Advertisement

Quick Links

Advertisement

Subscribe to Our Youtube Channel

Summary of Contents for MTU 12 V 4000 G21R

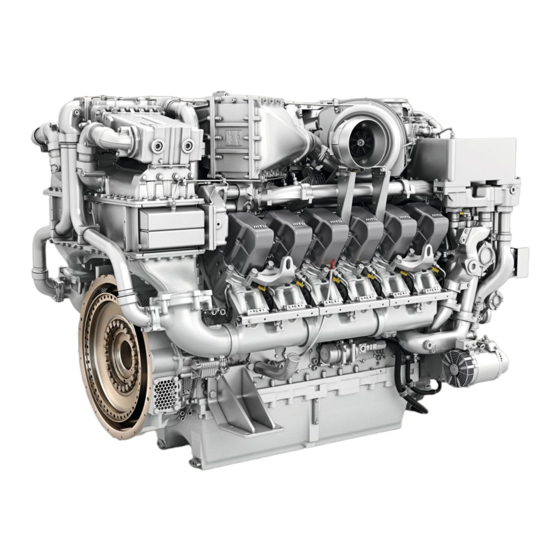

- Page 1 Operating Instructions Diesel engine 12 V 4000 G21R 12 V 4000 G41R MS150064/01E...

- Page 2 This Publication is protected by copyright and may not be used in any way whether in whole or in part without the prior written permission of MTU Friedrichshafen GmbH. This restriction also applies to copyright, distribution, translation, micro‐ filming and storage or processing on electronic systems including data bases and online services.

- Page 3 Commissioning Note Important Please complete and return the “Commissioning Note” card below to MTU Friedrichshafen GmbH. The Commissioning Note information serves as a basis for the contractually agreed logistic support (war‐ ranty, spare parts, etc.).

- Page 5 Table of Contents 1 Safety 4.5 Operational checks 4.6 Stop engine in manual mode (testing 1.1 General conditions mode) 1.2 Personnel and organizational requirements 4.7 Emergency stop 1.3 Transport 4.8 After stopping the engine – Engine remains 1.4 Crankshaft transport locking device ready for operation 1.5 Safety regulations for startup and operation 4.9 After stopping the engine –...

- Page 6 8 Appendix A 7.14.2 Centrifugal oil filter – Cleaning and filter sleeve replacement 8.1 Abbreviations 7.15 Coolant Circuit, General, High- 8.2 MTU contacts/service partners Temperature Circuit 7.15.1 Coolant level - Check 7.15.2 Engine coolant – Change 9 Appendix B 7.15.3 Engine coolant – Draining 7.15.4 Engine coolant –...

- Page 7 Modifications or conversions Unauthorized modifications to the engine represent a safety risk. MTU will accept no liability or warranty claims for any damage caused by unauthorized modifications or conversions. Spare parts Only genuine MTU spare parts must be used to replace components or assemblies. MTU accepts no liability whatsoever for damage or injury resulting from the use of other spare parts and the warranty shall be voided in such case.

- Page 8 1.2 Personnel and organizational requirements Personnel requirements Work on the engine must only be carried out by appropriately qualified and instructed personnel. Observe the minimum legal age. Responsibilities of the operating, maintenance and repair personnel must be specified by the operating company.

- Page 9 Place the engine only on an even, firm surface. Ensure appropriate consistency and load-bearing capacity of the ground or support surface. Never place an engine on the oil pan, unless expressively authorized by MTU on a case-to-case basis to do so.

- Page 10 1.4 Crankshaft transport locking device Special tools, Material, Spare parts Designation / Use Part No. Qty. Torque wrench, 10-60 Nm F30510423 Torque wrench, 60-320 Nm F30047446 Engine oil Transport locking device Note: The locking device protects the crankshaft bearings from shocks and vibration damage during engine transport.

- Page 11 Fitting the transport locking device on driving end (KS) Note: Always use the screws supplied with or installed in the transport locking device to secure it on the en‐ gine. Secure the two plates (2) with screws (6) and washers (5) at the bores on both sides of the flywheel housing and tighten to the specified tightening torque.

- Page 12 Installing guard plates and engine mounting brackets (if applicable) on driving end (KS) Note: Always use the screws supplied with the or removed from the guard plates and engine mounting brackets to secure them on the engine. Install engine mounting brackets (2) on both sides with guard plates (1) washers (3), and screws (4).

- Page 13 Safety requirements for initial operation Prior to initial operation of the unit, install the assembly or unit according to the specifications and check the installation according to the MTU specifications. Before putting the device or plant into operation, always ensure: •...

- Page 14 1.6 Explosion hazard when removing inspection port cover on engine DANGER Explosion hazard due to oil vapors. Risk of serious injury – danger to life! • Allow the engine to cool down before opening the crankcase! • Avoid open flames, electrical sparks and ignition sources. Safety instructions Before starting maintenance work, allow the engine to cool down for at least 10 min.

- Page 15 1.7 Safety regulations for maintenance and repair work Safety regulations for maintenance and repair work Have maintenance and repair work carried out by qualified and authorized personnel only. Allow the engine to cool down before starting maintenance work (risk of explosion of oil vapors). Before starting work, relieve pressure in systems and compressed-air lines which are to be opened.

- Page 16 Do not use the assembly or system as ground terminal. Do not route the welding lead over or near the wiring harnesses of MTU systems. The welding current may otherwise induce an interference voltage in the wiring harnesses which could conceivably damage the electrical system.

- Page 17 For conducting light-beam procedures and measurement work, only the following laser devices must be used: • Laser devices of classes 1, 2 or 3A. • Laser devices of class 3B, which have maximum output in the visible wavelength range (400 to 700 nm), a maximum output of 5 mW, and in which the beam axis and surface are designed to prevent any risk to the eyes.

- Page 18 Use only fuel of prescribed quality to comply with emission limit values. Dispose of used fluids, lubricants and filters in accordance with local regulations. Within the EU, batteries can be returned free of charge to MTU FN / MTU Onsite Energy where they are subjected to proper recycling procedures.

- Page 19 Lead • When working with lead or lead-containing compounds, avoid direct contact to the skin and do not inhale lead vapors. • Adopt suitable measures to avoid the formation of lead dust. • Switch on extraction system. • Wash hands after contact with lead or lead-containing substances. Compressed air Observe special safety precautions when working with compressed air: •...

- Page 20 1.9 Conventions for safety instructions in the text DANGER In the event of immediate danger. Consequences: Death or serious injury • Remedial action WARNING In the event of potentially dangerous situations. Consequences: Death or serious injury • Remedial action CAUTION In the event of dangerous situations.

Need help?

Do you have a question about the 12 V 4000 G21R and is the answer not in the manual?

Questions and answers