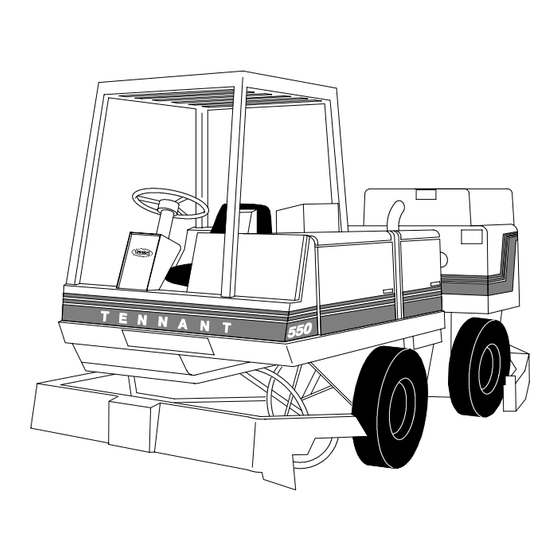

Tennant 550 Operator's Manual

Rider scrubber (gas/lpg/diesel)

Hide thumbs

Also See for 550:

- Manual (200 pages) ,

- Operator's manual (92 pages) ,

- Instruction bulletin (4 pages)

Subscribe to Our Youtube Channel

Summary of Contents for Tennant 550

- Page 1 (Gas/LPG/Diesel) Rider Scrubber English EN Operator Manual TennantTruet Parts and Supplies MP148EN Rev. 32 (03-2011) *MP148EN* www.tennantco.com Home Find... Go To..

- Page 2 Specifications and parts are subject to change without notice. Oriiginal instuctions, Copyright E 1997- -1999, 2001, 2002, 2005, 2006, 2008, 2011 TENNANT Company, Printed in The Netherlands DECLARATION OF CONFORMITY FOR MACHINERY (according to Annex II A of the Machinery Directive) Herewith declares, on our own responsibility, that the machinery TENNANT N.V.

-

Page 3: Safety Precautions

And Rear Halves Of Machine. Engage Pivot Lock. WARNING: Heavy LP Tank May Fall. Remove LP Tank Before Opening Cover. WARNING: Strong Vacuum. Keep Away From Fan Inlet When Fan Is Running. 550 MP148EN (3- -11) Home Find... Go To.. - Page 4 System Service Area. Keep Area Well Ventilated. - - Use Cardboard To Locate Leaking Hydraulic Fluid Under Pressure. - - Use TENNANT Supplied Or Approved Replacement Parts. FAN SUCTION DANGER DECAL - - TRAVEL SPEED CAUTION DECAL - - LOCATED ON THE SOLUTION TANK...

- Page 5 ENGINE FAN WARNING DECAL - - LOCATED PINCH SPACE DANGER DECAL - - ON THE LEFT SIDE TOP ACCESS DOOR LIP LOCATED ON THE SOLUTION TANK 03784 ENGINE FAN WARNING DECAL - - LOCATED ON THE FAN SHROUD 550 MP148EN (12- -01) Home Find... Go To..

-

Page 6: Table Of Contents

....PARKING BRAKE LEVER ... . 550 MP148EN (3- -05) Home Find... Go To.. - Page 7 ..LPG FUEL TROUBLESHOOTING REAR WHEELS ..... 550 MP148EN (3- -05) Home Find... Go To..

-

Page 8: For Machines Serial Number

CONTINENTAL TM27 ENGINES (For machines between serial number 003934--006408) ..CYLINDER HEAD BOLT TIGHTENING -- GM ENGINES (For machines serial number 006409 and above) 550 MP148EN (3- -05) Home Find... Go To.. -

Page 9: Home Find... Go To

......HIGH PRESSURE SPRAYER ..550 MP148EN (3- -05) Home Find... Go To.. -

Page 10: Machine Specifications

(std), 100 A alternator (HD) NA hp ( kw) @ NA rpm maximum Fuels -- gasoline, 85 octane unleaded, or LPG Cooling system -- water Electrical system -- 12 V nominal, 50 A alternator 550 MP148EN (9- -08) Home Find... Go To.. -

Page 11: Power Train

-- 6.4 qt (6 L) total system -- 13.4 qt (13 L) Engine lubricating oil, gasoline, LPG -- 4.5 qt (4 L) Engine lubricating oil, diesel -- 7 qt (6.5 L) 550 MP148EN (2- -06) Home Find... Go To.. -

Page 12: General Machine Dimensions/Capacities

Maximum rated climb and ascent angle when tanks are full -- 8_ Sound level continuous 88 + 1 dB (A) Sound level peak 102 + 1 dB (C) Viberation does not exceed 2.5 m/s 550 MP148EN (2- -06) Home Find... Go To.. -

Page 13: Machine Dimensions

61 in 52.3 in (1550 mm) (1330 mm) 156 in (3960 mm) SIDE VIEW 52.6 in (1335 mm) 61 in 55.75 in (1550 mm) 46.6 in (1415 mm) (1185 mm) TOP VIEW 00362 550 MP148EN (2- -06) Home Find... Go To.. -

Page 14: Preparation For Operation

3. Check the hydraulic fluid level in the hydraulic fluid reservoir, using the dipstick provided. TENNANT hydraulic fluid is recommended. If TENNANT hydraulic fluid is not available, use only new, approved hydraulic fluid. See the HYDRAULICS in the MAINTENANCE section. -

Page 15: Operation Of Controls

A. Steering Wheel G. Articulated Joint B. Instrument Panel H. Side Squeegee C. Solution Tank Head Pivot D. Rear Squeegee J. Debris Trough Release Lever E. Recovery Tank K. Fuel Tank F. Clean-out Door 550 MP148EN (9- -08) Home Find... Go To.. -

Page 16: And Diesel Engines (For Machines Below Serial Number 007003)

K. Operating Lights Switch (Option) Z. Choke Knob (Continental) L. Rotating Light Switch (Option) AA.Throttle Lever M. Hazard Light Switch (Option) BB.Steering Wheel N. Fuel Level Gauge CC.Horn Button O. Panel Lamp (Option) DD.Throttle Switch 550 MP148EN (3- -05) Home Find... Go To.. -

Page 17: Instruments And Controls -- Gas/Lpg

Y. Low Engine Oil Pressure Light Z. Charging System Light K. Operating Lights Switch (Option) L. Rotating or Hazard Light Switch (Option) M. Steering Wheel N. Fuel Level Gauge O. Panel Lamp (Option) 550 MP148EN (3- -05) Home Find... Go To.. -

Page 18: Cat Engines (For Machines Serial Number 007003 And Above)

Y. Low Engine Oil Pressure Light Z. Charging System Light K. Operating Lights Switch (Option) L. Rotating or Hazard Light Switch (Option) M. Steering Wheel N. Fuel Level Gauge O. Panel Lamp (Option) 550 MP148EN (3- -05) Home Find... Go To.. -

Page 19: Brake Pedal

The operator seat is of a fixed back style with a forward-backward adjustment. To adjust the seat, loosen the seat mounting bolts, slide the seat to the position desired, and tighten the bolts. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 20: Pivot Lock Pin

The check engine light comes on if the engine control system detects a fault during machine operation. If the check engine light comes on while operating the machine, contact a TENNANT service representative. IGNITION SWITCH The key-operated ignition switch has four positions. -

Page 21: Diesel Pre-Heat Indicating Lamp

(about 10 to 15 minutes). If the light comes on after the oil is warm, the cause may be operating on a rough floor-use “restricted” brush down pressure. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 22: Circuit Breakers (For Machines Serial Number 007003 And Above)

If the gauge registers an oil pressure reading below 30 psi (207 kPa), stop the engine immediately and determine the cause. Failure to stop the engine will result in severe engine damage. 550 MP148EN (2- -06) Home Find... Go To.. -

Page 23: Squeegee Switch

Using the choke on a warm engine is not necessary. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 24: Throttle Lever -- Diesel, Gas/Lpg Continental Engines

The throttle switch controls the engine governed speed. To speed the engine to the maximum governed speed, move the switch into the “FULL” position. To slow the engine to idle speed, move the switch to the “IDLE” position. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 25: Machine Operation

NOTE: Do not operate the starter motor for more ten requirements. seconds at a time or after the engine has started. Allow the starter to cool between starting attempts. The starter motor may be damaged if it is operated incorrectly. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 26: To Fill Solution Tank

For specific recommendations, contact the local TENNANT representative. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 27: To Drain And Clean Recovery Tank And Empty Hopper

7. Plug and secure the drain hose to the machine after tank is drained. 8. SRS machines: Partially fill the solution tank with clean water. Run the SRS pump for a few minutes to flush the solution hoses. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 28: Post Operation Checklist

Remove the ignition key from the ignition switch. 11. Diesel powered machines: Hold the throttle lever in the “STOP” position to stop the engine. 12. LPG powered machines: Close the LPG tank liquid service valve. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 29: Machine Troubleshooting

Solution spreader holes plugged Flush spreader holes Poor scrubbing performance Debris caught on scrub brushes Remove debris Improper detergent or brushes used Check with Tennant representative for advice Worn scrub brushes Replace scrub brushes Scrub brushes out of adjustment Adjust scrub brushes... -

Page 30: Options Operation

600 to 800 psi (4140 to 5515 kPa) when operating the sprayer. The maximum pressure when not spraying is 1200 psi (8275 kPa). To change the water pressure, adjust the red pressure adjustment knob on the regulator, or adjust the engine idle. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 31: Towing And Transporting The Machine

BYPASS VALVE ATTACH WINCHING CHAIN A. Bypass Valve B. Propelling Pump A. Towing Bracket B. Winching Chain Turn the bypass valve 90_ from the normal position before towing the machine. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 32: Home Find... Go To

6. Position the machine onto the truck or trailer as far as possible. If the machine starts to veer off the centerline of the truck or trailer, stop and turn the steering wheel to center the machine. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 33: Machine Jacking Locations

FOR SAFETY: When unloading machine off truck or trailer, use winch. Do not drive the machine off the truck or trailer unless the loading surface is horizontal AND 380 mm (15 in) or less from the ground. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 34: Machine Storage

5. Replace the high tension coil wire and spark plugs. 6. Drain the gasoline from the carburetor. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 35: Diesel Powered Machines

11. Clean the engine breather pipe. Seal the end with waterproof tape or a cork. 12. Remove all of the belts from the engine and save for future use. Attach them to the engine to prevent loss. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 36: Home Find... Go To

OPERATION 550 MP148EN (3- -05) Home Find... Go To.. -

Page 37: Recommended First 50-Hour Machine Inspection

5. Check the scrub head side squeegee blades for maintenance procedures listed in the wear or damage. MAINTENANCE CHART. 6. Check the rear squeegee for worn or damaged blades or for incorrect adjustment. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 38: Maintenance Chart

Scrub brush idler plugs Lubricate Vacuum fan shaft Lubricate Radiator Clean exterior SRS cleaning solution filter on Clean machines below serial number 003790 Solution dispensing tube Flush 50 Hours Vacuum fan drive belt Check tension 550 MP148EN (12- -01) Home Find... Go To.. -

Page 39: Home Find... Go To

(Diesel) EO -- 10W--30, 10W--40 or 15W--40 Engine oil, API diesel classification CF or better HYDO -- TennantTrue premium hydraulic fluid or equivalent SPC -- Special lubricant, Lubriplate EMB grease, TENNANT Part No. 01433--1 WBG -- Wheel bearing grease WG -- Water and permanent-type ethylene glycol antifreeze, one-to-one ratio NOTE: More frequent intervals may be required in extremely dusty conditions. -

Page 40: Lubrication

Snap the cap open and apply Lubriplate EMB SINGLE VISCOSITY OILS grease (TENNANT Part No. 01433--1) to the vacuum fan grease fitting. Wipe off all excess grease - -10 to 32... -

Page 41: Machine Pivot

50 hours of steering cylinder. Apply grease to these fittings after operation. Use a Lubriplate EMB grease (TENNANT every 50 hours of operation. Use a Lubriplate EMB Part No. 01433--1). -

Page 42: Scrub Head Hinges

50 hours of caps. Snap the caps open to apply grease to the operation. Use a Lubriplate EMB grease (TENNANT fittings. Use a Lubriplate EMB grease (TENNANT Part No. 01433--1). -

Page 43: Hydraulics

For Gas/LPG (machines below serial number 007003) TENNANT’s hydraulic fluid is designed to meet the the reservoir holds up to 11.5 gal (44 L) of hydraulic special needs of its machines. -

Page 44: To Drain The Hydraulic Fluid Reservoir

3. Pour the new hydraulic fluid into the hydraulic fluid reservoir through a 200 mesh screened funnel. Watch the hydraulic fluid level on the sight gauge. Do not overfill the reservoir. TennantTrue Fluid Previous Fluid 550 MP148EN (3- -11) Home Find... Go To.. -

Page 45: Hydraulic Fluid Reservoir Breather

3. Unthread and discard the hydraulic fluid filter Use Cardboard To Locate Leaking elements. Hydraulic Fluid Under Pressure. NOTE: Discard all hydraulic fluid drained from the system. Drained hydraulic fluid may contain foreign material harmful to the hydraulic system. 550 MP148EN (3- -11) Home Find... Go To.. -

Page 46: Hydraulic Components Troubleshooting

Relief valve stuck Clean or replace relief valve Integral charge pump failure Replace charge pump Rotating group worn Replace rotating group Shaft failure Replace shaft Backplate worn Replace backplate Engine-to-pump coupling failure Replace coupling 550 MP148EN (5- -97) Home Find... Go To.. -

Page 47: Engine

Wear Eye And Ear Protection When Using 10W 30 Pressurized Air Or Water. The engine oil capacity for the Diesel Continental TMD27 engine (machines below serial number 006409) is 7 qt (6.6 L) with filter. 550 MP148EN (9- -08) Home Find... Go To.. -

Page 48: Air Intake System

The service indicator red line may return to a lower reading on the scale when the engine is shut off. The red line will return to a correct reading when the engine is started. 550 MP148EN (2- -99) Home Find... Go To.. -

Page 49: To Replace Air Filter Element

Use care so the fins are not damaged. Tighten the wing nut attaching the element. 353633 REMOVING AIR FILTER ELEMENT A. Filter Element B. Mounting Clamp C. Dust Cap D. Filter Housing 550 MP148EN (3- -05) Home Find... Go To.. -

Page 50: Continental Engines (For Machines Below Serial Number 006409)

WARNING: Engine Emits Toxic Gases. Severe Respiratory Damage Or Asphyxiation Can Result. Provide Adequate Ventilation. Consult With Your Regulatory Agency For Exposure Limits. Keep Engine Properly Tuned. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 51: Fuel System -- Gasoline -- Gm Engines

ELECTRONIC FUEL INJECTION WARNING: Engine Emits Toxic Gases. Severe Respiratory Damage Or Asphyxiation Can Result. Provide Adequate Ventilation. Consult With Your Regulatory Agency For Exposure Limits. Keep Engine Properly Tuned. 550 MP148EN (2- -06) Home Find... Go To.. -

Page 52: In--Line Fuel Filter --Gm Engines

Do not tamper with the relief valve setting. Vapor and Liquid Service Valves -- Check for proper functioning and presence of the handwheel. The valve must be closed except when in service. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 53: To Change An Lpg Fuel Tank

Take care to insure that the tanks are 8. Store the tank in a designated safe area. stored in such a way that if the safety relief valves do function, they will relieve vapor, rather than liquid. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 54: Fuel Filter Lock

400 hours or if diminished gas flow indicates the filter is clogged. A drain plug is provided for purging the filter bowl. Clean out the bowl when replacing the filter pack. 550 MP148EN (2- -06) Home Find... Go To.. -

Page 55: Lpg Fuel Troubleshooting

Replace filter Kinked or restricted fuel line Straighten or replace fuel line Engine out of tune Tune-up engine Restricted air filter Replace air filter element Vaporizer -- regulator maladjusted Adjust vaporizer -- regulator 550 MP148EN (2- -99) Home Find... Go To.. -

Page 56: Fuel System -- Diesel

After the fuel filter has been reassembled, it is B. Spigot necessary to remove air from the fuel system. See PRIMING THE FUEL SYSTEM. 7. Prime the fuel system as described in PRIMING THE FUEL SYSTEM. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 57: Continental Engines (For Machines Serial Number 005002--006408)

After the fuel filter has been reassembled, it is necessary to remove air from the fuel system. See PRIMING THE FUEL SYSTEM. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 58: Water Separator/Fuel Filter

Tighten injectors evenly to 52 ft lb (70 Nm). IN- -LINE FUEL FILTER - - PERKINS ENGINES (For machines serial number 006409 - - 007002) A. In- -Line Fuel Filter B. Fuel Pump 550 MP148EN (3- -05) Home Find... Go To.. - Page 59 When fuel flows free of air, tighten the connections. Stop operating the priming lever and place it in the vertical position. 550 MP148EN (3- -05) Home Find... Go To..

-

Page 60: Continental Engines (For Machines Serial Number 005002--006408)

3. Open the side and top engine access doors. cranking speed might still be good. 4. Loosen the vent screw on the top of the fuel 4. Start the engine. filter. 5. Turn the ignition switch on. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 61: To Adjust Governor, F163

This can be varied and the governor spring attached at operating tension. sensitivity of the governor is changed by Disconnect the governor spring and check movement changing the length of the sensitivity screw. of levers and rods. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 62: To Adjust Governor, Tm27

Turn the governor idle surge adjusting screw “in” or to the right until corrected. 5. Continue surging: This may indicate an excessive looseness or binding of the governor linkage, and sometimes too lean a fuel mixture. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 63: Governor -- Gas/Lp Gm Engines (For Machines Serial Number 006409 And Above)

2. Use a new seat gasket and screw the plug in by hand. 3. Tighten the spark plugs to 22 to 28 ft lb (30 to 38 Nm) with a socket wrench of the correct size. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 64: Distributor Ignition Timing

3. Connect the black primary negative lead to the cylinder head cap screw or the alternator bracket. Disconnect the vacuum line from the distributor to the manifold, and clamp the end of the line leading to the manifold. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 65: Cylinder Head -- Gasoline, Lpg

(90 degrees); then re-torque it to the correct value. NOTE: Power wrench torque limit must be held at least 10 ft lb (14 Nm) below hand torque specification; then hand torque to the specifications. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 66: Cylinder Head -- Diesel

Check the valve tappet clearance. NOTE: Power wrench torque limit must be held at least 10 ft lb (15 Nm) below hand torque specification; then hand torque to the specifications. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 67: Continental F163 Engines (For Machines Serial Number 003370--003933)

01473 ADJUSTING VALVE TAPPET CLEARANCE (For 00061 machines serial number 003934- -006408) ADJUSTING CONTINENTAL F163 VALVE TAPPET CLEARANCE (For machines serial number 003370- -003933) 550 MP148EN (12- -01) Home Find... Go To.. -

Page 68: Pcv System

0.035 in (0.9 mm) Timing, TM27 gasoline 15_ BTDC @ 1850 Timing, TM27 LPG 18_ BTDC @ 1850 Firing order 1--3--4--2 Valve clearances, TM27 intake 0.014 in warm (0.36 mm) exhaust 0.018 in (0.46 mm) 550 MP148EN (3- -05) Home Find... Go To.. -

Page 69: Electrical System

Avoid Contact With Battery Acid. If, when checking battery specific gravity, one or more battery cells tests lower than the other battery cells (0.050 or more), the cell is damaged, shorted, or is about to fail. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 70: Belts And Chains

A. Vacuum Fan Housing B. Tension Spring C. Tension Spring Eyebolt. D. Jam Nut E. Intermediate Drive Belt F. Vacuum Fan Drive Belt G. Belt Tension Bolt H. Belt Tension Adjusting Eye Bolt 550 MP148EN (3- -05) Home Find... Go To.. -

Page 71: Intermediate Drive Belt (For Machines Serial Number 003370 -- 004110)

FOR SAFETY: Before Leaving Or Servicing Machine; Stop On Level Surface, Set Parking Brake, And Turn Off Machine. 2. Open the left rear engine access door. 3. Loosen the alternator clamp bolt. 550 MP148EN (3- -05) Home Find... Go To.. -

Page 72: Scrub Head

With a soft B. Scrub Head Link brush the polish mark should not exceed 3 in (75 mm) wide, evenly, the full length of the brush. 550 MP148EN (5- -97) Home Find... Go To.. - Page 73 LEVELING BRUSH 00284 BRUSH SHAFT MOUNTING A. Top Nut B. Brush Leveling Adjusting Nut A. Scrub Head C. Operator Side of Scrub Head B. Shim C. Bearing Mounting Bracket D. Bearing Protector 550 MP148EN (5- -97) Home Find... Go To..

-

Page 74: Scrub Brushes

E. Raised Scrubber Head 9. Repeat the steps 7 and 8 for the other brush. 10. Unhook the chain and lower the access door. 11. Release the scrub head lock before lowering the scrub head. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 75: Solution System

Three clean-out doors are provided for the recovery damaged. tank; two at the front and one at the rear of the tank. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 76: Srs Water Spray Deflector

CORRECT POSITIONING OF LOWER SPRAY DEFLECTOR A. Spray Deflector Frames B. Spray Deflector C. Rear Squeegee Discharge Tube 00346 INSTALLING TOP SPRAY DEFLECTOR A. Solution Tank B. Top Access Cover C. Spray Deflector 550 MP148EN (5- -97) Home Find... Go To.. -

Page 77: Srs Solution Tank

NOTE: Keep laminar tube sections facing the outside filters. Check for dirt buildup in the laminar flow tubes. of the machine. To clean tubes, remove and flush. Also, check the return hoses and connections for clogging or damage. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 78: Solution Dispensing Tube

Remove pump inlet hose. b. Fill pump chamber with approximately one ounce SRS solution. c. Reinstall pump inlet hose. d. Pump should start metering tank solution after 3 to 4 minutes run time. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 79: Squeegees

The screw mounting holes are slotted, allowing vertical adjustment of the squeegee blade by simply loosening the screws and moving the squeegee up or down. Check the side squeegee blades adjustment daily. 550 MP148EN (5- -97) Home Find... Go To.. -

Page 80: To Replace Rear Squeegee Blades

004507 and above, the adjustment should be A. Band 6.00 + 0.12 in (150 + 3mm). B. Blade and Back-Up Strips on Pins C. Clamp 01725 SQUEEGEE LIFT CYLINDER A. Cylinder B. Adjustment Length 550 MP148EN (5- -97) Home Find... Go To.. - Page 81 0.06 in (6 + 2 mm) off the floor with the squeegee blade perpendicular to the floor. The tip casters should touch the floor with the squeegee blade perpendicular to the floor. 550 MP148EN (5- -97) Home Find... Go To..

- Page 82 M. Block Link E. Down Pressure Spring N. Cylinder Rod End F. Roller Switch O. Vacuum Hose Connection G. Fiberglide Washer P. Squeegee Frame H. Bearing Q. Lift Shaft Sleeve R. Caster 550 MP148EN (5- -97) Home Find... Go To..

- Page 83 MAINTENANCE 00196 REAR SQUEEGEE A. Adjuster F. Frame B. Spring Guide G. Rear Blade C. Front Band H. Back-Up Strip D. Front Blade Band E. Band Clamp 550 MP148EN (12- -01) Home Find... Go To..

-

Page 84: To Adjust Rear Squeegee

Press the directional pedal into the “reverse” direction. The squeegee should rise as soon as the machine moves backward. Press the directional pedal into the “forward” direction. The squeegee should lower. 550 MP148EN (12- -01) Home Find... Go To.. -

Page 85: Brakes And Tires

During the remaining steps, keep this end submerged at all times and never let the level in the brake fluid reservoir drop below one half full. 550 MP148EN (5- -01) Home Find... Go To.. -

Page 86: Options

Then change the oil every three months or at 500 hour intervals when using genuine Cat Pump Crankcase Oil. If other approved oil is used, change oil every month or at 200 hour intervals. 550 MP148EN (5- -01) Home Find... Go To..

Need help?

Do you have a question about the 550 and is the answer not in the manual?

Questions and answers