Endress+Hauser Liquicap M FMI51 Operating Instructions Manual

Capacitance level measurement

Hide thumbs

Also See for Liquicap M FMI51:

- Operating instructions manual (114 pages) ,

- Safety instructions (28 pages) ,

- Operating instructions manual (56 pages)

Summary of Contents for Endress+Hauser Liquicap M FMI51

-

Page 1: Operating Instructions

Operating Instructions Liquicap M FMI51, FMI52 FEI57C PFM Capacitance level measurement BA00297F/00/EN/13.10 71128821 Valid as of software version: FW: V 01.00.00 HW: V 01.00... -

Page 2: Table Of Contents

Operational safety ......3 Contact addresses at Endress+Hauser ..38 Notes on safety conventions and icons . -

Page 3: Safety Instructions

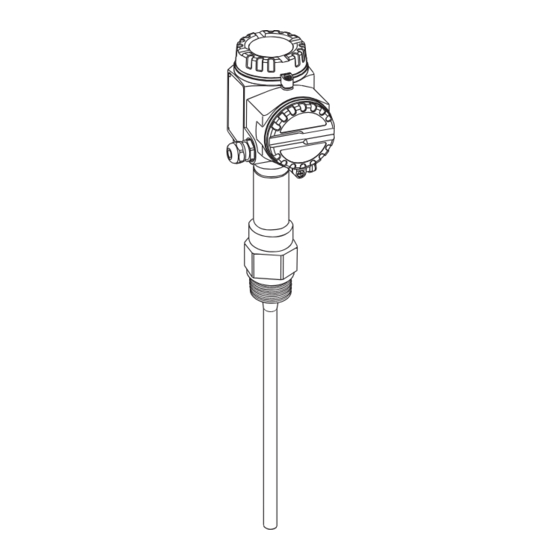

Liquicap M FMI51, FMI52 (PFM) Safety instructions Safety instructions Designated use Liquicap M FMI51, FMI52 are compact, capacitance level transmitters for the continuous measurement of liquids. Installation, commissioning and operation Liquicap M is designed to meet state-of-the-art safety regulations and complies with the applicable requirements and EC Directives. -

Page 4: Notes On Safety Conventions And Icons

Safety instructions Liquicap M FMI51, FMI52 (PFM) Notes on safety conventions and icons To highlight safety-related or alternative processes, we have designed the following safety instructions where every instruction is indicated by a corresponding pictogram. Safety instructions Warning! Draws attention to activities or procedures that can result in serious injuries to persons, a safety risk or the destruction of the device if not carried out properly. -

Page 5: Identification

Liquicap M FMI51, FMI52 (PFM) Identification Identification Device designation 2.1.1 Nameplate You can take the following technical data from the nameplate of the device: Order number (see ordering information) Made in Germany, D- 79689 Maulburg Liquicap M Order Code.: FMI51-xxxxxxxxxxxxxx... - Page 6 Identification Liquicap M FMI51, FMI52 (PFM) Approval: IECEx Ga/Gb Ex ia IIC T6 Special version, to be specified Inactive Length L3: Price per 100 mm/1 inch L3: 100 to 2000 mm/4 to 80 inch for 316L L3: 150 to 1000 mm/6 to 40 inch for PTFE fully insulated...

- Page 7 Liquicap M FMI51, FMI52 (PFM) Identification ∅ inactive length Process Connection: (mm) DN50 PN25/40 A, 316L Flange EN1092-1 22/43*** (DIN2527 B) DN50 PN25/40 B1, 316L Flange EN1092-1 (DIN2527 C) DN50 PN40 C, 316L Flange EN1092-1 (DIN2512 F) DN50 PN40 D,...

- Page 8 Identification Liquicap M FMI51, FMI52 (PFM) Electronics; Output: FEI50H; 4 to 20 mA HART + display FEI50H; 4 to 20 mA HART FEI57C; None; Prepared for FEI5x + display, cover high, transparent W None; Prepared for FEI5x, cover flat Special version, to be specified...

- Page 9 Liquicap M FMI51, FMI52 (PFM) Identification Liquicap M FMI51 (device identification) Approval: A Non-hazardous area Non-hazardous area, ATEX II 1/2 GD Ex ia IIB T6 ATEX II 1/2 GD Ex ia IIB T6, G ATEX II 1/2 G Ex d (ia) IIB T6,...

- Page 10 Identification Liquicap M FMI51, FMI52 (PFM) ∅ inactive length (mm) Process Connection: DN40-51 (2"), EHEDG PTFE >316L, 3A, Tri-Clamp ISO2852 – EN flanges DN25 PN25/40 A, 316L Flange EN1092-1 (DIN2527 B) DN32 PN25/40 A, 316L Flange EN1092-1 (DIN2527 B) DN40 PN25/40 A,...

- Page 11 Liquicap M FMI51, FMI52 (PFM) Identification ∅ inactive length (mm) Process Connection: 10K 25 RF, PTFE >316L Flange JIS B2220 – 10K 40 RF, PTFE >316L Flange JIS B2220 – 10K 50 RF, PTFE >316L Flange JIS B2220 – 10K 80 RF, PTFE >316L...

-

Page 12: Scope Of Delivery

The device complies with the applicable standards and regulations that are listed in the EC Declaration of Conformity and thus meets the legal requirements of the EC Directives. Endress+Hauser confirms that the device has been tested successfully by affixing the CE mark. -

Page 13: Installation

Liquicap M FMI51, FMI52 (PFM) Installation Installation Quick installation guide < 80 Nm (G ) ½ < 100 Nm (G ) ¾ < 180 Nm (G1) < 500 Nm (G1 ) ½ ... 270° L00-FMI5xxxx-17-06-xx-xx-001 1.) Screw in the device 2. -

Page 14: Planning Instructions

Planning instructions 3.3.1 Installation The Liquicap M FMI51 (rod probe) can be installed from above and from below. The Liquicap M FMI52 (rope probe) can be installed vertically from above. Note! • Recommended distance from the container floor: ≥10 mm. -

Page 15: Measuring Condition

Liquicap M FMI51, FMI52 (PFM) Installation 3.3.2 Support with marine approval (GL) Conductive or nonconductive support can be provided for fully insulated rod probes. Partially insulated rod probes may only be supported with insulation at the uninsulated end of the probe. -

Page 16: Minimum Probe Length For Nonconductive Media (<1Μs/Cm)

Installation Liquicap M FMI51, FMI52 (PFM) Minimum probe length for nonconductive media (<1μs/cm) = ΔC / (C * [εr - 1]) = Minimum probe length ΔC = 5 pF = Probe capacitance in air (see also → ä 38, "Additional capacitance") εr... - Page 17 Liquicap M FMI51, FMI52 (PFM) Installation FMI51: rod probe with ground tube Nonconductive tanks (plastic tanks) When installing in a plastic tank, a probe with a ground tube must be used. L00-FMI5xxxx-11-06-xx-xx-005 FMI51: rod probe with inactive length (e.g. for insulated tanks)

- Page 18 Installation Liquicap M FMI51, FMI52 (PFM) FMI51: rod probe with ground tube and inactive length (for mounting nozzles) L00-FMI5xxxx-11-06-xx-xx-007 FMI51: fully insulated probe with clad flange for aggressive media L00-FMI5xxxx-11-06-xx-xx-011 Endress+Hauser...

- Page 19 Liquicap M FMI51, FMI52 (PFM) Installation 3.6.2 Rope probes Note! These application examples show the installation of rope probes for continuous level measurement. FMI52: rope probe L00-FMI5xxxx-11-06-xx-xx-008 FMI52: rope probe with inactive length (e.g. for insulated tanks) L00-FMI5xxxx-11-06-xx-xx-009 Endress+Hauser...

- Page 20 Installation Liquicap M FMI51, FMI52 (PFM) FMI52: rope probe with fully insulated inactive length (for mounting nozzles) L00-FMI5xxxx-11-06-xx-xx-010 3.6.3 Shortening the rope Note! See Operating Instructions, rope shortening kit KA061F/00. 3.6.4 Tensioning weight with tension The end of the probe needs to be secured if the probe would otherwise touch the silo wall or another part in the tank.

-

Page 21: With Separate Housing

Liquicap M FMI51, FMI52 (PFM) Installation With separate housing Zone 1 Zone 0 ≤ L00-FMI5xxxx-14-00-06-xx-002 Rod length L1 max. 4 m Rope length L1 max. 9.7 m (the maximum total length of L1 + L4 should not exceed 10 m). - Page 22 Installation Liquicap M FMI51, FMI52 (PFM) Polyester housing Stainless steel Aluminum housing (F16) housing (F15) (F17) B (mm) H1 (mm) H5 (mm) D (mm) Probes Ø10 mm rod Probes Ø16 mm rod or rope G¾", G1", NPT¾", NPT1", Clamp 1", (without fully insulated inactive Clamp 1½", Universal Ø44,...

- Page 23 Liquicap M FMI51, FMI52 (PFM) Installation • Screw the separate housing on a pipe of max. 2”. L00-FMI5xxxx-03-05-xx-xx-011 3.7.5 Shortening the connecting cable Recalibration must be performed before commissioning → ä 33 Note! The maximum connection length between the probe and the separate housing is 6 m. When ordering a device with a separate housing, the desired length must be specified.

-

Page 24: Installation Instructions

Installation Liquicap M FMI51, FMI52 (PFM) • Loosen the pressing screw (1) with an open-end wrench (AF22). If necessary, hold the process connection. Please make sure that neither the connecting cable nor the probe is turning with the pressing screw. - Page 25 Liquicap M FMI51, FMI52 (PFM) Installation Probe with Tri-Clamp, sanitary connection or flange • The process seal must meet the specifications of the application (resistant to temperature and medium). • If the flange is PTFE-clad, this generally suffices as the seal up to the permitted operating pressure.

-

Page 26: Post-Installation Check

Installation Liquicap M FMI51, FMI52 (PFM) ... 270° L00-FMI5xxxx-04-00-00-xx-002 1. Loosen clamping screw until the housing rotates easily. 2. Align the housing. 3. Tighten clamping screw (< 1 Nm) until the housing can no longer be rotated. 4. Additional protection against moisture penetration for electronics compartment. -

Page 27: Wiring

Liquicap M FMI51, FMI52 (PFM) Wiring Wiring " Caution! Before connecting the supply voltage, note the following: • The supply voltage must match the data specified on the nameplate (1). • Switch off the supply voltage before connecting the device. -

Page 28: Wiring And Connecting

Wiring Liquicap M FMI51, FMI52 (PFM) 4.1.4 Connector For the version with a connector M12, the housing does not have to be opened for connecting the signal line. PIN assignment for plug M12 2-Wire Electronic Insert FEI57C not used –... - Page 29 Liquicap M FMI51, FMI52 (PFM) Wiring I=16mA FEI55 – 8/16mA 11...36V DC – L00-FTI5xxxx-04-06-xx-xx-003 a. + b. L00-FTI5xxxx-04-06-xx-xx-004 Information on connecting shielded cables is provided in TI241 "EMC test procedures". Cable entry Cable gland: M20x1.5 Cable entry: G ½ or NPT ½, NPT ¾...

- Page 30 Wiring Liquicap M FMI51, FMI52 (PFM) 4.2.1 Connecting the FEI57C to Silometer FMX570 Silometer FMX570 FMX570 – – – d2 d4 (+) (–) 2 (+) 1 (–) L00-FMI5xxxx-04-00-00-en-012 The Silometer FMX570 is no longer available. 4.2.2 Connecting the FEI57C to Silometer FMC671Z...

-

Page 31: Post-Connection Check

Liquicap M FMI51, FMI52 (PFM) Wiring 4.2.3 Connecting the FEI57C to Prolevel FMC661, FMC662 Endress+Hauser Prolevel PROLEVEL 123.4 FMC661 FMC662 FMC662 – 92 91 (Sensor 2) 82 81 (Sensor 1) (+) (–) 2 (+) 1 (–) L00-FMI5xxxx-04-00-00-en-014 The Prolevel FMC661 and FMC662 are no longer available. -

Page 32: Operation

Operation Liquicap M FMI51, FMI52 (PFM) Operation Operating options DIP switch green LED red LED > 6 m > 6 m Probe Build up FEI57C length L00-FMI5xxxx-07-05-xx-en-101 Display and operating elements Green LED ( indicates operation) • Flashes every 5 s: Indicates that the device is ready for operation. -

Page 33: Commissioning

Liquicap M FMI51, FMI52 (PFM) Commissioning Commissioning Function check Make sure that the post-installation check and final check have been completed before you start your measuring point: • For the "Post-installation check" checklist, see → ä 26 • For the "Post-connection check" checklist, see → ä 31... -

Page 34: Maintenance

Repair The Endress+Hauser repair concept is devised in such a way that the devices have a modular design and repairs can be carried out by the customers. Spare parts are grouped into handy kits with related replacement instructions. The "Spare parts"... -

Page 35: Accessories

Liquicap M FMI51, FMI52 (PFM) Accessories Accessories Protective cover For F13 and F17 housing Order number: 71040497 For F16 housing Order number: 71127760 Shortening set for FMI52 For Liquicap M FMI52 (no hygienic approval: EHEDG, 3A) Order number: 942901-0001 Commubox FXA195 HART For intrinsically safe HART communication with FieldCare via the RS232C interface or USB. -

Page 36: Application Errors

Troubleshooting Liquicap M FMI51, FMI52 (PFM) Cause/error Green LED Red LED Red LED (indicates operation) (indicates a fault) flashes (indicates a fault) flashes is not flashing five times a second (s) once a second (s) The temperature in the electronic... -

Page 37: Spare Parts

Return The following measures must be taken before returning a device to Endress+Hauser for repair: • Remove all traces of fluid. Pay particular attention to crevices and grooves for seals into which fluid can penetrate. -

Page 38: Disposal

HW: V 01.00 Contact addresses at Endress+Hauser On the back page of these Operating Instructions, you can find an internet address for Endress+Hauser. The web site provides contact addresses that you can use in case of any questions. Technical data 10.1 Technical data: probe 10.1.1... -

Page 39: Input

Liquicap M FMI51, FMI52 (PFM) Technical data 10.2 Input 10.2.1 Measured variable Continuous measurement of change in capacitance between probe rod and container wall or ground tube, depending on the level of the liquid. Probe covered => high capacitance Probe not covered =>... - Page 40 Technical data Liquicap M FMI51, FMI52 (PFM) 10.4.3 Influence of ambient temperature Electronic insert < 0.06 %/10 K related to the full scale value Separate housing Change in capacitance of connecting cable 0.015 pF/m per K 10.4.4 Switch-on behavior FEI57C 1.5 s (stable measured value after switch-on procedure).

-

Page 41: Power Supply

Liquicap M FMI51, FMI52 (PFM) Technical data 10.4.6 Accuracy of factory calibration Probe length < 2 m ≤ 5 mm Probe length > 2 m Empty calibration (0 %) ≤ 5 mm Approx. 2 % Full calibration (100 %) Approx. 2 % Medium conductivity ≥... -

Page 42: Operating Conditions: Environment

Technical data Liquicap M FMI51, FMI52 (PFM) 10.5.2 Terminal assignment 2-wire, PFM Speisegerät The twin-core, shielded connecting cable with FMC671* 50 Ω is connected to the screw terminals a cable resistance of max. (conductor cross-section 0.5 to 2.5 mm) in the connection compartment. - Page 43 Liquicap M FMI51, FMI52 (PFM) Technical data • Observe derating → ä 44 • If operating outdoors, use a protective cover! → ä 35. 10.6.2 Storage temperature –50 to +85 °C 10.6.3 Climate class DIN EN 60068-2-38/IEC 68-2-38: Z/AD check 10.6.4...

-

Page 44: Operating Conditions: Process

Technical data Liquicap M FMI51, FMI52 (PFM) 10.7 Operating conditions: Process 10.7.1 Process temperature range The following diagrams apply for: • Rod and rope version • Insulation: PTFE, PFA, FEP • Standard applications outside hazardous areas Note! The temperature is restricted to T –40 °C if the polyester housing F16 is used and if additional... - Page 45 Liquicap M FMI51, FMI52 (PFM) Technical data 10.7.2 Process pressure limits Probe ø10 mm (including insulation) –1 to 25 bar Probe ø16 mm (including insulation) • –1 to 100 bar • In the event of an inactive length, the maximum permitted process pressure is 63 bar •...

-

Page 46: Certificates And Approvals

Technical data Liquicap M FMI51, FMI52 (PFM) +40/ +100 +80/ 63 * +200/ °C –80 160 180 –60 –40 –20 +200/ –1 L00-FMI5xxxx-05-05-xx-xx-010 Pp : process pressure Tp : process temperature * For probes with an inactive length . With a fully insulated inactive length (22 mm rod):... -

Page 47: Documentation

Liquicap M FMI51, FMI52 (PFM) Technical data 10.8.2 Other approvals • See also "Identification" on → ä 5 ff. • TSE Certificate of Suitability (FMI51) The following applies to wetted device components: – They do not contain any materials derived from animals. - Page 48 Technical data Liquicap M FMI51, FMI52 (PFM) Control Drawings (CSA and FM) • Liquicap M FMI51, FMI52 ZD00220F/00/en • Liquicap M FMI51, FMI52 ZD00221F/00/en CRN registration • CRN 0F1988.75 10.9.3 Patents This product is protected by at least one of the following patents.

-

Page 49: Index

Liquicap M FMI51, FMI52 (PFM) Index Index Accessories ........35 Operating menus . - Page 50 Liquicap M FMI51, FMI52 (PFM) Index Endress+Hauser...

- Page 51 Erklärung zur Kontamination und Reinigung Please reference the Return Authorization Number (RA#), obtained from Endress+Hauser, on all paperwork and mark the RA# clearly on the outside of the box. If this procedure is not followed, it may result in the refusal of the package at our facility.

- Page 52 www.endress.com/worldwide BA00297F/00/EN/13.10 71128821 CCS/FM+SGML 6.0 71128821...