Table of Contents

Advertisement

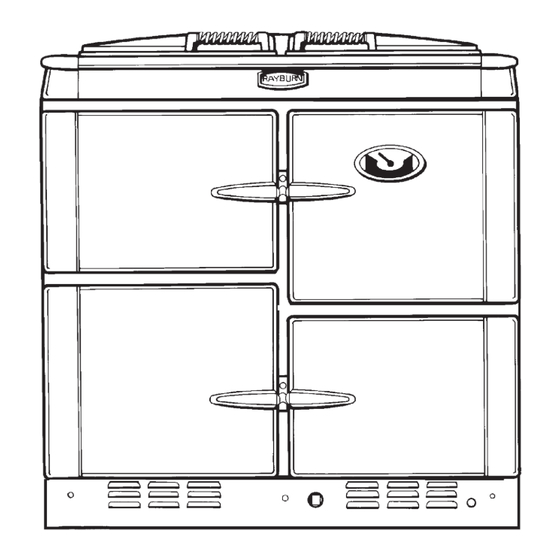

Installation

Instructions

XT - Gas (GPF)

For use in GB and IE

DESN 514112 B

Remember, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety

and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly

authorised by AGA.

PLEASE READ THESE INSTRUCTIONS BEFORE INSTALLING THIS APPLIANCE

raywarranty@aga-web.co.uk

10/13 EINS 514103

Advertisement

Table of Contents

Summary of Contents for Rayburn XT

- Page 1 Installation Instructions XT - Gas (GPF) For use in GB and IE DESN 514112 B Remember, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by AGA.

-

Page 2: Table Of Contents

Contents SECTION CONTENTS PAGE CONSUMER PROTECTION HEALTH & SAFETY TECHNICAL DATA SITE REQUIREMENTS INTRODUCTION IMPORTANT REGULATIONS GAS SUPPLY LOCATION ELECTRICAL SUPPLY FLUE SYSTEM FLUE TERMINAL LOCATION INSTALLATION PCB CONNECTIONS INSTALLATION REQUIREMENTS CLEARANCES PRELIMINARY INSTALLATION SITE LOCATION SETTING COMBUSTION INSTALLATION INSTRUCTIONS BURNER ACCESS ELECTRICAL CONNECTION BOILER CONTROL (BURNERTECH BURNER) -

Page 3: Consumer Protection

Consumer Protection As responsible manufacturers we take care to make sure that our products are designed and constructed to meet the required safety standards when properly installed and used. IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING WARRANTY. Any alteration that is not approved by AGA could invalidate the approval of the appliance, operation of the warranty and could affect your statutory rights. -

Page 4: Technical Data

PLEASE NOTE: IT IS ADVISABLE TO CHECK THE ACTUAL SIZE/WIDTH DIMENSIONS IN MM OF YOUR APPLIANCE BEFORE FINALLY FIXING ANY KITCHEN UNITS, SINCE ENAMELLED CAST DESN 514106 B IRON CAN VARY IN SIZE TECHNICAL DATA Fuel - Natural Gas (G20) I Fuel - Propane (G31) I Gas Inlet... -

Page 5: Site Requirements

Site requirements INTRODUCTION LOCATION The Rayburn is a floor standing cooker, fired by a gas The appliance is floor mounted and must be installed on burner. a solid floor or base of non-combustible material which is capable of supporting the total weight. -

Page 6: Electrical Supply

Site requirements ELECTRICAL SUPPLY Wiring external to the appliance must be installed in accordance with current National Wiring Regulations and and local regulations which apply. The appliance is supplied for 230 Volt ~ 50 Hz and a fuse rating of 3 amps. The method of connection to the mains supply should facilitate complete electrical isolation of the appliance, by the use of a fused double pole switch having a contact... -

Page 7: Flue System

Site requirements FLUE SYSTEM The flue can be to the left or right of the appliance. The cooker is supplied with the flue pipe to the left, this can be adjusted to suit the installation. FLUE DIRECTION - EXIT TO THE LEFT 1. - Page 8 Site requirements FLUE DIRECTION - EXIT TO THE RIGHT Follow previous instructions in FLUE SYSTEM (Page 7), Steps 1 to 3. 4. Reposition the flexible tube from the oven vent down the back of the oven. 5. Smear sealant on the end of the manifold and replace the bend.

-

Page 9: Flue System

Site requirements FLUE SYSTEM The flue system used on this appliance must be provided by AGA and must be installed in accordance with the instructions and standards. A maximum flue of 5 metres and 5 bends can be used (including horizontal length on the terminal). Any upwards vertical runs must be immediate to the appliance to a maximum of 3 metres. -

Page 10: Flue Terminal Location

Site requirements - Flue terminal location FIG. 9 - Location of flue terminal DISTANCES STATED HERE ARE MINIMUM ALLOWABLE REQUIREMENTS A BELOW AN OPENING 300mm K FROM A TERMINAL FACING THE 1200mm TERMINAL B ABOVE AN OPENING 300mm L FROM AN OPENING IN THE CAR PORT 1200mm C HORIZONTALLY TO AN OPENING 300mm... - Page 11 Site requirements INSTALLATION 1. Cut out card template from packaging and affix to wall. 2. Cut ø60 mm hole in the wall for the flue pipe. (See Fig. 10). NOTE: Larger holes are required through combustible material. 3. Drill 4 wall fixing holes through template (1 in each corner.

-

Page 12: Pcb Connections

Site Requirements PCB CONNECTIONS EXTERNAL CONNECTIONS: FAN CONNECTIONS - AT TERMINAL MAINS CONNECTIONS FIG. 14... -

Page 13: Installation Requirements

Installation requirements CLEARANCES The appliance is floor mounted. The space in which the appliance is to be fitted must have the following minimum dimensions. Between wall or unit and LH side of appliance - 10mm top plate Between wall or unit and RH side of appliance - 10mm top plate SHOULD THE WALL PROJECT BEYOND THE FRONT OF THE APPLIANCE, THEN THE GAP AT THE R.H. -

Page 14: Site Location

2. Connect and terminate the flue system in accordance with these instructions. Connect the relevant services to the appliance:- 1. Gas (XT GPF) 2. Electric 3. Flue Pipe 3. Fit plinth assembly (See Fig. 16). FIG. 16 DESN 514191 A 4. -

Page 15: Setting Combustion

Installation requirements SETTING COMBUSTION Because this appliance uses a pre-mix burner. No setting up of combustion is required, the burner automatically controls the air to gas rate ratio. IMPORTANT: Ensure that the bottom louvered plinth is in place during combustion testing and setting procedures. Ensure the outer door is closed. -

Page 16: Installation Instructions

Installation Instructions BURNER ACCESS SEE FIG. 18 1. Open the burner access door. 2. Remove (4) inner panel securing screws and remove panel. 3 Remove the (3) plinth securing screws and remove plinth. FIG. 18 DESN 514110 B ELECTRICAL CONNECTION 1. -

Page 17: Combustion Discharge Device

Installation Instructions BURNER CONTROL (BURNERTECH BURNER) When the thermostat is calling for heat, 230V is supplied to terminals 10 and 11 on the control box and tab 1 and 2 on the fan. The fan should start straight away. There will then be a short delay while the control box checks that the fan is running and pre-purges. -

Page 18: Burner Control (Ecoflam Burner)

Installation Instructions BURNER CONTROL (ECOFLAM BURNER) When the thermostat is calling for heat, 230V is supplied to terminals 10 and 11 on the control box and tab 1 and 2 on the fan. The fan should start straight away. There will then be a short delay while the control box checks that the fan is running and pre-purges. -

Page 19: Ancillary Controls Check

Installation Instructions ANCILLARY CONTROLS CHECK INSTRUCT THE USER Before leaving the site, check that the operation of cooker 1. Advise the User that, for continued efficient and safe timer and thermostat are capable of controlling the burner operation of the appliance, it is important that correctly. -

Page 20: Wiring Diagram - Appliance

Wiring Diagram WIRING DIAGRAM - APPLIANCE FIG. 21... -

Page 21: Single Channel Programmer

Single Channel Programmer USING A SINGLE CHANNEL OPTIONAL PROGRAMMER IN CONJUNCTION WITH THE RAYBURN XT - GAS (GPF) Always use the same isolating switch for both the cooker and programmer. Ideally: use the supply connections on the appliance. Before carrying out any maintenance work on either the programmer or the cooker ensure the supply is isolated. - Page 24 With AGA Rangemaster’s policy of continuous product improvement, the Company reserves the right to change specifications and make modifications to the appliance described at any time. Manufactured by AGA Rangemaster Station Road Ketley Telford Shropshire TF1 5AQ England www.rayburn-web.co.uk www.agacookshop.co.uk...

Need help?

Do you have a question about the XT and is the answer not in the manual?

Questions and answers