Kodak DryView 5800 Service Manual

Laser imager

Hide thumbs

Also See for DryView 5800:

- User manual (78 pages) ,

- Safety manual (22 pages) ,

- User manual (80 pages)

Table of Contents

Advertisement

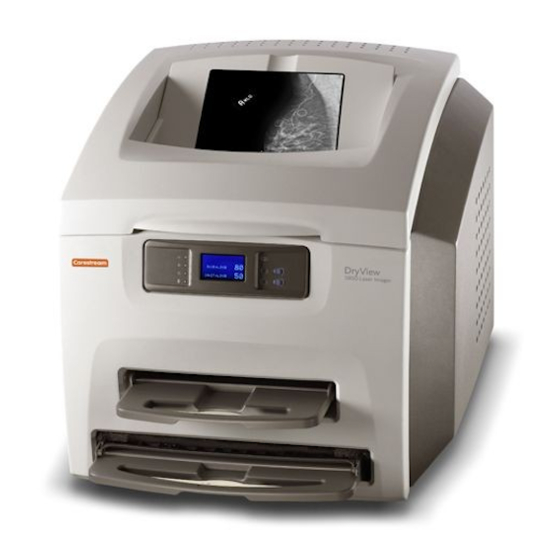

Kodak DryView 5800 LASER IMAGER

IMPORTANT

:

•

Qualified service personnel must install and repair this equipment.

•

When doing the procedures in this document, you must use safe work practices and wear the correct Personal

Protective Equipment (i.e., SAFETY EYEWEAR) according to your Company's Standard Operating

Procedures.

© Carestream Health, 2008

SERVICE MANUAL

for the

Service Code: 1115

Publication No. 2G0947

31JAN08

Advertisement

Table of Contents

Summary of Contents for Kodak DryView 5800

-

Page 1: Service Manual

Publication No. 2G0947 31JAN08 SERVICE MANUAL for the Kodak DryView 5800 LASER IMAGER Service Code: 1115 IMPORTANT • Qualified service personnel must install and repair this equipment. • When doing the procedures in this document, you must use safe work practices and wear the correct Personal Protective Equipment (i.e., SAFETY EYEWEAR) according to your Company’s Standard Operating... - Page 2 PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the subject matter gained by Carestream Health, Inc. prior to publication. No patent license is granted by this information. Carestream Health, Inc. reserves the right to change this information without notice, and makes no warranty, express or implied, with respect to this information.

-

Page 3: Table Of Contents

Table of Contents Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1-1 Installation Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1 Packing List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1 Necessary Materials - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2-1... - Page 4 PROCESSOR COVER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-29 BELT, DRUM DRIVE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-30 MOTOR, DRUM DRIVE (M8) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-31 FAN AY, PROCESSOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-32...

- Page 5 Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1 Using the SERVICE SWITCH - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-1 LOCAL PANEL LEDs and Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-2 LOCAL PANEL Icons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-3...

- Page 6 Condition Code: 06-430 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-34 Condition Code: 06-440 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-35 Condition Code: 06-500 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-35 Condition Code: 06-501 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-36...

- Page 7 Condition Code: 21-632 or 23-632 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-77 Condition Code: 25-922 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-78 Condition Code: 25-931 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-78 Condition Code: 25-932 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-79...

- Page 8 Functions of the MICRO BOARD LEDs and Test Points - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-114 FILM PATH MICROCONTROLLER (FPM) BOARD - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-114 PROCESSOR CONTROL BOARD (PCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-117 Densitometer Control Board (DCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-118 MOTORS and SENSORS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-119...

-

Page 9: Safety Information

Section 1: Safety Information Before doing the installation, read the Safety Manual for the Kodak DryView 5800 LASER IMAGER, 2G0734. The following information defines the safety and information icons used in this publication. LASER WARNING This icon is used for conditions that could cause injury to a person, or damage to equipment or software data. -

Page 11: Installation Instructions

Getting Started with the Kodak DryView 5800 LASER IMAGER 2G0734 Safety Manual for the Kodak DryView 5800 LASER IMAGER 2G1249 CD - USER DOCUMENTATION for the Kodak DryView 5800 LASER IMAGER SP2G0987 FILM TRAY AY - 10 x 8 in. SP2G0986 FILM TRAY AY - 14 x 17 in. -

Page 12: Connecting The Laptop Computer To The Imager

Installation Instructions Connecting the LAPTOP COMPUTER to the IMAGER TOP COVER 2 Captive THUMB SCREWS RIGHT PANEL 1. Open the TOP COVER. 2. Loosen the 2 Captive THUMB SCREWS. 3. Remove the RIGHT PANEL. Service port 4. Connect one end of the CROSSOVER CABLE to the LAPTOP COMPUTER and the other end to the service port on the IMAGER. -

Page 13: Energizing The Imager

Installation Instructions Energizing the IMAGER RISK OF ELECTRIC SHOCK Dangerous voltage present. 1. Check that the AC POWER CORD is connected into the back of the IMAGER and into the wall OUTLET. CAUTION Double Pole/Neutral Fusing. 2. Press the POWER SWITCH on the IMAGER to the ON position. De-energizing the IMAGER CAUTION Double Pole/Neutral Fusing. -

Page 14: Logging Onto The Service Tool

The main menu of the SERVICE TOOL displays. Logging Off the SERVICE TOOL 1. In the right corner of the SERVICE TOOL, click [Log Off]. 2. At the Kodak Service WebLink screen, click [Log Off]. 3. Close the WebLink Client Software. 4. At the Secure Link screen: •... -

Page 15: Doing The Mechanical Setup

Installation Instructions Doing the Mechanical Setup Completing the Uncrating 1. Locate and remove the box that has the DOCUMENTATION and CABLES. 2. Remove the other boxes that have the 2 FILM TRAYS and FILTERS. 3. Remove the SIDE PANELS from the CRATE. FOIL BAG 4. -

Page 16: Checking The Accessories

Installation Instructions 7. Lift the BRACKET up and remove it. 8. Do Step 6 Step 7 for the other BRACKETS. CAUTION The Imager is 70 kg (155 lbs). Lift point front Lift point back 9. Using safe "lifting techniques", lift the IMAGER from the shipping pallet at the locations shown above. -

Page 17: Moving The Imager

Installation Instructions Moving the IMAGER 1. Move the IMAGER and accessories to the installation area. 2. Position the IMAGER to allow a space of at least 1 m (39 in.) at the back of the IMAGER for installation of the POWER CORD and NETWORK CABLE. - Page 18 Installation Instructions TOP COVER 2 Captive THUMB SCREWS RIGHT PANEL 4. Loosen 2 Captive THUMB SCREWS. 5. Remove the RIGHT PANEL. 6. Close the TOP COVER. 10 SCREWS BACK PANEL 1. At the back of the IMAGER, remove: • 10 SCREWS •...

- Page 19 Installation Instructions Installed for shipping SHIPPING WASHER Installed for storing OPTICS AY 2. Remove the 2 SHIPPING WASHERS from the back of the OPTICS AY. 3. Store the SHIPPING WASHERS by "pushing" the WASHERS onto the PINS below the BAR. 4.

- Page 20 Installation Instructions TOP COVER CHARCOAL FILTER FRONT PANEL 8. Install the CHARCOAL FILTER. 9. Close: • FRONT PANEL • TOP COVER 10. Open the package of electrical accessories. IMPORTANT The 5800 IMAGER will automatically detect the AC power line voltage and will automatically configure itself for the applied voltage.

- Page 21 Installation Instructions One of the following single-phase, 15 A power sources, with grounding, must be provided within 2.5 m (8 ft) of the Imager. • 120 V AC +6% to -10%, 60 Hz ±3Hz 240 V AC ±10%, 50 Hz ±3Hz •...

- Page 22 Installation Instructions POWER SWITCH 13. Energize the IMAGER by pressing the POWER SWITCH to the ON position. Wait for the "startup" to complete. 14. Install the 2 FILM TRAYS. NOTE: Do not install film or the FILM SAVERS at this time. 15.

-

Page 23: Doing The Configuration

Installation Instructions Doing the Configuration IMPORTANT You must restart the IMAGER from the SERVICE TOOL in order to permanently save configuration information. Setting the Language IMPORTANT The language is set by the customer in the WEB PORTAL. Checking the Values for the DICOM Source Communications 1. -

Page 24: Setting The Imager To Be A Destination

Installation Instructions Setting the IMAGER to be a Destination 1. Select Configuration>DICOM SCP>Destination. IMPORTANT The AE Title, is the name by which the modalities will recognize the IMAGER. 2. Check with the customer to determine the AE Title to be used. 3. - Page 25 Installation Instructions 6. In the Available field, select the check box next to the Media Type to be used. NOTE: Under normal operations, all media types should be allowed. 7. Select the "Page and Image Options" tab. NOTE: Do not disable any of the "Page Formatting" settings of the IMAGER except if instructed by the customer.

-

Page 26: Setting The System Clock

Installation Instructions Setting the System Clock 1. Select Configuration>System>Clock. IMPORTANT The System Clock is set in the FACTORY. At installation, the Time Zone has to be reset if the IMAGER is installed in some other Time Zone. When you reset the Time Zone value, the Time and Date should display correctly. - Page 27 Installation Instructions 4. Is the Time value correct? Continue with Step a. Click [Modify]. b. Select a field and use the "arrows" to increase or decrease the time. c. Click [Save]. d. Continue with Step 5. Is the Date correct: Advance to Step Continue with...

- Page 28 Installation Instructions 16. Click [Modify]. 17. Select the "Enable time synchronization" check box. 18. In the IP Address field, type the address of the time SERVER to be used for synchronization. 19. Select the synchronization period (how often the clock is synchronized) from the drop-down menu.

-

Page 29: Setting The Host Name And The Ip Address

Installation Instructions Setting the Host Name and the IP Address 1. Obtain from the customer the Host Name, IP Address, Subnet, and Gateway for the LASER IMAGER. 2. Select Configuration>System>Network. 3. Click [Modify]. IMPORTANT The Host Name is the network name for this IMAGER. It can be a maximum of 14 characters and a minimum of one. -

Page 30: Setting Up Service Tracking

Installation Instructions Setting up Service Tracking 1. Select System Information>Identification. 2. Click [Modify]. IMPORTANT The values for Serial Number, K-Number, Windows OS ID, and Service Code are set at the FACTORY. • Model Name - set at the FACTORY, and can not be changed. •... -

Page 31: Loading Customer Film

Installation Instructions 5. Select Utilities>Session>Restart. 6. Click [Restart]. Wait for the IMAGER to restart. 7. Continue with “Loading Customer Film”. Loading Customer Film 1. Load customer film into the FILM SUPPLY. 2. Install the FILM SUPPLY. 3. Continue with “Checking the Installed Hardware and Film Type”. -

Page 32: Doing The Scp Services Configuration

Installation Instructions Doing the SCP Services Configuration 1. Have each SCU send an image to make a connection with the IMAGER. 2. Select Configuration>DICOM SCP>SCP Configuration. 3. When the SCP Configuration screen appears, select the "SCP Config AutoSetup" tab. Note: •... -

Page 33: Checking Image Quality

Installation Instructions Checking Image Quality 1. Ask the customer to send images from the modalities to the IMAGER. 2. Check for image skew. If necessary, adjust the IMAGING AY (see Adjustments And Replacements, “IMAGING AY - Alignment” on page 3-5). 3. - Page 34 • Tables Specification for TFT Sets, 8F5224 • MetalutsB TFTShop and the 2 documents above are located on the intranet at: http://know.us.kodak.com/audience_fe001/stage/global/en/Health-Me dical/Digital_Output/index.shtml#Tools. c. Check the quality of an image sent down from the SCU. d. If necessary, change the parameters.

- Page 35 Installation Instructions 12. Select the parameters. Note: • The value selected will be the default for this SCU. • The field to the right of the parameter value is an indication of whether the parameter value sent from the SCU will be "overridden". If you select "Always Apply", the parameter on the screen will "override"...

-

Page 36: Editing The Service History Log

Installation Instructions Editing the Service History Log 1. Select System Information>Service History. 2. Click [Modify]. Note: The following fields on the screen are filled in automatically: DateTime, Service Code, and your UserID and UserName for "Secure Tunnel". 3. Type data about the installation in the other fields. 4. -

Page 37: Configuring The Carestream Remote Management Services

Installation Instructions Configuring the CARESTREAM REMOTE MANAGEMENT SERVICES 1. Will the CARESTREAM REMOTE MANAGEMENT SERVICES be enabled on the IMAGER? Continue with Step Advance to Step 2. Select Configuration>System>Remote Management. 3. Select the "Identification" tab. 4. Are all fields filled in correctly?. Continue with Step a. - Page 38 Installation Instructions 6. Does the customer use a proxy SERVER? a. Click [Modify]. a. Check that the Proxy Type field is none. b. Select the Proxy Type from the drop-down menu. b. Continue with Step c. Type the information for: Proxy Address Proxy Port Number Proxy Username...

- Page 39 Installation Instructions 9. Do all of the "Asset Names" begin with the correct K-Number and Country Code? Continue with Step a. Return to “Setting up Service Tracking”. b. Check all entries and save the screen. c. Return to this screen. d.

- Page 40 Installation Instructions 11. Click [Modify]. 12. In the "Remote Services Activation" block, select "Remote Monitoring and Remote Access" from the drop-down menu. 13. Click: • [Save] • [Start] Note: The 2 fields in the Status block will change when the IMAGER is "registered"...

-

Page 41: Backing Up The System Configuration

Installation Instructions Backing Up the System Configuration 1. Select Utilities>Backup/Restore. 2. To make a backup of the configuration parameters to the DRE HARD DRIVE, click [Backup]. 3. To download the backup data to your LAPTOP COMPUTER, do: a. Click [Download Backup]. b. -

Page 42: Instructing The Operator

1. Instruct the operator about changing the CHARCOAL FILTER. 2. Instruct the operator to read the Safety Manual, 2G0734 and User Guide, 2G0733, for the Kodak DryView 5800 LASER IMAGER. Using the Default Passcode All IMAGERS from the FACTORY are set for the following default Passcodes: •... -

Page 43: Adjustments And Replacements

Section 3: Adjustments and Replacements Adjustments PROCESSOR - DRUM Temperature Adjustment Specification Purpose: To set the correct temperature for the DRUM. Setting Temperature: This procedure is required after replacing the PROCESSOR AY, PROCESSOR DRUM, or the DRE BOARD, or if you expect that DRUM temperatures are causing image quality problems. - Page 44 Adjustments and Replacements BLOCK 203.2 mm (8.00 in.) PROBE SENSOR PROBE METER 2. Prepare the METER: a. Install the BLOCK on the PROBE 203.2 mm (8.00 in.) from the PROBE SENSOR. b. Clean the PROBE with ALCOHOL WIPES. c. Set the METER to display in ° C. 3.

- Page 45 Adjustments and Replacements PROCESSOR AY DRUM SLOT PROBE 4. Insert the PROBE into the slot on the right back of the PROCESSOR AY and let the rotation of the PROCESSOR DRUM pull the PROBE until the BLOCK reaches the slot. 5.

- Page 46 Adjustments and Replacements To Adjust 1. Log on to the SERVICE TOOL (see Installation Instructions, “Logging Onto the SERVICE TOOL” on page 2-4). 2. Select Configuration>Hardware>Processor Configuration. 3. In the "Temperature" field, enter the temperature measured by the METER. Note: The "Offset"...

-

Page 47: Imaging Ay - Alignment

Adjustments and Replacements IMAGING AY - Alignment Adjustment Specification Purpose: To align the image on the film. Specification: The image is aligned. Special Tools: None Prerequisites Remove the “BACK PANEL”. To Check 1. Make a test print. 2. Check that the image is not skewed on the film. To Adjust IMAGING AY SPRING AY... - Page 48 Adjustments and Replacements 6. Push the ALIGNMENT PINS into the down position. 7. Make a test print. If the image is skewed, repeat the adjustment procedure until the skew is eliminated. 2G0947 - 31JAN08...

-

Page 49: Imaging Ay - Start Index Delay, Start Of Scan

Adjustments and Replacements IMAGING AY - Start Index Delay, Start of Scan Adjustment Specification Purpose: To adjust Start of Scan timing to center an image left to right on the film. Specification: Borders on the left and right of the image should be equal. •... - Page 50 Adjustments and Replacements To Adjust 1. Select Configuration>Hardware>Optics. 2. Observe the number displayed in the "Index Delay" window. NOTE: There are 2 Index Delay adjustments depending on the width of the film: • When viewing the film on a LIGHT BOX, the notch on the film must be in the upper right.

-

Page 51: Imaging Ay - Page Start Delay, Start Of Page

Adjustments and Replacements IMAGING AY - Page Start Delay, Start of Page Adjustment Specification Purpose: To adjust Start of Page timing to obtain a 2 mm (0.08 in.) half-tone density border at the leading edge of the film. Specification: A 2 mm (0.08 in.) half-tone border only is visible at the leading edge of the film. •... - Page 52 Adjustments and Replacements Printing above half-tone border Virtual notch Virtual notch Correct Incorrect 2 mm (0.08 in.) half-tone density border 5. Check for a 2 mm (0.08 in.) half-tone density at the leading edge of the film with no transparent area appearing. To Adjust 1.

- Page 53 Adjustments and Replacements 3. To: Decrease the top border on the test print, do: Increase the top border on the test print, do: a. Click [Modify] and decrease the number in the a. Click [Modify] and increase the number in the "Page "Page Start Delay"...

-

Page 54: Replacements

Adjustments and Replacements Replacements LEFT PANEL Prerequisites: None. To Remove: 1. De-energize the IMAGER (see Installation Instructions, “De-energizing the IMAGER” on page 2-3). TOP COVER LEFT PANEL 2 Captive THUMB SCREWS 2. Open the TOP COVER. 3. Loosen the 2 Captive THUMB SCREWS. 4. -

Page 55: Right Panel

Adjustments and Replacements RIGHT PANEL Prerequisites: None. To Remove: 1. De-energize the IMAGER (see Installation Instructions, “De-energizing the IMAGER” on page 2-3). TOP COVER 2 Captive THUMB SCREWS RIGHT PANEL 2. Open the TOP COVER. 3. Loosen the 2 Captive THUMB SCREWS. 4. -

Page 56: Back Panel

Adjustments and Replacements BACK PANEL Prerequisites: Remove: • “LEFT PANEL” • “RIGHT PANEL” To Remove: 1. Disconnect: • NETWORK CABLE • POWER CORD POWER CORD NETWORK CABLE 10 SCREWS BACK PANEL 2. Remove 10 SCREWS. 3. Lift the BACK PANEL from the IMAGER. To Install: IMPORTANT When replacing the BACK PANEL you must install an "Agency Statements"... -

Page 57: Top Cover

Adjustments and Replacements TOP COVER Prerequisites: Remove the “BACK PANEL”. To Remove: TOP COVER SUPPORT ARM SCREW 1. Open the TOP COVER. 2. Lock the SUPPORT ARM. 3. Remove: • • SCREW 4. Close the TOP COVER. 2G0947 - 31JAN08 3-15... - Page 58 Adjustments and Replacements 2 SCREWS 5. At the back of the IMAGER remove 2 SCREWS. 6. Shift the TOP COVER 1.27 cm (0.5 in.) to the left and lift from the IMAGER. To Install: 1. Reverse the steps in the removal procedure. 3-16 2G0947 - 31JAN08...

-

Page 59: Front Panel

Adjustments and Replacements FRONT PANEL Prerequisites: Remove the FILM TRAYS. To Remove: 1. De-energize the IMAGER (see Installation Instructions, “De-energizing the IMAGER” on page 2-3). 2 SCREWS TOP COVER 2 LANYARDS FRONT PANEL LOCAL PANEL CONNECTOR 2. Open: • TOP COVER •... -

Page 60: Local Panel Ay

Adjustments and Replacements LOCAL PANEL AY Prerequisites: Remove the “FRONT PANEL”. To Remove: LIGHT SHIELD 6 SCREWS FRONT PANEL ELECTRONICS BOARD CONTROL PANEL CONNECTOR 1. Disconnect the CONNECTOR. 2. Remove 6 SCREWS holding the CONTROL PANEL, ELECTRONICS BOARD and LIGHT SHIELD to the FRONT PANEL. 3. -

Page 61: Switch, Interlock - Left And Right Panels

Adjustments and Replacements SWITCH, INTERLOCK - LEFT and RIGHT PANELS Prerequisites: None. To Remove: 1. De-energize the IMAGER (see INSTALLATION INSTRUCTIONS, “De-energizing the IMAGER” on page 2-3). IMPORTANT This procedure is used for both LEFT and RIGHT PANEL INTERLOCK SWITCHES. 2 SCREWS 2 BUMPERS TOP COVER... - Page 62 Adjustments and Replacements CONNECTOR INTERLOCK SWITCH HOUSING 4. Disconnect the CONNECTOR. 5. Remove: • 2 SCREWS • HOUSING • INTERLOCK SWITCH To Install: 1. Reverse the steps in the removal procedure. 3-20 2G0947 - 31JAN08...

-

Page 63: Switch, Interlock - Top Cover

Adjustments and Replacements SWITCH, INTERLOCK - TOP COVER Prerequisites: Remove the “RIGHT PANEL”. To Remove: TOP COVER INTERLOCK SWITCH CONNECTOR SWITCH COVER 2 SCREWS 1. Remove: • 2 SCREWS • SWITCH COVER • INTERLOCK SWITCH 2. Disconnect the CONNECTOR. To Install: 1. -

Page 64: Switch, Service

Adjustments and Replacements SWITCH, SERVICE Prerequisites: None. To Remove: SCREW (SERVICE SWITCH Activator) 4 CONNECTORS SERVICE SWITCH 2 SCREWS 1. Open: • TOP COVER • FRONT PANEL 2. Remove: • 2 SCREWS • SERVICE SWITCH 3. Disconnect the 4 CONNECTORS. To Install: 1. -

Page 65: Processor Ay

Adjustments and Replacements PROCESSOR AY Prerequisites: Remove: • “BACK PANEL” • “FRONT PANEL” • “TOP COVER” • “PROCESSOR DRUM” • “PROCESSOR COVER” To Remove: 2 SCREWS RIGID DUCT 1. From the right side of the IMAGER, remove: • 2 SCREWS •... - Page 66 Adjustments and Replacements 2 SCREWS 2 BUMPERS LIGHT SHIELD 2. Remove: • 2 SCREWS • 2 BUMPERS • LIGHT SHIELD 3-24 2G0947 - 31JAN08...

- Page 67 Adjustments and Replacements 5 SCREWS 3. Disconnect the 6 CONNECTORS from the PROCESSOR AY. 4. Cut the TIE WRAPS. 5. Remove 5 SCREWS. CAUTION Hot Surface When the IMAGER is initially de-energized, the PROCESSOR DRUM and ROLLERS are hot. Take care when removing the DRUM. 2G0947 - 31JAN08 3-25...

- Page 68 Adjustments and Replacements STEEL ROD INLET SHIELD 6. To remove the PROCESSOR AY: a. Put 1 hand under the INLET SHIELD. b. Grip the STEEL ROD near the FRAME. c. Lift and place the PROCESSOR AY on a flat, stable surface. To Install: IMPORTANT To prevent damage to CABLES, install new TIE WRAPS in place of those that...

-

Page 69: Processor Drum

Adjustments and Replacements PROCESSOR DRUM Prerequisites: Remove: • “LEFT PANEL” • “RIGHT PANEL” To Remove: DRUM PULLEY DRUM DRIVE BELT DRUM CABLE TIE WRAP CONNECTOR PROCESSOR CONTROL BOARD 2 SCREWS RIGID DUCT 1. Remove: • 2 SCREWS • RIGID DUCT 2. - Page 70 Adjustments and Replacements CAUTION Hot Surface When the IMAGER is initially de-energized, the PROCESSOR DRUM and ROLLERS are hot. Take care when removing the PROCESSOR DRUM. PROCESSOR DRUM 2 LATCHES PROCESSOR COVER 5. Release the 2 LATCHES. 6. Open the PROCESSOR COVER. CAUTION •...

-

Page 71: Processor Cover

Adjustments and Replacements PROCESSOR COVER Prerequisites: Remove the “BACK PANEL”. To Remove: CAUTION Hot Surface When the IMAGER is initially de-energized, the PROCESSOR DRUM and ROLLERS are hot. Take care when working in the area of the PROCESSOR. PROCESSOR COVER 2 LATCHES 1. -

Page 72: Belt, Drum Drive

Adjustments and Replacements BELT, DRUM DRIVE Prerequisites: Remove the “RIGHT PANEL”. To Remove: DRUM PULLEY DRUM DRIVE BELT BELT TENSIONER EXIT PULLEY EXIT DRIVE BELT CONNECTOR PROCESSOR CONTROL BOARD 2 SCREWS RIGID DUCT 1. Remove: • 2 SCREWS • RIGID DUCT 2. -

Page 73: Motor, Drum Drive (M8)

Adjustments and Replacements MOTOR, DRUM DRIVE (M8) Prerequisites: Remove the “RIGHT PANEL”. To Remove: EXIT PULLEY EXIT DRIVE BELT 3 STANDOFFS MOTOR CONNECTOR 3 SCREWS 1. Disconnect the CONNECTOR. 2. Disengage the EXIT DRIVE BELT from the EXIT PULLEY. 3. Loosen the 3 SCREWS so they are no longer in the STANDOFFS. 4. -

Page 74: Fan Ay, Processor

Adjustments and Replacements FAN AY, PROCESSOR Prerequisites: Remove the “PROCESSOR AY”. To Remove: 2 SCREWS CONNECTOR FAN AY Left Side of IMAGER 1. Disconnect the CONNECTOR. 2. Remove: • 2 SCREWS • FAN AY To Install: 1. Reverse the steps in the removal procedure. 3-32 2G0947 - 31JAN08... -

Page 75: Film Diverter Ay And Felt Pad Ay

Adjustments and Replacements FILM DIVERTER AY and FELT PAD AY Prerequisites: None To Remove: CAUTION Hot Surface When the IMAGER is initially de-energized, the PROCESSOR DRUM and ROLLERS are hot. Take care when working in the area of the PROCESSOR. HEAT SHIELD 2 SCREWS FELT PAD AY... - Page 76 Adjustments and Replacements 4. Install the new FILM DIVERTER AY and FELT PAD AY, but do not tighten the 2 SCREWS. 5. Push: • the FILM DIVERTER AY away from the PROCESSOR DRUM • the FELT PAD AY against the 2 SCREWS 6.

-

Page 77: Processor Gasket

Adjustments and Replacements PROCESSOR GASKET Prerequisites: None To Remove: NOTE: There are 2 GASKETS, 1 on the HEAT SHIELD and 1 on the INLET SHIELD. To remove the GASKET on the HEAT SHIELD: TOP COVER 2 LATCHES HEAT SHIELD GASKET HEAT SHIELD 1. - Page 78 Adjustments and Replacements To remove the GASKET on the INLET SHIELD: 2 SCREWS INLET SHIELD GASKET 1. Remove: • “PROCESSOR COVER” • 2 SCREWS • INLET SHIELD 2. Pull off the old GASKET. To Install: 1. Use ALCOHOL WIPES to clean the adhesive from the GASKETS. 2.

-

Page 79: Processor Rollers

Adjustments and Replacements PROCESSOR ROLLERS Prerequisites: Remove the “PROCESSOR COVER”. To Remove: ROLLER PROCESSOR COVER BEARING RETAINER SPRING IMPORTANT The BEARINGS on the ends of each ROLLER are loose. Take care not to lose the BEARINGS or the SPRINGS in the RETAINER. 1. -

Page 80: Densitometer Ay

Adjustments and Replacements DENSITOMETER AY Prerequisites: None. To Remove: 2 SCREWS TOP COVER 2 BUMPERS LIGHT SHIELD FRONT PANEL 1. Open: • TOP COVER • FRONT PANEL 2. Remove: • 2 SCREWS • 2 BUMPERS • LIGHT SHIELD 3-38 2G0947 - 31JAN08... - Page 81 Adjustments and Replacements EXIT TRAY CONNECTOR 3 TIE WRAPS FILM GUIDE 2 SCREWS 3. Disconnect the CONNECTOR from the DENSITOMETER. 4. Remove: • 2 SCREWS • EXIT TRAY 5. Cut the 3 TIE WRAPS to disengage the WIRES from the FILM GUIDE. 2G0947 - 31JAN08 3-39...

- Page 82 Adjustments and Replacements 2 SCREWS FILM GUIDE DENSITOMETER 4 SCREWS 6. Remove • 2 SCREWS • FILM GUIDE • 4 SCREWS • DENSITOMETER To Install: 1. Reverse the steps in the removal procedure. 3-40 2G0947 - 31JAN08...

-

Page 83: Turnaround Drive Shaft, Drive Wheel And Hubs

Adjustments and Replacements TURNAROUND DRIVE SHAFT, DRIVE WHEEL and HUBS Prerequisites: Remove: • “RIGHT PANEL” • “LEFT PANEL” • “FRONT PANEL” • CHARCOAL FILTER To Remove: 2 SCREWS 2 BUMPERS LIGHT SHIELD 1. Remove: • 2 SCREWS • 2 BUMPERS •... - Page 84 Adjustments and Replacements CONNECTOR EXIT TRAY 2 SCREWS 2. Disconnect the CONNECTOR to the DENSITOMETER. 3. Remove: • 2 SCREWS • EXIT TRAY 3-42 2G0947 - 31JAN08...

- Page 85 Adjustments and Replacements 2 E-RINGS BEARING 3 BELTS ROLLERS DRIVE SHAFT PULLEY TURNAROUND DRIVE BELT 4. Slide the 3 BELTS off the ROLLERS. 5. Disengage the TURNAROUND DRIVE BELT from the PULLEY. 6. Remove: • 2 E-RINGS (1 on the outside of the PULLEY and 1 from inside the FRAME) •...

- Page 86 Adjustments and Replacements 3 E-RINGS DRIVE SHAFT DRIVE WHEEL and DRIVE WHEEL COVER 2 HUBS 8. Remove: • 3 E-RINGS • 2 HUBS • DRIVE WHEEL and DRIVE WHEEL COVER To Install: 1. Reverse the steps in the removal procedure. 3-44 2G0947 - 31JAN08...

-

Page 87: Turnaround Idler Shafts And Rollers

Adjustments and Replacements TURNAROUND IDLER SHAFTS and ROLLERS Prerequisites: Remove: • “RIGHT PANEL” • “LEFT PANEL” • “FRONT PANEL” • CHARCOAL FILTER To Remove: IMPORTANT This procedure is used for all 3 IDLER SHAFTS and the 9 ROLLERS. 2 SCREWS 2 BUMPERS LIGHT SHIELD 1. - Page 88 Adjustments and Replacements INTERLOCK SWITCH Left side of IMAGER E-RING IDLER ROLLERS 3 BELTS SHAFT 4. Slide the 3 BELTS off the ROLLERS. 5. Remove the E-RING from the inside left of the IDLER SHAFT. NOTE: For the upper IDLER SHAFT you should remove the LEFT PANEL INTERLOCK SWITCH (see “SWITCH, INTERLOCK - LEFT and RIGHT PANELS”...

-

Page 89: Motor, Turnaround Roller Drive (M9)

Adjustments and Replacements MOTOR, TURNAROUND ROLLER DRIVE (M9) Prerequisites: Remove: • “FRONT PANEL” • “RIGHT PANEL” • CHARCOAL FILTER To Remove: BELT E RING PULLEY 4 SCREWS CONNECTOR TURNAROUND MOTOR 1. Disconnect the CONNECTOR. 2. Remove: • E RING • BELT •... -

Page 90: Film Feed

Adjustments and Replacements FILM FEED AY Prerequisites: Remove: • “BACK PANEL” • “PICKUP AY - UPPER” To Remove: ALIGNMENT PIN (down position) IMPORTANT Verify that the OPTICS AY ALIGNMENT PINS are in the down position. 3-48 2G0947 - 31JAN08... - Page 91 Adjustments and Replacements 2 SCREWS RIGID DUCT 2. On the right side of the IMAGER, remove: • 2 SCREWS • RIGID DUCT 2 SCREWS ELECTRONICS BRACKET 3. Remove2 SCREWS. 4. Open the ELECTRONICS BRACKET. 2G0947 - 31JAN08 3-49...

- Page 92 Adjustments and Replacements SCREWS SCREWS 5. Remove 4 SCREWS. 3-50 2G0947 - 31JAN08...

- Page 93 Adjustments and Replacements 2 SCREWS LIGHT SHIELD SCREW EXHAUST DUCT 6. From the left side of the IMAGER, remove: • 2 SCREWS • LIGHT SHIELD • SCREW • EXHAUST DUCT 4 CONNECTORS 7. Disconnect the 4 CONNECTORS. 2G0947 - 31JAN08 3-51...

- Page 94 Adjustments and Replacements IMPORTANT Cut TIE WRAPS that secure the FILM TRANSPORT HARNESS to the IMAGER FRAME AY 6 SCREWS FILM FEED AY 8. Remove 6 SCREWS. IMPORTANT Remove slowly, moving electrical harnesses out of the way. 9. Slide the FILM FEED AY out the left side of the IMAGER and place it on a flat, stable surface.

-

Page 95: Motor, Feed Roller Nip Open/Close (M1)

Adjustments and Replacements MOTOR, FEED ROLLER NIP OPEN/CLOSE (M1) Prerequisites: Remove: • “BACK PANEL” • “LEFT PANEL” To Remove: CONNECTOR FEED ROLLER BELT NIP OPEN/CLOSE MOTOR E RING PULLEY 4 SCREWS Left Side Back 1. Disconnect the CONNECTOR. 2. Remove: •... -

Page 96: Motor, Nip Position Drive (M2)

Adjustments and Replacements MOTOR, NIP POSITION DRIVE (M2) Prerequisites: Remove: • “BACK PANEL” • “RIGHT PANEL” To Remove: MOTOR CONNECTOR 4 CIRCUIT BREAKER CONNECTORS NIP POSITION MOTOR 4 SCREWS BELT TENSIONER Back of IMAGER SCREW 1. Disconnect: • MOTOR CONNECTOR •... -

Page 97: Feed Roller Nip Drive Belt

Adjustments and Replacements FEED ROLLER NIP DRIVE BELT Prerequisites: Remove the “RIGHT PANEL”. To Remove: 2 SCREWS ELECTRONICS BRACKET 1. Remove 2 SCREWS. 2. Open the ELECTRONICS BRACKET. 2G0947 - 31JAN08 3-55... - Page 98 Adjustments and Replacements 4 CONNECTORS TENSIONER SCREW BELT 3. Disconnect the 4 CONNECTORS for the CIRCUIT BREAKERS. 4. Loosen TENSIONER SCREW. 5. Remove the BELT. To Install: 1. Reverse the steps in the removal procedure. 3-56 2G0947 - 31JAN08...

-

Page 99: Nip Roller Set Ay - Upper

Adjustments and Replacements NIP ROLLER SET AY - UPPER Prerequisites: Remove the “ FEED ROLLER NIP DRIVE BELT“ To Remove: 4 SCREWS CAM ARM E-RING 1. Remove: • E-RING • CAM ARM • 4 SCREWS To Install: 1. Reverse the steps in the removal procedure. 2G0947 - 31JAN08 3-57... -

Page 100: Nip Roller Set Ay - Lower

Adjustments and Replacements NIP ROLLER SET AY - LOWER Prerequisites: Remove the “ FEED ROLLER NIP DRIVE BELT“ To Remove: IMPORTANT This procedure is used for both UPPER and LOWER NIP ROLLER AY. 4 SCREWS UPPER FILM GUIDE 1. Remove: •... - Page 101 Adjustments and Replacements 4 SCREWS CAM ARM E-RING 2. Remove: • E-RING • CAM ARM • 4 SCREWS To Install: 1. Reverse the steps in the removal procedure. 2G0947 - 31JAN08 3-59...

-

Page 102: Film Separation Fan Ay - Upper

Adjustments and Replacements FILM SEPARATION FAN AY - UPPER Prerequisites: Remove the “FILM FEED AY”. To Remove: 4 SCREWS UPPER FILM GUIDE 1. Remove: • 4 SCREWS • FILM GUIDE 3-60 2G0947 - 31JAN08... - Page 103 Adjustments and Replacements SCREW CONNECTOR 2. Disconnect the CONNECTOR. 3. Remove the SCREW. 4. Lift the FAN off the PIN. To Install: 1. Reverse the steps in the removal procedure. 2G0947 - 31JAN08 3-61...

-

Page 104: Film Separation Fan Ay - Lower

Adjustments and Replacements FILM SEPARATION FAN AY - LOWER Prerequisites: Remove the “BACK PANEL”. To Remove: CONNECTOR 2 SCREWS 1. Disconnect the CONNECTOR. 2. Remove 2 SCREWS. To Install: 1. Reverse the steps in the removal procedure. 3-62 2G0947 - 31JAN08... -

Page 105: Film Separation Fan Filter

Adjustments and Replacements FILM SEPARATION FAN FILTER Prerequisites: Remove the “BACK PANEL”. To Remove: FILTER 1. Pull the FILTER off the PLENUM. NOTE: The FILTER is held on by an adhesive and may require scraping the PLENUM to remove. To Install: 1. -

Page 106: Cam Ay, Cassette Registration - Upper (M6U)

Adjustments and Replacements CAM AY, CASSETTE REGISTRATION - UPPER (M6U) Prerequisites: Remove the “FILM FEED AY”. To Remove: 2 SCREWS CONNECTOR CAM AY 1. Disconnect the CONNECTOR. 2. Remove: • 2 SCREWS • CAM AY To Install: 1. Reverse the steps in the removal procedure. 3-64 2G0947 - 31JAN08... -

Page 107: Cam, Ay Cassette Registration - Lower (M6L)

Adjustments and Replacements CAM, AY CASSETTE REGISTRATION - LOWER (M6L) Prerequisites: Remove the “LEFT PANEL”. To Remove: CONNECTOR 2 SCREWS CAM AY 1. Disconnect the CONNECTOR. 2. Remove: • 2 SCREWS • CAM AY To Install: 1. Reverse the steps in the removal procedure. 2G0947 - 31JAN08 3-65... -

Page 108: Sensor, Film Saver Detect - Upper (S6U)

Adjustments and Replacements SENSOR, FILM SAVER DETECT - UPPER (S6U) Prerequisites: Remove the “FILM FEED AY”. To Remove: 4 SCREWS UPPER FILM GUIDE 1. Remove: • 4 SCREWS • UPPER FILM GUIDE 3-66 2G0947 - 31JAN08... - Page 109 Adjustments and Replacements CONNECTOR MOTOR BELT CONNECTOR 2 SCREWS PULLEY LOWER FILM 4 SCREWS FEED ROLLER NIP SEPARATION FAN OPEN/CLOSE MOTOR 2. Disconnect the FAN CONNECTOR. 3. Remove: • 2 SCREWS • LOWER FILM SEPARATION FAN 4. Disconnect the MOTOR CONNECTOR. 5.

- Page 110 Adjustments and Replacements ALIGNMENT BAR 2 SCREWS LOWER FILM GUIDE Notch for CABLES 4 SCREWS IMPORTANT Avoid damaging CABLES when removing the LOWER FILM GUIDE. Swing the LOWER FILM GUIDE out on the right side so that the CABLES pass through the "notch".

- Page 111 Adjustments and Replacements CONNECTOR FILM SAVER DETECT SENSOR SCREW 8. Disconnect the CONNECTOR. 9. Remove: • SCREW (from the bottom) • FILM SAVER DETECT SENSOR To Install: 1. Reverse the steps in the removal procedure. 2G0947 - 31JAN08 3-69...

-

Page 112: Sensor, Film Saver Detect - Lower (S6L)

Adjustments and Replacements SENSOR, FILM SAVER DETECT - LOWER (S6L) Prerequisites: Remove the “BACK PANEL”. To Remove: SCREW FILM SAVER DETECT SENSOR CONNECTOR 1. Disconnect the CONNECTOR. 2. Remove: • SCREW • FILM SAVER DETECT SENSOR To Install: 1. Reverse the steps in the removal procedure. 3-70 2G0947 - 31JAN08... -

Page 113: Sensor, Film Tray Detect - Upper (S5U)

Adjustments and Replacements SENSOR, FILM TRAY DETECT - UPPER (S5U) Prerequisites: Remove the “FILM FEED AY”. To Remove: 4 SCREWS UPPER FILM GUIDE 1. Remove: • 4 SCREWS • UPPER FILM GUIDE 2G0947 - 31JAN08 3-71... - Page 114 Adjustments and Replacements FILM TRAY DETECT SENSOR SCREW CONNECTOR 2. Disconnect the CONNECTOR. 3. Remove: • SCREW • FILM TRAY DETECT SENSOR To Install: 1. Reverse the steps in the removal procedure. 3-72 2G0947 - 31JAN08...

-

Page 115: Sensor, Film Tray Detect - Lower (S5L)

Adjustments and Replacements SENSOR, FILM TRAY DETECT - LOWER (S5L) Prerequisites: Remove the “BACK PANEL”. To Remove: SCREW FILM TRAY DETECT SENSOR CONNECTOR 1. Disconnect the CONNECTOR. 2. Remove: • SCREW • FILM TRAY DETECT SENSOR To Install: 1. Reverse the steps in the removal procedure. 2G0947 - 31JAN08 3-73... -

Page 116: Vacuum Pump (M4)

Adjustments and Replacements VACUUM PUMP (M4) Prerequisites: Remove the “LEFT PANEL”. To Remove: TIE WRAP CONNECTOR TUBING 2 VALVES LOOP CLAMP VACUUM PUMP 1. Disconnect: • TUBING from the 2 VALVES • CONNECTOR NOTE: When disconnecting the TUBING, leave the TIE WRAP in place. 3-74 2G0947 - 31JAN08... - Page 117 Adjustments and Replacements 2. Remove: • • VACUUM PUMP • ADHESIVE FOAM PAD • LOOP CLAMP To Install: 1. Use ALCOHOL WIPES to clean the adhesive from the VACUUM PUMP installation area. 2. Place the LOOP CLAMP on the new VACUUM PUMP. 3.

-

Page 118: Pickup Ay - Upper

Adjustments and Replacements PICKUP AY - UPPER Prerequisites: Remove: • “FRONT PANEL” • “LEFT PANEL” To Remove: SCREW SCREW (inner) (outer) SCREW FILM PICKUP AY (inner) CONNECTOR SCREW TUBING (outer) 1. Disconnect the CONNECTOR. 2. Remove: • SCREW (inner) on the inside of the FILM TRAY slot. •... -

Page 119: Pickup Ay - Lower

Adjustments and Replacements PICKUP AY - LOWER Prerequisites: Remove: • “FRONT PANEL” • “LEFT PANEL” To Remove: SCREW (outer) SCREW (inner) SCREW (inner) FILM PICKUP AY SCREW CONNECTOR (outer) TUBING 1. Disconnect the CONNECTOR. 2. Remove: • SCREW (inner) on the inside of the FILM TRAY slot. •... -

Page 120: Motor, Pickup Drive - Upper (M3U) And Lower (M3L)

Adjustments and Replacements MOTOR, PICKUP DRIVE - UPPER (M3U) and LOWER (M3L) Prerequisites: Remove the “PICKUP AY - UPPER” “PICKUP AY - LOWER”. To Remove: IMPORTANT This procedure is used for both UPPER and LOWER PICKUP AY. CONNECTOR PICKUP DRIVE MOTOR 2 E-RINGS 2 GEARS... -

Page 121: Suction Cup

Adjustments and Replacements SUCTION CUP Prerequisites: Remove the “PICKUP AY - UPPER” “PICKUP AY - LOWER”. To Remove: IMPORTANT This procedure is used for all PICKUP AY SUCTION CUPS. SUCTION CUP 1. Remove each SUCTION CUP as follows: a. Insert a small flat-blade screwdriver into the slot at the center of each SUCTION CUP and turn counterclockwise to remove the SUCTION CUP and HUB. -

Page 122: Valve, Solenoid - Upper (M5U) And Lower (M5L)

Adjustments and Replacements VALVE, SOLENOID - UPPER (M5U) and LOWER (M5L) Prerequisites: Remove the “PICKUP AY - UPPER” “PICKUP AY - LOWER”. To Remove: IMPORTANT This procedure is used for both UPPER and LOWER PICKUP AY. VALVE CONNECTOR TUBING 1. Disconnect: •... -

Page 123: Sensor, Pickup Home - Upper (S1U) And Lower (S1L)

Adjustments and Replacements SENSOR, PICKUP HOME - UPPER (S1U) and LOWER (S1L) Prerequisites: Remove the “PICKUP AY - UPPER” “PICKUP AY - LOWER”. To Remove: IMPORTANT This procedure is used for both UPPER and LOWER PICKUP AY. CONNECTOR PICKUP HOME SENSOR SCREW 1. -

Page 124: Sensor, Film Contact - Upper (S2U) And Lower (S2L)

Adjustments and Replacements SENSOR, FILM CONTACT - UPPER (S2U) and LOWER (S2L) Prerequisites: Remove the “PICKUP AY - UPPER” “PICKUP AY - LOWER”. To Remove: IMPORTANT This procedure is used for both UPPER and LOWER PICKUP AY. CONNECTOR SCREW FILM CONTACT SENSOR 1. -

Page 125: Sensor, Film Separated - Upper (S3U) And Lower (S3L)

Adjustments and Replacements SENSOR, FILM SEPARATED - UPPER (S3U) and LOWER (S3L) Prerequisites: Remove the “PICKUP AY - UPPER” “PICKUP AY - LOWER”. To Remove: IMPORTANT This procedure is used for both UPPER and LOWER PICKUP AY. SCREW FILM SEPERATED SENSOR CONNECTOR 1. -

Page 126: Imaging

Adjustments and Replacements IMAGING AY Prerequisites: Remove the “PROCESSOR AY”. To Remove: 3 PINS CONNECTOR IMAGING AY E-RING FILM ADVANCE KNOB 1. Disconnect the CONNECTOR from the IMAGING AY. 2. Remove: • 3 PINS • E-RING • FILM ADVANCE KNOB 3. -

Page 127: Sensor, Start Of Page (Sop, S8)

Adjustments and Replacements SENSOR, START OF PAGE (SOP, S8) Prerequisites: Remove the “RIGHT PANEL”. To Remove: 2 SCREWS ELECTRONICS BRACKET 1. Remove 2 SCREWS. 2. Open the ELECTRONICS BRACKET. 2G0947 - 31JAN08 3-85... - Page 128 Adjustments and Replacements CONNECTOR BRACKET with SOP SENSOR SCREW B SCREW A SOP SENSOR BRACKET 3. Disconnect the CONNECTOR. 4. Remove: • SCREW A • BRACKET with SOP SENSOR • SCREW B • SOP SENSOR To Install: 1. Reverse the steps in the removal procedure. 3-86 2G0947 - 31JAN08...

-

Page 129: Power Supply

Adjustments and Replacements POWER SUPPLY Prerequisites: 1. Do “Making a Configuration Backup” on page 8-1. 2. Remove the “DRE MOTHERBOARD”. To Remove: IMPORTANT When installing CIRCUIT BOARDS, always use a WRIST STRAP to prevent damage from electrostatic discharge. 2 SCREWS ELECTRONICS BRACKET 1. - Page 130 Adjustments and Replacements 4 SCREWS OUTPUT CONNECTOR POWER SUPPLY INPUT CONNECTOR 3. Disconnect the INPUT and OUTPUT CONNECTORS. 4. Remove: • 4 SCREWS • POWER SUPPLY To Install: 1. Reverse the steps in the removal procedure. NOTE: If necessary, do “Restoring the Configuration”...

-

Page 131: Hard Drive

Adjustments and Replacements HARD DRIVE Prerequisites: 1. Do “Making a Configuration Backup” on page 8-1. 2. Remove the “RIGHT PANEL”. To Remove: IMPORTANT When installing CIRCUIT BOARDS, always use a WRIST STRAP to prevent damage from electrostatic discharge. 2 SCREWS ELECTRONICS BRACKET 1. - Page 132 Adjustments and Replacements 4 SCREWS CONNECTOR HARD DRIVE 3. Disconnect the CONNECTOR. 4. Remove: • 4 SCREWS • HARD DRIVE To Install: 1. Reverse the steps in the removal procedure. 2. Do “Restoring the Configuration” on page 8-2. 3-90 2G0947 - 31JAN08...

-

Page 133: Film Path Microcontroller Board

Adjustments and Replacements FILM PATH MICROCONTROLLER BOARD Prerequisites: 1. Do “Making a Configuration Backup” on page 8-1. 2. Remove the “RIGHT PANEL”. To Remove: IMPORTANT When installing CIRCUIT BOARDS, always use a WRIST STRAP to prevent damage from electrostatic discharge. CONNECTORS 3 SCREWS FILM PATH... -

Page 134: Dre Motherboard

Adjustments and Replacements DRE MOTHERBOARD Prerequisites: 1. Do “Making a Configuration Backup” on page 8-1. 2. Remove the “RIGHT PANEL”. To Remove: IMPORTANT When installing CIRCUIT BOARDS, always use a WRIST STRAP to prevent damage from electrostatic discharge. DRE MOTHERBOARD 4 SCREWS CONNECTORS 1. - Page 135 Adjustments and Replacements DRE to DPB USB CABLE (plugged into outside CONNECTOR) 1. Reverse the steps in the removal procedure. NOTE: If necessary, do “Restoring the Configuration” on page 8-2. 2G0947 - 31JAN08 3-93...

-

Page 137: Preventive Maintenance

Section 4: Preventive Maintenance Necessary Materials The materials necessary for performing Preventive Maintenance (PM) are: • Tools • PM materials Required Tools Tool No. Description LAPTOP COMPUTER with Microsoft Windows 98 OPERATING SYSTEM or higher and Microsoft INTERNET EXPLORER 5.5 SERVICE TOOL for the 5800 LASER IMAGER TL5568 CROSSOVER CABLE... -

Page 138: Pm Intervals

Preventive Maintenance PM Intervals IMPORTANT A Preventive Maintenance (PM) call must be made every 20,000 film cycles. To consistently produce high quality images, the IMAGER must receive periodic routine maintenance. Perform PM procedures: • Every EM (Emergency Maintenance Call) • Every 20,000 cycles the LOCAL PANEL displays a message prompting the user to schedule preventive maintenance. -

Page 139: Performing The Pm

Preventive Maintenance Performing the PM Every PM, perform all of the following procedures in the order listed: 1. Print a “flat-field inspection” film (i.e., gray-out) to compare against the film after PM is complete. FILM SAVER FILM TRAY 2. Insert the FILM SAVERS. 3. - Page 140 Preventive Maintenance CAUTION The PROCESSOR DRUM is very hot. Allow it to cool for 30 minutes before cleaning. CHARCOAL FILTER FILTER DUCT (output side) EXHAUST PLENUM 8. Remove the CHARCOAL FILTER. 9. Use a VACUUM CLEANER to clean: • the FILTER area •...

- Page 141 Preventive Maintenance PROCESSOR DRUM EXHAUST PORT 2 SCREWS RIGID DUCT FILTER DUCT (input side) 10. On the right side of the IMAGER, remove: • 2 SCREWS • RIGID DUCT 11. Vacuum: • ends of the RIGID DUCT • PROCESSOR DRUM EXHAUST PORT •...

- Page 142 Preventive Maintenance Used FILM IMAGING AY 12. Insert a sheet of used film above the IMAGING AY to catch any debris that may fall during the PM procedure. HEAT SHIELD 2 SCREWS FELT PAD AY FILM DIVERTER AY COOLING SIDE PLATE PLATE 2G0947 - 31JAN08...

- Page 143 Preventive Maintenance 13. Remove: • HEAT SHIELD • 2 SCREWS • FELT PAD AY • FILM DIVERTER AY 14. Discard the FELT PAD AY. CAUTION ISOPROPYL ALCOHOL is highly flammable. Follow the manufacturer’s instructions for safe use and handling. 15. Use ALCOHOL WIPES and SCRAPER to inspect and clean the following components: •...

- Page 144 Preventive Maintenance PROCESSOR COVER ROLLERS 2 HEAT SHIELD SUPPORT BARS DENSITOMETER GUIDE ROLLERS 19. Clean and inspect: • PROCESSOR COVER ROLLERS • HEAT SHIELD SUPPORT BARS • DENSITOMETER GUIDE • DENSITOMETER GUIDE ROLLERS 20. Vacuum: • TOP COVER • FRONT PANEL •...

- Page 145 Preventive Maintenance 23. For the FILM DIVERTER AY and FELT PAD AY: a. Install the FILM DIVERTER AY and a new FELT PAD AY, but do not tighten the 2 SCREWS. b. Push: • the FILM DIVERTER AY away from the PROCESSOR DRUM •...

-

Page 146: Resetting The Pm Counts And Changing The Service History

Preventive Maintenance Resetting the PM Counts and Changing the Service History 1. Use the SERVICE TOOL and select, Monitoring and Control>ImagerMonitor. The Imager Monitor screen is displayed. 2. Click: • [Reset Prints To PM] • [Reset Prints To Filter Replacement] 3. - Page 147 Preventive Maintenance 4. Click [Add]. 5. Enter: • “Activity Code”: PM • “Problem”: PM due • “Cause”: N/A • “Solution”: N/A • “Parts”: part number and description of any part that was replaced • “Notes”: any information about the PM Note: This information will be reviewed by the Field Engineer at the start of the next PM.

-

Page 148: Completing The Pm

Preventive Maintenance Completing the PM 1. Allow the PROCESSOR to warm to “Ready.” 2. Check the temperature of the DRUM (see Adjustments And Replacements, “PROCESSOR - DRUM Temperature” on page 3-1). 3. If necessary, adjust the temperature. 4. Make a “Flat-field” or “Grayout” test print. 5. - Page 149 Section 5: Diagnostics Using the SERVICE SWITCH The SERVICE SWITCH is located behind the FRONT PANEL at the top right front of the IMAGER. Activator SCREW SERVICE SWITCH FRONT PANEL 1. Open: • TOP COVER • FRONT PANEL 2. To activate the SERVICE SWITCH, turn the activator SCREW counterclockwise.

- Page 150 Diagnostics LOCAL PANEL LEDs and Buttons Ready LED. This LED, when lit indicates that the IMAGER is ready for printing. When flashing, the IMAGER is processing and printing films. When unlit, the IMAGER is not ready to print. Error LED. When lit, this LED indicates that the IMAGER has an error.

- Page 151 Diagnostics LOCAL PANEL Icons Icon Description This icon indicates that film calibration is required. The IMAGER is unable to print jobs from this supply until a successful calibration occurs. This icon indicates that a COVER or PANEL is open on the IMAGER. This icon indicates an error with the FILM TRAY.

- Page 152 Diagnostics DICOM Printer Status Messages In response to a DICOM printer N-GET status request, a printer status message and printer status info message are returned to the requesting Service Class User (SCU). Every error has an associated printer status info message. If more than 1 error exists when a printer N-GET request is received, a status message is sent in response according to an established priority.

- Page 153 Diagnostics Machine Control System (MCS) Printer Status Messages The following table describes how the LOCAL PANEL and Web Portal indicate printer status to the user. Table 5-2: MCS Printer Status Messages Printer Web Portal Local Panel Display DICOM Status Description Status Display Any FILM...

- Page 154 Diagnostics Table 5-2: MCS Printer Status Messages (Cont’d) Printer Web Portal Local Panel Display DICOM Status Description Status Display Warming • Ready LED off Warming=xx WARNING / The PROCESSOR is • Warming LED on PROC INIT warming up and will not be •...

- Page 155 Diagnostics Table 5-3: Film Supply Status Messages (Cont’d) Film Supply Web Portal Local Panel Display Description State Display Manual Mode • Attention LED on The film in this FILM SUPPLY does • Status code: 21002 (upper), not meet AIQC standards. However, 23002 (lower) the user has selected “Manual •...

-

Page 156: Job Manager Status Messages

Diagnostics Job Manager Status Messages The following table describes how the LOCAL PANEL and Web Portal indicate job status to the user. Table 5-4: Job Manager Status Messages Job Manager Local Panel Web Portal Display Description Status Display Active Shows how many The IMAGER is accepting DICOM job jobs having this requests and film is available for all current... -

Page 157: Condition Codes

Diagnostics Condition Codes Subsystems in the 5800 Each subsystem has an ID number that allows: • some error history, retrieved through the SERVICE TOOL by subsystem • logs to be written, sorted, and retrieved by subsystem Each subsystem has a range of error numbers. The numbers have 2 parts, a subsystem ID number and an error ID number. - Page 158 Diagnostics Table 5-5: Subsystem IDs (Cont’d) Subsys ID Subsystem/Component Name Error ID MCS: - General MCS System 20-xxx - Upper FILM SUPPLY 21-xxx - N/A For The 5800 IMAGER - Lower FILM SUPPLY 23-xxx - N/A For The 5800 IMAGER - RF Tag 25-xxx - FILM TRANSPORT...

- Page 159 Diagnostics Condition Code: 01-000 Web Portal Message Log Message DICOM Message Severity None General Error in Configuration NORMAL 3-Notify and Control Subsystem. Description A general, non-specific error has occurred in the Configuration and Control Subsystem. System Impact Unknown. User Action None FE Action None, this is a log notification only.

- Page 160 Diagnostics Condition Code: 01-002 Web Portal Message Log Message DICOM Message Severity None Error reading configuration NORMAL 2-Warning information. Description An error occurred while reading the Configuration and Control Subsystem configuration information. System Impact The Configuration and Control Subsystem may not execute correctly. User Action None FE Action...

- Page 161 Diagnostics Condition Code: 01-005 Web Portal Message Log Message DICOM Message Severity None Error stopping subsystem xxxx NORMAL 1-Alert Description An error occurred while attempting to stop subsystem xxxx. System Impact The subsystem in question may still be running, in which case full shutdown will not be achievable.

- Page 162 Diagnostics Condition Code: 01-008 Web Portal Message Log Message DICOM Message Severity None All subsystems successfully NORMAL 3-Notify started. Description All subsystems to be started by the Configuration and Control Subsystem have been started. System Impact None - the system will function normally. User Action None FE Action...

- Page 163 Diagnostics Condition Code: 01-010 Web Portal Message Log Message DICOM Message Severity None Subsystem xxxx terminated. NORMAL 3-Notify Description A subsystem (xxxx) that was started by the Configuration and Control Subsystem terminated abnormally. System Impact The subsystem will be temporarily unavailable until it is restarted by the Configuration and Control Subsystem.

- Page 164 Diagnostics Condition Code: 04-100 Web Portal Message Log Message DICOM Message Severity None Maximum Number of NORMAL 1-Alert Associations Exceeded. Description The maximum number of associations configured has been exceeded. The association is rejected. System Impact The Service Class User (SCU) will not be able to open an association, and therefore will not be able to deliver a print job.

- Page 165 Diagnostics Condition Code: 04-110 Web Portal Message Log Message DICOM Message Severity None The association request was NORMAL 1-Alert rejected. Description An association request was rejected for one or more of the following reasons: • The Service Class User (SCU) did not specify an implementation UID. •...

- Page 166 Diagnostics Condition Code: 04-200 Web Portal Message Log Message DICOM Message Severity MIM Core: Disk Full Disk Full. NORMAL 1-Alert Description The partition of the DISK where studies are stored is full. System Impact If a study is currently in progress, it cannot be completed. New studies will not be accepted.

- Page 167 Diagnostics Condition Code: 04-202 Web Portal Message Log Message DICOM Message Severity None Network Connection Lost. NORMAL 2-Warning Description The Service Class Provider (SCP) has lost the network connection to a Service Class User (SCU). System Impact The SCP will abort the association tied to this connection. User Action None FE Action...

- Page 168 Diagnostics Condition Code: 04-301 Web Portal Message Log Message DICOM Message Severity None Required attribute XXXX NORMAL 1-Alert (GGGG,EEEE) is missing from YYYY SOP. Description A required attribute for the specified Service Object Pair (SOP) class is missing. Where XXXX (GGGG,EEEE) is the tag name and number, and YYYY is the SOP name.

- Page 169 Diagnostics Condition Code: 05-000 Web Portal Message Log Message DICOM Message Severity None Error Unknown. NORMAL 2-Warning Description An unknown error has occurred in the Study Reclamation Subsystem. System Impact Unknown. User Action None FE Action None, this is a log notification only. Condition Code: 05-001 Web Portal Message Log Message...

- Page 170 Diagnostics Condition Code: 05-002 Web Portal Message Log Message DICOM Message Severity None High water-mark reached. NORMAL 3-Notify Scheduled study reclamation time reached. Description Study reclamation has been initiated because either the high-water mark has been reached, or the scheduled time for study reclamation has occurred. System Impact Completed studies will be systematically removed from the system until the low-water mark is reached.

- Page 171 Diagnostics Condition Code: 05-004 Web Portal Message Log Message DICOM Message Severity None Low-water-mark reached. NORMAL 3-Notify Description Study reclamation has been completed because the low-water mark was successfully reached. System Impact None. User Action None FE Action None, this is a log notification only. Condition Code: 05-005 Web Portal Message Log Message...

- Page 172 Diagnostics Condition Code: 06-000 Web Portal Message Log Message DICOM Message Severity None General error in delivery NORMAL 3-Notify subsystem. Description A general, non-specific error has occurred in the Delivery Subsystem. System Impact Unknown. User Action None FE Action None, this is a log notification only. Condition Code: 06-001 Web Portal Message Log Message...

- Page 173 Diagnostics Condition Code: 06-002 Web Portal Message Log Message DICOM Message Severity None Bad or missing configuration NORMAL 1-Alert information. Description An error occurred while reading the Delivery Subsystem configuration information. System Impact The Delivery Subsystem may not execute correctly. This should be a recoverable error.

- Page 174 Diagnostics Condition Code: 06-101 Web Portal Message Log Message DICOM Message Severity None General job processing error. NORMAL 1-Alert Description The job delivery component has encountered a general error while processing a job. • Startup error • Bad or missing configuration data •...

- Page 175 Diagnostics Condition Code: 06-102 Web Portal Message Log Message DICOM Message Severity None Printer not in ready state. NORMAL 2-Warning Description The printer is not ready to accept delivery jobs. System Impact Jobs will not be delivered while the printer is in this state. User Action None FE Action...

- Page 176 Diagnostics Condition Code: 06-104 Web Portal Message Log Message DICOM Message Severity None Media unavailable. NORMAL 2-Warning Description The currently requested media is not available. System Impact The submitted job will not be delivered. User Action None FE Action None, this is a log notification only. Condition Code: 06-105 Web Portal Message Log Message...

- Page 177 Diagnostics Condition Code: 06-106 Web Portal Message Log Message DICOM Message Severity None Job delivery success. NORMAL 3-Notify Description Notification that a job was successfully delivered; this is not an error condition. System Impact None. User Action None FE Action None, this is a log notification only.

- Page 178 Diagnostics Condition Code: 06-300 Web Portal Message Log Message DICOM Message Severity Database access error. NORMAL 1-Alert Description An error occurred in the destination business logic component. The database may be corrupted, or simply a timeout occurred. System Impact The current job will not deliver. This error should be recoverable. User Action None FE Action...

- Page 179 Diagnostics Condition Code: 06-410 Web Portal Message Log Message DICOM Message Severity MIM Core: Image Rendering (see Description) NORMAL 1-Alert Error Description The page builder component has encountered the following rendering error: • General error rendering the page. • Error after completion of chain-forming. •...

- Page 180 Diagnostics Condition Code: 06-411 Web Portal Message Log Message DICOM Message Severity MIM Core: Image Data Error (see Description) NORMAL 1-Alert Description The page builder component has encountered the following image data error: • width and/or height is less than zero, •...

- Page 181 Diagnostics Condition Code: 06-420 Web Portal Message Log Message DICOM Message Severity MIM Core: Internal Software (see Description) NORMAL 1-Alert Error Description The page builder component has encountered the following data error: • The specified page width and/or height is less than zero. •...

- Page 182 Diagnostics Condition Code: 06-430 Web Portal Message Log Message DICOM Message Severity MIM Core: Internal Software (see Description) NORMAL 1-Alert Error Description The page builder has encountered one of the following errors while building the image processing chain: • General chain-building error. •...

- Page 183 Diagnostics Condition Code: 06-440 Web Portal Message Log Message DICOM Message Severity None sendPage(): NORMAL 2-Warning myMPageBuilder.RenderPage() call has high bits masked out. Description The 12-bit image data had pixels that were greater than 12 bits. System Impact None. The system will automatically compensate for the problem. User Action None FE Action...

- Page 184 Diagnostics Condition Code: 06-501 Web Portal Message Log Message DICOM Message Severity None Media XXX not loaded. [where NORMAL 2-Warning XXX is the requested media] Description The requested media is not currently loaded in the printer. System Impact The current job will not be delivered until the specified media is loaded. User Action None FE Action...

- Page 185 Diagnostics Condition Code: 06-503 Web Portal Message Log Message DICOM Message Severity None Media xxx is calibrating. NORMAL 3-Notify Description The requested media (xxx) is currently being calibrated. System Impact Jobs will not be delivered until the calibration cycle is completed. User Action None FE Action...

- Page 186 Diagnostics Condition Code: 06-505 Web Portal Message Log Message DICOM Message Severity None Media xxx is empty. NORMAL 2-Warning Description The requested media (xxx) is empty. System Impact The current job will not be delivered until the specified media is loaded. User Action 1.

- Page 187 Diagnostics Condition Code: 06-600 Web Portal Message Log Message DICOM Message Severity General error in delivery NORMAL 1-Alert subsystem. Description A general, non-specific error has occurred in the Delivery Subsystem. System Impact Unknown. User Action None FE Action Condition Code: 10-001 Web Portal Message Log Message DICOM Message...

- Page 188 Diagnostics Condition Code: 10-003 Web Portal Message Log Message DICOM Message Severity MIS: Image Buffer Error MIS Image Buffer Error PRINTER DOWN 0-Fatal Description This represents any of a number of errors that indicate that image memory buffer functionality of the MCS Interface Server (MIS) Subsystem has failed. System Impact The DRE is not functional.

- Page 189 Diagnostics Condition Code: 10-015 Web Portal Message Log Message DICOM Message Severity MIS: Database Error MIS Database Error CHECK PRINTER 1-Alert Description This represents any of a number of errors indicating that database software functionality of the MCS Interface Server (MIS) Subsystem has failed. Examples include: SQL server down, incorrect database table installation, database read/ write/ update failed.

- Page 190 Diagnostics Condition Code: 10-910 Web Portal Message Log Message DICOM Message Severity MIS: MCS Communication MIS to MCS Communications PRINTER DOWN 0-Fatal Failure Fail Description This error occurs when the Machine Control System (MCS) fails to respond to the MCS Interface Server (MIS). The error is declared by the MIS and a log message is generated.

- Page 191 Diagnostics Condition Code: 14-001 Web Portal Message Log Message DICOM Message Severity None General Error in WEB PORTAL NORMAL 3-Notify Subsystem. Description A Web Portal internal error has occurred. This represents any of a number of errors indicating that internal software functionality of the Web Portal Subsystem has failed.

- Page 192 Diagnostics Condition Code: 20-004 Web Portal Message Log Message DICOM Message Severity USB Failure. USB failed to initialize PRINTER DOWN 0-Fatal Description This error occurs when the DRE is unable to successfully initialize its USB circuits and thus cannot transfer image data. The error is declared by the Machine Control System (MCS) and a log message is generated.

- Page 193 Diagnostics Condition Code: 20-154 Web Portal Message Log Message DICOM Message Severity MCS: Internal Communications MCS failed to read/write to the ELEC DOWN 0-Fatal Failure hard drive. Description This error occurs when the Machine Control System (MCS) application reports that it has detected an error while attempting to read or write from its storage space on the HARD DRIVE.

- Page 194 Diagnostics Condition Code: 20-156 Web Portal Message Log Message DICOM Message Severity Incompatible Software Versions One or more micros have PRINTER DOWN 0-Fatal Installed software versions installed that are incompatible with the MCS version Description This error occurs during Machine Control System (MCS) diagnostics when the MCS determines that the software version of one or more of the MICROCONTROLLERS is incompatible with the MCS software version.

- Page 195 Diagnostics Condition Code: 20-209 Web Portal Message Log Message DICOM Message Severity Laser Imager Opened During Hood or Cover Opened During PRINTER DOWN 0-Fatal Self Test Self Test Description This error occurs during Machine Control System (MCS) diagnostics when the IMAGER determines that the TOP COVER or a PANEL was opened during the execution of Self Test.

- Page 196 Diagnostics Condition Code: 20-449 Web Portal Message Log Message DICOM Message Severity None Processor Filter Maintenance NORMAL 3-Notify Required Description This notification is written to the log when the processor filter maintenance (PFM) sheet count exceeds the PFM sheet count limit. System Impact None - the system will function normally.

- Page 197 Diagnostics Condition Code: 20-700 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description This auxiliary code indicates that the IMAGER entered Service Mode. System Impact The printer is unable to print films. The spooler is still able to accept jobs but new films will not be initiated.

- Page 198 Diagnostics Condition Code: 20-702 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description This auxiliary code indicates that one of the FILM SUPPLIES has no FILM TRAY inserted. System Impact The printer is unable to print films. The spooler is still able to accept and queue jobs, but new films will not be initiated.

- Page 199 Diagnostics Condition Code: 20-704 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description This auxiliary code indicates that the DICOM network is offline. System Impact The printer is unable to print films. User Action FE Action Condition Code: 20-705 Web Portal Message Log Message...

- Page 200 Diagnostics Condition Code: 20-706 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description This auxiliary code indicates that a user-initiated system shutdown is complete. System Impact The printer is unable to print films. User Action 1.

- Page 201 Diagnostics Condition Code: 20-915 Web Portal Message Log Message DICOM Message Severity Internal Image Data Transfer Image transfer failure after ELEC DOWN 0-Fatal Failed multiple attempts. Wrong number of bytes delivered in the allotted timeframe. Description This error occurs when the wrong number of pixels is transferred between the DRE and the DPB in the allotted timeframe on 3 successive films.

- Page 202 Diagnostics Condition Code: 20-919 Web Portal Message Log Message DICOM Message Severity Internal Image Data Render Image Render did not complete. ELEC DOWN 0-Fatal Failed Description This error occurs when image data transfer between the DRE and the Machine Control System (MCS) is interrupted and does not complete within a reasonable time.

-

Page 203: Condition Code: 21-000 Or

Diagnostics Condition Code: 21-000 or 23-000 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description This auxiliary code indicates that the FILM SUPPLY needs attention due to a failure. The failure information is specified by a separate error code. System Impact None - the system will function normally. -

Page 204: Condition Code: 21-002 Or

Diagnostics Condition Code: 21-002 or 23-002 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description This auxiliary code indicates that the supply is operating in "manual" mode, which means that the image quality is not within the normal range. System Impact None - the system will function normally. -

Page 205: Condition Code: 21-004 Or

Diagnostics Condition Code: 21-004 or 23-004 Web Portal Message Log Message DICOM Message Severity None (none) (Not Applicable) 4-Auxiliary Description The FILM SAVER has not yet been applied. The FILM TRAY will not be unlocked for removal until the FILM SAVER is applied, in order to prevent film exposure. -

Page 206: Condition Code: 21-116 Or

Diagnostics Condition Code: 21-116 or 23-116 Web Portal Message Log Message DICOM Message Severity Film Jam in Area 1: xxxxx xxxxx Supply: Film Pickup FILM TRANS ERR 1-Alert Supply Failure. Film did not lift successfully as indicated by Film Separated sensor (S3x), Pickup Home sensor (S1x), or Contact sensor (S2x). - Page 207 Diagnostics Check: If an existing problem: FILM SEPARATED SENSOR Install a new SENSOR (see Adjustments and Replacements, “SENSOR, FILM SEPARATED - UPPER (S3U) and LOWER (S3L)” on page 3-83). PICKUP HOME SENSOR Install a new SENSOR (see Adjustments and Replacements, “SENSOR, PICKUP HOME - UPPER (S1U) and LOWER (S1L)”...

-

Page 208: Condition Code: 21-117 Or

Diagnostics Condition Code: 21-117 or 23-117 Web Portal Message Log Message DICOM Message Severity None xxxxx Supply: Film pickup NORMAL 3-Notify retry. Film did not lift successfully. Description This notification occurs if the IMAGER fails to pick up a sheet of film as indicated by the FILM SEPARATED SENSOR (S3x) or the PICKUP HOME SENSOR (S1x). -

Page 209: Condition Code: 21-118 Or

Diagnostics Condition Code: 21-118 or 23-118 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Internal xxxxx Supply: Pickup Home FILM TRANS ERR 1-Alert Hardware Failure Sensor (S1x) failed to sense the pickup assembly in the appropriate home or off-home position. - Page 210 Diagnostics Check: If an existing problem: PICKUP DRIVE MOTOR Install a new MOTOR (see Adjustments and Replacements, “MOTOR, PICKUP DRIVE - UPPER (M3U) and LOWER (M3L)” on page 3-78). 3. Install a new PICKUP AY (see Adjustments and Replacements, “PICKUP AY - UPPER” on page 3-76 “PICKUP AY - LOWER”...

-

Page 211: Condition Code: 21-119 Or

Diagnostics Condition Code: 21-119 or 23-119 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Internal xxxxx Supply: Film contact FILM TRANS ERR 1-Alert Hardware Failure sensor (S2x) failed to confirm that the pickup arm assembly lowered and contacted the film Description This error occurs only while attempting to pick up a film or checking for film in the FILM TRAY. - Page 212 Diagnostics Check: If an existing problem: FILM CONTACT SENSOR Install a new SENSOR (see Adjustments and Replacements, “SENSOR, FILM CONTACT - UPPER (S2U) and LOWER (S2L)” on page 3-82). PICKUP DRIVE MOTOR Install a new MOTOR (see Adjustments and Replacements, “MOTOR, PICKUP DRIVE - UPPER (M3U) and LOWER (M3L)”...

-

Page 213: Condition Code: 21-122 Or

Diagnostics Condition Code: 21-122 or 23-122 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Internal xxxxx Supply: Film Separation FILM TRANS ERR 1-Alert Hardware Failure sensor (S3x) failed to confirm film separation. Description This error occurs only while attempting to pick up a film. The PICKUP CUPS were lowered onto the film and the suction was applied, but the FILM SEPARATED SENSOR (S3x) did not actuate. - Page 214 Diagnostics Check: If an existing problem: PICKUP DRIVE MOTOR Install a new MOTOR (see Adjustments and Replacements, “MOTOR, PICKUP DRIVE - UPPER (M3U) and LOWER (M3L)” on page 3-78). 3. Install a new PICKUP AY (see Adjustments and Replacements, “PICKUP AY - UPPER” on page 3-76 “PICKUP AY - LOWER”...

-

Page 215: Condition Code: 21-125 Or

Diagnostics Condition Code: 21-125 or 23-125 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Internal xxxxx Supply: Feed Roller FILM TRANS ERR 1-Alert Hardware Failure Sensor (S4) failed to detect feed roller open/closed position. Description This error occurs if the FEED ROLLER NIP SENSOR (S4) does not change from blocked to unblocked when opening or from unblocked to blocked when closing. -

Page 216: Condition Code: 21-126 Or

Diagnostics Condition Code: 21-126 or 23-126 Web Portal Message Log Message DICOM Message Severity Film Jam in Area 1: xxxxx xxxxx Supply: Film Jam - SOP FILM JAM 1-Alert Supply sensor (S8) failed to activate in specified time. Description This error occurs if the leading edge of the film does not reach the START OF PAGE (SOP) SENSOR (S8) as a result of being fed from the supply to the exposure assembly. -

Page 217: Condition Code: 21-127 Or

Diagnostics Condition Code: 21-127 or 23-127 Web Portal Message Log Message DICOM Message Severity None xxxxx Supply: Film feed retry. NORMAL 3-Notify Film did not feed successfully to SOP sensor (S8) in specified time. Description This notification occurs if the leading edge of the film does not reach the START OF PAGE (SOP) SENSOR (S8) as a result of being fed from the supply to the exposure assembly. -

Page 218: Condition Code: 21-130 Or

Diagnostics Condition Code: 21-130 or 23-130 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Internal xxxxx Supply: Film Separation FILM TRANS ERR 1-Alert Hardware Failure Sensor (S3x) stuck on Description This error occurs only while attempting to pick up a film. The FILM SEPARATED SENSOR (S3x) is in an incorrect state for PICKUP is in home position, prior to film lift. -

Page 219: Condition Code: 21-131 Or

Diagnostics Condition Code: 21-131 or 23-131 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Internal xxxxx Supply: Film did not FILM TRANS ERR 1-Alert Hardware Failure release from cups after pickup, as indicated by Film Separation Sensor (S3x) Description This error occurs only while attempting to pick up a film. -

Page 220: Condition Code: 21-139 Or

Diagnostics Condition Code: 21-139 or 23-139 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Unable to xxxxx Supply: RF Tag Reader BAD SUPPLY MGZ 1-Alert Identify Film Pack failed to Read or Write RF Tag data in film pack Description The IMAGER attempts to read the RF TAG in the film pack at powerup and when a FILM TRAY is inserted. -

Page 221: Condition Code: 21-145 Or

Diagnostics Condition Code: 21-145 or 23-145 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Unsupported xxxxx Supply: Media Type in BAD SUPPLY MGZ 1-Alert Film Type film pack is not supported Description The IMAGER obtains the media type and CE mark information from the RF TAG when the FILM TRAY is loaded or when the IMAGER power is turned on. -

Page 222: Condition Code: 21-146 Or

Diagnostics Condition Code: 21-146 or 23-146 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Unsupported xxxxx Supply: Media Size in BAD SUPPLY MGZ 1-Alert Film Size film pack is not supported Description The IMAGER obtains the media size information from the RF TAG when the FILM TRAY is loaded or when the IMAGER power is turned on. -

Page 223: Condition Code: 21-624 Or

Diagnostics Condition Code: 21-624 or 23-624 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Film Calibration xxxxx Supply: Calibration CALIBRATION 1-Alert Failure Failed Description This error occurs when the density readings that come from the calibration print are not monotonic or the DENSITOMETER did not find exactly 21 steps in the calibration wedge. -

Page 224: Condition Code: 21-631 Or

Diagnostics Condition Code: 21-631 or 23-631 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Film Calibration xxxxx Supply: Calibration CALIBRATION 1-Alert Failure - Dmin Outside Target failed - Dmin Not Met. Description The error occurs when the calibration sheet does not have a step density at or below the required Dmin value. - Page 225 Diagnostics Condition Code: 21-632 or 23-632 Web Portal Message Log Message DICOM Message Severity xxxxx Supply: Film Calibration xxxxx Supply: Calibration CALIBRATION 1-Alert Failure - Dmax Outside Target failed - Dmax Not Met. Description The error occurs when the calibration sheet does not have a step density at or above the required Dmax value.

- Page 226 Diagnostics Condition Code: 25-922 Web Portal Message Log Message DICOM Message Severity RF Tag: Internal Diagnostic RF Tag reader failed self BAD SUPPLY MGZ 0-Fatal Failure diagnostics Description When the RF Tag reader is told to perform diagnostics and returns a diagnostics failure, the Machine Control System (MCS) commands a retry.

- Page 227 Diagnostics Condition Code: 25-932 Web Portal Message Log Message DICOM Message Severity None MCS failed to communicate NORMAL 3-Notify with RF Tag micro Description This notification occurs when the Machine Control System (MCS) tries to communicate with the MICROCONTROLLER but receives no response. (Note: Error 25-931 is generated when this problem is detected on the 5th successive failed communication attempt.) System Impact...

- Page 228 Diagnostics Condition Code: 26-325 Web Portal Message Log Message DICOM Message Severity Film Jam in Area 2 Film Jam Entering Exposure FILM JAM 1-Alert Transport: SOP sensor (S8) failed to detect film leading edge. Description This error occurs if the leading edge is not detected at the START OF PAGE (SOP) SENSOR (S8) in a timely manner.

- Page 229 Diagnostics Condition Code: 26-326 Web Portal Message Log Message DICOM Message Severity Film Jam in Area 2 or 3 Film Jam Exiting Exposure FILM JAM 1-Alert Transport: SOP sensor (S8) failed to detect film trailing edge. Description This error occurs if the trailing edge is not detected at the START OF PAGE (SOP) SENSOR (S8) after the film has entered the EXPOSURE TRANSPORT area.

- Page 230 Diagnostics Condition Code: 26-543 Web Portal Message Log Message DICOM Message Severity Film Jam in Area 3 Film Jam Prior to Densitometer: FILM JAM 1-Alert Film at Densitometer sensor (S11) failed to detect film leading edge. Description This error occurs if the leading edge is not detected at the FILM AT DENSITOMETER SENSOR (S11) after the film leaves the exposure area.

- Page 231 Diagnostics Condition Code: 26-544 Web Portal Message Log Message DICOM Message Severity Film Jam in Area 3 Film Jam at Densitometer: Film FILM JAM 1-Alert at Densitometer sensor (S11) failed to detect film trailing edge. Description This error occurs if the trailing edge is not detected at the FILM AT DENSITOMETER SENSOR (S11) as the film exits the DENSITOMETER.

- Page 232 Diagnostics Condition Code: 26-931 Web Portal Message Log Message DICOM Message Severity Film Transport: Internal MCS failed to communicate ELEC DOWN 0-Fatal Communications Failure with Film Path Microcontroller after multiple attempts Description This error occurs when the Machine Control System (MCS) tries to communicate with the MICROCONTROLLER but receives no response to 5 attempts.

- Page 233 Diagnostics Condition Code: 26-933 Web Portal Message Log Message DICOM Message Severity Film Transport: Internal Film Path Microcontroller failed ELEC DOWN 0-Fatal Communications Failure to communicate with an SMD Microcontroller after multiple attempts Description This error occurs when the FILM PATH MICROCONTROLLER tries to communicate with one of the STEP MOTOR DRIVER (SMD) MICROCONTROLLERS but receives no response to 5 attempts.

- Page 234 Diagnostics Condition Code: 27-123 Web Portal Message Log Message DICOM Message Severity Optics: Internal Hardware Polygon fails to rotate at desired ELEC DOWN 0-Fatal Failure speed Description This error occurs when the polygon speed measured by the OPTICS MODULE MICROCONTROLLER is out of range. The error clears only when power is cycled.