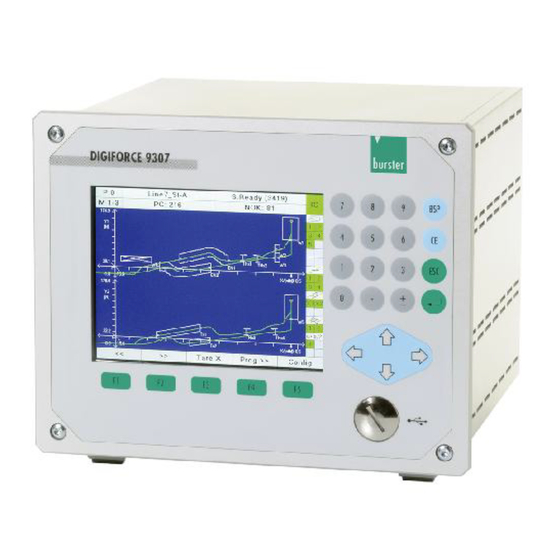

Burster DIGIFORCE 9307 Measurement Sensor Manuals

Manuals and User Guides for Burster DIGIFORCE 9307 Measurement Sensor. We have 5 Burster DIGIFORCE 9307 Measurement Sensor manuals available for free PDF download: Operation Manual, Operation Manuals

burster DIGIFORCE 9307 Operation Manual (503 pages)

instrument for monitoring repetitive production processes

Brand: burster

|

Category: Measuring Instruments

|

Size: 4 MB

Table of Contents

-

-

4 Commands

31-

PLC Outputs44

-

Info Menu53

-

LCD Setting56

-

Fieldbuses63

-

Order Sheet71

-

-

STOM - Stop Mode107

-

Channel Settings123

-

FILT - Filters128

-

Resistance162

-

Piezo Sensor164

-

-

SSI Sensor186

-

SKOD SSI Coding187

-

SFOR SSI Format189

-

Endat Sensor202

-

-

-

-

-

-

Switching Points385

-

Sensor Test388

-

Voltage Monitor406

-

Amplifier Test409

-

-

-

Reference Curve475

Advertisement

Burster DIGIFORCE 9307 Operation Manual (205 pages)

Brand: Burster

|

Category: Measuring Instruments

|

Size: 17 MB

Table of Contents

-

-

Symbols12

-

-

-

Sensor Test32

-

Setup Tools33

-

-

Interfaces36

-

-

Interface50

-

-

-

Info-Menu58

-

Interfaces59

-

Order Sheet65

-

-

Signal)68

-

-

-

Start/Stop Mode102

-

Bend-Up Factor103

-

-

Window106

-

Trapezoid Window114

-

Thresholds120

-

Envelopes127

-

-

-

Sensor Test161

-

Burster DIGIFORCE 9307 Operation Manuals (175 pages)

PROFIBUS Manual

Brand: Burster

|

Category: Measuring Instruments

|

Size: 3 MB

Table of Contents

-

5 Profibus

20 -

-

-

-

Reserved Slots120

-

-

(Evelem15)130

-

-

(Evelem16)130

-

-

-

(Evelem17)130

-

-

-

(Evelem18)130

-

-

Advertisement

Burster DIGIFORCE 9307 Operation Manual (154 pages)

instrument for monitoring repetitive production processes

Brand: Burster

|

Category: Measuring Instruments

|

Size: 4 MB

Table of Contents

-

Changes2

-

6 Profinet

20 -

7 Alarms

22 -

-

-

Burster DIGIFORCE 9307 Operation Manual (160 pages)

instrument for monitoring repetitive production processes

Brand: Burster

|

Category: Measuring Instruments

|

Size: 3 MB