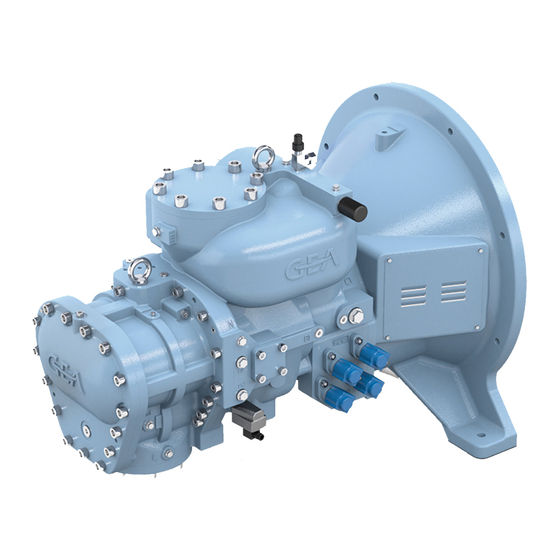

GEA Grasso M-Series Screw Compressors Manuals

Manuals and User Guides for GEA Grasso M-Series Screw Compressors. We have 1 GEA Grasso M-Series Screw Compressors manual available for free PDF download: Operating Manual

GEA Grasso M-Series Operating Manual (88 pages)

Screw Compressor Packages

Brand: GEA

|

Category: Air Compressor

|

Size: 18 MB

Table of Contents

Advertisement

Advertisement