the text DANGER In the event of immediate danger. Consequences: Death, serious or permanent injury! • Remedial action. WARNING In the event of a situation involving potential danger. Consequences: Death, serious or permanent injury! •... -

Page 16: Engine Layout

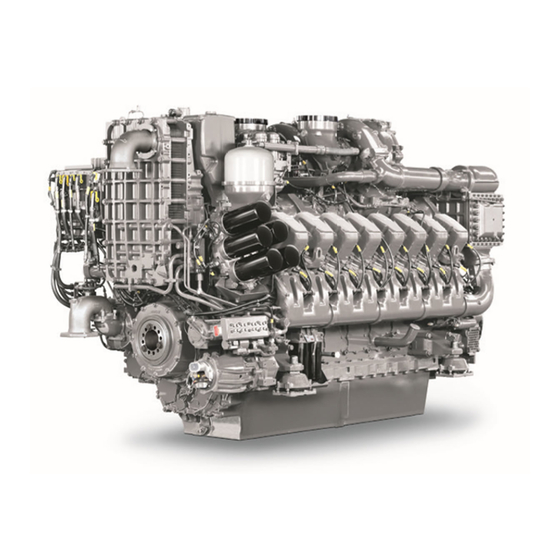

2 Product Summary 2.1 Engine Layout 2.1.1 Product description Description of the engine Engine The engine is a liquid-cooled four-stroke diesel engine, rotating counterclockwise (seen from driving end), with direct injection, sequential turbocharging and charge air cooling. The engine is monitored by an engine control and monitoring system (ADEC). Fuel system Electronically controlled common-rail-injection system with HP pump, pressure accumulator (rail) and single injectors with integrated individual store. - Page 17 • Interface to ECU and EMU • MCS5 dialog interface • Control of an MTU lube-oil priming pump (power components in separate MTU PPC Box) • Connection facility for an MTU Local Operating Station (LOS) Serial RS422 interface for diagnosis The engine interface comprises two parts.

- Page 18 2 Cleaning cycle 3 ditto MTU marine engine Series 4000M53R to …M93L may be operated in low-load operation. State-of-the- art design and equipment features, e.g. TE coolant circuit, sequential turbocharging, jacketed, coolant- cooled exhaust lines, Common Rail fuel injection and cylinder cutout allow engine operation at low load.

- Page 19 SOLAS – Fire protection specifications Fuel system, fuel lines with fuel pressure >1.8 bar All lines with SOLAS-compliant covers for pipe connections, according to MTU standard MTN5233, are shown. MS150067/02E 2014-04 | Product Summary | 19...

- Page 20 1 SOLAS clip on the fuel line: after LP pump 1 SOLAS clip on the fuel line: on fuel filter head retainer 1 SOLAS clip on the fuel line: on HP pump 2 SOLAS clip on the fuel line: after fuel filter head 20 | Product Summary | MS150067/02E 2014-04...

- Page 21 1 SOLAS clips on the fuel line: on fuel filter head Lube oil system, oil lines with oil pressure >1.8 bar All lines with SOLAS-compliant covers for pipe connections, according to MTU standard MTN5233, are shown. MS150067/02E 2014-04 | Product Summary | 21...

- Page 22 1 SOLAS clips on exhaust flap switch- ing cylinder ETC B1 1 SOLAS clips on air flap switching cylinder ETC B1 2 SOLAS clips on flap control T adapt- er ETC B1 1 SOLAS clips on distributor element 2 SOLAS clips on oil return 22 | Product Summary | MS150067/02E 2014-04...

- Page 23 1 SOLAS clip on oil return 1 SOLAS clip on oil line to ETC 2 SOLAS clip on oil line to flap control 3 SOLAS clip on oil line to recircula- tion valve 4 SOLAS clips on oil line from main gallery 1 SOLAS clips on recirculation valve MS150067/02E 2014-04 | Product Summary | 23...

- Page 24 1 SOLAS clip on HP pump oil supply: on HP pump 1 SOLAS clip on HP pump oil supply: on equipment carrier 1 SOLAS clip on ETC oil supply 2 SOLAS clip on ETC oil supply 24 | Product Summary | MS150067/02E 2014-04...

- Page 25 1 SOLAS clips of oil line on equipment carrier 1 Cover on oil filter cartridge Special connections The following types of union are spray-proof in case of leakage even without covers and have been con- firmed as being SOLAS-compliant by GL and DNV. MS150067/02E 2014-04 | Product Summary | 25...

- Page 26 Plugs and sensors (a) Screw-in plugs (4) are sealed toward the outside either with a copper sealing ring (1), according to DIN, or an O-ring (ISO). In case of a loose thread or a defective sealing ring (1), the liquid first has to pass the thread. The pressure is so greatly reduced by this and the faulty sealing ring (1) that any leakage is not under pressure.

- Page 27 HP connections 1 Jacket pipe 8 Thrust ring 15 Union nut 2 HP fuel line 9 Union nut 16 Thrust ring 3 O-ring 10 Union nut 17 HP line outer pipe 4 Union nut 11 Connecting piece 18 Internal pipe of HP line 5 Recess for O-ring 12 Snap ring 19 Ball-type seal area...

- Page 28 2.1.2 Engine layout Engines with remote heat exchanger and horizontal air intake 1 Engine management and 10 Recirculation line 19 Battery-charging generator monitoring 11 Exhaust manifold 20 HP fuel pump 2 Oil cooler 12 Engine mounts 21 Oil filter 3 Centrifugal oil filter 13 Charge-air line 22 Bilge pump (option) 4 Crankcase breather...

- Page 29 Engines with engine-mounted heat exchanger and horizontal air intake 1 Raw-water outlet 10 Exhaust outlet 19 Cylinder head 2 Engine management and 11 Air pipe to intercooler 20 Crankcase monitoring 12 Recirculation line 21 Fuel filter 3 Plate-core heat exchanger 13 Exhaust manifold 22 Battery-charging generator 4 Oil cooler...

- Page 30 Engines with remote heat exchanger and vertical air intake 1 Coolant outlet to remote 10 Exhaust turbocharger 19 Cylinder head cooling system 11 Exhaust outlet 20 Fuel filter 2 Coolant inlet from remote 12 Air pipe to intercooler 21 Oil filter cooling system 13 Intercooler 22 HP fuel pump...

- Page 31 Engines with engine-mounted heat exchanger and vertical air intake 1 Raw-water outlet 10 Recirculation line 19 Crankcase 2 Engine management and 11 Exhaust turbocharger 20 Cylinder head monitoring 12 Exhaust outlet 21 Fuel filter 3 Oil cooler 13 Air pipe to intercooler 22 Oil filter 4 Plate-core heat exchanger 14 Intercooler...

-

Page 32: Sensors, Actuators And Injectors On 16V Engines – Overview

2.1.3 Sensors, actuators and injectors on 16V engines – Overview Top view 16V 4000 M, external cooling 1 B49 (charge-air temp., air 2 B4.A1-B4.B8 (single ex- 3 B33 (fuel temperature in recirculation valve) haust temp., A1-A8, B1- common rail) Y26 (air recirculation valve 32 | Product Summary | MS150067/02E 2014-04... - Page 33 16V 4000 M free end, external cooling 1 B7 (engine oil temp.) 4 B33 (fuel temperature in 7 B54 (oil refill pump pres- 2 B5.3 (oil pressure up- common rail) sure) stream of filter) 5 B48 (fuel pressure in com- 8 B6.2 (coolant tempera- 3 B5.1 (oil pressure down- mon rail)

- Page 34 16V 4000 M driving end, external cooling 1 B4.21 (exhaust tempera- 3 B13 (crankshaft speed) 5 S37.1 (safety switch) ture, A bank) 4 S37.2 (safety switch) 6 B13.2 (crankshaft speed) 2 B4.22 (exhaust tempera- ture, B bank) 34 | Product Summary | MS150067/02E 2014-04...

- Page 35 16V 4000 M left side, external cooling 1 B50 (crankcase pressure) 4 B10 (charge-air pressure) 7 B34.1 (fuel pressure down- 2 B3 (intake air temperature) 5 B34.3 (fuel pressure up- stream of filter) 3 B44.1 (turbocharger A stream of filter) 8 F46 (fuel overflow level) speed) 6 B34.2 (fuel pressure up-...

- Page 36 16V 4000 M right side, external cooling 1 B44.2 (turbocharger B 3 B16 (coolant pressure) speed) 4 B9 (charge-air tempera- 2 Y27 (turbocharger control ture) valve) 36 | Product Summary | MS150067/02E 2014-04...

- Page 37 Top view 16V 4000 M, integral cooling 1 B4.A1-B4.B8 (single ex- 2 B33 (fuel temperature in 3 F33 (coolant level) haust temp., A1-A8, B1- common rail) MS150067/02E 2014-04 | Product Summary | 37...

- Page 38 16V 4000 M free end, integral cooling 1 B7 (engine oil temp.) 4 B33 (fuel temperature in 7 B54 (oil refill pump pres- 2 B5.3 (oil pressure up- common rail) sure) stream of filter) 5 B48 (fuel pressure in com- 8 B6.2 (coolant tempera- 3 B5.1 (oil pressure down- mon rail)

- Page 39 16V 4000 M driving end, integral cooling 1 B4.21 (exhaust tempera- 3 B13 (crankshaft speed) 5 S37.1 (safety switch) ture, A bank) 4 S37.2 (safety switch) 6 B13.2 (crankshaft speed) 2 B4.22 (exhaust tempera- ture, B bank) MS150067/02E 2014-04 | Product Summary | 39...

- Page 40 16V 4000 M left side, integral cooling 1 B50 (crankcase pressure) 4 B44.1 (turbocharger A 7 B34.2 (fuel pressure up- 2 B49 (charge-air temp., air speed) stream of filter) recirculation valve) 5 B10 (charge-air pressure) 8 B34.1 (fuel pressure down- Y26 (air recirculation valve 6 B34.3 (fuel pressure up- stream of filter)

- Page 41 16V 4000 M right side, integral cooling 1 B44.2 (turbocharger B 3 B16 (coolant pressure) 5 B9 (charge-air tempera- speed) 4 B21 (raw water pressure) ture) 2 Y27 (turbocharger control valve) MS150067/02E 2014-04 | Product Summary | 41...

-

Page 42: Engine Side And Cylinder Designations

2.2 Engine Side and Cylinder Designations 2.2.1 Engine side and cylinder designations Engine sides are always designated as viewed from the driving end (KS) (4). For designation of the cylinders (to DIN ISO 1204) the letter "A" (1) is used to refer to the cylinders on the left-hand side of the engine and the letter "B"... -

Page 43: Main Engine Dimensions

2.3 Main Engine Dimensions 2.3.1 16V 4000 M63L engines – Main dimensions Engines with horizontal air intake With remote heat exchanger Engine model Length (A) Width (B) without Width (B) with si- Height (C) silencer lencer 16V 4000 M63L approx. 3108 mm approx. -

Page 44: Firing Sequence

2.4 Firing Sequence 2.4.1 Firing order Cylinders Firing order 12 V A1-B5-A5-B3-A3-B6-A6-B2-A2-B4-A4-B1 16 V A1-A7-B4-B6-A4-B8-A2-A8-B3-B5-A3-A5-B2-A6-B1-B7 44 | Product Summary | MS150067/02E 2014-04... -

Page 45: Technical Data

2.5 Technical Data 2.5.1 16V 4000 M63L engine data Explanation: DL Ref. value: Continuous power BL Ref. value: Fuel stop power A Design value G Guaranteed value R Guideline value L Limit value, up to which the engine can be operated, without change (e.g. of power settings). N Not yet defined value - Not applicable X Applicable... - Page 46 Number of cylinders Engine-mounted heat Remote heat ex- exchanger changer Number of inlet valves per cylinder Number of exhaust valves per cylinder RAW WATER CIRCUIT (open circuit) Number of cylinders Engine-mounted heat Remote heat ex- exchanger changer Raw water pump: Inlet pressure, min. -0.4 -0.4 Raw water pump: Inlet pressure, max.

- Page 47 STARTING SYSTEM (electric) Number of cylinders Engine-mounted heat Remote heat ex- exchanger changer Rated starter voltage (standard design) STARTING (with compressed air/hydraulic starter) Number of cylinders Engine-mounted heat Remote heat ex- exchanger changer Starting-air pressure before starter, min. Starting-air pressure before starter, max. INCLINATIONS, STANDARD OIL SYSTEM (reference: waterline) Number of cylinders Engine-mounted heat...

- Page 48 Number of cylinders Engine-mounted heat Remote heat ex- exchanger changer Oil pan capacity at dipstick mark “min.” Liters (standard oil system) (Option: max. oper- ating inclinations) Oil pan capacity at dipstick mark “max.” Liters (standard oil system) (Option: max. oper- ating inclinations) WEIGHTS / MAIN DIMENSIONS Number of cylinders...

-

Page 49: Controls

3 Operation 3.1 Controls Automation system controls Refer to automation system operating instructions MS150067/02E 2014-04 | Operation | 49... -

Page 50: Putting The Engine Into Operation After Extended Out-Of-Service Periods (>3 Months)

3.2 Putting the engine into operation after extended out-of-service periods (>3 months) Preconditions ☑Engine is stopped and starting disabled. ☑MTU Preservation and Represervation Specifications (A001070/..) are available. Putting the engine into operation after extended out-of-service-periods (>3 months) Item Task Engine Depreserve (→... -

Page 51: Putting The Engine Into Operation After Scheduled Out-Of-Service-Period

3.3 Putting the engine into operation after scheduled out-of- service-period Preconditions ☑Engine is stopped and starting disabled. Putting into operation Item Task Lube oil system Check engine oil level (→ Page 192); Preheat engine oil if required. Coolant system Check coolant level (→ Page 208). Coolant system Preheat coolant with preheating unit. -

Page 52: Starting The Engine

3.4 Starting the engine Start the engine via the automation system Refer to automation system operating instructions 52 | Operation | MS150067/02E 2014-04... -

Page 53: Operational Checks

3.5 Operational checks DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. Risk of damage to hearing! •... - Page 54 3.6 Tasks after extended out-of-service periods (>3 weeks) Tasks after extended out-of-service periods (>3 weeks) Note: Operate fuel treatment system for at least 5 minutes. Start up fuel treatment system (→ Page 56). Shut down fuel treatment system (→ Page 60). 54 | Operation | MS150067/02E 2014-04...

-

Page 55: Checks Prior To Start-Up

Checks prior to start-up Check tank and the entire pipework for cleanness. If microorganisms are detected: a) Clean affected components. b) Disinfect affected components with biocides (→ MTU Fluids and Lubricants Specifications A001061/..). Close drain valves on housing. Open all supply and discharge valves. -

Page 56: Fuel Treatment System – Putting Into Operation

3.8 Fuel treatment system – Putting into operation Overview of fuel treatment system 1 Pressure-free overflow 9 Ball valve, outlet 17 Automatic water drain 2 Bypass 1 10 Check valve 700 mbar 18 Water level electrode 3 Bypass 2 11 Check valve 5 mbar 19 Ball valve, sample extrac- 4 Safety valve, 3 bar 12 Return to overflow con-... - Page 57 Initial operation: HAT Replace fuel filter on engine (→ Page 161). Note: Determine the suction pressure upstream of the engine-mounted fuel delivery pump. Install pressure gage in fuel supply line from Yard fuel system to engine. Switch on fuel treatment system and operate it for some minutes (→ Page 59). Result: The fuel is drawn from tank (24), cleaned by the water separator filter (15) and then routed via overflow tank (14) back to tank (24).

- Page 58 Simulation of power failure (emergency): SAT Switch on fuel treatment system (→ Page 59). Start engine (→ Page 52). Run engine at idling speed. Switch off pump (21) at switchgear cabinet (20). Result: The engine-mounted fuel delivery pump draws fuel via bypass (2) directly from tank (24). Check suction pressure at the engine-mounted fuel delivery pump.

-

Page 59: Fuel Treatment System – Switching On

3.9 Fuel treatment system – Switching on Preconditions ☑The on-board power supply is switched on. NOTICE Risk of damage to engine/system. Risk of severe damage to property! • Before switching on, ensure that the engine/system is ready for operation. • Before switching on, ensure that all housings are closed. •... -

Page 60: Fuel Treatment System – Shutdown

3.10 Fuel treatment system – Shutdown Shutting down fuel treatment system Press the illuminated pushbutton "Water drain" on the switch cabinet until water discharge from the outlet stops. Switch off fuel treatment system. Close ball valve at the inlet to the fuel treatment system. Close ball valve at the outlet of the fuel treatment system. -

Page 61: Stopping The Engine

3.11 Stopping the engine Stopping the engine via the automation system Refer to automation system operating instructions MS150067/02E 2014-04 | Operation | 61... -

Page 62: Emergency Engine Stop

3.12 Emergency engine stop NOTICE An emergency stop causes extreme stress to the engine plant. Risk of overheating, damage to components! • Initiate emergency stop only in emergency situations. Emergency stop Refer to automation system operating instructions. Follow instructions. 62 | Operation | MS150067/02E 2014-04... -

Page 63: After Stopping The Engine

Switch off. Out-of-service-period > 1 week Air intake and exhaust sys- • Seal engine on air and exhaust sides. Out-of-service-period > 1 month • Preserve engine (→ MTU Preservation and Re-preservation specifica- tions A001070/..). MS150067/02E 2014-04 | Operation | 63... -

Page 64: Plant – Cleaning

3.14 Plant – Cleaning Preconditions ☑Engine is stopped and starting disabled. ☑Operating voltage is not applied. Special tools, Material, Spare parts Designation / Use Part No. Qty. Steam jet cleaner Cleaner (Hakupur 312) 30390 WARNING Compressed air gun ejects a jet of pressurized air. Risk of injury to eyes and damage to hearing, risk of rupturing internal organs! •... -

Page 65: Maintenance Task Reference Table [Ql1]

4 Maintenance 4.1 Maintenance task reference table [QL1] The maintenance tasks and intervals for this product are defined in the Maintenance Schedule. The Maintenance Schedule is a stand-alone publication. The task numbers in this table provide reference to the maintenance tasks specified in the Maintenance Schedule. - Page 66 Task Maintenance tasks W1581 Replace oil separator of crankcase breather. (→ Page 145) W1675 Replace fuel prefilter or filter element of fuel prefilter. (→ Page 169) W1713 Injector: Reset drift correction parameters (CDC). (→ Page 240) Table 1: Maintenance task reference table [QL1] 66 | Maintenance | MS150067/02E 2014-04...

-

Page 67: Troubleshooting

5 Troubleshooting 5.1 Troubleshooting Engine does not turn when starter is actuated Cause Corrective action u Charge or replace (see separate documentation). Battery low or faulty u Check firm seating of cable connections (see separate Battery: Cable connections faulty documentation). Engine cabling or starter faulty u Check firm seating of cable connections, contact Service. - Page 68 Engine governor defective u Contact Service. Charge-air temperature too high Cause Corrective action Incorrect coolant concentration u Check (MTU test kit). Intercooler dirty u Contact Service. u Check fans and air supply/ventilation ducts. Engine room: Air-intake temperature too high Charge-air pressure too low...

- Page 69 White exhaust gas Cause Corrective action Engine is not at operating u Run engine to reach operating temperature. temperature Intercooler leaky u Contact Service. MS150067/02E 2014-04 | Troubleshooting | 69...

-

Page 70: Fuel Treatment System – Troubleshooting

5.2 Fuel treatment system – Troubleshooting Illuminated pushbutton 'water alarm' is lit. Cause Corrective action When the maximum water level 1. Press illuminated pushbutton 'Water alarm' for is reached, the water level acknowledgment. electrode opens the water drain 2. In addition to the automatic water drain function, water can also valve and water is discharged. -

Page 71: Application

5.3 Engine governor ADEC (ECU 7) fault messages for Series 4000 engines, marine application The fault code numbers are generated by the engine governor and transmitted to the display below (if fitted). The fault code (1) comprises 3 digits. Fault messages may also be caused by faulty sensors/actuators. Contact Service to have sensors/ actuators tested and replaced as necessary if troubleshooting as described in the table (→... -

Page 72: Engine Governor Adec (Ecu 7) – Fault Codes

5.4 Engine governor ADEC (ECU 7) – Fault codes 3 – HI T-Fuel ZKP-Number: 2.0122.931 Fuel temperature too high (limit value 1) Yellow alarm; warning Cause Corrective action Fuel tank may be exposed to 1. Reduce power. heat. 2. Contact Service. 4 –... - Page 73 9 – HI T-Coolant charge-air cooler ZKP-Number: 2.0124.931 Coolant temperature in charge-air cooler too high (limit value 1) Yellow alarm; warning Cause Corrective action Coolant circuit for charge air 1. Reduce power. defective. 2. Check charge-air cooler and coolant cooler. 3.

- Page 74 19 – HI T-Exhaust A ZKP-Number: 2.0126.931 Exhaust temperature too high, A-side (limit value 1) Yellow alarm; warning Cause Corrective action Wiring damage. 1. Check air filter and wiring (→ Page 239). 2. Contact Service. 20 – SS T-Exhaust A ZKP-Number: 2.0126.932 Exhaust temperature too high, A-side (limit value 2) Red alarm;...

- Page 75 25 – HI P-Diff. Lube Oil ZKP-Number: 2.0154.931 Differential oil pressure at oil filter too high (limit value 1) Yellow alarm; warning Cause Corrective action u Replace oil filter (→ Page 197). Oil filter not functioning correctly. 26 – HI P-Diff. Lube Oil ZKP-Number: 2.0154.932 Differential oil pressure at oil filter too high (limit value 2) Red alarm;...

- Page 76 31 – HI ETC1 Overspeed ZKP-Number: 2.3011.931 Speed of primary turbocharger too high (limit value 1) Yellow alarm; warning Cause Corrective action Clogged charge-air circuit or 1. Reduce power. fault in turbocharger. 2. Check air filter. 3. Contact Service. 32 – SS ETC1 Overspeed ZKP-Number: 2.3012.932 Speed of primary turbocharger too high (limit value 2) Red alarm;...

- Page 77 37 – SS ETC2 Overspeed ZKP-Number: 2.3013.912 Speed of 1st secondary turbocharger too high (limit value 2) Red alarm; engine shutdown Cause Corrective action u Contact Service. Clogged charge-air circuit or fault in turbocharger. 38 – AL ETC Speed Deviation ZKP-Number: 1.8004.205 Yellow alarm;...

- Page 78 52 – SS T-Lube Oil ZKP-Number: 2.0125.932 Lube oil temperature too high (limit value 2) Red alarm; engine shutdown Cause Corrective action Insufficient oil. 1. Check engine oil level (→ Page 192). 2. Contact Service. 57 – LO P-Coolant ZKP-Number: 2.0101.921 Coolant pressure too low (limit value 1).

- Page 79 60 – SS T-Coolant L4 ZKP-Number: 2.0120.934 Coolant temperature too high / low (limit value 4) Red alarm; engine shutdown Cause Corrective action Coolant circuit not functioning 1. Activate fan emergency operating mode if required. correctly (e.g. damage, leaks, 2. Allow engine to cool down. low coolant level).

- Page 80 66 – SS P-Fuel ZKP-Number: 2.0102.922 Fuel supply pressure too low (limit value 2) Red alarm; engine shutdown Cause Corrective action Leaking or clogged fuel lines or 1. Check fuel lines for leakage. fuel filter. 2. Check filter, fuel low-pressure side. 3.

- Page 81 82 – HI P-Fuel (Common Rail) ZKP-Number: 2.0104.931 Rail pressure > set value Red alarm - DBR fuel limitation, start of injection retarded; Cause Corrective action Suction restrictor of HP fuel 1. Check wiring (→ Page 239). block jamming or HP fuel control 2.

- Page 82 90 – SS Starter Speed Not Reached ZKP-Number: 2.1090.925 Idling speed not attained Red alarm; warning Cause Corrective action Various causes possible. 1. Check for additional messages. 2. Contact Service. 91 – SS Release Speed Not Reached ZKP-Number: 2.1090.924 Runup speed was not attained Red alarm;...

- Page 83 95 – AL Prelubrication Fault ZKP-Number: 2.1090.920 Oil priming fault Yellow alarm; warning Cause Corrective action Priming oil pressure not 1. Check priming system. reached. 2. Contact Service. 102 – AL Fuel Cons. Counter Defect ZKP-Number: 1.8004.624 Error in fuel consumption checksum Yellow alarm;...

- Page 84 120 – HI ECU Power Supply Voltage ZKP-Number: 2.0140.931 Supply voltage too high (limit value 1) Yellow alarm; warning Cause Corrective action Supply voltage at engine 1. Check Engine Control Unit supply voltage. governor too high. 2. Contact Service. 121 – HIHI ECU Power Supply Voltage ZKP-Number: 2.0140.932 Supply voltage too high (limit value 2) Red alarm - start cancelation of engine stop...

- Page 85 176 – AL LifeData not available ZKP-Number: 2.4000.004 No (matching) LifeData backup system available Yellow alarm; warning Cause Corrective action u Contact Service. After a wait time has elapsed after ECU reset: Backup system has no LifeData function or CAN bus to backup system disconnected.

- Page 86 182 – AL CAN Wrong Parameters ZKP-Number: 2.0500.682 Incorrect parameters on CAN Yellow alarm; warning Cause Corrective action u Contact Service. Wrong parameter value entered in data record. 183 – AL CAN No PU-Data ZKP-Number: 2.0500.683 CAN PU data not present or available Yellow alarm;...

- Page 87 187 – AL CAN1 Error Passive ZKP-Number: 2.0500.687 CAN controller 1 error Yellow alarm; warning Cause Corrective action Missing associated node, minor 1. Check CAN bus for short circuit, rectify short circuit as disruptions or temporary bus necessary. overload. 2. Check shielding, improve shielding as necessary. 3.

- Page 88 201 – SD T-Coolant ZKP-Number: 1.8004.570 Signal error, coolant temperature sensor Yellow alarm; warning Cause Corrective action Coolant temperature sensor 1. Check sensor and wiring (B6), replace as necessary faulty. (→ Page 239). Short circuit or wire break. 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 89 205 – SD T-Coolant Charge-Air Cooler ZKP-Number: 1.8004.574 Signal error, coolant temperature sensor Yellow alarm; warning Cause Corrective action Coolant pressure sensor of 1. Check sensor and wiring (B26), replace as necessary charge-air cooler faulty. (→ Page 239). Short circuit or wire break. 2.

- Page 90 211 – SD P-Lube Oil ZKP-Number: 1.8004.563 Signal error, lube oil pressure sensor Yellow alarm; warning Cause Corrective action Lube-oil pressure sensor faulty. 1. Check sensor and wiring (B5), replace as necessary Short circuit or wire break. (→ Page 239). 2.

- Page 91 215 – SD P-HD ZKP-Number: 1.8004.567 Signal error, rail pressure sensor Yellow alarm; high-pressure regulator emergency operation Cause Corrective action Rail pressure sensor faulty. ==> 1. Check sensor and wiring (B48), replace as necessary high-pressure regulator (→ Page 239). emergency operation. 2.

- Page 92 221 – SD P-Diff Lube Oil ZKP-Number: 1.8004.585 Signal error, lube oil differential pressure sensor faulty Yellow alarm; warning Cause Corrective action Lube oil differential pressure 1. Check sensor and cabling (F25), replace as necessary sensor faulty. (→ Page 239). Short circuit or wire break.

- Page 93 228 – SD P-Fuel before Filter ZKP-Number: 1.8004.595 Signal error, fuel pressure sensor Yellow alarm; warning Cause Corrective action Fuel pressure sensor faulty. 1. Check sensor and wiring (B5.3), replace as necessary Short circuit or wire break. (→ Page 239). 2.

- Page 94 232 – SD Charger 1 Speed ZKP-Number: 1.3011.128 Signal error, primary turbocharger speed sensor Yellow alarm; warning Cause Corrective action Speed sensor of primary 1. Check sensor and wiring (B44.1), replace as necessary turbocharger faulty. (→ Page 239). Short circuit or wire break. 2.

- Page 95 241 – SD T-Recirculation ZKP-Number: 1.8004.581 Cause Corrective action u Check sensor and wiring (B49), replace as necessary. Recirculation sensor faulty; Short circuit or wire break. Fault is rectified following engine restart. 242 – SD T-Coolant (R) ZKP-Number: 1.8004.622 Cause Corrective action u Check sensor and wiring, replace as necessary.

- Page 96 268 – SD Spinning Value ZKP-Number: 2.8006.591 Skid signal error Yellow alarm; warning Cause Corrective action Analog skid signal faulty. 1. Check sensor and wiring, replace as necessary (→ Page 239). Short circuit or wire break. 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 97 303 – AL Timing Cylinder A3 ZKP-Number: 1.8004.502 Time-of-flight measuring fault of injector Cause Corrective action u Replace injector if the fault message appears frequently Flight time value extremely low or extremely high. (→ Page 153). 304 – AL Timing Cylinder A4 ZKP-Number: 1.8004.503 Time-of-flight measuring fault of injector Cause...

- Page 98 309 – AL Timing Cylinder A9 ZKP-Number: 1.8004.508 Time-of-flight measuring fault of injector Cause Corrective action u Replace injector if the fault message appears frequently Flight time value extremely low or extremely high. (→ Page 153). 310 – AL Timing Cylinder A10 ZKP-Number: 1.8004.509 Time-of-flight measuring fault of injector Cause...

- Page 99 315 – AL Timing Cylinder B5 ZKP-Number: 1.8004.514 Time-of-flight measuring fault of injector Cause Corrective action u Replace injector if the fault message appears frequently Flight time value extremely low or extremely high. (→ Page 153). 316 – AL Timing Cylinder B6 ZKP-Number: 1.8004.515 Time-of-flight measuring fault of injector Cause...

- Page 100 321 – AL Wiring Cylinder A1 ZKP-Number: 1.8004.520 Wiring fault cylinder A1 Yellow alarm; misfire Cause Corrective action Short circuit fault in injector 1. Check injector solenoid, replace injector if necessary wiring cylinder A1. (→ Page 153). 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 101 325 – AL Wiring Cylinder A5 ZKP-Number: 1.8004.524 Wiring fault cylinder A5 Yellow alarm; misfire Cause Corrective action Short circuit fault in injector 1. Check injector solenoid, replace injector if necessary wiring cylinder A5. (→ Page 153). 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 102 329 – AL Wiring Cylinder A9 ZKP-Number: 1.8004.528 Wiring fault cylinder A9 Yellow alarm; misfire Cause Corrective action Short circuit fault in injector 1. Check injector solenoid, replace injector if necessary wiring cylinder A9. (→ Page 153). 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 103 333 – AL Wiring Cylinder B3 ZKP-Number: 1.8004.532 Wiring fault cylinder B3 Yellow alarm; misfire Cause Corrective action Short circuit fault in injector 1. Check injector solenoid, replace injector if necessary wiring cylinder B3. (→ Page 153). 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 104 337 – AL Wiring Cylinder B7 ZKP-Number: 1.8004.536 Wiring fault cylinder B7 Yellow alarm; misfire Cause Corrective action Short circuit fault in injector 1. Check injector solenoid, replace injector if necessary wiring cylinder B7. (→ Page 153). 2. Fault is rectified when engine is restarted (→ Page 52). 3.

- Page 105 341 – AL Open Load Cylinder A1 ZKP-Number: 1.8004.540 Injector wiring fault cylinder A1 Yellow alarm; misfire Cause Corrective action Disruption fault in injector wiring 1. Check injector wiring for open circuit. cylinder A1. 2. Exclude possible injector solenoid fault, replace injector if necessary (→...

- Page 106 345 – AL Open Load Cylinder A5 ZKP-Number: 1.8004.544 Injector wiring fault cylinder A5 Yellow alarm; misfire Cause Corrective action Disruption fault in injector wiring 1. Check injector wiring for open circuit. cylinder A5. 2. Exclude possible injector solenoid fault, replace injector if necessary (→...

- Page 107 349 – AL Open Load Cylinder A9 ZKP-Number: 1.8004.548 Injector wiring fault cylinder A9 Yellow alarm; misfire Cause Corrective action Disruption fault in injector wiring 1. Check injector wiring for open circuit. cylinder A9. 2. Exclude possible injector solenoid fault, replace injector if necessary (→...

- Page 108 353 – AL Open Load Cylinder B3 ZKP-Number: 1.8004.552 Injector wiring fault cylinder B3 Yellow alarm; misfire Cause Corrective action Disruption fault in injector wiring 1. Check injector wiring for open circuit. cylinder B3. 2. Exclude possible injector solenoid fault, replace injector if necessary (→...

- Page 109 357 – AL Open Load Cylinder B7 ZKP-Number: 1.8004.556 Injector wiring fault cylinder B7 Yellow alarm; misfire Cause Corrective action Disruption fault in injector wiring 1. Check injector wiring for open circuit. cylinder B7. 2. Exclude possible injector solenoid fault, replace injector if necessary (→...

- Page 110 361 – AL Power Stage Low ZKP-Number: 1.8004.496 Internal electronic fault Red alarm; engine shutdown possible Cause Corrective action Electronics faulty. 1. Start ITS. 2. Replace engine governor if required. 3. Check additional messages if ITS indicates diagnosis "Electronics OK" (e.g. wiring faulty). 4.

- Page 111 365 – AL Stop MV-Wiring Ground ZKP-Number: 1.8004.561 Injector wiring error Red alarm - engine shutdown via Protection Module possible Cause Corrective action Short circuit of injector positive 1. Check wiring (→ Page 239). connection to ground of one or 2.

- Page 112 381 – AL Wiring TOP 1 ZKP-Number: 2.8006.638 Line disruption on digital input 1 Yellow alarm; warning Cause Corrective action u Check wiring to plant. Short circuit or wire break on transistor output, plant-side 1 (TOP 1). 382 – AL Wiring TOP 2 ZKP-Number: 2.8006.639 Line disruption on digital input 2 Yellow alarm;...

- Page 113 390 – AL MCR exceeded ZKP-Number: 1.1085.009 Speed limiter/MCR function: the maximum continuous rate was exceeded Yellow alarm; engine power limited to permissible continuous power Cause Corrective action u With a continuous alarm, contact Service. Engine was overloaded continuously. 392 – HI T-Coolant Red ZKP-Number: 2.0129.931 Limit value 1 Cause...

- Page 114 397 – TD P-Oil Sensor Deviation ZKP-Number: 1.0480.293 Cause Corrective action Maximum lube oil pressure 1. Check wiring and sensor. deviation. 2. Contact Service. 400 – AL Open Load Digital Input 1 ZKP-Number: 2.8006.625 Line disruption on digital input 1 Yellow alarm;...

- Page 115 404 – AL Open Load Digital Input 5 ZKP-Number: 2.8006.629 Line disruption on digital input 5 Yellow alarm; warning Cause Corrective action Wiring faulty. 1. Check wiring (→ Page 239). No resistance over switch. 2. Check target device input. 3. Contact Service. 405 –...

- Page 116 408 – AL Open Load Emerg. Stop Input ESI ZKP-Number: 2.8006.633 Line disruption at input for emergency stop Yellow alarm; warning Cause Corrective action Wiring faulty or no resistance 1. Check wiring (→ Page 239). over switch. 2. Check target device input. 3.

- Page 117 413 – HIHI U-PDU ZKP-Number: 2.0141.932 Injector voltage too high (limit value 2) Red alarm; engine shutdown Cause Corrective action Wiring damage or faulty current 1. Check wiring (→ Page 239). supply. 2. Check supply. 3. Acknowledge alarm. 4. Contact Service. 414 –...

- Page 118 419 – SD T-Coolant b.Engine ZKP-Number: 18.004.604 Cause Corrective action u Check sensor and wiring (B3), replace as necessary. Coolant inlet temperature sensor faulty. Short circuit or wire break 420 – AL L1 Aux 1 ZKP-Number: 2.0160.921 Limit value 1 Cause Corrective action Input signal of Aux 1 has...

- Page 119 440 – AL L1 P-Aux 1 ZKP-Number: 2.0110.921 Limit value 1 Cause Corrective action u Determine cause of limit value violation and rectify fault. Pressure signal of Aux 1 has exceeded / not attained limit value 1, depending on configuration. 442 –...

- Page 120 446 – SD P-HD2 ZKP-Number: 1.8004.599 Signal error, rail pressure sensor Yellow alarm; high-pressure regulator emergency operation Cause Corrective action Rail pressure sensor faulty. 1. Check sensor and wiring (B48), replace as necessary Short circuit or wire break. (→ Page 239). 2.

- Page 121 454 – SS Power Reduction Active ZKP-Number: 2.7000.011 Power reduction activated Red alarm - power reduction activated Cause Corrective action u Check for additional messages. Engine operation outside standard limit values. This message has the following possible causes: Intake depression, exhaust back pressure, charge-air coolant temperature or intake air temperature outside the limit...

- Page 122 461 – LO T-Exhaust EMU ZKP-Number: 2.8006.653 Limit value 1 Cause Corrective action EMU exhaust gas temperature 1. Check wiring. value too low. 2. Contact Service. 462 – HI T-Coolant EMU ZKP-Number: 2.8006.654 Limit value 1 Cause Corrective action u Check configuration with DiaSys. EMU coolant temperature value too high / low.

- Page 123 469 – SD AUX 1 ZKP-Number: 1.8004.590 Cause Corrective action u Check signal sensor and wiring, replace as necessary. Analog input signal for Aux 1 faulty; short circuit or wire Fault is rectified following engine restart. break. 470 – SD T-ECU ZKP-Number: 1.8004.587 Signal error, engine governor temperature Yellow alarm;...

- Page 124 474 – AL Wiring FO ZKP-Number: 2.8006.655 Wiring fault on FO Yellow alarm; warning Cause Corrective action Wire break or short circuit on 1. Check wiring (→ Page 239). channel FO. 2. Contact Service. 475 – AL CR Engine Shutdown Trigger ZKP-Number: 1.8010.009 Crash recorder was triggered by an engine shutdown.

- Page 125 480 – AL Ext. Engine Protection ZKP-Number: 2.0291.921 External engine protection function active Yellow alarm; warning Cause Corrective action The external engine protection 1. Check plant signal. function is active. 2. Contact Service. Monitoring of plant signal by ECU active (plant side). 482 –...

- Page 126 486 – HI T-Exhaust D ZKP-Number: 20.134.931 Limit value 1 Cause Corrective action Exhaust gas temperature (D- 1. Reduce power. side) too high. 2. Contact Service. 487 – SS T-Exhaust D ZKP-Number: 20.134.932 Limit value 2 Cause Corrective action Exhaust gas temperature (D- 1.

- Page 127 491 – SS ETC4 Overspeed ZKP-Number: 2.3015.932 Speed of the 3rd secondary turbocharger too high (limit value 2) Red alarm; engine shutdown Cause Corrective action u Reduce power. Clogged charge-air circuit or fault in turbocharger. 492 – AL ETC4 Cutin Failure ZKP-Number: 18.004.202 Yellow alarm;...

- Page 128 502 – AL Open Load POM Battery-charging Generator ZKP-Number: 1.4500.902 Power disruption, battery-charging generator connection of POM Yellow alarm; warning Cause Corrective action u Check connection between POM and battery-charging Wiring faulty or no resistance over switch. generator. 503 – AL Battery Not Charging ZKP-Number: 1.4500.903 No battery charge Yellow alarm;...

- Page 129 508 – AL Incorrect POM ID ZKP-Number: 1.4500.908 POM sends a different ID number than expected Yellow alarm; warning Cause Corrective action u Check POM wiring harness. If alarm 504 occurs in addition, the resistor in the POM wiring is missing.

- Page 130 532 – AL Wiring PWM1 ZKP-Number: 1.1046.900 Red alarm Cause Corrective action u Check wiring to mixture throttle on A side, replace mixture Wire break or short circuit on channel PWM1. throttle on A side if necessary. 533 – AL Wiring PWM2 ZKP-Number: 1.1047.900 Red alarm Cause...

- Page 131 Limit value 2 Cause Corrective action Camshaft overspeed. 1. Acknowledge alarm. 2. Attempt engine restart. 555 – AL Call MTU Field Service ZKP-Number: 20.555.001 Cause Corrective action u Request activation code via Internet. This fault becomes active if a maintenance case has been...

- Page 132 582 – AL Emergency Stop Failure ZKP-Number: 1.1005.006 Emergency stop command was not executed Flashing pre-alarm and alarm Cause Corrective action u Contact Service. Engine speed does not come to a standstill within a configurable period. 584 – AL CAN Start clearance failed Yellow alarm;...

- Page 133 596 – AL Test Parameters ZKP-Number: 1.8004.645 Yellow alarm; warning Cause Corrective action u Contact Service. The parameter set is used for trials. The alarm remains set until a series parameter set is loaded. 600 – SD T-Exhaust A+B ZKP-Number: 1.8004.646 Signal error, exhaust temperature sensor A- and B-side Yellow alarm;...

- Page 134 606 – AL Double Nodes Lost CAN 1+2 ZKP-Number: 2.0500.691 ECU does not detect a monitored CAN bus. Red alarm; forced idle Cause Corrective action A node on both CANs has failed. 1. Check wiring and power supply of plant (→ Page 239). Short circuit or wire break.

- Page 135 690 – AL Oil Level too Low ZKP-Number: 1.0150.921 Cause Corrective action Alarm, lube oil level is too low. 759 – AL L1 T-Fuel b. Engine ZKP-Number: 2.0080.921 Fuel before engine (limit 1) Cause Corrective action Fuel temperature before engine too high.

- Page 136 850 – SD Alive FIP ZKP-Number: 2.0900.002 Frequency input faulty. Cause Corrective action Short circuit or wire break. Fault in Backup ECU, Alive signal not transmitted 856 – SD P-Lube oil ETC B ZKP-Number: 1.0223.920 Cause Corrective action ETC oil pressure sensor faulty. u Check sensor and wiring, replace as necessary.

-

Page 137: Engine

6 Task Description 6.1 Engine 6.1.1 Engine – Barring manually Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Barring device F6555766 Ratchet with extension F30006212 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •... - Page 138 Engage barring device (2) in ring gear of fly- wheel and mount on flywheel housing. Fit ratchet (1) onto barring device (2). Note: No resistance other than compression re- sistance must be encountered. Rotate crankshaft in engine direction of ro- tation.

-

Page 139: Engine – Barring With Starting System

6.1.2 Engine – Barring with starting system Barring using the automation system Refer to automation system operating instructions MS150067/02E 2014-04 | Task Description | 139... -

Page 140: Cylinder Liner

6.2 Cylinder Liner 6.2.1 Cylinder liner – Endoscopic examination Preconditions ☑Engine is stopped and starting disabled Special tools, Material, Spare parts Designation / Use Part No. Qty. Rigid endoscope Y20097353 Preparatory steps Remove cylinder head cover (→ Page 150). Remove injector (→ Page 154). Positioning crankshaft at BDC Using barring gear, turn crankshaft until crankshaft journal of the cylinder to be inspected has reached BDC. - Page 141 Final steps Install injector (→ Page 154). Install cylinder head cover (→ Page 150). MS150067/02E 2014-04 | Task Description | 141...

-

Page 142: Instructions And Comments On Endoscopic And Visual Examination Of Cylinder Liners

6.2.2 Instructions and comments on endoscopic and visual examination of cylinder liners Terms used for endoscopic examination Use the terms listed below to describe the condition of the cylinder-liner surface in the endoscopic ex- amination report. Findings Explanations/Action Minor dirt scores Minor dirt scores can occur during the assembly of a new engine (honing products, particles, broken-off burrs). - Page 143 Evaluation of findings and further measures The findings in the start phase of oxidation discoloration and heat discoloration are similar. A thorough investigation and compliance with the above evaluation criteria allow an unambiguous evaluation. To avoid unnecessary disassembly work, it is recommended that another inspection be carried out after further operation of the engine.

-

Page 144: Crankcase Breather

6.3 Crankcase Breather 6.3.1 Crankcase ventilation ‒ Overview For 16V engines 1 Vent pipe 5 Service block 9 Bracket 2 Impactor carrier 6 Vent housing 10 Plug 3 Bracket 7 Spigot pipe 11 Oil separator 4 Oil line 8 Drain pipe 144 | Task Description | MS150067/02E 2014-04... -

Page 145: Crankcase Breather – Oil Mist Fine Separator Replacement

6.3.2 Crankcase breather – Oil mist fine separator replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Oil mist fine separator (→ Spare Parts Catalog) O-ring (→ Spare Parts Catalog) WARNING Hot oil. -

Page 146: Valve Drive

6.4 Valve Drive 6.4.1 Valve gear – Lubrication Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil Valve gear – Lubrication Remove cylinder head covers (→ Page 150). Fill oil chambers of valve bridges with oil. Fill oil chambers of rocker arms and adjust- ing screws with oil. -

Page 147: Valve Clearance – Check And Adjustment

6.4.2 Valve clearance – Check and adjustment Preconditions ☑Engine stopped and starting disabled. ☑Engine coolant temperature is max. 40 °C. ☑Valves are closed. Special tools, Material, Spare parts Designation / Use Part No. Qty. Feeler gauge Y20098771 Torque wrench, 60-320 Nm F30452768 Box wrench socket, 24 mm F30039526... - Page 148 Rotate crankshaft with barring device in di- rection of engine rotation until the "OT-A1" marking and pointer are aligned. Diagram for 16V engines (two crankshaft positions) Checking valve clearance at two crankshaft positions Check TDC position of piston in cylinder A1: •...

-

Page 149: Adjusting Valve Clearance

Adjusting valve clearance Release locknut (1). Insert feeler gauge (3) between valve bridge and rocker arm. Use Allen key to set adjusting screw (2) so that the specified valve clearance is estab- lished. Feeler gauge (3) must just pass through gap. -

Page 150: Installation

6.4.3 Cylinder head cover – Removal and installation Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Assembly compound (Kluthe Hakuform 30-11C/Emulgier) X00059351 O-ring (→ Spare Parts Catalog) Removing cylinder head cover Clean very dirty cylinder head covers (1) prior to removal. -

Page 151: Injection Pump / Hp Pump

6.5 Injection Pump / HP Pump 6.5.1 HP pump – Filling with engine oil Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine oil WARNING Fuels are combustible. Risk of fire and explosion! •... -

Page 152: Hp Pump – Relief Bore Check

6.5.2 HP pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 153: Injection Valve / Injector

6.6 Injection Valve / Injector 6.6.1 Injector – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Injector (→ Spare Parts Catalog) Replacing injector Remove injector and install new injector (→ Page 154). MS150067/02E 2014-04 | Task Description | 153... -

Page 154: Injector – Removal And Installation

6.6.2 Injector – Removal and installation Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Installation/removal jig F6789889 Milling cutter F30452739 Torque wrench, 0.5-5 Nm 0015384230 Torque wrench, 10-60 Nm F30452769 Ratchet adapter F30027340 Torque wrench, 60-320 Nm... - Page 155 Remove HP fuel line 4). Note: While the adapter is removed, the injector is drained. Remove adapter (3). Remove screw (2) and take off hold-down clamp (1). Install installation/removal jig on cylinder head. Remove injector with installation/removal jig. Remove installation/removal jig. Remove sealing ring (4) from injector or use a self-made hook to take it out of the cylinder head.

- Page 156 Installing injector Remove plug before installing the injec- tor. (Do not remove the plug from the HP line before installing the adapter). Coat injector with assembly paste at the seat of the nozzle retaining nut. Fit new sealing ring (included in the scope of delivery of the injector) with assembly compound on injector, observe installation position of sealing ring.

- Page 157 Coat screw head mating face (2) and thread with engine oil. Fit hold-down clamp (1) in the correct position and use torque wrench to tighten screw (2) to the speci- fied initial tightening torque. Name Size Type Lubricant Value/Standard Screw Preload torque (Engine oil) 5 Nm to 10 Nm...

- Page 158 Fit connectors on injector. Note: Failure to reset drift compensation (CDC) will void the emissions certification. Reset drift compensation (CDC) with Dia- Sys® (→ E531920/...). If DiaSys® is not available, contact Service. Final steps Install cylinder head cover (→ Page 150). Open fuel supply to engine.

-

Page 159: Fuel Filter

6.7 Fuel Filter 6.7.1 Supplementary fuel filter – Overview 1 Storage tank 3 Passive standard prefilter 5 Supplementary fuel filter 2 Day tank with water separator 6 Main engine filter 4 LP pump MS150067/02E 2014-04 | Task Description | 159... -

Page 160: Additional Fuel Filter – Replacement

6.7.2 Additional fuel filter – Replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Diesel fuel Easy-change filter (→ Spare Parts Catalog) Synthetic ring (→ Spare Parts Catalog) DANGER Rotating and moving engine parts. -

Page 161: Fuel Filter – Replacement

6.7.3 Fuel filter – Replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Diesel fuel Easy-change filter (→ Spare Parts Catalog) Synthetic ring (→ Spare Parts Catalog) DANGER Rotating and moving engine parts. - Page 162 Replacing fuel filter with the en- gine running Cut out the filter to be replaced (1): B Left filter cut out C Right filter cut out Remove the cut-out oil filter (1) using an oil filter wrench. Clean sealing surface on filter head. Check sealing ring of new filter (1) and coat with fuel.

-

Page 163: Fuel System – Venting

6.7.4 Fuel system – Venting Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. •... -

Page 164: Fuel Prefilter – Differential Pressure Check And Adjustment Of Gauge

6.7.5 Fuel prefilter – Differential pressure check and adjustment of gauge DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 165: Fuel Prefilter – Draining

6.7.6 Fuel prefilter – Draining Preconditions ☑Engine is stopped and starting disabled. WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Draining fuel prefilter Cut out the filter to be replaced (A or B). 1 Filter A cut out 2 Filter B cut out Open vent plug (1) of filter to be drained. - Page 166 Connect filling pump to filling connection (1) on the suction side of the filter. Open vent valve (2) and fill with fuel until fuel emerges from the vent pipe (3). Close vent valve (2). Open rotary slide valve (4) a little (by ap- prox.

-

Page 167: Fuel Prefilter – Flushing

6.7.7 Fuel prefilter – Flushing Special tools, Material, Spare parts Designation / Use Part No. Qty. Diesel fuel DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING Fuels are combustible. - Page 168 Open vent plug (1) of filter to be flushed. Open drain valve (2) and drain fuel. Result: Fuel flows from filtered side back to the un- filtered side, flushing the filter deposits downwards out of the filter. Close vent plug (1) and drain valve (2). Fuel prefilter –...

-

Page 169: Fuel Prefilter With Water Separator – Filter Element Replacement

6.7.8 Fuel prefilter with water separator – Filter element replacement Preconditions ☑Engine is stopped and starting disabled. ☑System is at atmospheric pressure. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 10-60 Nm F30452769 Ratchet adapter F30027340 Filter element (→... - Page 170 Open vent valve (1) of the filter to be re- placed. Open drain valve (5) and drain fuel. Loosen screws (3) and screw out filter housing (A or B). Remove filter element (4). Insert new filter element in filter housing. Fit O-ring.

-

Page 171: Fuel Prefilter With Water Separator – O-Ring Replacement In Rotary Slide Valve

6.7.9 Fuel prefilter with water separator – O-ring replacement in rotary slide valve Preconditions ☑Engine is stopped and starting disabled. ☑System is at atmospheric pressure. Special tools, Material, Spare parts Designation / Use Part No. Qty. O-ring (→ Spare Parts Catalog) WARNING Tank is pressurized. -

Page 172: Exhaust Turbocharger

6.8 Exhaust Turbocharger 6.8.1 Overview of turbocharger Turbocharger 1 Impeller housing, left 6 Bearing bush 11 Bolt 2 Impeller housing, right 7 Shaft 12 Turbine housing, right 3 Washer 8 Sprung pin 13 Turbine housing, left 4 Nut 9 Sealing ring 5 Shaft 10 Sealing flange 172 | Task Description | MS150067/02E 2014-04... - Page 173 Turbine housing, left turbocharger 1 R-ring 10 Circlip 19 Dished washer 2 Turbine housing 11 Circlip 20 Dished washer 3 Turbine 12 Washer 21 Stud bolt 4 Piston ring 13 Bearing bush 22 Bolt 5 Heat shield 14 O-ring 23 Washer 6 Housing cover 15 Bearing housing 24 Blanking plate...

- Page 174 Impeller housing, left 1 O-ring 10 O-ring 19 Sealing ring 2 Bearing body 11 Retaining ring 20 Plug bolt 3 O-ring 12 Impeller 21 Clamping piece 4 Washer 13 Magnetic nut 22 Washer 5 Thrust bearing 14 Grooved pin 23 Bolt 6 Washer 15 Identification plate 24 Bolt...

- Page 175 Turbine housing, right turbocharger 1 R-ring 11 Circlip 21 Stud bolt 2 Turbine housing 12 Washer 22 Bolt 3 Turbine 13 Bearing bush 23 Washer 4 Piston ring 14 O-ring 24 Bush 5 Heat shield 15 Bearing housing 25 Pin 6 Housing cover 16 Bolt 26 Wastegate...

- Page 176 Impeller housing, right turbocharger 1 O-ring 10 O-ring 19 Sealing ring 2 Bearing body 11 Retaining ring 20 Identification plate 3 O-ring 12 Impeller 21 Grooved pin 4 Washer 13 Magnetic nut 22 Plug bolt 5 Thrust bearing 14 Bolt 23 Sealing ring 6 Washer 15 Washer...

- Page 177 Impeller housing 1 Impeller housing 2 Plug bolt 3 Sealing ring Bearing housing 1 Bearing housing 2 Sprung pin MS150067/02E 2014-04 | Task Description | 177...

- Page 178 Thrust bearing 1 Ball 2 Thrust bearing Magnetic nut 1 Magnetic nut 2 Magnet 178 | Task Description | MS150067/02E 2014-04...

- Page 179 6.8.2 Compressor wheel – Cleaning Preconditions ☑Engine is stopped and starting disabled Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 10-60 Nm F30452769 Ratchet adapter F30027340 Cleaner 40377 Engine oil Engine coolant Sealing rings (→ Spare Parts Catalog) Sealing rings (→...

- Page 180 Remove charge-air pipework (1) from ex- haust turbocharger to intercooler. Remove oil lines (2). Loosen clamp (1). Remove intake housing (3) with actuating cylinder (2). Remove coolant lines (1) from compressor housing (3). Remove coolant ventilation line (2) from compressor housing (3). 180 | Task Description | MS150067/02E 2014-04...

- Page 181 Undo screws (1). Remove compressor housing (2). Cleaning compressor wheel Note: Do not use wire brushes, scrapers or simi- lar tools for cleaning! Clean compressor housing with a smooth paint brush or brush. Clean compressor wheel (2) and bearing housing (1). Thoroughly remove cleaner from all compo- nents.

- Page 182 Tighten screws (1) to specified torque using a torque wrench. Name Size Type Lubricant Value/Standard Screw Tightening torque (Engine oil) 20 Nm + 2.5 Nm Install coolant ventilation line and coolant lines on compressor housing. Install intake housing (3) with actuating cyl- inder (2).

- Page 183 Preparatory steps – Vertical air intake Drain engine coolant (→ Page 210). Remove air filter (→ Page 189). Seal all openings with suitable covers. Remove charge-air pipework (1) from ex- haust turbocharger to intercooler. Remove oil lines (2). Loosen clamp (1). Remove intake housing (3) with actuating cylinder (2).

- Page 184 Remove coolant lines (1) from compressor housing (3). Remove coolant ventilation line (2) from compressor housing (3). Undo screws (1). Remove compressor housing (2). Cleaning compressor wheel Note: Do not use wire brushes, scrapers or simi- lar tools for cleaning! Clean compressor housing with a smooth paint brush or brush.

- Page 185 Final steps – Vertical air intake Install compressor casing (2). Tighten screws (1) to specified torque using a torque wrench. Name Size Type Lubricant Value/Standard Screw Tightening torque (Engine oil) 20 Nm + 2.5 Nm Install coolant ventilation line and coolant lines on compressor housing. Install intake housing (3) with actuating cyl- inder (2).

- Page 186 Install oil lines (2). Tighten threaded adapter at actuating cylinder to specified torque using a torque wrench. Name Size Type Lubricant Value/Standard Threaded adapter 10 G 1/4 Tightening torque (Engine oil) 40 Nm +4 Nm Install charge-air pipework (1) between exhaust turbocharger and intercooler. Install air filter (→...

- Page 187 6.9 Charge-Air Cooling 6.9.1 Intercooler – Checking condensate drain for water discharge and obstruction DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running.

-

Page 188: Air Filter

6.10 Air Filter 6.10.1 Air filter – Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Air filter (→ Spare Parts Catalog) Replacing the air filter Remove old air filter and install new air filter (→ Page 189). Reset signal ring of contamination indicator (→... - Page 189 6.10.2 Air filter – Removal and installation Preconditions ☑Engine is stopped and starting disabled. Air filter Loosen clamp (2). Remove air filter (1) and clamp (2) from connecting flange of housing (3). Verify that there are no objects in the flange of the intake housing (3) and clean Attach air filter (1) with clamp (2) onto in- take housing (3).

-

Page 190: Air Intake

6.11 Air Intake 6.11.1 Service indicator – Signal ring position check (optional) Preconditions ☑Engine is stopped and starting disabled. Checking signal ring position If the signal ring is completely visible in the control window (2), replace air filter (→ Page 188). After installation of new filter, press reset button (1). -

Page 191: Starting Equipment

6.12 Starting Equipment 6.12.1 Starter – Condition check Preconditions ☑Engine is stopped and starting disabled. Checking starter condition Check securing screws of starter for secure seating and tighten if required. Check wiring (→ Page 239). MS150067/02E 2014-04 | Task Description | 191... - Page 192 6.13 Lube Oil System, Lube Oil Circuit 6.13.1 Engine oil – Level check Preconditions ☑Engine is stopped and starting disabled. Oil level check prior to engine start Withdraw dipstick from guide tube and wipe it. Insert dipstick into guide tube to stop, withdraw after approx.

- Page 193 6.13.2 Engine oil – Change Preconditions ☑Engine is stopped and starting disabled. ☑Engine is at operating temperature. ☑MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 40-200 Nm...

- Page 194 Tighten drain plugs (1) and (2) to specified torque using a torque wrench: Name Size Type Lubricant Value/Standard Screw M26x1.5 Tightening torque (Engine oil) 100 Nm+10 Nm Filling with new oil Open cap on filler neck. Pour oil in at filler neck up to 'max.' mark at oil dipstick.

- Page 195 6.13.3 Engine oil – Sample extraction and analysis Preconditions ☑MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. MTU test kit 5605892099/00 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •...

- Page 196 Drain approx. 1 liter engine oil into a clean container. Close screw. Using the equipment and chemicals in the MTU test kit, analyze the engine oil for: • Dispersion capability (spot test); • Water content; • Dilution by fuel. 196 | Task Description | MS150067/02E 2014-04...

- Page 197 6.14 Oil Filtration / Cooling 6.14.1 Engine oil filter ‒ Replacement Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Engine oil Oil filter (→ Spare Parts Catalog) DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •...

-

Page 198: Engine Running

Oil filter with diverter (option): Oil filter replacement with the engine stopped Stop engine (→ Page 61) and disable en- gine start. Unscrew oil filter using oil filter wrench. Clean sealing surface on connecting piece. Check condition of new oil filter sealing ring and moisten it with oil. - Page 199 6.14.2 Oil indicator filter – Cleaning and check Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Cleaning agent (Snow-White 11-0) 40460 Cleaning agent (Hakupur 312) 30390 Engine oil Strainer (→ Spare Parts Catalog) Square-section ring (→...

- Page 200 Checking strainer Item Findings Action • Clean Strainer Metallic residues • Monitor engine operation • Check strainer daily • Contact Service Strainer Damaged Fit new part Square-section ring Damaged Fit new part O-ring Damaged Fit new part Cleaning strainer Wash strainer (5) with cleaner. Remove stubborn deposits with soft brush.

- Page 201 6.14.3 Centrifugal oil filter – Cleaning and filter sleeve replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Filter wrench F30379104 Cleaner Hakutex 60 Grease (Kluthe Hakuform 30-10/emulsifier) X00029933 Filter sleeve (→...

- Page 202 Centrifugal oil filter – Cleaning and filter sleeve replacement Remove clamp (14). Release Tommy nut (2) and take off cov- er (1). Carefully lift rotor (11), allow oil to drain and remove from housing. Holding the rotor (11) firmly, release rotor cover nut (3).

- Page 203 Cleaning centrifugal oil filter and replacing filter sleeve (en- gines with switchable oil filter) Undo and remove screw (1). Remove clamp (3) and take off hood (2). Carefully remove rotor (5) from housing. Hold rotor assembly (5) firmly in position with filter wrench and undo knurled nut (7).

- Page 204 6.15 Coolant Circuit, General, High-Temperature Circuit 6.15.1 Drain and vent points Coolant lines on ETC 1 Vent point Coolant line to intercooler 1 Vent point 204 | Task Description | MS150067/02E 2014-04...

- Page 205 1 Vent point Coolant line to raw water cooler 1 Vent point MS150067/02E 2014-04 | Task Description | 205...

- Page 206 Vent line – Distribution cross 1 Vent point Coolant drain point, engine driving end 1 Drain point 206 | Task Description | MS150067/02E 2014-04...

- Page 207 Coolant drain point, engine free end 1 Drain point MS150067/02E 2014-04 | Task Description | 207...

- Page 208 6.15.2 Engine coolant level – Check Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001061/..) are available. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. • Wear protective clothing, gloves, and goggles / safety mask.

- Page 209 6.15.3 Engine coolant – Change Special tools, Material, Spare parts Designation / Use Part No. Qty. Coolant Engine coolant change Drain engine coolant (→ Page 210). Fill with engine coolant (→ Page 213). MS150067/02E 2014-04 | Task Description | 209...

- Page 210 6.15.4 Engine coolant – Draining Preconditions ☑Engine is stopped and starting disabled. WARNING Coolant is hot and under pressure. Risk of injury and scalding! • Let the engine cool down. • Wear protective clothing, gloves, and goggles / safety mask. Preparatory steps Provide an appropriate container to drain the coolant into.

- Page 211 Open vent valve on exhaust pipework (driv- ing end) (1). Open vent valve on seawater cooler (1) (or remote heat exchanger). Open drain plug (1) and drain coolant at crankcase. MS150067/02E 2014-04 | Task Description | 211...

- Page 212 Open drain screw (1) and drain coolant on coolant pump elbow. Final steps Seal all open vent and drain points. Set breather valve onto filler neck and close it. 212 | Task Description | MS150067/02E 2014-04...

- Page 213 6.15.5 Engine coolant – Filling Preconditions ☑Engine is stopped and starting disabled. ☑MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. Engine coolant WARNING Coolant is hot and under pressure.

- Page 214 Filling coolant through filler neck Open vent points on charge-air cooler, ex- haust turbochargers and on plate-core heat exchanger (arrows). Fill coolant through the filler neck of the expansion tank (for engines with remote heat exchanger: the expansion tank is part of the remote cooling system) until the coolant level at the top edge of the filler neck remains constant.

- Page 215 6.15.6 HT coolant pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running.

- Page 216 6.15.7 Engine coolant – Sample extraction and analysis Preconditions ☑MTU Fluids and Lubricants Specifications (A001061/..) are available. Special tools, Material, Spare parts Designation / Use Part No. Qty. MTU test kit 5605892099/00 DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! •...

- Page 217 6.15.8 Engine coolant filter – Replacement Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Filter wrench F30379104 Engine oil Engine coolant filter (→ Spare Parts Catalog) WARNING Coolant is hot and under pressure. Risk of injury and scalding! •...

-

Page 218: Preheating Unit

6.15.9 Preheating unit Hotstart preheating unit 1 Plastic cap (drain) 4 Shutoff valve 7 Thermostat 2 On/Off switch 5 Continuous flow heater 8 Circulation pump 3 Plastic cap (supply line) 6 Vent valve Cylinders Nominal voltage / frequency Heating power kW 12 V 230 V / 50 Hz 400 V / 50 Hz... - Page 219 Hilzinger preheating unit 1 On/Off switch Cylinders Nominal voltage / frequency Heating power kW 12 V and 16 V 230 V / 50 Hz 400 V / 50 Hz 230 V / 60 Hz 440 V / 60 Hz MS150067/02E 2014-04 | Task Description | 219...

- Page 220 Hilzinger preheating unit, side view 1 Flange (supply and return) 3 Non-return flap 5 Thermostat 2 Junction box 4 Continuous flow heater 6 Circulation pump Function The preheating unit is intended to warm up the engine coolant. The circulation pump (6) ensures the circulation of the preheated coolant through the engine.

- Page 221 6.15.10 Preheater – Overhaul Preconditions ☑Engine is stopped and starting disabled. DANGER Electric voltage supply for operation. Danger of burns and fatal electric shock! • Make certain that the power supply to the product is switched off before starting work. Secure against unintentional switching on! WARNING Coolant is hot and under pressure.

- Page 222 6.15.11 Preheater – Function and leak-tightness check Preconditions ☑Preheater is switched on. WARNING Coolant is hot and highly pressurized. Risk of injury! Risk of scalding! • Allow engine to cool down. • Wear protective clothing, protective gloves, and safety glasses / facial protection. Checking operation Note: The coolant temperature must correlate to the control range of the thermostat when the preheater is...

-

Page 223: Raw Water Pump With Connections

6.16 Raw Water Pump with Connections 6.16.1 Raw water pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. - Page 224 6.17 Engine Mounting / Support 6.17.1 Engine mounting – Check Engine mounting – Check Item Findings Action • Damage Visually inspect mounts. Replace (contact Service). • Brittleness • Deformation • Crack formation • Swelling visible 224 | Task Description | MS150067/02E 2014-04...

- Page 225 6.18 Battery-Charging Generator 6.18.1 Battery-charging generator drive – Coupling condition check Preconditions ☑Engine is stopped and starting disabled. Battery-charging generator drive – Coupling condition check Remove screws (1). Remove protective cover (2). Check resilient coupling (3) for cracks and plastic deformation. If there is serious deformation or crack for- mation, contact Service.

-

Page 226: Auxiliary Pto

6.19 Auxiliary PTO 6.19.1 Bilge pump – Relief bore check DANGER Rotating and moving engine parts. Risk of crushing, danger of parts of the body being caught or pulled in! • Only run the engine at low power. Keep away from the engine's danger zone. WARNING High level of engine noise when the engine is running. -

Page 227: Fuel Supply System

6.20 Fuel Supply System 6.20.1 Water drain valve – Check Water drain valve – Check Open water drain valve. Check water outlet for obstructions. Close water drain valve. MS150067/02E 2014-04 | Task Description | 227... - Page 228 6.20.2 Differential pressure gauge – Check WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Checking differential pressure gauge Switch on fuel treatment system (→ Page 59). Set the alarm points at the differential pressure gauge to zero.

-

Page 229: Water Level Probe (3-In-1 Rod Electrode) – Check

6.20.3 Water level probe (3-in-1 rod electrode) – Check Preconditions ☑System is put out of operation and emptied. WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Checking water level probe (3-in-1 rod electrode) Disconnect connector from water level probe. - Page 230 6.20.4 Pump capacity – Check WARNING Fuels are combustible. Risk of fire and explosion! • Avoid open flames, electrical sparks and ignition sources. • Do not smoke. Pump capacity – Check Install suitable pressure gauge at the neck of the intake side of the pump. Check pump pressure.

- Page 231 6.20.5 Coalescer filter element – Replacement Preconditions ☑System is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 6-50 Nm F30027336 Ratchet F30027339 Diesel fuel Engine oil Coalescer filter element (→ Spare Parts Catalog) Gasket (→...

- Page 232 Tighten nut (3) to specified tightening torque using a torque wrench. Name Size Type Lubricant Value/Standard Tightening torque (Engine oil) 30 Nm +3 Nm Fit gasket (10). Install cover. Install screws (1), washers (2) and nuts (9). Tighten nuts (9). Open ball valve at the inlet and outlet of the fuel treatment system.

-

Page 233: Wiring (General) For Engine/Gearbox/Unit

6.21 Wiring (General) for Engine/Gearbox/Unit 6.21.1 Engine wiring harness – Overview Engine wiring harnesses – Terminal assignment Description Terminal assignment Sensors Camshaft speed Intake air temperature B4.21 Exhaust temperature, A side B4.22 Exhaust temperature, B-side B5.1 Oil pressure downstream of filter B5.3 Oil pressure upstream of filter Coolant temperature... - Page 234 Description Terminal assignment Injectors Y39A1 to Y39AX Engine A side Y39B1 to Y39BX Engine B side Engine wiring harness for sensors, 12V engine 1 M8 13 B4.22 25 B4.21 2 B1 14 B9 26 B10 3 B6 15 S37.1 27 B13 4 X2 16 B34.3 28 S37.2...

- Page 235 Engine wiring harness for sensors, 16V engine 1 M8 13 B4.22 25 B4.21 2 B1 14 B9 26 B10 3 B6 15 S37.1 27 B13 4 X2 16 B34.3 28 S37.2 5 Y27 17 B34.2 29 B7 6 B44.2 18 B34.1 30 B5.1 7 X37 19 B50...

- Page 236 Engine wiring harness for injectors, 12V engine 1 Y39A1 6 Y39A6 11 Y39B3 2 Y39A2 7 X4 12 Y39B2 3 Y39A3 8 Y39B6 13 Y39B1 4 Y39A4 9 Y39B5 5 Y39A5 10 Y39B4 236 | Task Description | MS150067/02E 2014-04...

- Page 237 Engine wiring harness for injectors, 16V engine 1 Y39A1 7 Y39A7 13 Y39B5 2 Y39A2 8 Y39A8 14 Y39B4 3 Y39A3 9 X4 15 Y39B3 4 Y39A4 10 Y39B8 16 Y39B2 5 Y39A5 11 Y39B7 17 Y39B1 6 Y39A6 12 Y39B6 MS150067/02E 2014-04 | Task Description | 237...

- Page 238 Engine wiring harness for electric starter 1 Connection terminals, EIM 2 Fuse F1 3 Connection terminals, starter 238 | Task Description | MS150067/02E 2014-04...

-

Page 239: Engine Wiring – Check

6.21.2 Engine wiring – Check Preconditions ☑Engine is stopped and starting disabled. Special tools, Material, Spare parts Designation / Use Part No. Qty. Isopropyl alcohol X00058037 Engine wiring – Check Check securing screws of cable clamps on engine and tighten loose threaded connections. Ensure that cables are fixed in their clamps and cannot swing freely. - Page 240 6.22 Accessories for (Electronic) Engine Governor / Control System 6.22.1 CDC parameters – Reset Preconditions ☑Engine is stopped and starting disabled. Note: Failure to reset drift compensation (CDC parameters) will void the emissions certification. Resetting CDC parameters with DiaSys® (→ Dialog system DiaSys® E531920/..). Resetting CDC parameters without DiaSys®...

-

Page 241: Limit Switch For Start Interlock ‒ Check

6.22.2 Limit switch for start interlock ‒ Check Preconditions ☑Engine is stopped and starting disabled. Note: In the OFF position, the limit switch initiates a start interlock, i.e. the engine cannot be started. Checking limit switch for start interlock Check whether switches (3) and guard plate (1) with engine support (4) are instal- led on both sides of flywheel housing (2). - Page 242 6.22.3 Engine Control Unit ECU 7 – Checking plug connections Preconditions ☑Engine is stopped and starting disabled. Check plug connections on ECU Check all connectors on ECU for firm seat- ing. Ensure that the clips (1) are engaged. Check screws (2) of cable clamps on ECU for firm seating.

- Page 243 6.22.4 Engine Monitoring Unit EMU 7 – Plug connection check Preconditions ☑Engine is stopped and starting disabled. Checking EMU plug connections Check both connectors on EMU (2) for firm seating. Ensure that the clips (1) are engag- Check screws (3) of cable clamps on EMU (2) for firm seating.

- Page 244 6.22.5 Interface module EIM plug connections – Check Preconditions ☑Engine is stopped and starting disabled. Checking EIM plug connections Check both Tyco plugs (62-pole) (2) on EIM for firm seating. Ensure that clips (3) are engaged. Check screws (1) of cable clamps on EIM for firm seating.

- Page 245 6.22.6 Engine Control Unit ECU 7 – Removal and installation Preconditions ☑Engine is stopped and starting disabled. NOTICE Wrong engine governor installed. Engine damage! • When reassembling an engine, make sure that the governor with the data record for the given engine is installed.