Table of Contents

Advertisement

Owner's Manual

M45811F

2.5 GPM, 3000 PSI Pressure Washer — EPA, CARB-Compliant

Instructions for Installation/Set-up, Operation, Maintenance, & Storage

This pressure washer produces cold water high pressure spray. Cleaning chemicals may be incorporated into the

spray if desired. The pressure pump for this equipment is powered by a gasoline internal combustion engine.

WARNING: SPECIAL HAZARDS

CO Poisoning: Exhaust from engine contains carbon monoxide, a poisonous gas that can cause carbon monoxide

poisoning and possible death if inhaled.

Injection Injury: High-pressure spray can pierce skin and underlying tissues, leading to serious injury and possible

amputation. Such an injection injury can result in blood poisoning and/or severe tissue damage.

Flying Debris: High-pressure spray can cause flying debris and possible surface damage.

Electric shock: Operating equipment in wet conditions or near water can cause electric shock.

Chemical Exposure: Cleaning chemical vapors or contact with skin may be hazardous.

Fire/Explosion: Engine sparking can ignite fuel or other flammable liquids or vapors in the vicinity. Hot exhaust from engine

can ignite combustible materials.

Burns: Pressure Washer pump and engine are hot surfaces that can cause burn injuries.

Detailed safety information about these hazards appears throughout this manual.

Inspect Upon Delivery: FIRST! Inspect for missing or damaged components. See "Initial Set-Up/Installation" section

for where to report missing or damaged parts.

Add Engine Oil: Engine is shipped without oil. See the "Engine Manual" section of this manual for instructions on

capacity and viscosity recommendations.

Replace Temporary Pump Oil Plug: Pump is shipped with oil but with temporary shipping plug. Check pump oil

level before starting and replace temporary shipping plug with permanent oil fill plug provided within plastic bag

containing this Owner's Manual.

Water Flow Requirements: Make sure your supply water flow rate is 20% higher than the pressure washer's flow

rate (see "Operations", section for detail), and that your water is clean and particle free.

Chemical Spraying: Use only approved pressure washer chemicals designed for high-pressure use. Use soap

adjustment knob to regulate cleaning power (on select units).

Storage: Do not allow water to freeze in the pump, hose, or spray gun(s). See "Storage" for more information.

Maintenance Schedule: Engine and pump require periodic inspection and servicing to keep pressure washer

functioning efficiently. See "Maintenance Schedule Summary" for frequency of servicing.

Equipment Protection Quick Facts

Any Questions, Comments, Problems, or Parts Orders

Call Powerhorse Product Support 1-866-443-2576

ITEM NUMBER: 45811

SERIAL NUMBER: _____________

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Powerhorse M45811F

-

Page 1: Equipment Protection Quick Facts

Storage: Do not allow water to freeze in the pump, hose, or spray gun(s). See “Storage” for more information. Maintenance Schedule: Engine and pump require periodic inspection and servicing to keep pressure washer functioning efficiently. See “Maintenance Schedule Summary” for frequency of servicing. Any Questions, Comments, Problems, or Parts Orders Call Powerhorse Product Support 1-866-443-2576... -

Page 2: Table Of Contents

Table of Contents Equipment Protection Quick Facts ............................1 TABLE OF CONTENTS ..............................2 ABOUT YOUR PRESSURE WASHER ......................... 4 SPECIFICATIONS ................................ 5 COMPONENT IDENTIFICATION ..........................6 SAFETY ..................................7 Hazard Signal Word Definitions ............................7 SAFETY LABELING ..............................8 Safety Decal Locations ................................. - Page 3 PARTS LIST - MODEL 45811 - REV F ........................30 PUMP EXPLODED VIEW- REV F ..........................31 PUMP PARTS LIST- REV F ............................32 KIT PARTS LIST-REV F ............................. 33 ENGINE EXPLODED VIEW (45811)-REV F ....................... 34 ENGINE PARTS LIST (45811)-REV F ........................35 ENGINE KIT PARTS LIST (45811)-REV F .........................

-

Page 4: About Your Pressure Washer

About Your Pressure Washer Thank you for purchasing a Powerhorse Pressure Site Location. Intended for outdoor use only. Washer! It is designed for long life, dependability, and Personal Protection. Wear safety apparel during top performance. operation, including safety glasses with side and top Intended Use. -

Page 5: Specifications

Specifications Model # 45811 FLOW OUTPUT PSI (bar) 3000 (207) GPM (l/min) 2.5 (9.4) Max Water Temp 140F (60C) ENGINE Engine Powerhorse Horsepower 208CC DIMENSIONS / COMPONENTS Length 22.3” Width 25” Height 38.6” Weight 75lbs Pump Oil Capacity 4 oz. -

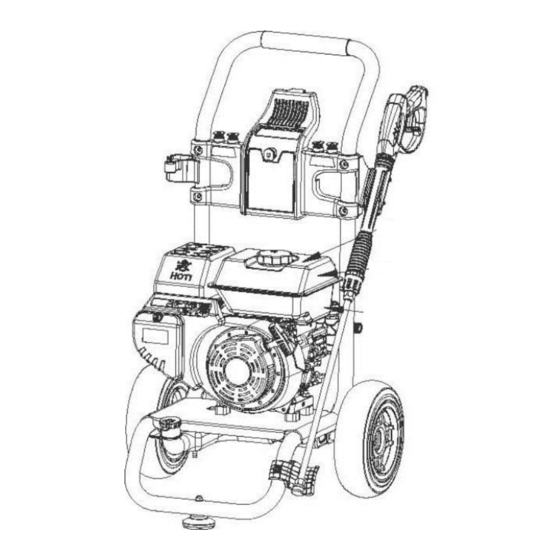

Page 6: Component Identification

Component Identification 1. Pressure Washer Pump: Inspect for 9. Engine: The air-cooled engine powers the pump. loose/broken parts prior to each use. 10. Upper Gun Holder: Store gun here. 2. Pump Oil Fill: Add pump oil here. Replace 11. Lower Gun Holder: Store lance here. shipping plug with vented dipstick. -

Page 7: Safety

Safety Hazard Signal Word Definitions This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. DANGER (red) indicates a hazardous situation, which if DANGER not avoided, will result in death or serious injury. -

Page 8: Safety Labeling

Safety Decal Locations WARNING: ALWAYS make sure safety labels are in place and in good condition. If a safety label is missing or not legible, order new labels from Powerhorse Product Support at 1-866-443-2576 On-Product Warning Labels Location Part numbers... -

Page 9: Safety Decals

Safety Decals To order replacement safety labels, call Powerhorse Product Support at 1-866-443-2576... -

Page 10: Initial Set-Up

Initial Set-Up Step 1. Inspect & Unpack Upon receiving your item check for missing or damaged parts. See “Component Identification” section of this manual for a diagram of the pressure washer and its components. For missing or damaged components, please contact Product Support at 1-866-443-2576. ... - Page 11 Step 2. Assembly Handle to Base Assembly Note: Remove contents from pallet and assembly can 3. Install handle to the pressure washer base occur at this time. Wheel to Base Assembly Handle 1. Install wheels on the pressure washer base using: ...

-

Page 12: Outdoor Use Only

Step 3. Select Suitable Location Accessory Hook to Base Assembly 6. Attach upper gun hook on the pressure washer Moving and Handling base using: Moving your pressure washer around (2) Plastic rivet Use the handles to manually move the pressure washer. - Page 13 Keep a fire extinguisher rated "ABC" nearby. Positioning: Keep it properly charged and be familiar with its 1. The pressure washer should be positioned use. on a firm, level (less than 3 degree slope), heat-resistant surface with good drainage Place the unit so that the exhaust fumes will not and a nearby water supply.

-

Page 14: Operation

Operation Safety Rules for Operation NOTE! After you have checked and fueled the equipment Before starting the pressure washer, review the following general safety rules for operation: and positioned it in a suitable worksite, it is time to start your pressure washer. The following are the Conditions for Use procedures necessary for safe, successful operation Know how to stop. -

Page 15: Preparing For Operation

Preparing for Operation Never pull by hose. Do not move this machine by pulling on the hose. Hose or connections could fail and Make sure that any regular maintenance has been result in catastrophic high pressure release of fluid as performed as prescribed in “Maintenance &... -

Page 16: Check/Add Engine Oil

4. Thread the breather plug tube back into the 2) Fill fuel tank OUTDOORS – never indoors. Fuel pump housing. vapors can ignite if they collect inside and 5. Align the arrow on the dipstick cap with the enclosure and explosion can result. arrow on the breather plug tube, insert it, and 3) Stay away from all sources of heat, sparks, and twist it to secure. -

Page 17: Inspect Fuel System/Check For Leaks

Fill Engine Fuel Tank WARNING: High Pressure Fluid Injection Hazard Check the gasoline tank level. If needed, fill tank High-pressure fluid discharge from leaks (even pin- with fresh unleaded gasoline from a portable sized) or ruptured components can pierce skin and container: inject fluid into the body. - Page 18 Drawing water out of a tank may cause pump Black-Low pressure Chemicals cavitation and damage to your pump. This *Please call Powerhorse Customer Service to order pressure washer is designed for a pressurized additional nozzles. water source such as a city water faucet. However,...

-

Page 19: Prime The Water Supply

CAUTION: Chemicals Containing Muriatic Acid Certain chemicals, such as bleach or those containing muriatic acid, will cause pump damage if introduced upstream through the pump's water inlet. It mixes the cleaning chemical into a low pressure Prime the Water Supply spray. -

Page 20: Start-Up Procedures

Start-Up Procedures Start the Engine to Power the Pump. 1. Make sure water supply is connected and primed. CAUTION: Warranty Void Running the pump dry will cause damage and void the warranty. 2. To prevent accidental spraying, engage the safety latch on spray gun trigger by rotating it to the locked position. -

Page 21: Begin High Pressure Spray

Begin High Pressure Spray Procedure: WARNING: High Pressure Spraying 1. Put on the high-pressure spray nozzle (always Safety relieve system pressure first and follow Keep spray away from people. Never direct instructions for attaching a nozzle). discharge stream at or near any person. Do not 2. -

Page 22: Shutdown

Shutdown Spray Gun Safety Lock When not spraying, use the spray gun safety lock Stop the engine using the following steps: to prevent accidental high pressure discharge. WARNING: High Pressure Fluid Hazard Never disconnect the high-pressure hose from the pump or spray gun while the system is pressurized. -

Page 23: Storage

Storage When you are finished using the pressure washer, you 1. Drain the water from the high pressure hose and must prepare the sprayer for storage and store it in a spray gun by depressing the trigger on the spray proper location. -

Page 24: Prepare Engine For Long Term Storage

Prepare Pressure Washer for Storage Prepare Engine for Long Term Storage Prepare the pressure washer for storage. First prepare the engine for long term storage if you will not be using the pressure washer for more than 1. Make sure the engine start switch is OFF. 30 days. -

Page 25: Maintenance & Repair

Major repair. Major service, including the installation or replacement of parts, should be performed only by a qualified service technician. Obtain factory approved parts from Powerhorse Product Support at 1-866-443- 2576. -

Page 26: Inspect Spray System

Inspect Spray System Inspect Fuel System Inspect spray system for damage and leaks before Inspect the engine fuel system and check for leaks each use. before each use. Do not start pressure washer until all needed repairs have been completed. Do not start pressure washer until all needed repairs have been completed. -

Page 27: Change Pump Oil

All mechanical equipment, no matter how well designed, Change the pump oil after the first 50 hours of use, will need maintenance and repairs. A Powerhorse and then after every 3 months or 500 hours of use after pressure washer is no exception. At times, a that. -

Page 28: Troubleshooting

Troubleshooting This section provides a list of the more frequently encountered pressure washer malfunctions, their causes and corrective actions. Some corrective actions can be performed by the operator or maintenance personnel, and others may require assistance of a qualified electrician or Service Center. ENGINE WILL NOT START Causes Solutions... -

Page 29: Parts Explosion- Model 45811- Rev F

Parts Explosion- Model 45811- Rev F *Generic engine model shown... -

Page 30: Parts List - Model 45811 - Rev F

Parts List - Model 45811 - Rev F Ref# Part# Description 794444 Powerhorse 208cc Engine, Recoil GBT16674-B6-40 Bolt M6 x 40mm 770021 Cap, Soap Tank 770032 Soap Tank 680042 Lower "A" Frame assembly GB889-N-8 M8 Self-Lock Nut 770002 Rubber Feet... -

Page 31: Pump Exploded View- Rev F

Pump Exploded View- Rev F... -

Page 32: Pump Parts List- Rev F

Pump Parts List- Rev F Item Description Part # Item Description Part # Kit #4 Socket head screw 781361 O-ring 14.2X1.9 Kit #5 Pump basal flange Kit #1 Hose barb seat Kit #4 O-ring 80X2.4 Kit #1 Outlet nut M22×1.5-14 Kit #4 Radial shaft seal FB36- Kit #1... -

Page 33: Kit Parts List-Rev F

Kit Parts List-Rev F Kit Qty Kit # Description Item # Items Included Kit Part # Needed Pump basal flange Flange w/ Seal Kit O-ring 80X2.4 782837 Radial shaft seal FB36-50-7 Oil seal O-ring 15X2.2 Spacer Seal Kit 782843 O-ring 21.8X1.9 Water seal Compaction washer O-ring 9.8X1.9... -

Page 34: Engine Exploded View (45811)-Rev F

Engine Exploded View (45811)-Rev F... -

Page 35: Engine Parts List (45811)-Rev F

Engine Parts List (45811)-Rev F Ref# Part # Description Ref# Part # Description PACKING, HEADCOVER CRANKCASE Kit # 8 COVER COMP, CYLINDER BALL BEARING HEAD OIL SEAL WIND SHIEL COMP. GOVERNOR ASSEMBLY BOLT SHAFT, GOVERNOR ARM FLYWHEEL ASSEMBLY WASHER, GOVERNOR ARM FAN, RECOIL STARTER SHAFT Kit # 1... -

Page 36: Engine Kit Parts List (45811)-Rev F

Engine Kit Parts List (45811)-Rev F Kit Ref # Kit Part # Description 791621 Recoil & Fan Kit 791622 Air Filter Kit 791623 Vent Hose Kit 789262 Fuel Cap Kit 791624 Tank Kit 789693 Muffler Kit 791625 Carburetor Kit 791626 Valve Cover Kit 789696 Ignition Coil Kit... -

Page 37: Engine Manual

Engine Manual Safety CAUTION This engine is shipped without oil. If you start the engine without oil, the engine will be damaged beyond repair and will not be covered under warranty. -

Page 38: Safety Precautions

Safety Precautions WARNING Before operating the engine, be sure to read and familiarize yourself with the manual, otherwise personal injury or equipment damage may result. Pay special attention to the following: 1.) To prevent fire hazards and to provide adequate ventilation, keep engine at least 7 feet away from buildings and other equipment during operation. -

Page 39: Parts Descriptions

Parts Descriptions (Not included on this model) (Not included on this model) (Not included on this model) (Not included on this model) -

Page 40: Pre-Operation Inspection

Pre-Operation Inspection CAUTION Engine oil is a major factor affecting engine performance and service life. Non-detergent oils and vegetable oils are NOT recommended. Be sure to check the engine oil level on a level surface with the engine stopped. 1. -

Page 41: Pre-Operation Inspection (Cont'd)

If “spark knock” or “pinging” occurs at a steady engine speed under normal load, change brands of gasoline. If spark knock or pinging persists, consult an authorized Powerhorse dealer. If this continues, it could result in engine damage. -

Page 42: Starting The Engine

Starting the Engine 1. Push the fuel valve to the “ON” position. 2. Move the Choke Lever to the “CLOSED” position. Note: if the engine is hot, closing the choke is not necessary. 3. Move the throttle lever slightly to the left. 4. -

Page 43: Stopping The Engine

2. Replacement of Parts It’s recommended that you should choose parts which are manufactured by Powerhorse. Using a lower standards or an incompatible part may impair the exhaust control system. -

Page 44: Exhaust Control System (Cont'd)

** Only for paper core air cleaners. Every two years or 600 hours for dust collecting air cleaners. Service engine more frequent if used in dusty conditions. Should be done by your Powerhorse dealer, unless you are trained and equipped with the proper tools. WARNING Shut off the engine before performing any maintenance. -

Page 45: Maintenance (Cont'd)

Maintenance (cont’d) Change engine oil While engine is still hot, drain all engine oil out from the crankcase. 1.) Remove the oil filler cap and drain plug to drain oil 2.) Install the drain plug and tighten it securely. 3.) Refill with the recommended oil and check the oil level. 4.) Install the oil filler cap. -

Page 46: Maintenance (Cont'd)

Maintenance (cont’d) Sediment Cup Cleaning Turn the fuel valve to “OFF”. Remove the sediment cup and o-ring and wash them in nonflammable or high flash point solvent. Dry them thoroughly and reinstall securely. Turn the fuel valve on and check for leaks. WARNING Gasoline is extremely flammable and is explosive under certain conditions. -

Page 47: Maintenance (Cont'd)

Maintenance (cont’d) 2. Visually inspect the spark plug. Discard if the insulator is cracked or chipped. Clean the spark plug with a wire brush if it is to be reused. 3. Measure the plug gap with a feeler or gauge. The gap should be .07-.08mm (0.028-0.031 in). Correct as necessary by bending the side electrode. -

Page 48: Transport, Storage, And Removal From Storage

Transport, Storage, and Removal from Storage Transport Transport with the fuel vale turned to the “OFF” position. Only store the engine when it has cooled off to avoid fires or burns. CAUTION Do not tilt engine, keep engine at a level position to prevent fuel spillage. Fuel vapor or spilled fuel may ignite. -

Page 49: Transport, Storage, And Removal From Storage (Cont'd)

WARNING Fuel is extremely flammable and explosive under certain conditions. Keep cigarette, open flames and sparks away from operating site. Engine Specifications Powerhorse 208cc Engine Type 4-Stroke, OHV, Single Cyl., Forced Air Cooled Bore x Stroke (mm) -

Page 50: Troubleshooting

Troubleshooting Trouble Cause Remedy Engine will not start using 1. Is the engine switch in 1. See “Starting Engine” recoil starter. the “ON” position? Section. 2. Is the fuel valve “ON”? 2. See “Starting Engine” Section. 3. Is there fuel in the fuel 3. -

Page 51: Wiring Diagram

Wiring Diagram Note: The diagram for other types may be different with the exception of electric-start type. -

Page 52: Limited Warranty

In addition to the normal warranty, Powerhorse shall warrant any normal wear item from defects in material or workmanship for a period of 90 days from the date of purchase by user. - Page 53 U.S EPA AND CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT YOUR WARRANTY RIGHTS AND OBLIGATIONS The California Air Resources Board, The United States Environmental Protection Agency (US EPA) and Northern Tool and Equipment Company Inc., are pleased to explain the emission control system warranty on your 2015 and later model year small off-road engine.

- Page 54 If you have any questions regarding your warranty rights and responsibilities, contact Northern Tool and Equipment Company Inc. authorized warranty service facility: Tell: 1-866-443-2576 Website: www.northerntool.com Brand: Power horse Engine Family: FCDPS.1401GB, FCDPS.2081D J, FCDPS.1961DJ and FCDPS.4572DJ This telephone number is only for the engines which the company name Northern Tool and Equipment Company Inc.

- Page 55 time prior to the first scheduled replacement point for that part. If the part fails prior to the first scheduled replacement, the part must be repaired or replaced by Northern Tool and Equipment Company Inc. according to Subsection (4) below. Any such part repaired or replaced under warranty must be warranted for the remainder of the period prior to the first scheduled replacement point for the part.

- Page 56 (iii) Air filter. (3) Ignition System (i) Spark Plugs. (ii) Magneto or electronic ignition system. (iii) Spark advance/retard system. (4) Exhaust Gas Recirculation (EGR) System (i) EGR valve body,and carburetor spacer if applicable. (ii) EGR rate feedback and control system. (5) Air Injection System (i) Air pump or pulse valve.

- Page 57 This page left intentionally blank...

- Page 58 Assembled by Northern Tool & Equipment Company, Inc. Burnsville, MN 55306 NorthernTool.com...

Need help?

Do you have a question about the M45811F and is the answer not in the manual?

Questions and answers