Summary of Contents for Endress+Hauser Proline t-mass B 150 HART

- Page 1 Operating Instructions Proline t-mass B 150 HART Thermal Mass Flow Measuring System BA01043D/06/EN/01.12 71165061 Valid as of version 01.00.zz (Device firmware)

- Page 2 Proline t-mass B 150 HART • Make sure the document is stored in a safe place such that it is always available when working on or with the device. • To avoid danger to individuals or the facility, read the "Basic safety instructions" section carefully, as well as all other safety instructions in the document that are specific to working procedures.

-

Page 3: Table Of Contents

Proline t-mass B 150 HART Table of contents Table of contents Document information ....5 Electrical connection ....23 Document function . - Page 4 10.4.3 Configuring the sensor data ... 51 13.3 Endress+Hauser services ....92 10.4.4 Determining the installation factor ..51 10.4.5 Configuring the current output .

-

Page 5: Document Information

Proline t-mass B 150 HART Document information Document information Document function These Operating Instructions contain all the information that is required in various phases of the life cycle of the device: from product identification, incoming acceptance and storage, to mounting, connection, operation and commissioning through to troubleshooting, maintenance and disposal. -

Page 6: Symbols For Certain Types Of Information

Document information Proline t-mass B 150 HART Symbol Meaning Allen key A0011221 Hexagon wrench A0011222 1.2.4 Symbols for certain types of information Symbol Meaning Allowed Indicates procedures, processes or actions that are allowed. A0011182 Preferred Indicates procedures, processes or actions that are preferred. -

Page 7: Documentation

The document types listed are available: • On the CD-ROM supplied with the device • In the Download Area of the Endress+Hauser Internet site: www.endress.com ® Download 1.3.2 Supplementary device-dependent documentation If the device is being used in a hazardous location: Instructions in the relevant supplementary documentation must be consistently observed. -

Page 8: Basic Safety Instructions

Observe the specified maximum process pressure. ► Verification for borderline cases: For special fluids and fluids for cleaning, Endress+Hauser is glad to provide assistance in verifying ► the corrosion resistance of fluid-wetted materials, but does not accept any warranty or liability. -

Page 9: Workplace Safety

It meets general safety standards and legal requirements. It also complies with the EC directives listed in the device-specific EC Declaration of Conformity. Endress+Hauser confirms this by affixing the CE mark to the device. Endress+Hauser... -

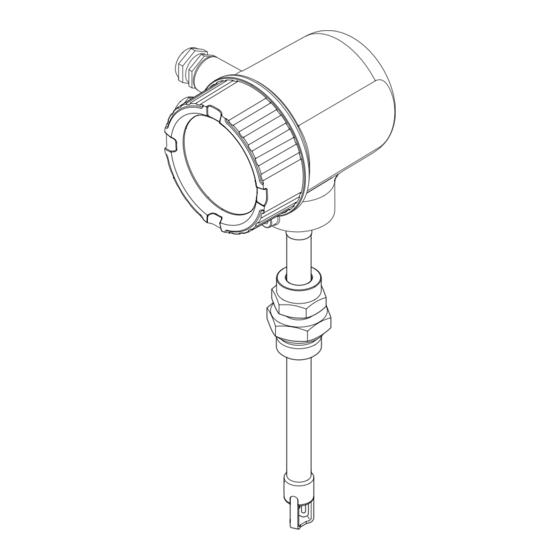

Page 10: Product Description

Electronics module Cable gland Transmitter housing Sensor S-DAT Registered trademarks Ò HART Registered trademark of the HART Communication Foundation, Austin, USA Ò Ò Ò Applicator , FieldCare , Field Xpert , HistoROM Registered or registration-pending trademarks of the Endress+Hauser Group Endress+Hauser... -

Page 11: Incoming Acceptance And Product

Are the goods undamaged? A0015502 A0013699 Do the nameplate data match the ordering information on the delivery note? A0015502 A0013697 Is the CD-ROM with the Technical Documentation and documents present? If one of the conditions does not comply, contact your Endress+Hauser distributor. Endress+Hauser... -

Page 12: Product Identification

Incoming acceptance and product identification Proline t-mass B 150 HART Product identification The following options are available for identification of the measuring device: • Nameplate specifications • Order code with breakdown of the device features on the delivery note • Enter serial numbers from nameplates in W@M Device Viewer (www.endress.com/deviceviewer): All information about the measuring device is displayed. -

Page 13: Sensor Nameplate

Proline t-mass B 150 HART Incoming acceptance and product identification 4.2.2 Sensor nameplate Ser. no.: Materials: Seals: Ser.No.: A0017233 å 2 Example of 1st sensor nameplate Name of the sensor Serial number (Ser. no.) CE mark, C-Tick Process pressure range... -

Page 14: Storage And Transport

Storage and transport Proline t-mass B 150 HART Storage and transport Storage conditions Observe the following notes for storage: • Store in the original packaging to ensure protection from shock. • Do not remove the protection cap mounted on the transducer. It prevents mechanical damage and contamination in the measuring tube. -

Page 15: Installation

Proline t-mass B 150 HART Installation Installation Installation conditions For mechanical reasons and to protect the pipe, support is recommended for heavy sensors (e.g. with a hot-tap retractable assembly). 6.1.1 Mounting position Mounting location Thermal measuring devices require a fully developed flow profile as a prerequisite for correct flow measurement. - Page 16 Choosing the sensor length The minimum length of the senor can be calculated using the Endress+Hauser calculation program Applicator (from version 10.00) or using the following calculation. The minimum length of the sensor is determined by the required insertion depth. The required insertion depth that is calculated must be within the adjusting range of the selected insertion version.

- Page 17 C1 + C2 = 107 mm (4.21 in) DK6MB-CXA mounting boss 3/4" NPT C1 + C2 = 102 mm (4.02 in) Determining C1 and C2 (not limited to Endress+Hauser original parts) Length of pipe connection used C2 (compression fitting with G1A thread) 39 mm (1.54 in)

- Page 18 Installation Proline t-mass B 150 HART Align the insertion version with the direction of flow. 90° (±3°) 90°(±7°) A0015746 Check and ensure that the sensor on the pipe/duct is aligned at a 90° angle to the direction of flow. Rotate the sensor so that the arrow marking on the sensor body corresponds to the direction of flow.

-

Page 19: Requirements From Environment And Process

Proline t-mass B 150 HART Installation Outlet run for pressure or temperature transmitter If a pressure or temperature measuring device is installed downstream of the measuring device, make sure there is sufficient distance between the two devices. 2…5 × DN... -

Page 20: Mounting The Measuring Device

Installation Proline t-mass B 150 HART Mounting the measuring device 6.2.1 Required tools For transmitter For turning the transmitter housing (in increments of 90°): Allen screw 4 mm (0.15 in) For sensor For the sensor gland: Corresponding mounting tools 6.2.2 Preparing the measuring device 1. -

Page 21: Turning The Display Module

Proline t-mass B 150 HART Installation max. 2 × 90° 4 mm 4 mm A0017227 1. Unscrew the securing screw using an Allen key. 2. Rotate the housing in the desired direction. 3. Firmly tighten the securing screw. 6.2.5 Turning the display module... - Page 22 Installation Proline t-mass B 150 HART Has the correct orientation for the sensor been selected (® ä 15)? • According to sensor type • According to medium properties • According to medium temperature • According to process pressure Does the arrow on the sensor match the direction of flow of the medium through the piping (® ä 15)?

-

Page 23: Electrical Connection

Proline t-mass B 150 HART Electrical connection Electrical connection Connection conditions 7.1.1 Required tools • For cable entries: Use corresponding tools • Wire stripper • When using stranded cables: Crimping tool for wire end ferrule • Flat blade screwdriver£ 3 mm (0.12 in) 7.1.2... -

Page 24: Preparing The Measuring Device

Electrical connection Proline t-mass B 150 HART Power Supply DC 24 V L– – Pulse/freq./ switch output – 4…20 mA HART – A0017222 7.1.5 Preparing the measuring device 1. Remove dummy plug if present. 2. NOTICE! Insufficient sealing of the housing. Operational reliability of the measuring device could be defeated. -

Page 25: Connecting The Cables

Proline t-mass B 150 HART Electrical connection 7.2.1 Connecting the cables 20 mm 3 (0.12) – 10 (0.4) mm (in) A0017250 1. Unscrew the connection compartment cover. 2. Remove the display module. 3. Push the supply cable through the cable entry. To ensure tight sealing, do not remove the sealing ring from the cable entry. -

Page 26: Post-Connection Check

Electrical connection Proline t-mass B 150 HART 2. Tighten all housing screws and screw covers. 3. Firmly tighten the cable glands. 4. To ensure that moisture does not enter the cable entry, route the cable so that it loops down before the cable entry ("water trap"). -

Page 27: Operation Options

Proline t-mass B 150 HART Operation options Operation options Overview of operation options A0015607 Local operation via display module Computer with operating tool (e.g. FieldCare, AMS Device Manager, SIMATIC PDM) Field Xpert SFX100 Field Communicator 375, 475 Control system (e.g. PLC) Structure and function of the operating menu 8.2.1... - Page 28 Operation options Proline t-mass B 150 HART Operating menu for operators and maintenances Language Display/operat. Access status display Locking status Display Operation Setup Wizard 1 / Parameter 1 Wizard 2 / Parameter 2 Wizard n / Parameter n Advanced setup...

-

Page 29: Operating Philosophy

Proline t-mass B 150 HART Operation options 8.2.2 Operating philosophy The individual parts of the operating menu are assigned to certain user roles. Each user role contains typical tasks within the device lifecycle. Menu User role and tasks Content/meaning Language task-oriented Role "Operator", "Maintenance"... -

Page 30: Access To The Operating Menu Via The Local Display

Operation options Proline t-mass B 150 HART Access to the operating menu via the local display 8.3.1 Operational display X X X X X X X 1120.50 kg/h A0016501 Operational display Device tag (® ä 55) Status area Display area for measured values (4-line) Operating elements (®... - Page 31 Proline t-mass B 150 HART Operation options Communication Symbol Meaning Communication via remote operation is active. A0013965 Display area In the display area, each measured value is prefaced by certain symbol types for further description: Measured variable Measurement channel number Diagnostic behavior ¯...

-

Page 32: Navigation View

Operation options Proline t-mass B 150 HART 8.3.2 Navigation view Of the submenu In the wizard 0091-1 /../Display/operat. /../Curr. output 1 Access stat.disp Assign curr. Operator Mass flow Locking status Display A0013993-EN A0013995-EN Navigation view Navigation path to current position... - Page 33 Proline t-mass B 150 HART Operation options Display area Menus Symbol Meaning Display/operat. Appears: • In the menu next to the "Display/operat." selection A0013973 • At the left in the navigation path in the "Display/operat." menu Setup Appears: • In the menu next to the "Setup" selection A0013974 •...

-

Page 34: Editing View

Operation options Proline t-mass B 150 HART 8.3.3 Editing view Numeric editor Text editor A0013941 A0013999 Editing view Display area of the entered values Input mask Operating elements (® ä 35) Input mask The following input symbols are available in the input mask of the numeric and text editor:... -

Page 35: Operating Elements

Proline t-mass B 150 HART Operation options Confirms selection. A0013985 Switches to the selection of the correction tools. A0013987 Exits the input without applying the changes. A0013986 Clears all entered characters. A0014040 Correction symbols under Symbol Meaning Clears all entered characters. -

Page 36: Opening The Context Menu

Operation options Proline t-mass B 150 HART Meaning Enter key For operational display • Pressing the key briefly opens the operating menu. • Pressing the key for 2 s opens the context menu. In a menu, submenu • Pressing the key briefly: –... - Page 37 Proline t-mass B 150 HART Operation options 2. Press S + O simultaneously. Ã The context menu is closed and the measured value display appears. Calling up the menu via the context menu 1. Open the context menu. 2. Press O to navigate to the desired menu.

-

Page 38: Navigating And Selecting From List

Operation options Proline t-mass B 150 HART 8.3.6 Navigating and selecting from list Different operating elements are used to navigate through the operating menu. The navigation path is displayed on the left in the header. Icons are displayed in front of the individual menus. These icons are also shown in the header during navigation. - Page 39 Proline t-mass B 150 HART Operation options The user is in the navigation view and the selection bar is on a parameter. 1. 2 s Press F for à The help text for the selected parameter opens. Ent. access code Enter access code to disable write protec.

-

Page 40: Changing The Parameters

Operation options Proline t-mass B 150 HART 8.3.8 Changing the parameters For a description of the editing display - consisting of text editor and numeric editor - with symbols (® ä 34), for a description of the operating elements (® ä 30) Example: Changing the parameter "20 mA value"... -

Page 41: User Roles And Related Access Authorization

Proline t-mass B 150 HART Operation options A message is displayed if the value entered is outside the permitted value range. Ent. access code Invalid or out of range input value Min:0 Max:9999 A0014049-EN 8.3.9 User roles and related access authorization The two user roles "Operator"... - Page 42 Operation options Proline t-mass B 150 HART XXXXXXXXXX 20.50 Keylock on kg/h A0014000-EN After disabling the keypad lock: XXXXXXXXXX 20.50 Keylock off kg/h A0014001-EN If the user attempts to access the operating menu while the keylock is enabled, the message "Keylock on"...

-

Page 43: Access To The Operating Menu Via The Operating Tool

FieldCare Function scope Field Device Table (FDT) based plant asset management tool from Endress+Hauser. It can configure all smart field units in a system and helps you manage them. By using the status information, it is also a simple but effective way of checking their status and condition. -

Page 44: Simatic Pdm

Operation options Proline t-mass B 150 HART 8.4.4 SIMATIC PDM Function scope SIMATIC PDM is a standardized, manufacturer-independent program from Siemens for the operation, configuration, maintenance and diagnosis of intelligent field devices via HART protocol. Source for device description files See data (®... - Page 45 Proline t-mass B 150 HART Operation options Via service interface (CDI) – A0017253 Service interface (CDI) of the measuring device (= Endress+Hauser Common Data Interface) Commubox FXA291 Computer with "FieldCare" operating tool Endress+Hauser...

-

Page 46: System Integration

System integration Proline t-mass B 150 HART System integration Overview of device description files 9.1.1 Current version data for the device Firmware version 01.00.zz • On the title page of the Operating instructions • On transmitter nameplate(® ä 12) • Parameter firmware version Diagnostics ®... -

Page 47: Other Settings

Proline t-mass B 150 HART System integration • Expert ® Communication ® HART output ® Output ® Assign PV • Expert ® Communication ® HART output ® Output ® Assign SV • Expert ® Communication ® HART output ® Output ® Assign TV •... -

Page 48: Commissioning

Commissioning Proline t-mass B 150 HART Commissioning 10.1 Function check Before commissioning the device, make sure that the post-installation and post-connection checks have been performed. • "Post-mounting check" checklist (® ä 21) • "Post-connection check" checklist (® ä 26) 10.2 Switching on the measuring device After a successful function check, switch on the measuring device. -

Page 49: Configuring The Measuring Device

Proline t-mass B 150 HART Commissioning 10.4 Configuring the measuring device The Setup menu with its guided wizards contains all parameters needed for standard operation. Navigation to the "Setup" menu X X X X X X X 20.50 Main menu... -

Page 50: Specifying The Process Pressure

Commissioning Proline t-mass B 150 HART Parameter overview with brief description Parameter Description Selection/ Factory setting User entry Select gas type Select the gas type for the Gas type choose list measurement application. • Air • Argon Ar • Carbon dioxide CO2 •... -

Page 51: Configuring The Sensor Data

Proline t-mass B 150 HART Commissioning 10.4.3 Configuring the sensor data Configuring the pipe shape Navigation path "Setup" menu ® Pipe shape Parameter overview with brief description Parameter Description Selection/ Factory setting User entry Pipe shape Select the shape of the pipe... - Page 52 Commissioning Proline t-mass B 150 HART Parameter overview with brief description Parameter Description Selection/ Factory setting User entry Installation factor The factor is multiplied by 0 to 9 the mass flow to correct sub- optimum installations Endress+Hauser...

-

Page 53: Configuring The Current Output

Proline t-mass B 150 HART Commissioning 10.4.5 Configuring the current output Navigation path "Setup" menu ®Assign current output "Setup" menu ®4mA value "Setup" menu ®20mA value Parameter overview with brief description Parameter Description Selection/ Factory setting User entry Assign current output... -

Page 54: Output

Commissioning Proline t-mass B 150 HART Assign switch output Select the function for the • Off switch output. • On • Diagnostic behavior • Limit value • Status Assign limit Select the process variable for • Mass flow Mass flow the limit function. -

Page 55: Advanced Settings

Proline t-mass B 150 HART Commissioning 10.5 Advanced settings The Advanced setup menu with its submenus contains all parameters needed for specific settings. Navigation path "Setup" menu ® Advanced setup Navigation to the "Advanced setup" menu X X X X X X X 20.50... -

Page 56: Defining The Tag Name

Commissioning Proline t-mass B 150 HART Low flow cut off ® (® ä 68) Totalizer ® (® ä 69) ® Display (® ä 49) ® Conf. backup disp. (® ä 48) 10.5.1 Defining the tag name XXXXXXXXX A0013375 Device tag The number of characters displayed depends on the characters used. -

Page 57: Setting The System Units

Proline t-mass B 150 HART Commissioning Parameter Description Selection/ Factory setting User entry Select gas type Select the gas type for the Gas type choose list measurement application. • Air • Argon Ar • Carbon dioxide CO2 • Nitrogen N2... - Page 58 Commissioning Proline t-mass B 150 HART Mass unit Corrected volume flow unit Corrected volume unit FAD volume flow unit FAD volume unit Density unit Pressure unit Temperature unit Length unit Parameter overview with brief description Parameter Description Selection/ Factory setting...

- Page 59 Proline t-mass B 150 HART Commissioning Parameter Description Selection/ Factory setting User entry Corrected volume flow unit Select the unit for corrected Nl/s Country-dependent: volume flow. Nl/min • Nm³/h Nl/h • Scf/min Result Nl/d The selected unit applies for: Nm³/s –...

-

Page 60: Configuring The Current Output

Commissioning Proline t-mass B 150 HART Parameter Description Selection/ Factory setting User entry Temperature unit Select the unit for °C Country-dependent: • °C (Celsius) temperature. °F • °F (Fahrenheit) Result °R The selected unit applies for: – Current outputs – Reference temperature –... - Page 61 Proline t-mass B 150 HART Commissioning Parameter overview with brief description Parameter Description Selection/ Factory setting User entry Assign current output Use this function to assign a Mass flow Mass flow measured variable or process Corrected volume flow variable to the current output...

-

Page 62: Configuring The Pfs Output

Commissioning Proline t-mass B 150 HART Parameter Description Selection/ Factory setting User entry Temperature unit Select the unit for °C Country-dependent: • °C (Celsius) temperature. °F • °F (Fahrenheit) Result °R The selected unit applies for: – Current outputs – Reference temperature –... - Page 63 Proline t-mass B 150 HART Commissioning Pulse width Failure mode Pulse output Invert output signal Assign frequency Unit Minimum frequency value Maximum frequency value Value at minimum frequency Value at maximum frequency Response time Damping Failure mode Failure frequency Invert output signal...

- Page 64 Commissioning Proline t-mass B 150 HART Parameter overview with brief description Parameter Description Selection/ Factory setting User entry Operating mode Specify the output as a pulse, • Pulse Pulse frequency or switch output. • Frequency • Switch Assign pulse output Select the process variable for •...

- Page 65 Proline t-mass B 150 HART Commissioning Parameter Description Selection/ Factory setting User entry FAD volume flow unit Use this function to select the Country-dependent: preferred unit that is to be Nm³ • m³ FAD/h displayed for the FAD • cf FAD/min volume flow.

- Page 66 Commissioning Proline t-mass B 150 HART Parameter Description Selection/ Factory setting User entry Failure mode Select the value the current • Min. current Max. current output adopts in an alarm • Max. current condition. • Last valid value Prerequisite: The "FIXED •...

-

Page 67: Configuring The Output Conditioning

Proline t-mass B 150 HART Commissioning 10.5.6 Configuring the output conditioning The damping and the step response time can be configured in the Display behavior submenu. Navigation path "Setup" menu ® Advanced setup ® Output conditioning Structure of the submenu Output conditioning ®... -

Page 68: Configuring The Low Flow Cut Off

Commissioning Proline t-mass B 150 HART 10.5.7 Configuring the low flow cut off Navigation path "Setup" menu ® "Advanced setup" menu ®Low flow cut off Structure of the submenu ® Low flow cut off Assign process variable Switch-on value Switch-off value... -

Page 69: Configuring The Totalizer

Proline t-mass B 150 HART Commissioning 10.5.8 Configuring the totalizer You can configure the totalizer in the Totalizer submenu. Navigation path "Setup" menu ® Advanced setup ® Totalizer Structure of the submenu Totalizer ® Assign process variable Unit Failure mode... - Page 70 Commissioning Proline t-mass B 150 HART Value 1 display Select the measured value • Mass flow Mass flow that is shown on the local • Corrected volume flow display. • FAD volume flow • Temperature • Totalizer • Current output...

-

Page 71: Configuration Management

Proline t-mass B 150 HART Commissioning Decimal places 4 Select the number of decimal x.xx places for the display value. x.xx x.xxx x.xxxx Display interval Set time measured values are 1 to 10 shown on display if display alternates between values. -

Page 72: Simulation

Commissioning Proline t-mass B 150 HART Configuration management Select action for managing • Cancel Cancel the device data in the display • Execute backup module • Restore • Duplicate • Compare • Clear backup data Comparison result Comparison between • Settings identical... -

Page 73: Protecting Settings From Unauthorized Access

Proline t-mass B 150 HART Commissioning Assign simulation Select a process • Off process variable variable for the • Mass flow simulation process • Corrected that is activated. volume flow • FAD volume flow • Energy flow • Temperature Value process... -

Page 74: Write Protection Via Lock Switch

Commissioning Proline t-mass B 150 HART Ã The -symbol appears in front of all write-protected parameters. Parameters that can always be changed The write protection does not include certain parameters that do not affect the measurement. Despite the defined access code, they can always be modified even if the other parameters are locked. - Page 75 Proline t-mass B 150 HART Commissioning A0017375 To make it easier to access the lock switch, attach the display module to the edge of the electronics compartment. 4. Setting the lock switch (WP) on the main electronics module to the ON position enables the hardware write protection.

-

Page 76: Operation

Operation Proline t-mass B 150 HART Operation 11.1 Adjusting the operating language See the "Commissioning" section for information on how to set the operating language (® ä 48). 11.2 Configuring the display • Basic settings for local display • Advanced settings for local display (® ä 55) 11.2.1... -

Page 77: Totalizer

Proline t-mass B 150 HART Operation Temperature display navigation path The temperature display can also be viewed directly in the Setup menu: "Setup" menu ® Temperature Structure of the submenu Process variables ® Mass flow Corrected volume flow FAD volume flow... -

Page 78: Output Values

Operation Proline t-mass B 150 HART Totalizer overflow One of the following options is selected Displays the number of Integer in the Assign process variable totalizer overflows. Value range: 0 to 32 000 parameter of the Totalizer submenu: • Mass flow •... -

Page 79: Performing A Totalizer Reset

Proline t-mass B 150 HART Operation 11.5 Performing a totalizer reset In the Operation submenu, 2 parameters with various options for resetting the totalizers are available: • Control totalizer • Preset value • Resetting the totalizer Navigation path "Display/operat." menu ® Operation Function scope of the "Control totalizer"... -

Page 80: Showing Data Logging

Operation Proline t-mass B 150 HART 11.6 Showing data logging In the device, the extended function of the HistoROM must be enabled (order option) so that the Data logging submenu appears. This contains all the parameters for the measured value history. -

Page 81: Diagnostics And Troubleshooting

Proline t-mass B 150 HART Diagnostics and troubleshooting Diagnostics and troubleshooting 12.1 General troubleshooting Problem Possible cause Remedy Local display dark and no signal output Supply voltage does not match that Apply the correct supply voltage at current output (0 mA) specified on the nameplate. - Page 82 Diagnostics and troubleshooting Proline t-mass B 150 HART No connection via HART protocol Commubox Observe the documentation for the • Connected incorrectly Commubox. • Configured incorrectly • FXA 191 HART: Document • Drivers not installed correctly "Technical Information" • USB or COM interface on computer...

-

Page 83: Diagnostic Information On Local Display

Proline t-mass B 150 HART Diagnostics and troubleshooting 12.2 Diagnostic information on local display 12.2.1 Diagnostic message Faults detected by the self-monitoring system of the measuring device are displayed as a diagnostic message alternating with the operational display. Operational display in alarm condition... -

Page 84: Calling Up Remedial Measures

Diagnostics and troubleshooting Proline t-mass B 150 HART Diagnostic information The fault can be identified using the diagnostic information. The short text helps you by providing information about the fault. In addition, the corresponding symbol for the diagnostic behavior is displayed in front of the diagnostic information. -

Page 85: Diagnostic Information In The Operating Tool

Proline t-mass B 150 HART Diagnostics and troubleshooting The user is in the diagnostic message. 1. Press O ( symbol). Ã The message for the remedial measures for the diagnostic event opens. 2. Press S + O simultaneously. Ã The message about the remedial measures closes. -

Page 86: Overview Of Diagnostic Information

Diagnostics and troubleshooting Proline t-mass B 150 HART Navigation path "Expert" menu ® System ® Diagnostic handling ® Diagnostic behavior ® Assign behavior of diagnostic no. xxx A0014048-EN You can assign the following options to the diagnostic number as the diagnostic behavior:... - Page 87 Proline t-mass B 150 HART Diagnostics and troubleshooting Memory content 1. Transfer data or reset device. Alarm 2. Contact service. Electronic failure 1. Transfer data or reset device. Alarm 2. Contact service. Electronic failure Maintenance required! Warning 1. Do not perform reset.

-

Page 88: Resetting The Measuring Device

Diagnostics and troubleshooting Proline t-mass B 150 HART Status Diagnostic signal Diagnostic behavior Short text Remedial measures number from the from the factory factory Diagnostics for the process Current loop 1. Check wiring. Alarm 2. Change electronics module. Ambient temperature Reduce ambient temperature. -

Page 89: Event Logbook

Proline t-mass B 150 HART Diagnostics and troubleshooting / ../Diagnose list Diagnostics F273 Main electronic Diagnostics 2 Diagnostics 3 A0014006-EN Calling up and closing remedial measures 1. Press F. Ã The message for the remedial measures for the selected diagnostic number opens. -

Page 90: Filtering The Event Logbook

Diagnostics and troubleshooting Proline t-mass B 150 HART • For the structure of the remedial measure message (® ä 83) • For filtering the displayed event messages (® ä 89) 12.8.2 Filtering the event logbook Using the Filter options parameter, you can define which category of event messages is displayed in the Events list submenu. - Page 91 Proline t-mass B 150 HART Diagnostics and troubleshooting I1227 Sensor emergency mode activated I1228 Sensor emergency mode failed I264 Safety sequence aborted I327 Zero point adjust failed signal path I335 Firmware changed Endress+Hauser...

-

Page 92: Repair

• Spare parts are grouped into logical kits with the associated Installation Instructions. • Repairs are carried out by Endress+Hauser Service or by correspondingly trained customers. • Certified devices can be converted into other certified devices only by Endress+Hauser Service or at the factory. -

Page 93: Maintenance

• Follow the instructions in the "Installation" section when removing the sensor (® ä 20). 14.2 Measuring and test equipment Endress+Hauser offers a wide variety of measuring and test equipment, such as W@M or device tests. Your Endress+Hauser representative can provide detailed information on the services. -

Page 94: Return

Proline t-mass B 150 HART Return Observe the following points for returning the device: • Contact your Endress+Hauser Sales Center to obtain information about the procedure and basic conditions. • Enclose the completed "Decontamination declaration" form with the device. The form is available:... -

Page 95: Disposal

Proline t-mass B 150 HART Disposal Disposal 16.1 Removing the measuring device 1. Switch off the device. 2. WARNING! Danger to persons from process conditions. Beware of hazardous process conditions such as pressure in the measuring device, high temperatures or aggressive fluids. -

Page 96: Technical Data

Technical data Proline t-mass B 150 HART Technical data 17.1 Application The measuring device is suitable for flow measurement of gases only. To ensure that the device remains in proper operating condition for its service life, use the measuring device only for media against which the process-wetted materials are adequately resistant. - Page 97 Proline t-mass B 150 HART Technical data [kg/h] /h] at 0 °C (1.013 bar a) /h at 15 °C (1.013 bar a) [mm] min. Max. min. Max. min. Max. 80 000 62 000 65 500 1 150 115 000 89 000...

-

Page 98: Output

Technical data Proline t-mass B 150 HART US units for insertion version [lb/h] [Scf/min] at 32 °F (14.7 psi a) [Scf/min] at 59 °F (14.7 psi a) [in] min. Max. min. Max. min. Max. 6 714 1 386 1 466 12 403.5... - Page 99 Proline t-mass B 150 HART Technical data Pulse width Adjustable: 0.5 to 2 000 ms ® pulse rate: 0 to 1 000 Pulse/s Pulse value Adjustable Assignable measured • Mass flow variables • Corrected volume flow • FAD volume flow...

- Page 100 Technical data Proline t-mass B 150 HART Local display Plain text display With information on cause and corrective action Status signal as per NAMUR recommendation NE 107 Operating tool • Via digital communication: HART protocol • Via service interface Plain text display...

-

Page 101: Power Supply

Proline t-mass B 150 HART Technical data 17.5 Power supply Terminal assignment Transmitter Connection version 4-20 mA HART, pulse/frequency/switching output A0017178 Supply voltage Signal transmission: Pulse/frequency/switching output Signal transmission: 4-20 mA HART Ground terminal for cable shield Supply voltage Order characteristic for Terminal numbers "Power supply"... - Page 102 Technical data Proline t-mass B 150 HART Current consumption Order characteristic for Maximum current Maximum switch-on "Output" consumption current • Option A: 4-20mA HART 185 mA < 2.5 A • Option B: 4-20mA HART, pulse/frequency/switching output • Option K: Pulse/frequency/switching output Power supply failure •...

-

Page 103: Performance Characteristics

Proline t-mass B 150 HART Technical data Pulse/frequency/switch output Standard installation cable is sufficient. Supply voltage cable Standard installation cable is sufficient. 17.6 Performance characteristics Reference operating • Calibration systems traceable to national standards conditions • Accredited in accordance with ISO/IEC 17025 •... -

Page 104: Installation

Technical data Proline t-mass B 150 HART Accuracy of outputs o.r. = of reading; o.f.s. = of full scale value Current output Accuracy Max. ±0.05 % o.f.s. or ±10 µA ±0.5 % of value for velocities > 1.0 m/s (3.3 ft/s) Repeatability Typically <... -

Page 105: Process

Proline t-mass B 150 HART Technical data 17.9 Process Medium temperature range Sensor –40 to +100 °C (–40 to +212 °F) Seals (G thread only) • HNBR: –40 to +100 °C (–40 to +212 °F) • EPDM: –35 to +100 °C (–31 to +212 °F) Clamping ring PEEK: –40 to +100 °C (–40 to +212 °F) -

Page 106: 17.10 Mechanical Construction

Technical data Proline t-mass B 150 HART 17.10 Mechanical construction Design, dimensions Compact version G 1 A, G ¾ A 1" NPT, ¾" NPT A0015743 Dimensions in SI units [mm] [mm] [mm] [mm] [mm] 597.4 770.4 For version without local display values - 7 mm... - Page 107 Proline t-mass B 150 HART Technical data Hot tap Low pressure version (up to 4.5 bar g (65 psi g)) G ¾ A, G 1 A, ¾" NPT, 1" NPT 1" NPT 36 mm, 42 mm G 1 A, 1" NPT...

- Page 108 Technical data Proline t-mass B 150 HART Medium pressure version (up to 16 bar g (230 psi g) G ¾ A, G 1 A, ¾" NPT, 1" NPT 1" NPT 1" NPT 36 mm / 42 mm G ¾ A, G 1 A, ¾"...

- Page 109 Proline t-mass B 150 HART Technical data Hot tap Hot tap versions [kg] with retrofit adapter (version V1) with mounting boss (version V2) with flange (version V3) Extractor assembly Weight in US units Compact version Sensor length [in] Weight [lbs]...

-

Page 110: 17.11 Operability

Technical data Proline t-mass B 150 HART Accessories Mounting boss 1.4404 as per EN 10272 and 316/316L as per ASTM A479 Hot tap • Process connection: – Mounting boss: 1.4404 as per EN 10272 and 316/316L as per ASTM A479 –... - Page 111 Proline t-mass B 150 HART Technical data Additional functionality • Data backup function The device configuration can be saved in the display module. • Data comparison function The device configuration saved in the display module can be compared to the current device configuration.

-

Page 112: 17.12 Certificates And Approvals

Directives. These are listed in the corresponding EC Declaration of Conformity along with the standards applied. Endress+Hauser confirms successful testing of the device by affixing to it the CE mark. C-Tick symbol The measuring system meets the EMC requirements of the "Australian Communications and Media Authority (ACMA)". -

Page 113: 17.13 Application Packages

Proline t-mass B 150 HART Technical data Other standards and guidelines • EN 60529 Degrees of protection provided by enclosures (IP code) • EN 61010-1 Protection Measures for Electrical Equipment for Measurement, Control, Regulation and Laboratory Procedures. • IEC/EN 61326 Emission in accordance with Class A requirements. -

Page 114: Appendix

Appendix Proline t-mass B 150 HART Appendix 18.1 Overview of the Operator/Maintenance operating menu The following table provides an overview of the operating menu structure with the specific parameters for operators, maintenance staff and experts. The page reference indicates where a description of the parameter can be found in the manual. - Page 115 Proline t-mass B 150 HART Appendix Measuring value at (® ä 53) minimum frequency (0476) Measuring value at (® ä 53) maximum frequency (0475) Switch output function (® ä 54) (0481) Assign limit (0483) (® ä 54) Switch-off value (0464) (®...

- Page 116 Appendix Proline t-mass B 150 HART FAD volume flow unit (® ä 58) (0601) FAD volume unit (0591) (® ä 58) Density unit (0555) (® ä 58) Pressure unit (0564) (® ä 58) Temperature unit (0557) (® ä 58) Length unit (0551) (®...

- Page 117 Proline t-mass B 150 HART Appendix Temperature unit (0557) (® ä 64) Value per pulse (0455) (® ä 64) Pulse width (0452) (® ä 64) Failure mode (0480) (® ä 64) Minimum frequency value (® ä 64) (0453) Maximum frequency value (®...

- Page 118 Appendix Proline t-mass B 150 HART PFS output ® (® ä 67) Response time (0491) (® ä 67) Damping output (0477) (® ä 67) Low flow cut off ® (® ä 68) Assign process variable (® ä 68) (1837) On value low flow cutoff (®...

- Page 119 Proline t-mass B 150 HART Appendix Separator (0101) (® ä 71) Conf. backup disp. ® (® ä 71) Operating time (0652) (® ä 71) Last backup (0102) (® ä 71) Configuration management (® ä 72) (0100) Comparison result (0103) (® ä 72) ®...

- Page 120 Appendix Proline t-mass B 150 HART Manufacturer ID (0223) (® ä 46) Measured values ® (® ä 76) Process variables ® (® ä 76) Mass flow (1838) (® ä 76) Corrected volume flow (® ä 76) (1847) FAD volume flow (1851) (®...

- Page 121 Proline t-mass B 150 HART Appendix Simulation current output 1 (® ä 48) (0354) Value current output 1 (® ä 48) (0355) Frequency simulation (® ä 48) (0472) Frequency value (0473) (® ä 48) Pulse simulation (0458) (® ä 48) Pulse value (0459) (®...

- Page 122 Appendix Proline t-mass B 150 HART 100% bargraph value 3 (® ä 70) (0126) Decimal places 3 (0118) (® ä 70) Value 4 display (0109) (® ä 70) Decimal places 4 (0119) (® ä 71) Display interval (0096) (® ä 71) Display damping (0094) (®...

- Page 123 Proline t-mass B 150 HART Appendix Totalizer ® (® ä 77) Totalizer value (0911) (® ä 77) Totalizer overflow (0910) (® ä 78) ® Output values (® ä 78) Output current (0361) (® ä 78) Pulse output 1 to 2 (0456) (®...

- Page 124 Appendix Proline t-mass B 150 HART On value low flow cutoff (® ä 68) (1805) Off value low flow cutoff (® ä 68) (1804) ® Calculated value ® Reference values Reference conditions (® ä 57) (3439) Reference pressure (3378) (® ä 57) Reference temperature (®...

- Page 125 Proline t-mass B 150 HART Appendix Flow reference in use (3440) Flow reference value 1 (3401) Power coefficient 1 (3425) Flow reference value 2 (3418) Power coefficient 2 (3426) Flow reference value 3 (3419) Power coefficient 3 (3427) Flow reference value 4...

- Page 126 Appendix Proline t-mass B 150 HART Power coefficient 2 (3393) Flow reference value 3 (3386) Power coefficient 3 (3394) Flow reference value 4 (3387) Power coefficient 4 (3395) Flow reference value 5 (3388) Power coefficient 5 (3396) Flow reference value 6...

- Page 127 Proline t-mass B 150 HART Appendix Failure mode (364) Output current (361) (® ä 78) Start-up mode (368) PFS output 1 ® Operating mode (469) (® ä 53) Assign pulse (460) (® ä 54) Value per pulse (455) (® ä 54) Pulse width (452) (®...

- Page 128 Appendix Proline t-mass B 150 HART Invert output signal (470) (® ä 64) ® Communication HART output ® Configuration ® Burst mode (208) Burst command (207) HART address (219) No. of preambles (217) HART short tag (220) Information Device revision (204) (®...

- Page 129 Proline t-mass B 150 HART Appendix ® Totalizer Assign process variable (® ä 69) (914) Unit (915) (® ä 69) Control totalizer (912) (® ä 79) Preset value (913) (® ä 79) Failure mode (901) (® ä 69) Diagnostics ®...

- Page 130 Appendix Proline t-mass B 150 HART Data logging ® (® ä 80) Assign channel 1 (851) (® ä 80) Assign channel 2 (852) (® ä 80) Assign channel 3 (853) (® ä 80) Assign channel 4 (854) (® ä 80) Logging interval (856) (®...

- Page 131 Proline t-mass B 150 HART Appendix Simulation device alarm (® ä 73) (654) Endress+Hauser...

-

Page 132: Index

Index Proline t-mass B 150 HART Index Design Measuring device ......10 Access authorization to parameters Designated use . - Page 133 Proline t-mass B 150 HART Index Electromagnetic compatibility ....104 Help text Electronic modules ......25 Calling up .

- Page 134 Index Proline t-mass B 150 HART Measuring device Operation options ......27 Configuration ......49 Control system .

- Page 135 Proline t-mass B 150 HART Index Notes ........92 Submenu Repair of a device .

- Page 136 Index Proline t-mass B 150 HART Transmitter housing Turning ....... . . 20 Transporting the measuring device .

- Page 137 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 138 www.endress.com/worldwide BA01043D/06/EN/01.12 71165061 EH-COSIMA ProMoDo...