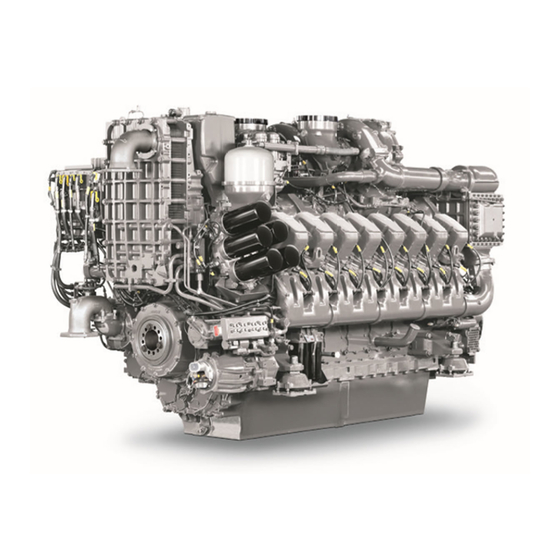

MTU 16 V 4000 M63L Manuals

Manuals and User Guides for MTU 16 V 4000 M63L. We have 1 MTU 16 V 4000 M63L manual available for free PDF download: Operating Instructions Manual

MTU 16 V 4000 M63L Operating Instructions Manual (262 pages)

Table of Contents

-

1 Safety

7-

-

-

Fuel System16

-

Functions17

-

-

-

-

Firing Order44

-

-

Controls49

-

3 Operation

49 -

-

-

HI T-Fuel72

-

SS T-Fuel72

-

LO P-Coolant78

-

SS P-Coolant78

-

LO P-Fuel79

-

HI T-Coolant80

-

SS P-Fuel80

-

SS T-Coolant80

-

410 – lo U-Pdu116

-

411 – Lolo U-Pdu116

-

412 – Hi U-Pdu116

-

413 – Hihi U-Pdu117

-

444 – Sd U-Pdu119

-

446 – Sd P-Hd2120

-

464 – Sd P-Aux 1122

-

469 – Sd aux 1123

-

470 – Sd T-Ecu123

-

472 – al Stop SD123

-

AL Wiring PWM2130

-

-

Valve Drive146

-

Filling HP Pump151

-

Fuel Filter159

-

-

Bearing Housing177

-

Impeller Housing177

-

Magnetic Nut178

-

Thrust Bearing178

-

Air Filter188

-

Air Intake190

-

-

MTU Test Kit195

-

Hot Oil197

-

Preheating Unit218

-

Auxiliary PTO226

-

-

-

Removing EMU246

-

-

Fuse Lamp (SILA)248

-

Abbreviations251

-

7 Appendix A

251 -

8 Appendix B

254-

Barring Device254

-

Feeler Gauge254

-

Special Tools254

-

Filter Wrench255

-

Milling Cutter255

-

Ratchet256

-

Ratchet Adapter256

-

Rigid Endoscope257

-

Index259

-

Advertisement

Advertisement