Table of Contents

Troubleshooting

Summary of Contents for Daikin VAM350J7VEB

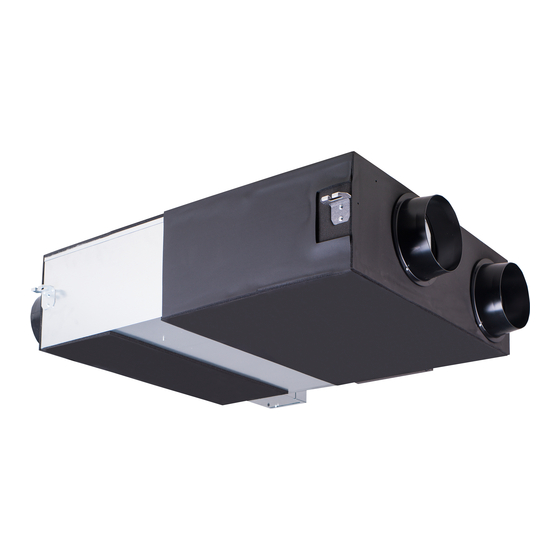

- Page 1 Installer and user reference guide Heat reclaim ventilation unit VAM350J7VEB VAM500J7VEB VAM650J7VEB VAM800J7VEB VAM1000J7VEB Installer and user reference guide VAM1500J7VEB English Heat reclaim ventilation unit VAM2000J7VEB...

-

Page 2: Table Of Contents

Table of contents 8 Configuration Table of contents Operating procedure ..............24 8.1.1 To change settings............24 List of settings ................25 Settings for all configurations ............. 29 1 General safety precautions 8.3.1 About setting 19(29)-0-04 and 19(29)-0-05 ....30 About the documentation ............ -

Page 3: General Safety Precautions

(on top of the ▪ If you are NOT sure how to operate the unit, contact your installer. instructions described in the Daikin documentation). ▪ This appliance can be used by children aged from 8 years and... -

Page 4: Installation Site

Make sure installation, servicing, maintenance and repair ▪ Do NOT sit, climb or stand on the unit. comply with instructions from Daikin and with applicable legislation (for example national gas regulation) and are NOTICE executed only by authorised persons. -

Page 5: Refrigerant

1 General safety precautions Ceiling-mounted Wall-mounted Floor-standing If the installation height is… Then use the graph or table for… unit unit unit <1.8 m Floor-standing units m (kg) m (kg) m (kg) 1.8≤x<2.2 m Wall-mounted units ≤1.842 — ≤1.842 — ≤1.842 — ≥2.2 m Ceiling-mounted units 1.843... -

Page 6: Brine

1 General safety precautions DANGER: RISK OF EXPLOSION CAUTION Pump down – Refrigerant leakage. If you want to pump When the refrigerant charging procedure is done or when down the system, and there is a leak in the refrigerant pausing, close valve refrigerant... -

Page 7: About The Documentation

Technical engineering data ▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). ▪ The full set of latest technical data is available on the Daikin extranet (authentication required). VAM350~2000J7VEB Installer and user reference guide Heat reclaim ventilation unit 4P487293-1A –... -

Page 8: For The Installer

3 About the box For the installer Models 650~1000 About the box Overview: About the box This chapter describes what you have to do after the box with the heat reclaim ventilation unit is delivered on-site. It contains information about: ▪... -

Page 9: To Remove The Accessories

3 About the box Models 1500+2000 3.2.2 To remove the accessories Models 350+500 Models 650~1000 Models 1500+2000 Connector for additional external damper General safety precautions Installation and operation manual Duct joints (models 350~1000 4×,models 1500+2000 8×) VAM350~2000J7VEB Installer and user reference guide Heat reclaim ventilation unit 4P487293-1A –... -

Page 10: To Handle The Heat Reclaim Ventilation Unit

4 About the units and options Screws (models 350+500 16×, models 650~1000 24×, About the units and options models 1500+2000 48×) 3.2.3 To handle the heat reclaim ventilation unit Overview: About the units and options NOTICE When removing the heat reclaim ventilation unit from the This chapter contains information about: packing, do NOT place the suction or discharge side of the ▪... -

Page 11: Combining Units And Options

5 Preparation Where. Replace the 2 duct joints of Ø250 mm with the plenum and a Operation range Temperature 0°C DB~40°C DB duct joint of Ø350 mm. Relative humidity ≤80% Unit location How. For installation instructions, see the installation manual of the It is possible that, due to condensation, the paper heat exchanger plenum kit. -

Page 12: Preparing The Unit

5 Preparation 6 After the wires are connected, fasten the switch box cover. CAUTION ▪ The appliance is designed to be a built-in appliance. It For model 650 must NOT be accessible to the general public. Adequate measures have to be taken to prevent access by other than qualified persons. -

Page 13: To Install The Duct Joints

5 Preparation Complete system example 2 Attach the optional mounting plate (EKMPVAM) on top of the plate connecting the 2 units. 3 Attach the optional adapter PCB (KRP2A51) in the installation box (KRP1BA101). 4 Follow the installation instructions provided with the option kits (BRP4A50A, KRP2A51 and KRP1BA101). -

Page 14: Preparing The Installation Of The Ducts

5 Preparation Power supply wiring Preparing the installation of the Wire H05VV-U3G ducts Size Wire size MUST comply with the applicable legislation. INFORMATION Transmission wiring ▪ Flexible ducting with sound insulation is effective to reduce blowing noises. Wiring Shielded wire (2 wire) ▪... -

Page 15: Installation

6 Installation Installation Service space: Heat reclaim ventilation unit >1000 >600 150-250 >50 INFORMATION (mm) When the unit is installed vertically, the installer must provide a support under the unit to distribute the weight of Service space the unit between the support and the installation bolts in the wall. -

Page 16: To Install The Anchor Bolts

6 Installation Service cover Washer Inspection hole Double nut NOTICE NOTICE When the heat reclaim ventilation unit is installed upside Always hang up the unit by its suspension brackets. down, the minimum allowed outdoor air temperature is 5°C. If this cannot be guaranteed, you MUST install a Duct connections heater to heat up the outdoor air to 5°C. -

Page 17: Electrical Wiring

6 Installation Models 350~1000 WARNING ▪ ONLY use copper wires. ▪ Make sure the field wiring complies with the applicable legislation. ▪ All field wiring MUST be performed in accordance with Name Plate the wiring diagram supplied with the product. ▪... - Page 18 6 Installation Models 350~650 J3 J2 J1JC F2F1P2P1 X33A X14A X35A Switch box X24A Switch box cover Securing screw and washer Grounding terminal Terminal board Transmission wiring terminal board (P1, P2, F1, F2) Transmission wiring (to optional controller) Power supply cable Wires for connection of additional external damper X29A (supplied accessory)

- Page 19 6 Installation Models 1500+2000 J3 J2 J1JC F2 F1 P2 P1 X33A X14A X35A X24A X29A Switch box Switch box cover Securing screw and washer Grounding terminal X27A Terminal board Transmission wiring terminal board (P1, P2, F1, F2) Transmission wiring (to optional controller) Power supply cable Wires for connection of additional external damper (supplied accessory)

-

Page 20: Electrical Connections For Additional Field Supplied Damper

6 Installation Terminal board Transmission wiring terminal board (P1, P2, F1, F2) Transmission wiring (to optional controller) Power supply cable Wires for connection of additional external damper (supplied accessory) Insulated splices-closed barrel connector (0.75 mm²) (field supply) Double or reinforced insulated flexible cable (0.75 mm²) to external damper (field supply) Tie wrap (field supply) BRP4A50A (optional accessory) -

Page 21: Guidelines When Connecting The Electrical Wiring

7 System configuration 6.5.5 Guidelines when connecting the electrical wiring J3 J2 J1 JC F2 F1 P2 P1 J1 JC F2 F1 N/P2 P/P1 Keep the following in mind: X6A X12A X11A ▪ If stranded conductor wires are used, install a round crimp-style terminal on the end of the wire. -

Page 22: Independent System

7 System configuration Controller Purposes and applications Description of the system Central Unified ON/ Schedule timer Controller for Controller for Operation/stop controller OFF controller heat reclaim air conditioner ventilation unit Available functions in case of an independent system control system: ▪... -

Page 23: Linked Operation Control System

8 Configuration Linked operation control system System Standard method Related items in electric wiring Combined 1-group ▪ A total of up to 16 air conditioners and heat reclaim ventilation units can be controlled. "8.3.3 1-group linked-control operation linked system" on page 30 ▪ The ventilation mode can be operated independently when air conditioners are NOT system with operation... -

Page 24: Operating Procedure

8 Configuration Operating procedure The heat reclaim ventilation unit settings can be adjusted using the controller of either the heat reclaim ventilation unit or the air conditioner. Initial settings ▪ Mode numbers 17, 18, and 19: group control of heat reclaim ventilation units. -

Page 25: List Of Settings

8 Configuration VAM350~2000J7VEB Installer and user reference guide Heat reclaim ventilation unit 4P487293-1A – 2018.05... - Page 26 8 Configuration Installer and user reference guide VAM350~2000J7VEB Heat reclaim ventilation unit 4P487293-1A – 2018.05...

- Page 27 8 Configuration VAM350~2000J7VEB Installer and user reference guide Heat reclaim ventilation unit 4P487293-1A – 2018.05...

- Page 28 8 Configuration Installer and user reference guide VAM350~2000J7VEB Heat reclaim ventilation unit 4P487293-1A – 2018.05...

-

Page 29: Settings For All Configurations

8 Configuration Settings for all configurations Setting 17(27)-4: First choose the fan speed. Set it to high or ultra-high. Direct duct connection All other system configurations or external fan Models 350~1000 Models 1500+2000 Warning: The ducting pressure drop of the top and bottom units must be equal in order to have a balanced system. -

Page 30: About Setting 19(29)-0-04 And 19(29)-0-05

8 Configuration 8.3.1 About setting 19(29)-0-04 and 19(29)-0-05 NOTICE Factory settings: Do NOT change the switch settings when ▪ When you have configured setting 19(29)‑0‑04 successfully, the a controller is connected. SS1 is a setting switch to operate system automatically changes it to setting 19(29)‑0‑01. the unit without controller. -

Page 31: Direct Duct Connection

8 Configuration All control F1 F2 F1 F2 P1 P2 D1 D2 HRV 1 F1 F2 HRV 1 X35A F1 F2 HRV 2 F1 F2 X35A HRV 2 F1 F2 P1 P2 Controller for air conditioner VRV 1 Maximum length of connection line: 1000 m F1 F2 P1 Adapter PCB for remote control (KRP2A51) P1 P2... -

Page 32: About The Controller

8 Configuration All/individual control Zone control F1 F2 F1 F2 HRV 1 F1 F2 F1 F2 HRV 1 HRV 2 F1 F2 F1 F2 P1 P2 HRV 2 F1 F2 HRV 3 P1 P2 F1 F2 VRV 1 F1 F2 P1 P2 F1 F2 Controller for air conditioner... -

Page 33: Controller For Vrv System Air Conditioner

8 Configuration 8.4.1 Controller for VRV system air conditioner To select ventilation mode Ventilation mode is used when cooling or heating is not necessary, Please read the manual supplied with the controller (BRC1E53) for so only the heat reclaim ventilation units are operating. more detailed instructions. -

Page 34: Controller For Heat Reclaim Ventilation Units

8 Configuration Time to clean filter indication When the filter pressure drop becomes too large, the following message or icon is displayed at the bottom of the basic screen: Time to clean filter or . Clean the filters. For more information, see "11 Maintenance and service" on page 40. -

Page 35: Detailed Explanation Of Settings

8 Configuration In this mode, the outdoor air passes through the heat exchange element to effect Heat Reclaim Ventilation. L . N " " Bypass mode X33A In this mode, the outdoor air does NOT pass through the heat exchange element, but bypasses it to effect Bypass ventilation. Indication of operation control method: Operation lamp When operation of the heat reclaim ventilation units is linked to... -

Page 36: About The External Damper Operation

8 Configuration Supply Fresh-up Exhaust Fresh-up (Excessive outdoor air supply) (Excessive exhaust air supply) Example Part of supply fresh-up operation Air exhaust Air supply Heat reclaim ventilation unit Normal ventilation fan Part of exhaust fresh-up operation Air exhaust Patient room If an external fan is connected to J1 and JC, take the following into account: ▪... - Page 37 8 Configuration Linear control Fixed control Measuring Every 5 minutes Every 20 minutes Evaluation Every 30 minutes Every 20 minutes (average of 6 measurements) Trigger Linear control (minutes) Fixed control value Mode A Mode B CO₂ ppm (1) ≥1450 — — 1300~1450 —...

-

Page 38: About Nighttime Free Cooling Operation

8 Configuration To route the wiring of the CO2 sensor 8.5.5 About nighttime free cooling operation Nighttime free cooling function X6A X12A X11A J1 JC F2 F1 N/P2 P/P1 The nighttime free cooling function is an energy-conserving function that works at night, when the air conditioner is off. This reduces the cooling load in the morning, when the air conditioner is switched on. -

Page 39: About Preventing A Feeling Of Draft

9 Commissioning INFORMATION Commissioning This function is NOT possible when there is a direct duct connection. Overview: Commissioning INFORMATION After installation and once the field settings are defined, the installer This function is NOT possible when the heat reclaim is obliged to verify correct operation. Therefore a test run MUST be ventilation unit is NOT linked to an air conditioner. -

Page 40: Checklist During Commissioning

10 Hand-over to the user Fuses, circuit breakers, or protection devices CAUTION Check that the fuses, circuit breakers, or the locally Before accessing, make sure to turn off the operation installed protection devices are of the size and type switch and disconnect the power. specified in "5.4 ... -

Page 41: Checklist For Maintenance Of The Heat Reclaim Ventilation Unit

12 Troubleshooting 11.3 Checklist for maintenance of the 12.2 Precautions when troubleshooting heat reclaim ventilation unit WARNING ▪ Check the following at least once a year: Air filters. ▪ When carrying out an inspection on the switch box of The air filters can get blocked due to dust, dirt, leaves, etc. It is the unit, ALWAYS make sure that the unit is recommended to clean the air filters yearly. -

Page 42: 13 Disposal

▪ A subset of the latest technical data is available on the regional Daikin website (publicly accessible). Motor (exhaust air fan) ▪ The full set of latest technical data is available on the Daikin Noise filter (ferrite core) extranet (authentication required). -

Page 43: For The User

15 Controller For the user Contact your installer or dealer for advice or to modify the Controller parameters to the needs of your building. Detailed information is given for the installer in the installation CAUTION manual. ▪ NEVER touch the internal parts of the controller. ▪... -

Page 44: Maintenance Of The Heat Exchange Element

19 Troubleshooting Service cover 6 Install the service cover securely in place. Hinge mechanism Hanging metal Models 350~1000 18.2 Maintenance of the heat exchange Models 1500+2000 element 2 Take out the air filters from the unit body. NOTICE ▪ NEVER wash the heat exchange element with water. ▪... -

Page 45: Relocation

ON/ Field supply OFF button. If NOT, ask your installer for advice. Equipment NOT made by Daikin that can be combined with If after checking all above items, it is impossible to fix the problem product... - Page 48 4P487293-1A 2018.05...