Summary of Contents for CreatBot DX

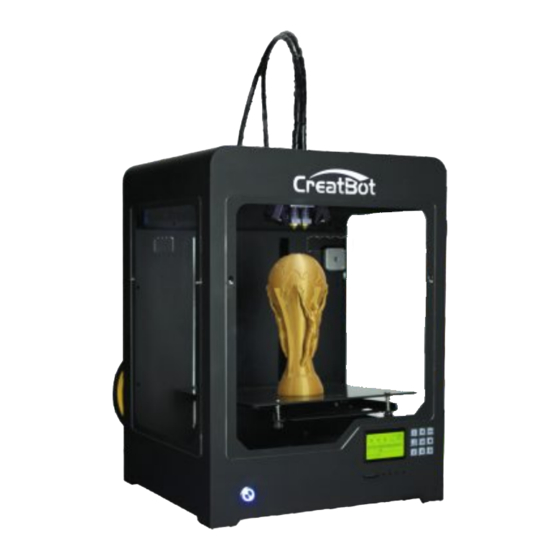

- Page 1 CreatBot 3D Printer User manual English V7.0 Henan Suwei Electronics Technology Co., Ltd. - 1 -...

-

Page 2: Table Of Contents

CONTENTS Notice ················································ 3 Model Mirror ·························· 19 Machine Diagram View Mode ······························ 19 Front and Back ························· 4 Right Click on Model ············ 20 Hotend / Feeder ····················· 5 Toolpath Structure ················ 20 Hardware Installation Basic Setting ··························· 21 Unpacking ·································... -

Page 3: Notice

Please use the filament provide by CreatBot, or high quality filament of third manufacturers. Due to the use of third party inferior material caused by the failure of the printer, the loss will be borne by the user. -

Page 4: Machine Diagram

Machine Diagram Front and Back 1. Power switch 2. SD-card slot 3. Keypad 4. LCD display 5. Leveling nut 6. Leveling spring 7. Build platform 8. Baffle holes 9. X stepper motor 10. Printer head 11. Filament guide pipe 12. Power socket 13. -

Page 5: Hotend / Feeder

Machine Diagram Printer Head 1. Thermostat tube 2. Heating tube 3. Nozzle 4. Heating block 5. Fan duct 6. Insulation tube 7. Cooling fan 8. Head Al. frame 9. Adapter plate 10. Head adjust 11. Linear bearing 12. Linear axis 13. -

Page 6: Hardware Installation

Hardware Installation Unpacking Unpacking Takeout accessories Takeout filament Turn on printer 1. Ensure the packing is not broken. 2. Need two people at the same time. 3. Lift it out by grasping the frame, not the belt or rails. 4. Takeout the accessories, will see the bracket and the filament. 5. -

Page 7: Install Build Platform

Hardware Installation Install Build Platform Takeout platform Insertplatform Connect the cables Tighten the screws 1. Enter "Move axis" menu, move the platform a little down. 2. Fix the M5 screw to the hole of bracket, do not tighten. 3. Insert platform to the bracket, the bracket is between plate and tray. 4. -

Page 8: Install Feeder

Hardware Installation Install Feeder Fixed feeder Connect joint Install spool's holders Plugin cable 1. Take out the feeder, pay attention to the order between left and right feeder. 2. Mount the feeder fixing hole on the back the chassis. 3. Tighten the screw nut firmly with a wrench. 4. -

Page 9: Printer Operation

Printer Operation LCD Display 1. Current temp. 1 9. Fan speed 2. Target temp. 1 10. Cur. Z position 3. Current temp. 2 11. Remaining time 4. Target temp. 2 12. SD card icon 5. Current temp. 3 13. printing speed 6. -

Page 10: Lcd Menu Tree

Printer Operation LCD Menu Preheat nozzle 1 Preheat PLA Preheat nozzle 2 Preheat ABS Preheat nozzle 3 Cooldown Preheat hotbed Preheat Preheat All Auto home 10 mm X axis Move axis 1 mm Y axis Z axis 0.1 mm Tune Extruder 1 Change filam. -

Page 11: Leveling Platform

Printer Operation Leveling Platform 1. Enter setting menu->leveling bed, waiting for the platform back to home. 2. Adjust first leveling nut, make nozzle close to the platform. 3. Press Up/Down button or rotating knob, adjust other three leveling nut. 4. To adjust repeatedly, eventually distance (0.2mm) to insert a name card is advisable. -

Page 12: Load Filament

Printer Operation Load Filament Back Preheat 1 PLA Preheat 2 PLA Preheat all PLA Preheat bed PLA Preheat head Straightened filament Tighten the nut Load filament 1. Preheat the head you want load filament. 2. Straightened filament and check the filament is not self-winding. 3. -

Page 13: Unload Filament 1

Printer Operation Unload/Change Filament Back Extruder 1 Extruder 2 Head heating: 210℃ Unload filament 1 Unload filament 2 Unload filament menu Preheat head Unloading ..Pull out filament Unloading filament 1. Enter "Filament" menu ->"Unload filament", and select the head you want unload. -

Page 14: Software Operation

Software Operation CreatWare Setup Download CreatWare installation package from the CD-ROM or www.CreatBot.com, follow the prompts to install the software, tr y using the default installation path as well. Please associated common 3D file format. Installation path can not contain non-Latinn characters. -

Page 15: Quick Print Ui

Software Operation Quick Print UI Save toolpath Load model Normal Overhang Transparent X-Ray Layers When insert SD card, the toolpath will saved to the SD card. The file name can not contain non-Latinn characters. Print Your First Model Insert SD card to the card reader, open the CreatWare, load 3D model file , choose correct filament and option , finally click... -

Page 16: Full Setting Ui

Software Operation Full Setting UI Load model Save toolpath Manual slicing View mode Setting area View area Rotate Zoom Mirror As you can see from the complete UI, the left side of the software is setting area, the right side is view area. The setting area contain "Basic", "Advanced", "Plugins", "Start/End GCode"... -

Page 17: Mouse Operation

Software Operation Mouse Operation Left click Right click Select model, hold and Hold and move to rotate move to change the viewpoint around position, double-click to the 3D model. load 3D models. Left + Right Scrollwheel Hold and move the Use the scroll wheel to mouse to zoom. -

Page 18: Model Rotate/Scale

Software Operation Model Rotate Click on the left corner of the rotate button , you can see three ring line around the model, respectively along the X, Y, Z direction. The default rotation angle is 5 degrees, press the Shift key can restrict the rotation angle to 1 degree. -

Page 19: Model Mirror

Software Operation Model Mirror Click the mirror button you can pop up the mirror menu. Button is a mirror along the X axis. Button is a mirror along the Y axis. Button is a mirror along the Z axis. Note that the mirror transformation is different from the rotation, such as the mirror transformation will lead to a... -

Page 20: Right Click On Model

Software Operation Right Click on Model Right-click on the model pop-up shortcut menu, here are more features: "Centered" make the model back to the center position of the platform. "Delete" to remove the currently selected model. "Multiply" to copy the currently selected model and automatically position, which is useful for printing more than one model at a time. -

Page 21: Basic Setting

Software Operation Basic Setting Layer height: This is the most important setting to determent the quality of your print, maximum value not exceed 80% of the nozzle diameter. Shell thickness: Refers to the total thickness of the inner and outer walls, the outer wall is only one, the inner wall can be more, set this value to an integer multiple of the diameter of the nozzle. -

Page 22: Advanced Setting

Software Operation Advanced Setting Solid fill top: Refers to whether to print the top surface of the model, uncheck will print it with infill method. Solid fill bottom: Same as above, and so on. Spiralis print: Refers to the method of spiral printing the outer wall of the model (single layer), and this feature is very suitable for print glass vase model. -

Page 23: Expert Setting

Software Operation Export Setting Nozzle size: Set the nozzle size. Diameter: Accurate measurement of your filament gives better quality prints. Minimum travel: The minimum distance which can trigger filament retract. Minimum extrusion: The minimal amount of extrusion that needs to be done before retracting. -

Page 24: Skirt/Brim/Raft

Software Operation Skirt · Brim · Raft Adhesion type: None Adhesion type: Brim Raft Adhesion type: Plugins Plugin enable you to easily include your own features, without having to modify the source code or Gcode. In the screen shot above, these can be enabled by clicking on the arrow down button, then you can configure the plugin. -

Page 25: Start/End Gcode

Software Operation Start / End GCode The start and end gcode are the startup and end procedure of the print, editing this requires knowledge of GCode. If you want to set the automatic heating station after printing, you can remove the ";" in the code ";M190 S50". -

Page 26: Align Dual Head Horizon

Software Operation Align Dual Head Horizontal There are alignment problem while printing dual color model, this is because the small difference in multi-nozzle assembly, CreatWare built fine-tuning features. Click menu "Machine">"Machine settings", default X offset is: 20.0, default Y offset is: 0.0, adjustment method as shown below: Extruder 2 Extruder 2 Offset X :... -

Page 27: Align Dual Head Vertical

Tip: You can rising right nozzle as long time not use. Add Multi Type Printer You can add more than one type of CreatBot to the software, and easily switch between them without re-config all the different machine settings. - 27 -... -

Page 28: Frequently Asked Questions

Frequently Asked Questions Routine Maintenance 1. Frequent cleaning stains on the rail. 2. Lubricate the four guide rail. 3. Frequent cleaning feeder gear. Notice: Don’t add too much lubricating oil. Print PLA and ABS Nozzle Close bed Cooling Enclosed Adhesion Tape 200 ℃... -

Page 29: Paving Kapton

Frequently Asked Questions Paving Kapton 1. Clean the platform first. 2. Kapton is a double-sides adhesive. 3. Paste the first side on platform. 4. Then another side. 5. Pierce the bubble. Tip: Kapton temperature resistance up to 120 ℃ , the film can be reused until not sticky so far. -

Page 30: Change Fuse

Frequently Asked Questions Change Fuse Open fuse tray Change new fuse Note: Please use the 10A fuse. Adjust Z Limit If the nozzle can't touch the platform even loosen all the leveling nut, you can move Z stop limit a little up, as you can see from figure. - 30 -... -

Page 31: Hardware Troubleshoot

Frequently Asked Questions Hardware Troubleshoot 1. Display "MINTEMP" ? The environment is too low, or temperature control tube is damaged, please keep the room temperature above 0 ℃ . 2. Display "MAXTEMP" ? Temperature of nozzle or bed too high, or temperature control tube is damaged, please keep their temperature in a suitable range. -

Page 32: Printing Troubleshoot

Frequently Asked Questions Printing Troubleshoot not over 120℃, and you can close the bed above 100mm. 3. The model not stick on the platform ? Please paste masking paper or Kapton on the platform, or the nozzle is too far away from the platform, or the bottom of the model is not flat. -

Page 33: Specifications

Specifications Model DM Plus DX Plus Build Size 250*250*300 250*250*450 300*250*300 300*250*520 400*300*300 Nozzles Single/Dual Single/Dual/Tris Single/Dual Diameter 0.3~1.0mm (other sizes can be customized) 0.3~1.5mm Temperature 250 ℃ (300 ℃ extruder update supported) Hot bed 120 ℃ (can be closed after certain layers) Min. - Page 34 Quality · Experience · Ser vice Henan Suwei Electronics Technology Co., Ltd. Telephone: +86 4000-558-930 Skype ID: creatbot Website: www.CreatBot.com Email: sales@creatbot.com Address: No. 86 Eighth Street, Zhengzhou City, China - 34 -...

Need help?

Do you have a question about the DX and is the answer not in the manual?

Questions and answers