Rayburn 660 Service Manual

Hide thumbs

Also See for 660:

- Installation instructions manual (36 pages) ,

- User instructions (16 pages)

Table of Contents

Advertisement

REMEMBER, when replacing a part on this appliance, use only spare parts that you can be assured conform to the

safety and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly

authorised by AGA.

PLEASE READ THESE INSTRUCTIONS BEFORE SERVICING THIS APPLIANCE

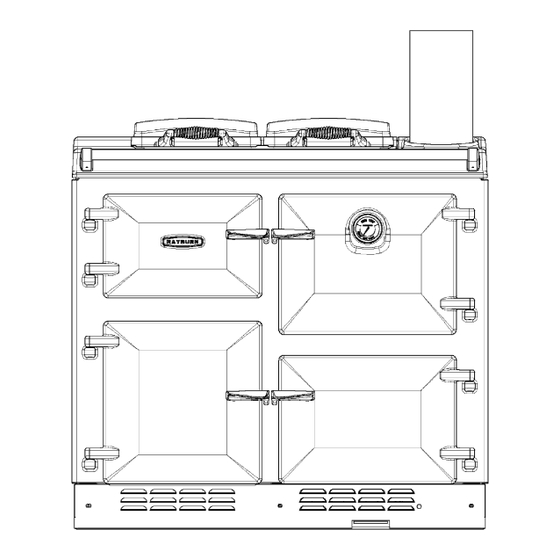

660/680/699K

760/780/799K

DESN 515618

Servicing

nstructions

For use in GB & IE

DESN 516825

05/14A EINS 515601

Advertisement

Table of Contents

Summary of Contents for Rayburn 660

- Page 1 660/680/699K 760/780/799K DESN 515618 DESN 516825 Servicing nstructions REMEMBER, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by AGA.

-

Page 2: Table Of Contents

Contents SECTION CONTENTS PAGE CONSUMER PROTECTION HEALTH & SAFETY BENCHMARK SCHEME INTRODUCTION SERVICE SCHEDULE BURNER REMOVAL PREPARATION BURNER ACCESS BURNER REMOVAL CLEANING HEAT EXCHANGER CLEANING 8 - 9 OVEN AND HOTPLATE FLUEWAY CLEANING 8 - 9 BURNER SERVICING INTRODUCTION BURNER NOZZLE REMOVAL BURNER NOZZLE REPLACEMENT PHOTO ELECTRIC CELL (PEC) CLEANING FAN CLEANING... -

Page 3: Consumer Protection

Consumer Protection As responsible manufacturers we take care to make sure that our products are designed and constructed to meet the required safety standards when properly installed and used. IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING WARRANTY Any alteration that is not approved by AGA could invalidate the approval of the appliance, operation of the warranty and could affect your statutory rights. -

Page 4: Benchmark Scheme

THE BENCHMARK SCHEME Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. -

Page 5: Introduction

BURNER SERVICING The Rayburn cannot be serviced whilst hot, so both oven OIL PUMP SERVICING - Cleaning of fuel line strainer. and boiler thermostats should be turned off on the RE-COMMISSIONING evening before the service visit. -

Page 6: Burner Removal

BURNER ACCESS SEE FIG. 1 1. Open up the bottom burner access door. Remove door and put in a safe place. (Rayburn 660/680/699K only). 2. Remove 4 inner panel securing screws and remove panel. -

Page 7: Burner Removal

1. Place a sheet on the floor in front of the cooker to act as a working area. 2. Remove lower LH door (Rayburn 660/680/699K only) and burner aperture cover and store in a safe place. 3. Unscrew jubilee clip and remove flexi air intake pipe from burner. -

Page 8: Cleaning

TAKEN NOT TO DAMAGE THE CERAMIC FIBRE INSULATION. SEE FIG. 5 1. Remove top LH door (Rayburn 660/680/699K only) and facia glass and store in a safe place. 2. Open control door and disconnect 3-pin plug. Remove boiler access door complete with gasket and insulation pad. - Page 9 Cleaning 660/680 760/780 660/680 760/780 ALL BAFFLES MUST BE STACKED IN PLACE AS DIAGRAM ABOVE Fig. 7...

-

Page 10: Burner Servicing

Burner Servicing INTRODUCTION BOILER 8 VANES SEE FIG. 8, 8A, 9A, 9B & 9C It is recommended that each side of the burner is serviced individually so as not to get the components from the two burners mixed up. The correct combination of burner blast tubes are shown. To remove blast tube, slacken two grub screws, pull forward. -

Page 11: Burner Nozzle Removal

Burner Servicing BURNER NOZZLE REMOVAL COOKER SEE FIG. 10 1. Remove two socket head screws. 2. Remove head assembly complete. 3. Disconnect ignition leads 4. Remove ignitor assembly, by removing countersunk screw and clamp. 5. Unscrew nozzle from its holder with a correctly fitting tubular spanner to avoid damage to hexagon. -

Page 12: Photo Electric Cell (Pec) Cleaning

Burner Servicing PHOTO ELECTRIC CELL (PEC) CLEANING SEE FIG. 12 Withdraw Photo Electric Cell from the burner head. Clean PEC sensing end with a soft cloth taking care not to scratch the light sensitive body. Re-insert PEC taking care to insert the correct way round. Should the cell show signs of distortion or cracking, replacement will be necessary. -

Page 13: Oil Pump Servicing

Oil Pump Servicing INTRODUCTION To carry out any servicing on the oil pump. Turn off the oil line isolating valve near to the appliance. SEAL STRAINER COVER OIL PUMP STRAINER CLEANING SEE FIG. 14 1. A container must be put under the pump to catch any oil when starting to clean the oil pump strainer. -

Page 14: Re-Commissioning

Re-commissioning BLEED AIR FROM OIL SUPPLY SEE FIG. 15 Disconnect the flexible oil pipe line at the pump inlet, open the stop valve slowly and run off some of the oil into a receptacle to establish an air free supply to the pump. Re- make the connection oil tight and leave valve open. -

Page 15: Set Combustion Air

Re-commissioning SET COMBUSTION AIR SEE FIG. 17 & 17A After 15 minutes of the boiler burner running. Remove the plug located behind the LH dome lid. Remove the plugging screw and insert the sensing end of a portable indicator to check the CO (Carbon Dioxide) level. -

Page 16: Replacement Of Parts

Replacement of parts (Burner) FAN MOTOR SEE FIG. 18 Follow instructions in sections BURNER ACCESS, Steps 1-3 and BURNER REMOVAL. 1. Isolate electric supply. 2. Remove 3-pin plug. 3. Remove solenoid plug. 4. Disconnect oil pipe. 5. Undo 2 screws and remove snorkel. 6. -

Page 17: Ignitor

Replacement of parts (Burner) IGNITOR SEE FIG. 20 Follow instructions in sections BURNER ACCESS, Steps 1 to 3, and BURNER REMOVAL. 1. Remove both HT leads from ignitor. 2. Remove mains plug from ignitor. 3. Remove earth screw. 4. Remove 2 ignitor securing screws. 5. -

Page 18: Control Box

Replacement of parts (Burner) CONTROL BOX SEE FIG. 22 Follow instructions in section BURNER ACCESS, Steps 1 to 3. 1. Undo centre fixing screw. 2. Gently pull control box away from base. 3. Fit new control box, re-assemble in reverse order. NOTE: Boiler burner must be removed from appliance in order to gain access to control box. -

Page 19: Pump Access

Replacement of parts (Burner) PUMP ACCESS SEE FIG. 24 Follow instructions in section BURNER ACCESS, Steps 1 to 3 and BURNER REMOVAL. 1. Isolate fuel supply. 2. Disconnect flexible hose (This must be replaced annually). 3. Remove solenoid plug. 4. Remove feed pipe. 5. -

Page 20: Replacement Of Parts (Electrical Controls)

APPLIANCE HAS BEEN SWITCHED OFF (SWITCH OFF AND REMOVE PLUG). SEE FIG. 25 1. Remove the controls door (Rayburn 660/680/699K only) and place in a safe position. 2. Remove both thermostat control knobs. 3. Remove the 2 cover panel fixing screws. - Page 21 Replacement of parts (Electrical controls) Fig. 27 DESN 514774...

-

Page 22: Fault Finding

Fault Finding Rayburn 600/700 Wiring Diagram 111MB for Individual Satronic boxes Fig. 28... - Page 23 Fault Finding Rayburn 600/700 Wiring Diagram 111MB self contained control Fig. 29...

-

Page 24: Burner Does Not Start

1. Isolate the electrical power supply. 2. Open up the bottom burner access door. Remove door and put in a safe place. (Rayburn 660/680/699K only). 3. Unscrew the 4 screws holding the inner panel in place and remove panel. -

Page 25: Error Table

Fault Finding Error Table In the next tables a description of the different errors is given Errors can be divided in two groups. Blocking errors will disappear when error is gone, and non-volatile locking errors can only be reset by the reset button. A blocking error is indicated with an ‘E’... - Page 26 Fault Finding Cooker Burner (Control Box Type - DKO 970) Information system The information system communicates with the outside world using a LED (the used Flash-Code is similar to the Morse Code). The messages are optically transmitted by flashing appropriately a LED. Using an (optional) additional terminal the messages can be recorded and displayed in easily readable form.

- Page 27 Fault Finding Cooker Burner (Control Box Type - DKO 970) In case of failure the LED is permanently illuminated. Every 10 seconds the illumination is interrupted by a flash code which indicates the cause of the error. Therefore the following sequence is performed which is repeated as long as the unit is not reset.

-

Page 28: Control Box Type Dko

Fault Finding Cooker Burner (Control Box Type DKO 970N)- Information system The information system is microprocessor based and reports on all aspects of burner control box operation and flame supervision. It informs continuously about the actual programming sequence the unit is just performing. Besides monitoring of the programming sequence it also allows to identify errors during start-up of operation without any additional testing devices. - Page 29 Fault Finding Fig. 31A DESN 516838...

- Page 30 Fault Finding...

- Page 31 Fault Finding...

- Page 32 Fault Finding HIGH SMOKE NUMBERS INCORRECT INCORRECT INTERNAL COMPONENTS NOZZLE FAULT AIR INTAKE OIL PRESSURE COMBUSTION INSULATION USED ON BLOCKED SETTINGS INCORRECT PANELS COMBUSTION REPLACE INCORRECTLY RE-ADJUST ADJUST TO HEAD CHECK AIR POSITIONED NOZZLE RECOMMENDED SEE SERVICING INLET TO INSTALLATION SETTINGS INSTRUCTIONS FAULTY...

- Page 36 With AGA Rangemaster’s policy of continuous product improvement, the Company reserves the right to change specifications and make modifications to the appliance described at any time. Manufactured by AGA Rangemaster Station Road Ketley Telford Shropshire TF1 5AQ England Tel.: 0845 815 2020 www.rayburn-web.co.uk www.agacookshop.co.uk...

Need help?

Do you have a question about the 660 and is the answer not in the manual?

Questions and answers