Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Bosch CE SPLIT series

- Page 1 CE Split Installation and Maintenance Manual Series 6 720 220 049 Revised 03-11...

- Page 2 ©Copyright 2011 Bosch, Inc All rights reserved...

-

Page 3: Table Of Contents

CE Split Series 3 Table of Contents TablE of ConTEnTS Model Nomenclature ..................3 Initial Inspection ..................4 General Description ..................4 Moving and Storage ..................4 Safety Considerations .................. 4 Location ....................... 4 Installation ....................5 Condensate Drain ..................6 Duct System .................... -

Page 4: Initial Inspection

Initial Inspection CE Split Series InITIal InSPECTIon required, stack units as follows: Vertical units no more than two high. Horizontal units no more than Be certain to inspect all cartons or crates on each three high. unit as received at the job site before signing the freight bill. -

Page 5: Installation

Installation CE Split Series 5 InSTallaTIon aIr HandlEr Locate the air handler unit in an indoor area that Remove all shipping blocks under blower allows easy removal of the filter and access panels, housing. and has enough room for service personnel to perform maintenance or repair. -

Page 6: Condensate Drain

Condensate drain CE Split Series (Heat Pumps are not internally trapped). A vertical air vent is sometimes required to avoid air pockets. (See Figure #4). The length of the trap depends on the amount of positive or negative pressure on the drain pan. -

Page 7: Electrical

CE Split Series 7 Electrical the power leads as indicated on the unit wiring seal within duct. The duct system and all diffusers diagrams. (Refer to Figure#12) should be sized to handle the designed air flow quietly. To maximize sound attenuation of the unit... - Page 8 CE Split Series Heater Package Compatibility figure 7: Heater Package Compatibility Model Heater Model Heater amps Circuit Max. fuse Min. 208v 240v 208v 240v 208v 240v ce025 thru 035 hp050-1Xs 17.3 20.0 l1/l2 27.1 30.4 ce049 thru 071 hp050-1XM 17.3 20.0...

-

Page 9: Thermostat Connections

(C) side of the thermostat to restore normal operation. transformer, the unit must be provided with a malfunction relay (Bosch option # 660-006) to Do not set the ADJ jumper to the (-) setting properly energize the light. The relay coil will when electric heaters are installed. -

Page 10: Safety Devices & The Upm Controller

Safety devices and the uPM Controller CE Split Series thermostat inputs on to the rest of the control enter a soft lockout. The compressor will not be circuit. Remember to always turn off unit power at energized until the low pressure switch closes and the the circuit breaker before attaching or disconnecting anti-short cycle time delay expires. -

Page 11: Sequence Of Operation Two-Stage Units

Considerations CE Split Series 11 • l.E.d. faulT IndICaTIon—Two L.E.D. indicators ConSIdEraTIonS are provided: 1. Always check incoming line voltage power • Green: Power L.E.D. indicates 18—30 VAC supply and secondary control voltage for present at the board. adequacy. Transformer primaries are dual •... -

Page 12: Piping

Heating Mode CE Split Series Never exceed the recommended water flow rates. A fault condition initiating a lockout will Serious damage or erosion of the water to de-energize the compressor irrespective of refrigerant heat exchanger could occur. which stage is engaged. -

Page 13: Refrigerant Lines

CE Split Series 13 Pressure / temperature ports are recommended in 2. Oil is continually being circulated with the both the supply and return lines for system flow refrigerant so, oil return to the compressor is balancing. The water flow can be accurately set by always a consideration in line sizing. -

Page 14: Charging The System

CE Split Series Charging the System factory charged with sufficient refrigerant to support The air handler is factory supplied with a the air handler, condensing section and 25 feet of holding charge of dry nitrogen. liquid line. If the lines are less or more than 25 feet, then a charge adjustment must be calculated. -

Page 15: Well Water Systems

In the cooling mode, heat is rejected from the Bosch response to refrigerant pressure. In some cases unit into the water loop. A cooling tower provides... -

Page 16: Earth Coupled Systems

7. Turn the thermostat to the lowest setting. installations should be made unless the dealer has 8. Set the thermostat switch to “HEAT”. received specialized training. Utilizing the Bosch Ground Loop Pumping Package (GLP), makes the 9. Increase the thermostat setting approximately 5 installation easy. -

Page 17: Water Tank Refill

CE Split Series 17 Hr water Piping figure #12 5. Once drained the tank should be flushed with 6. Before restoring the power or fuel supply to the water cold water until the water leaving the drain hose heater, adjust the temperature setting on the tank is clear and free of sediment. -

Page 18: Maintenance

Maintenance CE Split Series MaInTEnanCE 5. Periodic lockouts almost always are caused by air or water flow problems. The lockout (shutdown) 1. Filter changes or cleanings are required at of the unit is a normal protective measure in the regular intervals. The time period between filter design of the equipment. -

Page 19: Unit Specifications

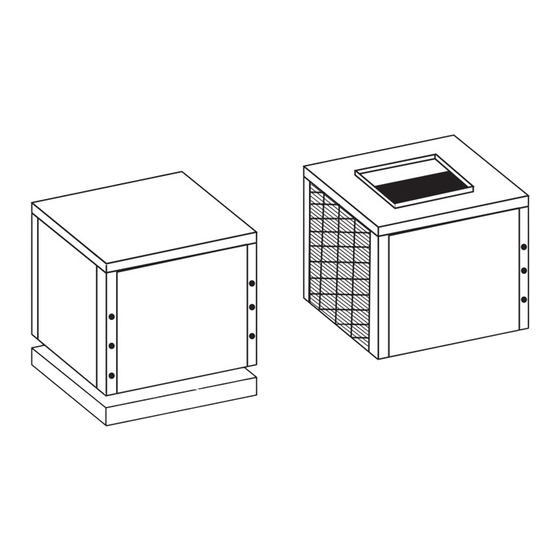

Unit Specifications CE Split Series 19 unIT SPECIfICaTIonS Table 2: dimensions CE Split dimensions (In) Model Vertical air Handler Horizontal air Condensing Section Supply return replacement Handler Connection Connection filter nominal Size Width Depth Height Width Depth Height Width Depth... -

Page 20: Wiring Diagrams

Typical wiring diagram CE Split Series figure 12: TYPICal wIrInG dIaGraM Two Stage Multi-Step - Single Phase - Air Handler 6 720 220 049 Subject to change without prior notice Revised 03-11... -

Page 21: Two Stage - Single Phase - Condensing Section

Typical wiring diagram CE Split Series 21 Two Stage - Single Phase - Condensing Section Revised 03-11 Subject to change without prior notice 6 720 220 049... -

Page 22: Operating Pressures & Temperatures

Pressures & Temperatures CE Split Series oPEraTInG PrESSurES & TEMPEraTurES Environmentally Safe r-410a refrigerant Table 5: operating data COOLING HEATING Entering Water Suction Water Suction Discharge Water Discharge Model Water Flow Pressure Temp Temp Pressure Pressure Temp Temp Pressure Temp. - Page 23 Pressures & Temperatures CE Split Series 23 oPEraTInG PrESSurES & TEMPEraTurES Environmentally Safe r-410a refrigerant Table 5 continued: operating data COOLING HEATING Entering Water Suction Discharge Water Suction Discharge Water Model Water Flow Pressure Pressure Temp Temp Pressure Pressure...

- Page 24 Pressures & Temperatures CE Split Series oPEraTInG PrESSurES & TEMPEraTurES Environmentally Safe r-410a refrigerant Table 5 continued: operating data COOLING HEATING Entering Water Suction Water Suction Discharge Water Discharge Model Water Flow Pressure Temp Temp Pressure Pressure Temp Temp Pressure Temp.

- Page 25 Pressures & Temperatures CE Split Series 25 oPEraTInG PrESSurES & TEMPEraTurES Environmentally Safe r-410a refrigerant Table 5 continued: operating data COOLING HEATING Entering Water Suction Discharge Water Suction Discharge Water Model Water Flow Pressure Pressure Temp Temp Pressure Pressure...

-

Page 26: Unit Check Out

Max Fuse Size (Amps) __________________________________ Volts / Amps_____________________ /______________________ Entering Air Temperature _______________________________ Leaving Air Temperature _______________________________ Bosch Group 601 NW 65th Court Fort Lauderdale, FL 33309 Phone: (954) 776-5471 Fax: (800) 776-5529 http://www.fhp-mfg.com 6 720 220 049 Subject to change without prior notice... -

Page 27: Troubleshooting

Troubleshooting CE Split Series 27 TroublESHooTInG problem possible cause checks and corrections entire unit power supply off apply power, close disconnect does not run blown Fuse Replace fuse or reset circuit breaker. check for correct fuses voltage supply low If voltage is below minimum voltage specified on unit data plate, contact local power company. - Page 28 Troubleshooting CE Split Series Insufficient unit undersized Recalculate heating and or cooling loads. if excessive, possibly adding insulation and shading will rectify the problem cooling or heating loss of conditioned check for leaks in duct work or introduction of ambient air through...

- Page 29 CE Split Series 29 Revised 03-11 Subject to change without prior notice 6 720 220 049...

- Page 30 CE Split Series 6 720 220 049 Subject to change without prior notice Revised 03-11...

- Page 31 CE Split Series 31 Revised 03-11 Subject to change without prior notice 6 720 220 049...

- Page 32 601 n.w. 65th court, Ft. lauderdale, Fl 33309 phone: 954-776-5471 | Fax: 954-776-5529 www.boschtaxcredit.com | www.fhp-mfg.com...

Need help?

Do you have a question about the CE SPLIT series and is the answer not in the manual?

Questions and answers